Waste gas cracking device

A technology of cracking device and waste gas, which can be used in tar processing by heat treatment, fibrous fillers, petroleum industry, etc., and can solve problems such as soil pollution, air pollution, and surface drinking water pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

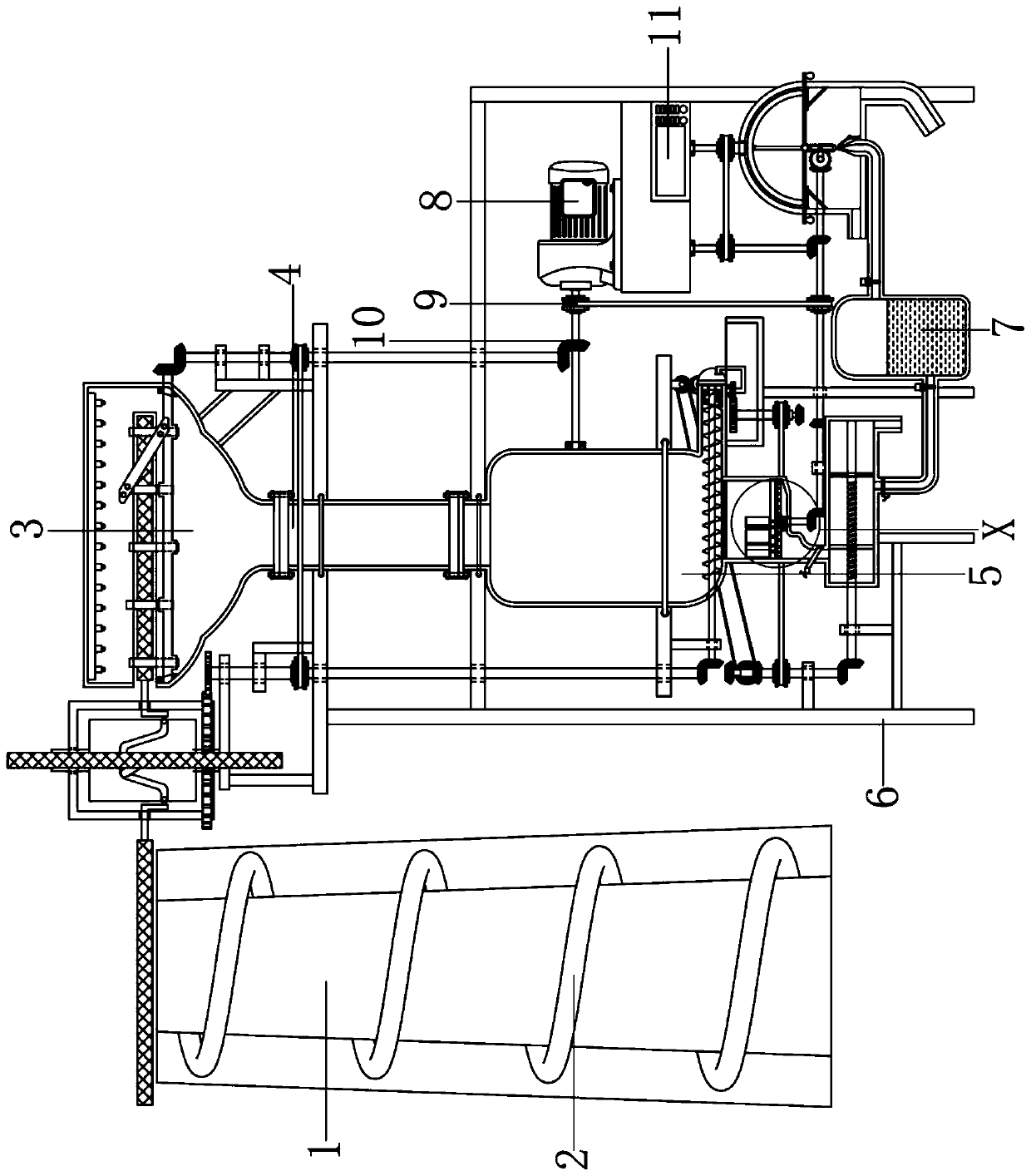

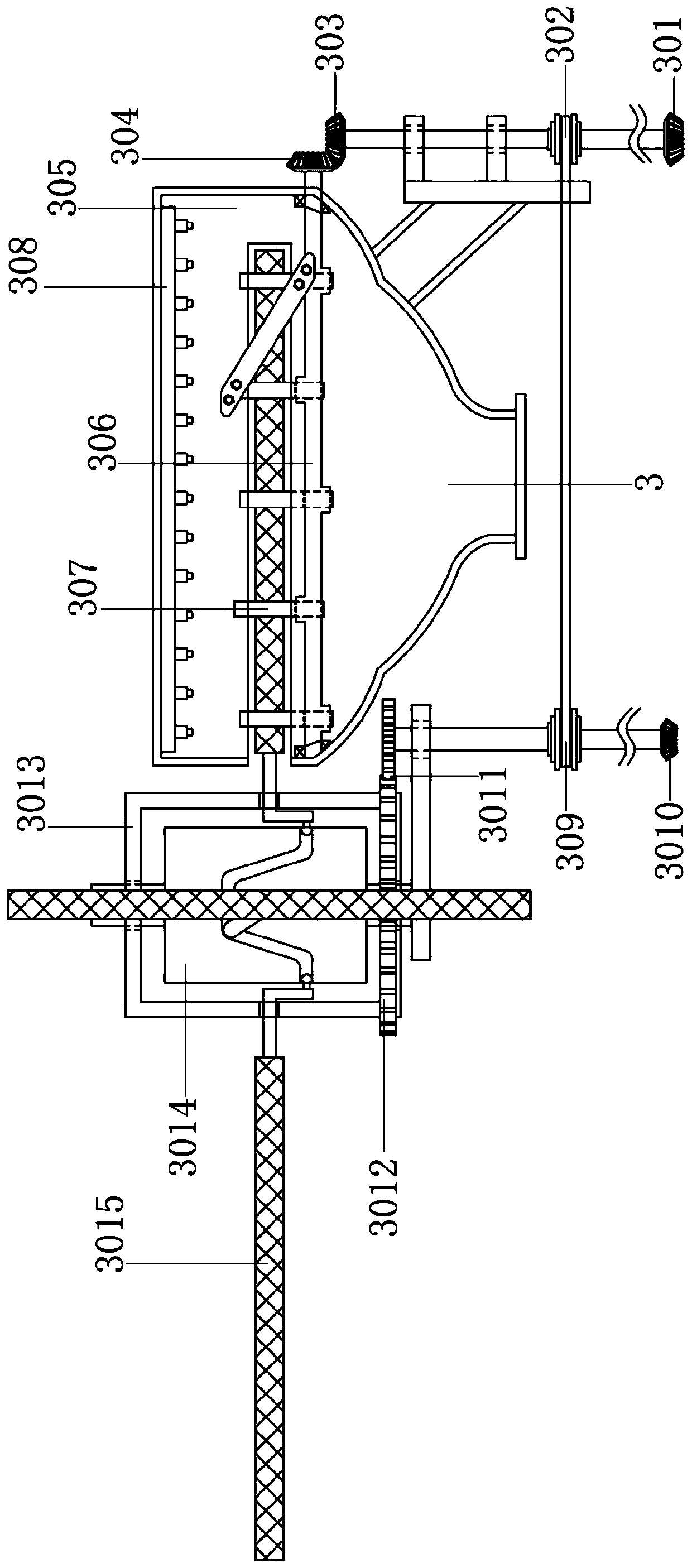

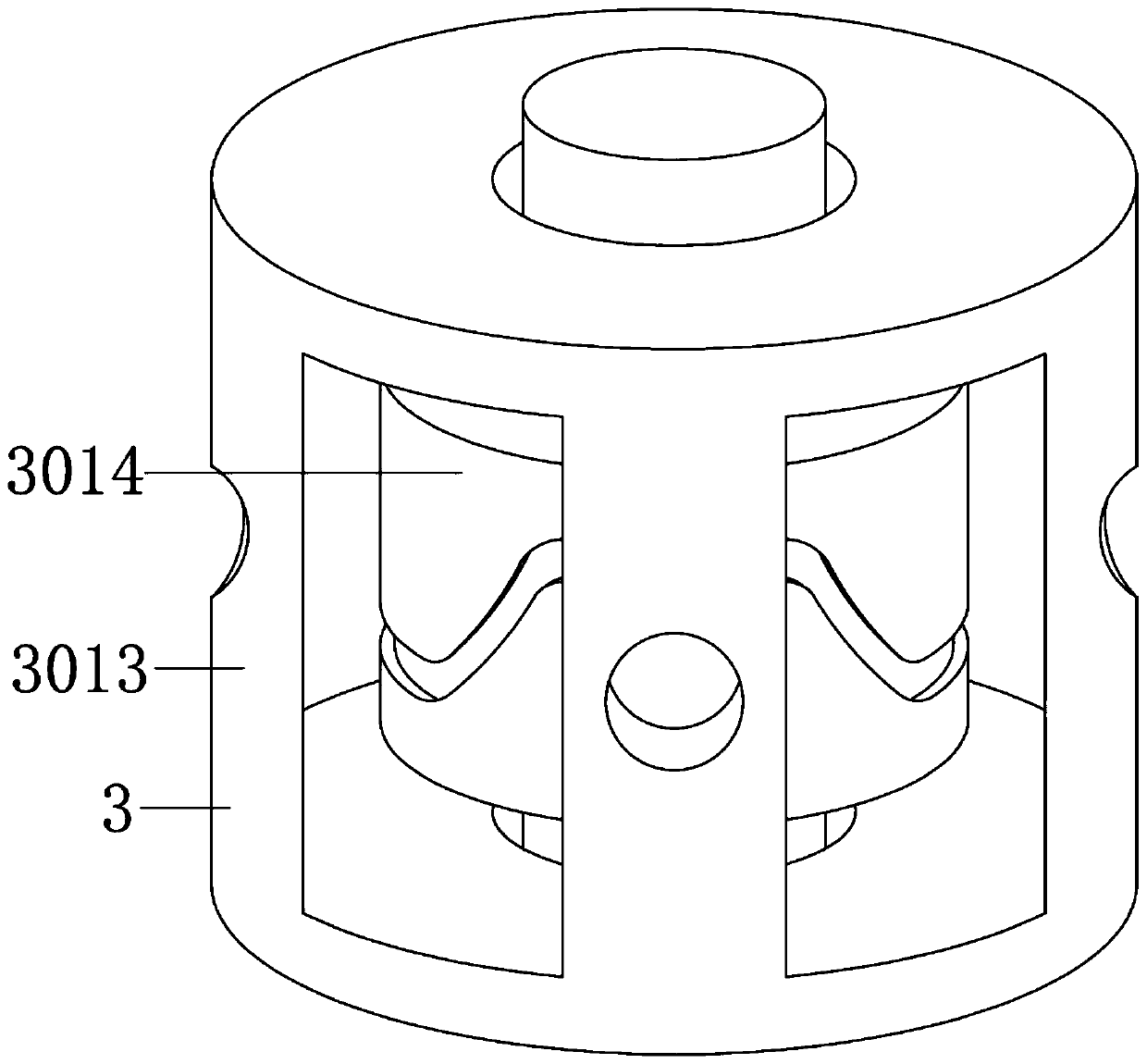

[0028] A waste gas cracking device, such as Figure 1-9 As shown, it includes exhaust chimney 1, cooling pipe 2, tar adhesion ammonia washing mechanism 3, extension pipe 4, tar residue compression mechanism 5, chassis 6, digestion and cracking mechanism 7, stepping motor 8, first transmission wheel 9, The first bevel gear 10 and the control display 11; the internal interlayer of the discharge chimney 1 is socketed with the cooling pipe 2; the top of the right end of the discharge chimney 1 is provided with a tar adhesion ammonia washing mechanism 3; The pipe 4 is connected by bolts; the floor of the tar-adhesive ammonia washing mechanism 3 is connected to the bottom frame 6, and the bottom frame 6 is connected to the left part of the inner top end and the extension pipe 4; the bottom end of the extension pipe 4 is bolted to the tar residue compression mechanism 5 connected; and the bottom of tar residue compression mechanism 5 is connected with underframe 6; The bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com