Method for preparing hollow spherical nickel-based catalyst for catalytic pyrolysis of oil tar

A nickel-based catalyst, catalytic cracking technology, applied in physical/chemical process catalysts, chemical instruments and methods, tar processing by heat treatment, etc., can solve the problems of unstable catalyst carrier structure, reduced catalyst activity, loss of active components, etc. , to achieve the effect of easy operation, improved stability and strong surface penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation process and steps in this embodiment are as follows:

[0033] a. Dissolve 2 mmol of aluminum nitrate in an equal-volume mixed solution of 40 ml of water and acetone, add 0.5 mmol of sodium citrate morphology control agent under stirring, place in a hydrothermal kettle, and react at 200°C for 24 hours, Centrifuge, wash, dry the sample at 60°C, and heat-treat at 550°C to obtain the desired core-shell alumina carrier.

[0034] b. Configure 10ml of nickel nitrate solution with a concentration of 2.3%, and slowly add the γ-Al obtained in step a while stirring 2 o 3 Carrier 0.1g, continue to stir and impregnate for 12h, then dry by rotary evaporation, dry in a drying oven at 60°C for 12h, calcinate at 700°C for 100min, extrude the obtained catalyst, crush it, and sieve it, then reduce it with hydrogen at 500°C for 2h , the core-shell alumina-nickel-based catalyst material can be obtained.

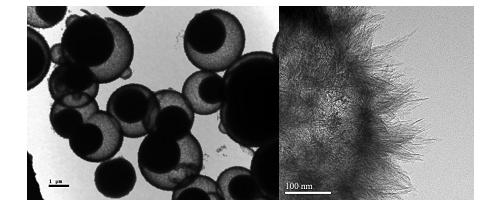

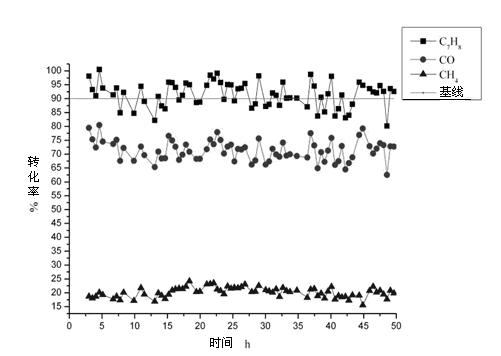

[0035] The morphology of the product obtained in this example was c...

Embodiment 2

[0037] The preparation process and steps in this embodiment are as follows:

[0038] a. Dissolve 2 mmol of aluminum nitrate in 40 ml of equal-volume mixed solution of water and ethanol, add 0.5 mmol of sodium citrate morphology control agent under stirring, place in a hydrothermal kettle, and react at 200°C for 24 hours, Centrifuge, wash, dry the sample at 60°C, and heat-treat at 350°C to obtain the desired hollow spherical alumina carrier.

[0039] b. Configure 10ml of nickel nitrate solution with a concentration of 5%, and slowly add the γ-Al obtained in step a while stirring 2 o 3 Carrier 0.1g, continue to stir and impregnate for 12h, then dry by rotary evaporation, dry in a drying oven at 60°C for 12h, calcinate at 550°C for 100min, extrude the obtained catalyst, crush it, and sieve it, then reduce it with hydrogen at 600°C for 2h , the core-shell alumina-nickel-based catalyst material can be obtained.

[0040] The product obtained in this example is dispersed in absolu...

Embodiment 3

[0042] Concrete steps in the present embodiment are as follows:

[0043] a. Dissolve 2 mmol of aluminum nitrate in an equal volume mixed solution of 40 ml of water and glycerin, add 0.5 mmol of sodium citrate morphology control agent under stirring, place in a hydrothermal kettle, and react at 200°C for 24 hours, Centrifuge, wash, dry the sample at 60°C, and heat-treat at 550°C to obtain the desired hollow spherical alumina carrier.

[0044] b. Configure 10ml of nickel nitrate solution with a concentration of 0.2%, and slowly add the γ-Al obtained in step a while stirring 2 o 3 Carrier 0.1g, continue to stir and impregnate for 12h, then dry by rotary evaporation, dry in a drying oven at 60°C for 12h, calcinate at 230°C for 100min, and calcinate at 350°C for 100min, extrude the obtained catalyst, crush it, and sieve it at 700°C The core-shell alumina-nickel-based catalyst material can be obtained by hydrogen reduction at ℃ for 2 hours.

[0045] The product obtained in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com