Device for preparing polishing glue

A technology for preparing equipment and polishing glue, which is applied in the field of auxiliary equipment for optical element processing and polishing material preparation equipment, can solve problems such as uneven distribution of temperature field and polishing glue properties, affecting the surface quality of optical elements, and composition changes The effect of shortening the convergence time of the surface shape, facilitating the control of the surface shape, and reducing the probability of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

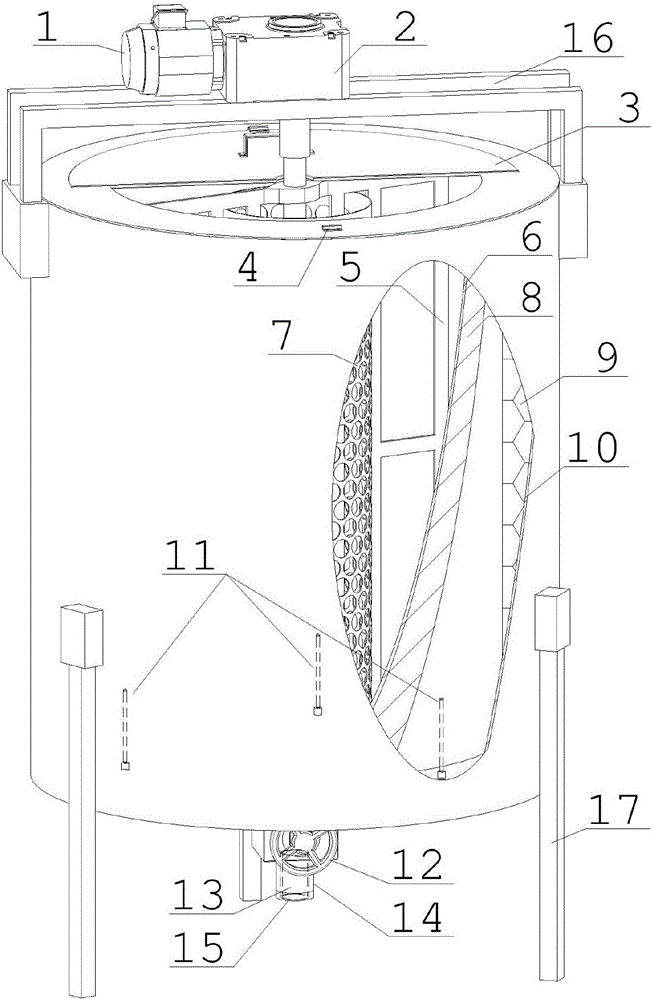

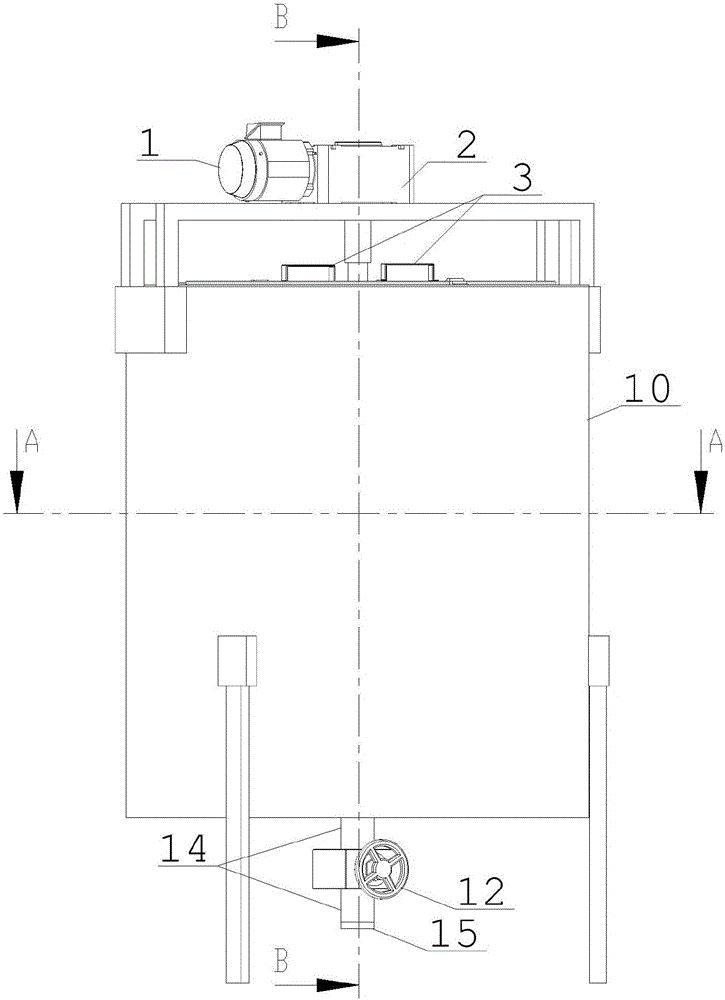

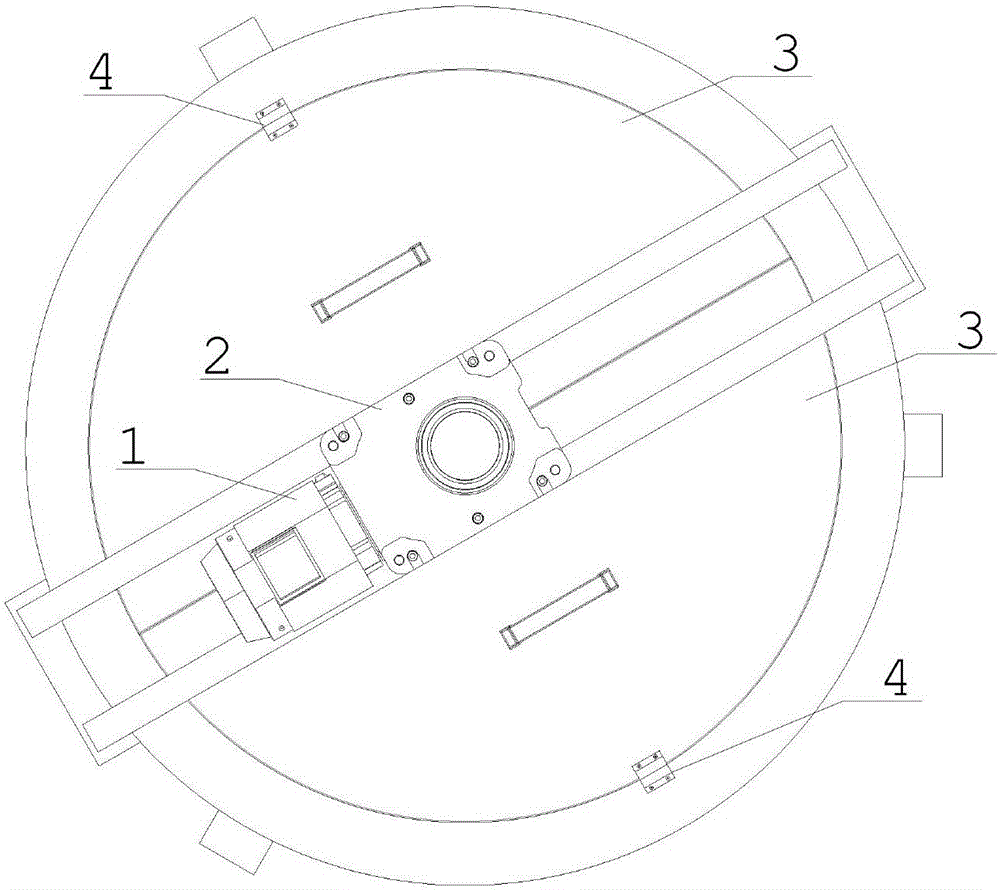

[0020] see figure 1 —5, polishing glue preparation device, comprise the bung and the upper bung 3 that are made up of bung shell 10, bucket inner layer 6 and the insulating layer 9 between the two, bung top is provided with upper bracket 16, upper bracket 16 A motor 1, a reducer 2 and a stirring paddle 5 are installed on the top of the barrel body. There is an annular filter screen 7; an annular ceramic heater 8 is arranged between the barrel inner wall 6 and the insulation layer 9.

[0021] The barrel inner layer 6 is provided with temperature sensors 11 at intervals, and is connected with the heating controller in the control box (not shown in the figure). Through real-time detection and feedback control of the heating controller, the temperature in the barrel is kept stable.

[0022] The outer wall of the discharge pipe 13 is wrapped with thermal insulation cotton 14 .

[0023] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com