Aluminum industry solid waste recovery/petroleum coke high temperature desulfurization device and its use method

A solid waste and desulfurization device technology, applied in the field of metallurgy and environmental protection, to achieve the effects of reducing pollution, reducing power consumption, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

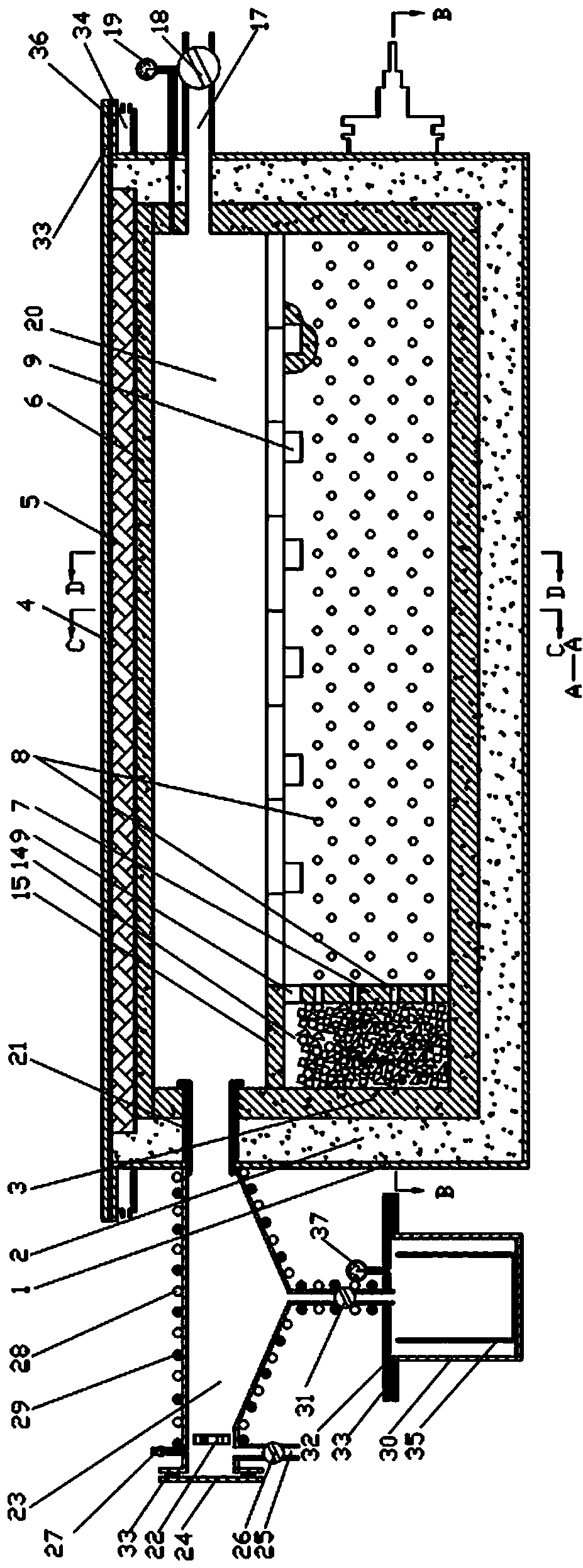

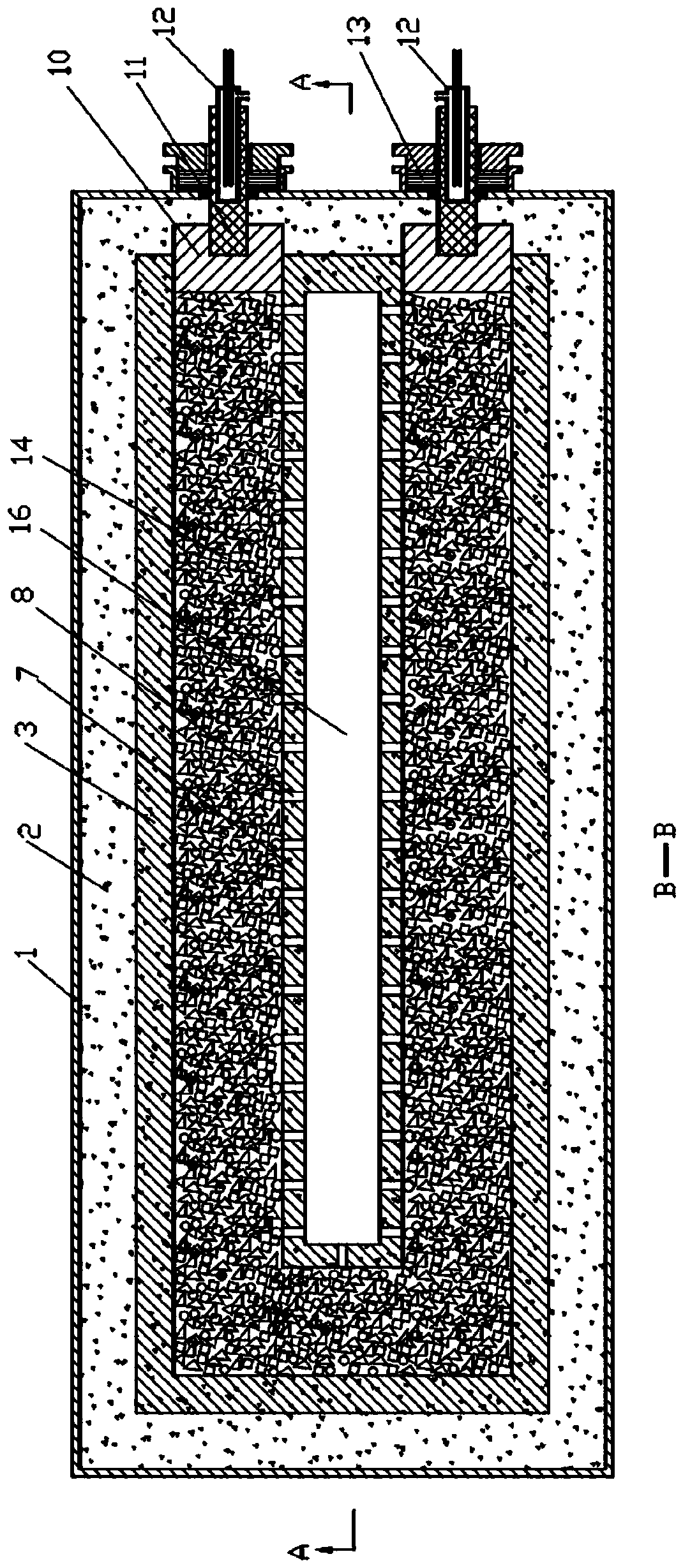

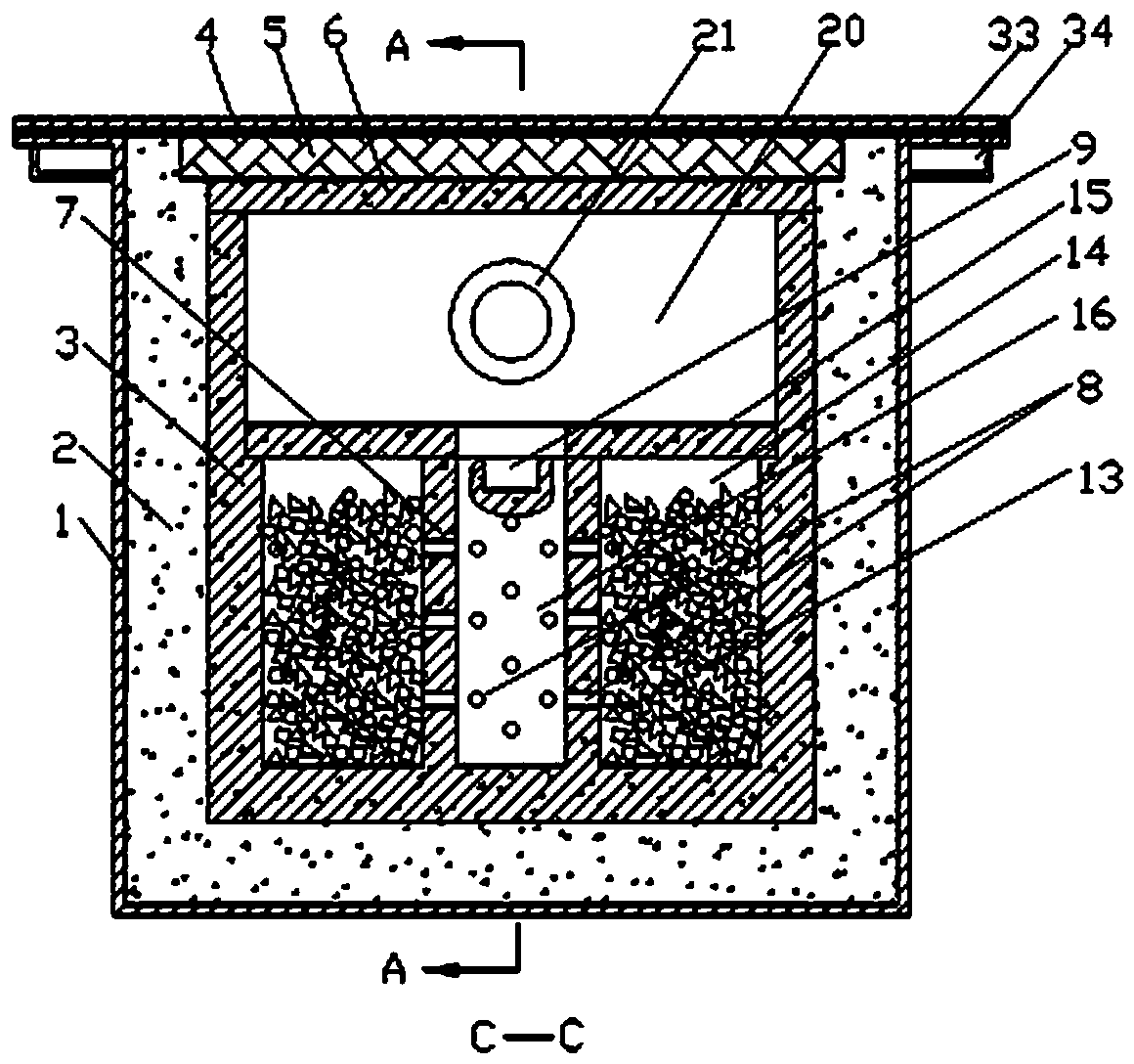

[0065] Aluminum industry solid waste recycling / petroleum coke high temperature desulfurization plant structure as follows figure 1 As shown, the cross-sectional view of B-B plane is as follows figure 2 As shown, the cross-sectional view of C-C plane is shown as image 3 As shown, the cross-sectional view of D-D plane is shown as Figure 4 Shown, comprise furnace body, low-melting-point material crystallizer 23 and liquid low-melting-point material collector 30; Shell 1 is sealed and connected to the furnace cover 4. The furnace shell 1 is provided