Resourceful treatment process of tar residue

A treatment process and tar residue technology, which is applied in the field of tar residue resource treatment technology, can solve the problems of complex process flow and inconspicuous separation effect, and achieve the effects of simplifying the separation process, saving energy and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

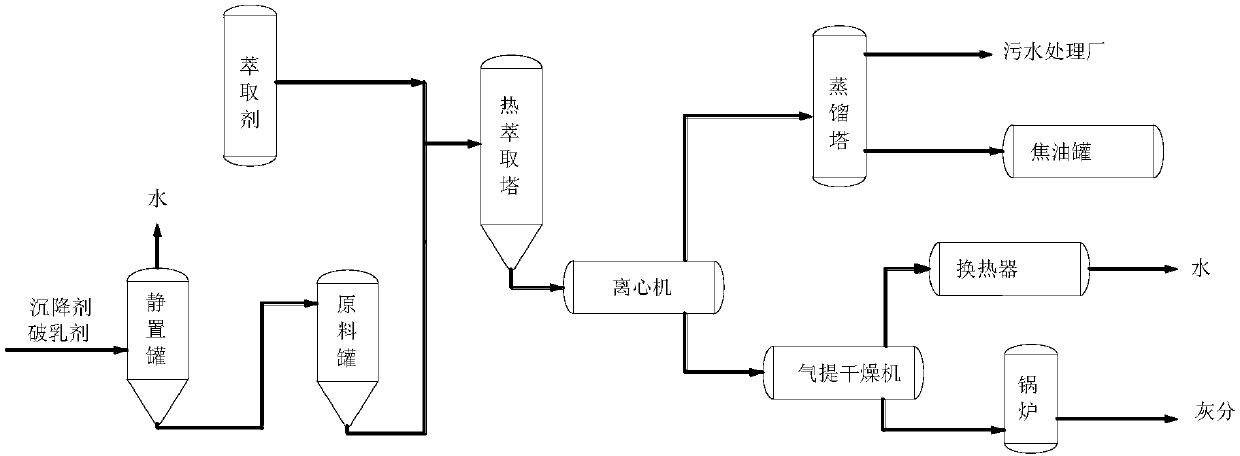

Method used

Image

Examples

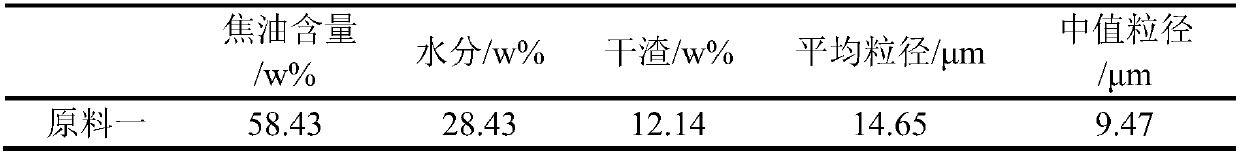

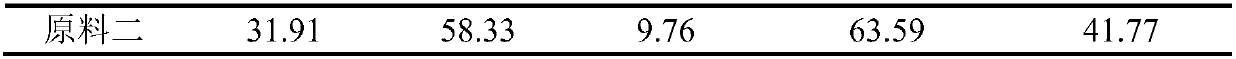

Embodiment 1

[0033] The tar residue recycling treatment process of the present embodiment comprises the following steps:

[0034] (1) In the process of conveying raw material tar residue, inject alkylphenolic resin and cationic polyacrylamide and mix them evenly. The volume ratio of alkylphenolic resin and cationic polyacrylamide is 2:1, and the volume ratio of alkylphenolic resin and cationic polyacrylamide is 2:1. The mixed addition amount of acrylamide is corresponding to 200mg tar residue per liter, that is, the dosage is 200mg / L. Once the material enters the static tank, stir it for 2 hours at a constant temperature of 40 °C and a stirring speed of 120 r / min, and let it stand at 25 °C for 4 hours. The moisture content of about 47wt% and the sedimentation material at the bottom of the tower (accounting for 53wt% of the raw material) are sent to the process raw material storage tank for use.

[0035] (2) in step (1), the tar residue of dehydration and demulsification and the composite e...

Embodiment 2

[0043] The tar residue recycling treatment process of the present embodiment comprises the following steps:

[0044] (1) Inject ethylene oxide and cationic polyacrylamide into the raw material tar residue and mix them evenly. The volume ratio of ethylene oxide and cationic polyacrylamide is 1.5:1. The mixed addition amount of acrylamide is 200mg of tar residue per liter, that is, the dosage is 200mg / L. The second material enters the static tank and is stirred for 2 hours at a constant temperature of 35°C and a stirring speed of 100r / min. Moisture of about 45wt%, the sedimentation material at the bottom of the tower (accounting for 55wt% of the raw material) is sent to the process raw material storage tank for use.

[0045] (2) in step (1), the tar residue of dehydration and demulsification and the composite extractant are mixed and preheated to 50 ℃ in the pipeline in front of the tower according to the mass ratio of 1.5:1 and sent into the hot extraction tower, and the extrac...

Embodiment 3

[0052] The tar residue recycling treatment process of the present embodiment comprises the following steps:

[0053] (1) In the process of conveying the raw material tar residue, inject polyethylene polyamine and cationic polyacrylamide and mix them evenly. The volume ratio of polyethylene polyamine and cationic polyacrylamide is 1:1. The mixed addition amount of acrylamide is corresponding to 100mg tar residue per liter, that is, the dosage is 100mg / L. Once the material enters the static tank, stir for 1 hour at a constant temperature of 50 °C and a stirring speed of 60 r / min, and stand at 20 °C for 4 hours. The bottom sedimentation material is sent to the process raw material storage tank for use.

[0054] (2) in step (1), the tar residue of dehydration and demulsification and the composite extractant are mixed and preheated to 50 ℃ in the pipeline in front of the tower according to the mass ratio of 2:1 and sent into the hot extraction tower, and the extraction condition is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com