Zero-additive gel-state bovine bone concentrated original soup and preparation method thereof

A gel state, zero-addition technology, applied in the field of food processing, can solve the problems of lack of fresh flavor, poor taste, heavy fishy smell, etc., to achieve a balance between meat and ester aroma, low difficulty in preparation and use, and strong Flavorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

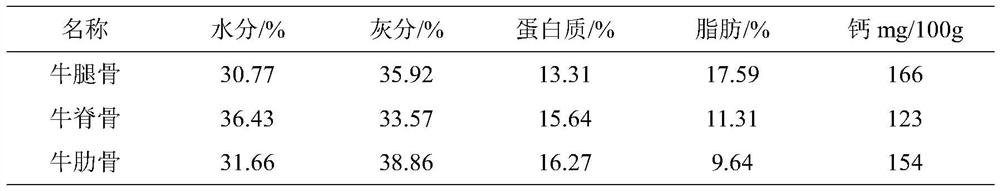

[0049] (1) Take beef leg bones, beef spines and beef ribs frozen at -18°C, 500kg each, put them into the bone washing tank for preliminary cleaning and removal of impurities, cut them to less than 15cm by a bone cutter, and put them into a bone crusher to crush until the length diameter is no larger than 15cm. Small pieces larger than 1.5cm.

[0050] (2) Put the crushed bone into the bubbling immersion tank, add drinking water at room temperature until the water level is 8 cm above the top surface of the aggregate, start the regular bubbling program, and automatically bubble for 3 minutes every 20 minutes; Change the water once in the 2nd hour, discharge the material at the 5th hour, and drain it; when the temperature is lower than 20°C, change the water once at the 3rd hour, discharge the material at the 8th hour, and drain it.

[0051] (3) Remove impurities and wash ginger and green onions, weigh 7.5kg each, weigh 4.5kg red pepper, wash them with water; put the above three r...

Embodiment 2

[0056] (1) Take beef leg bones, beef spines and beef ribs frozen at -18°C, 400kg, 600kg, and 500kg respectively, put them into the bone washing tank for preliminary cleaning and removal of impurities, cut them to less than 15cm by a bone cutter, and put them into a bone crusher Crush to small pieces with a long diameter not greater than 1.5cm.

[0057] (2) Put the crushed bone into the bubbling immersion tank, add drinking water at room temperature until the water level is 10cm higher than the top surface of the aggregate, start the timing bubbling program, and automatically bubbling for 5 minutes every 30 minutes; when the temperature is higher than 20°C, Change the water once in the 3rd hour, discharge the material at the 6th hour, and drain it; when the temperature is lower than 20°C, change the water once at the 4th hour, discharge the material at the 9th hour, and drain it.

[0058] (3) Remove impurities and wash ginger and scallions, weigh 12kg each, weigh 6kg red pepper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com