Rotational flow air floatation separation device and system

A technology of swirling air flotation and separation device, which can be used in oil/oily substance/float removal device, centrifugal separation water/sewage treatment, flotation water/sewage treatment, etc., and can solve the problem of low recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

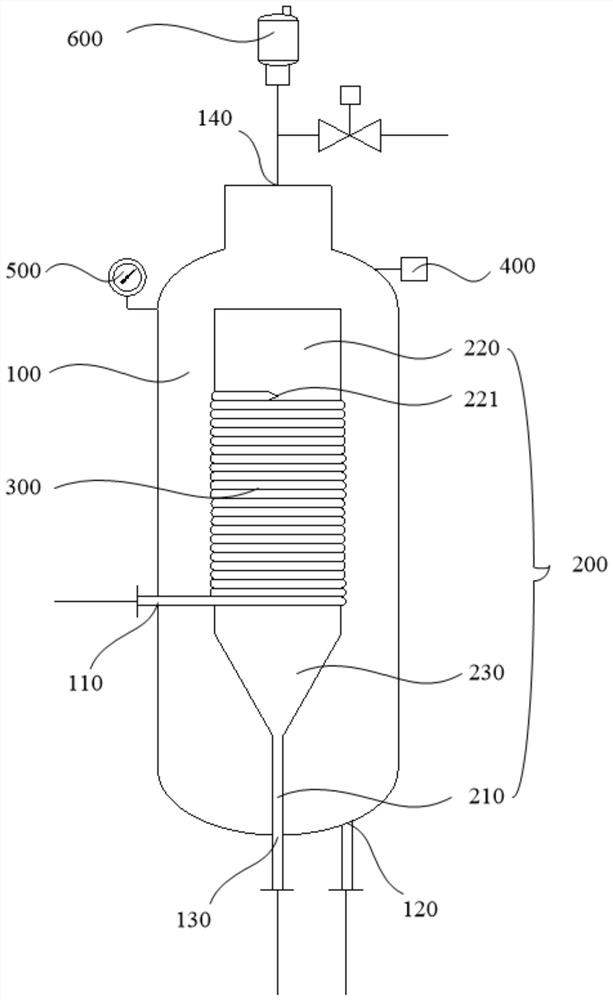

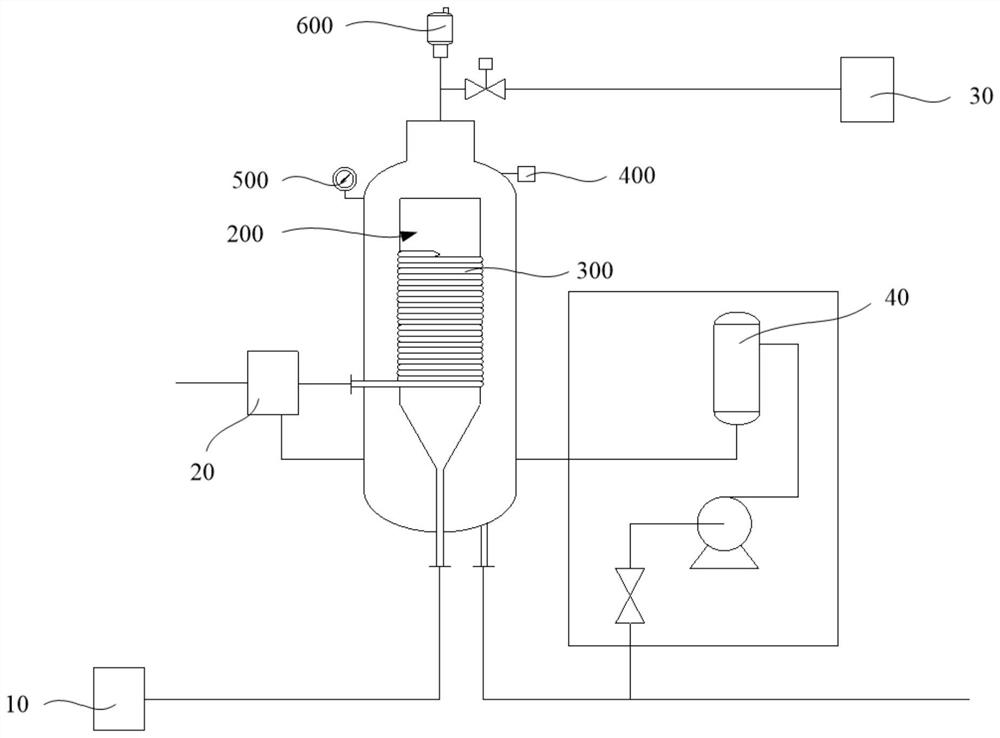

[0035] see figure 1 with figure 2 , the invention provides a cyclone air flotation separation device, comprising:

[0036] The separation chamber 100 has an accommodating space; the separation chamber 100 has a mixed gas-liquid entry position 110, a clean water outflow position 120 and a sludge discharge position 130;

[0037] The swirl chamber 200 is arranged in the separation chamber 100 and is located in the accommodating space; the swirl chamber 200 includes a first communication pipe 210 passing through the sludge discharge position 130 Connected to the sludge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com