Crude oil desalting method and device using rotational flow breakaway technology

A technology of swirl separation and crude oil, which is applied in swirl devices, devices with the axial direction of the swirl unchanged, and refining with the help of centrifugal force, etc., can solve the problems of complicated DC electric swirl desalination operations, high energy consumption of electric desalination equipment, and occupation of Large land and other issues, to achieve the effect of easy implementation, simple structure, and overcome large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

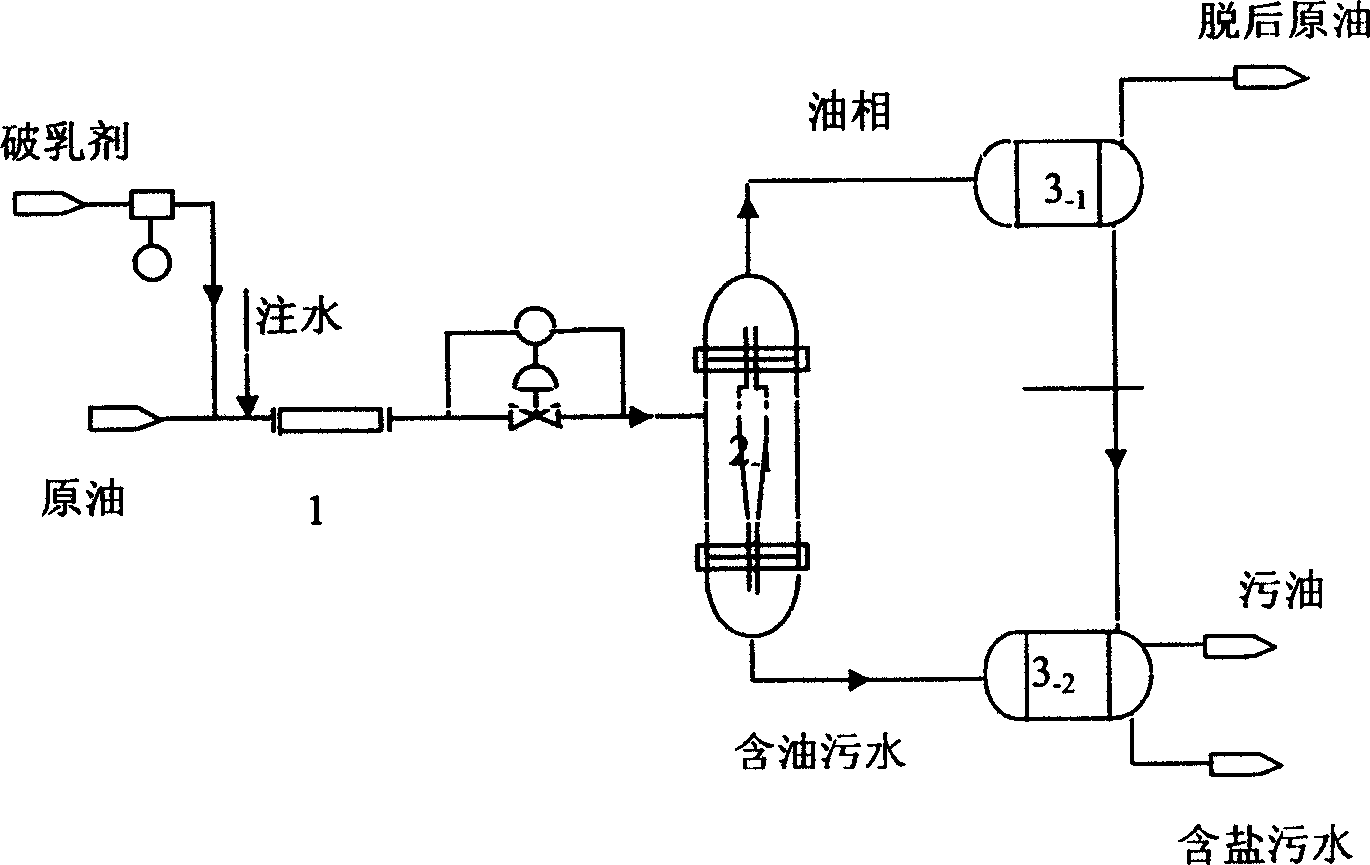

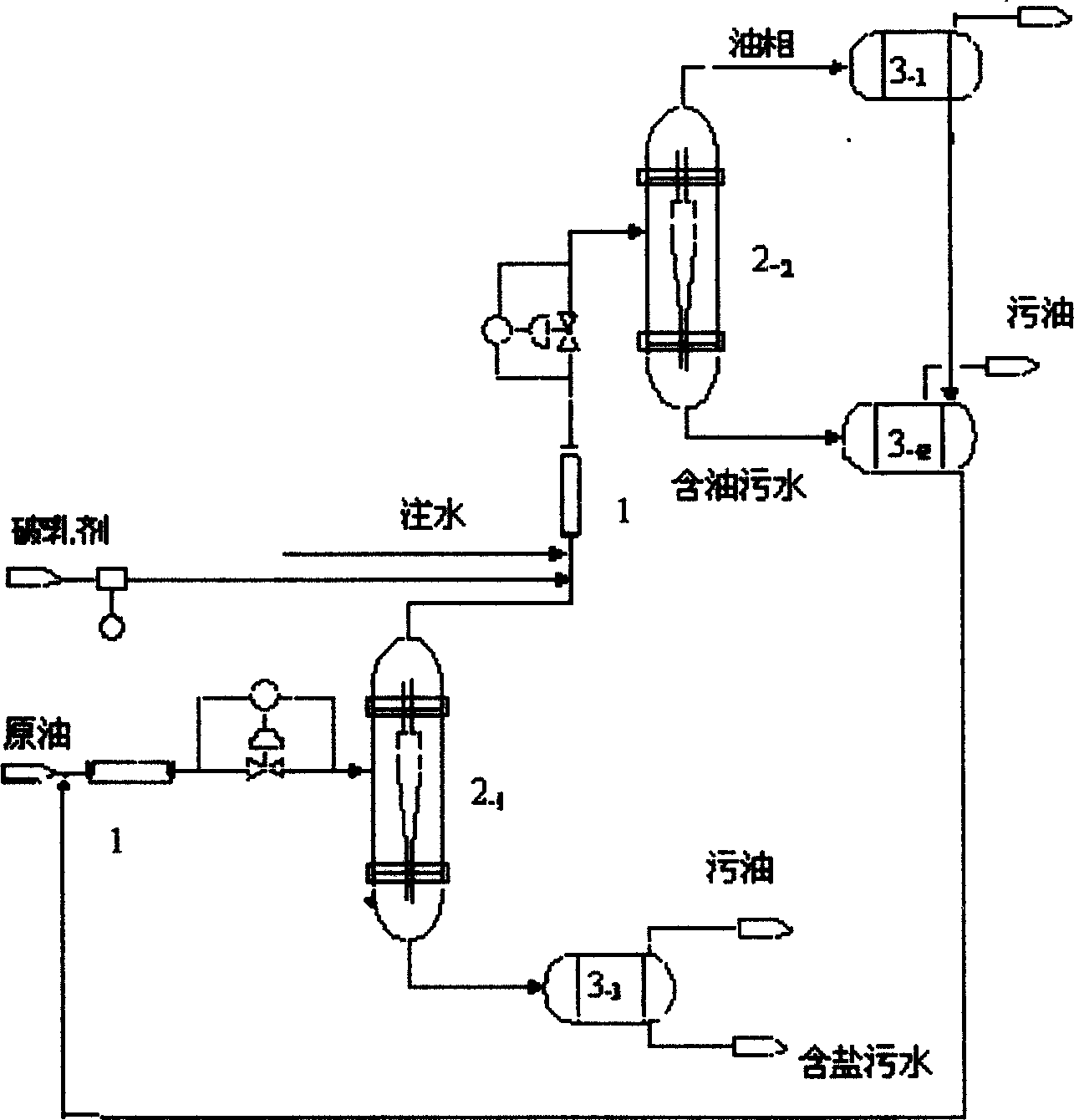

[0039] When the salt content at the inlet of the crude oil cyclone desalter is greater than 8mg / L, a secondary cyclone desalter device is used, and the process flow is shown in the attached figure 2. Utilize the primary cyclone desalter (2-1) to separate the crude oil into oil phase and oily sewage; the oily sewage enters the settling tank (3-3) to separate into sewage oil and salty sewage, and the sewage oil is discharged into the sewage tank, containing The salt water is discharged; the separated oil phase is injected into water and demulsifier and enters the secondary cyclone desalter (2-2), and then separated into oil phase and oily sewage by cyclone, and the oil phase enters the settling tank (3-1 ), the settled crude oil enters the downstream device, the oily sewage and the oily sewage from the secondary cyclone desalter (2-2) enter the settling tank (3-2) together, and the settled dirty oil is discharged into the dirty oil tank , the saline sewage is reinjected into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com