with an insulating material layer 2, and the insulating material layer 2 is provided with a trough-shaped refractory wall 3. The trough-shaped refractory wall 3 consists of four side wall panels and a Bottom wall panels; trough-shaped refractory wall 3 is provided with refractory concrete inner walls 7; refractory concrete inner walls 7 are composed of three inner wall panels perpendicular to the bottom wall panels, refractory con...

Embodiment 2

[0085] The structure of the device is as Figure 5 Shown, body of furnace and crystallizer of liquid low melting point material are the same as embodiment 1, and difference is:

[0086] The main material chamber is used to place raw coke;

[0087] The crystallizer 23 for low-melting-point material is a vertical structure consisting of an inclined section and a vertical section. The crystallizer 23 for low-melting-point material is composed of an inclined section and a vertical section. , the collection pipe communicates with the liquid low-melting point material collector 30 through a valve (discharging valve 31), and the top end of the vertical section is provided with an end cover 24 that is sealed and connected with the low-melting point material crystallizer 23;

[0088] Method is with embodiment 1, and difference is:

[0089] (1) Put raw coke in the main material chamber as a resistance heating element; the particle size of the raw coke is ≤8cm;

[0090] (2) No materia...

Embodiment 3

[0097] The structure of the device is the same as in Example 1, wherein the main material chamber is used to place calcined petroleum coke;

[0098] Method is with embodiment 2, and difference is:

[0099] (1) Put the calcined petroleum coke in the main material chamber as a resistance heating element; the particle size of the calcined petroleum coke is ≤8cm;

[0100] (2) Without opening the front-end vacuum exhaust pipe, the furnace body is evacuated to an air pressure of ≤80Pa through the rear-end vacuum exhaust pipe; the desulfurization rate of petroleum coke is 91.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com