Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Reduce the difficulty of process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for refinery sludge carbonization treatment and carbon recovery

ActiveCN103449701AReduce the difficulty of process controlEfficient process operationSludge treatment by thermal conditioningCarbon preparation/purificationSludgeGas phase

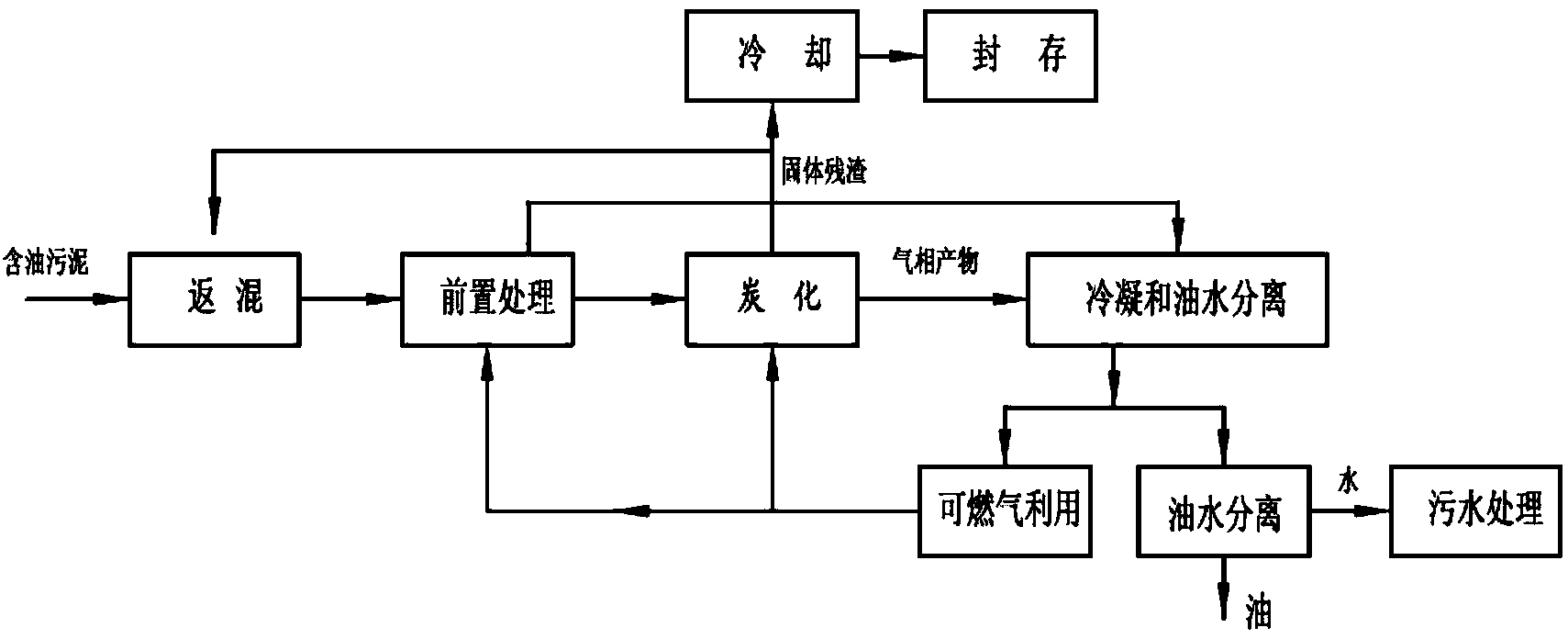

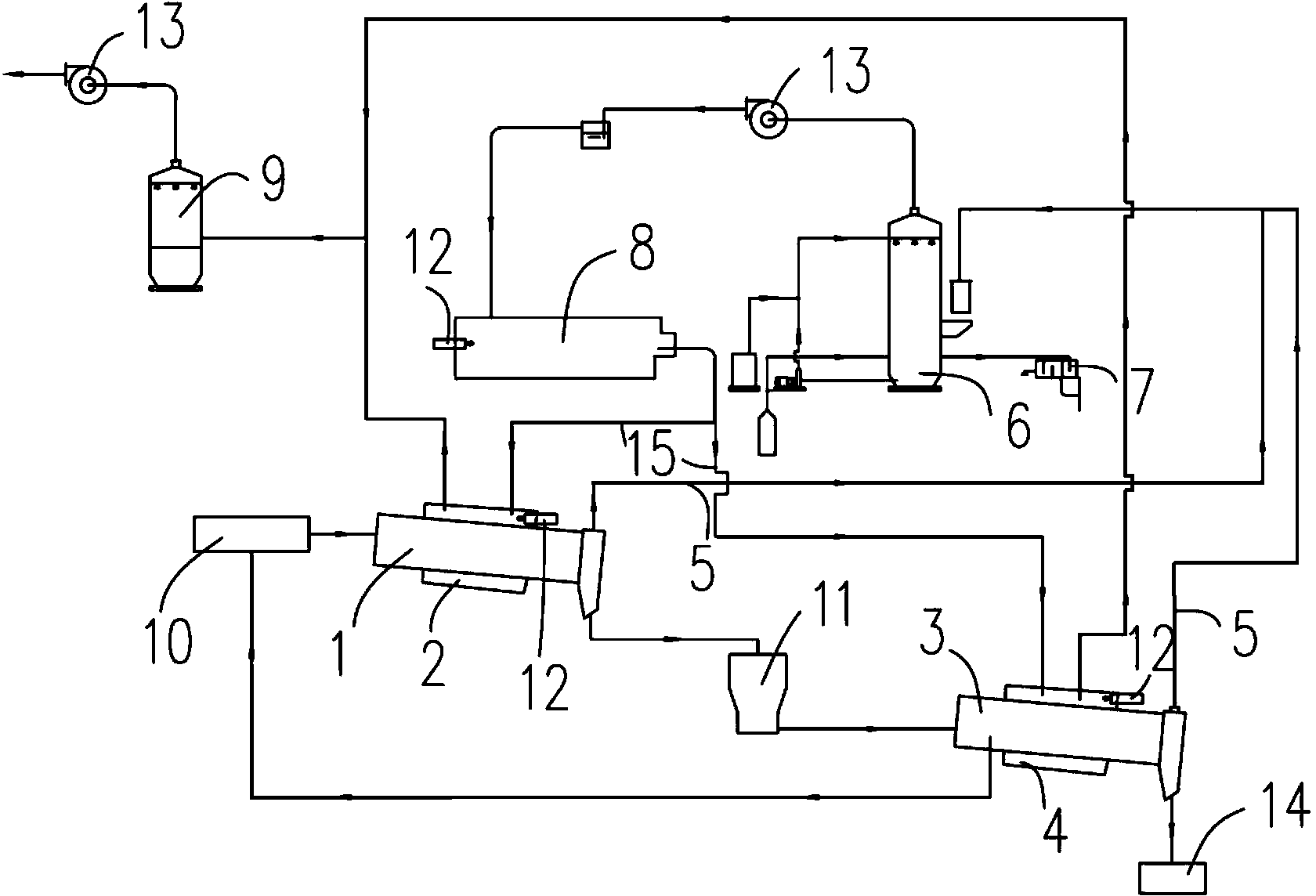

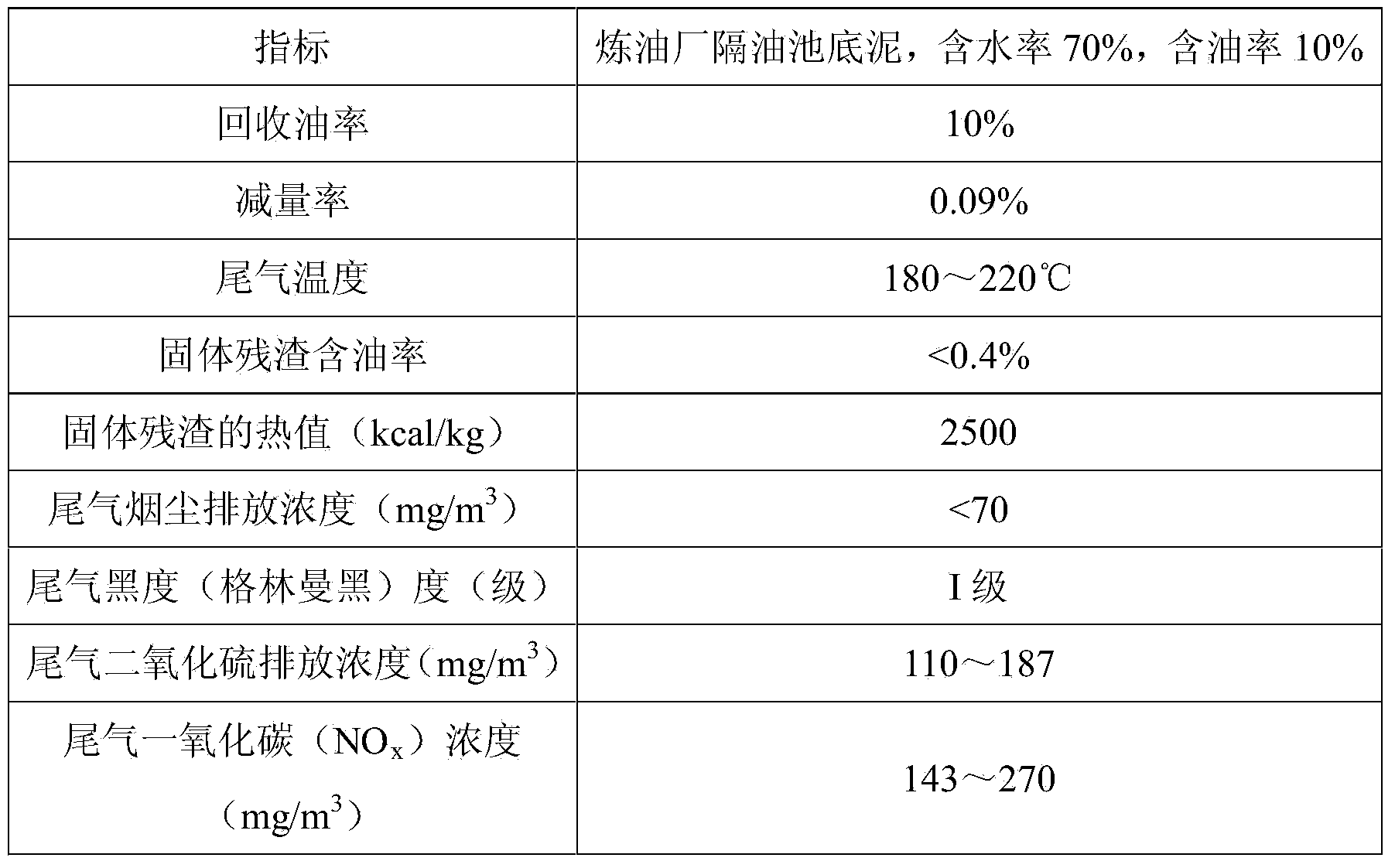

The invention relates to a method and device for refinery sludge carbonization treatment and carbon recovery. The method comprises the following steps: pre-treatment: heating oil-containing sludge to 160-180 DEG C in an external heating manner while isolating air, and ensuring that the water content of the oil-containing sludge is controlled at 20% or below; carbonization: carbonizing the oil-containing sludge at 600-650 DEG C for 30-45 minutes, and recovering the solid residue generated by carbonization; condensation and oil-water separation: collecting gas-phase products generated by pre-treatment and carbonization, condensing in a water spray manner to obtain carbonization liquid and non-condensable gas, and performing oil-water separation on the carbonization liquid to obtain carbonization oil; utilization of combustible gas: performing combustion treatment on the non-condensable gas, enabling high temperature generated by combustion to provide heat energy for pre-treatment and carbonization, and performing purification treatment on the tail gas before discharging. The invention also provides a device for realizing the method. According to the invention, the advantages of high oil content recovery rate and stable and reliable process operation are achieved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

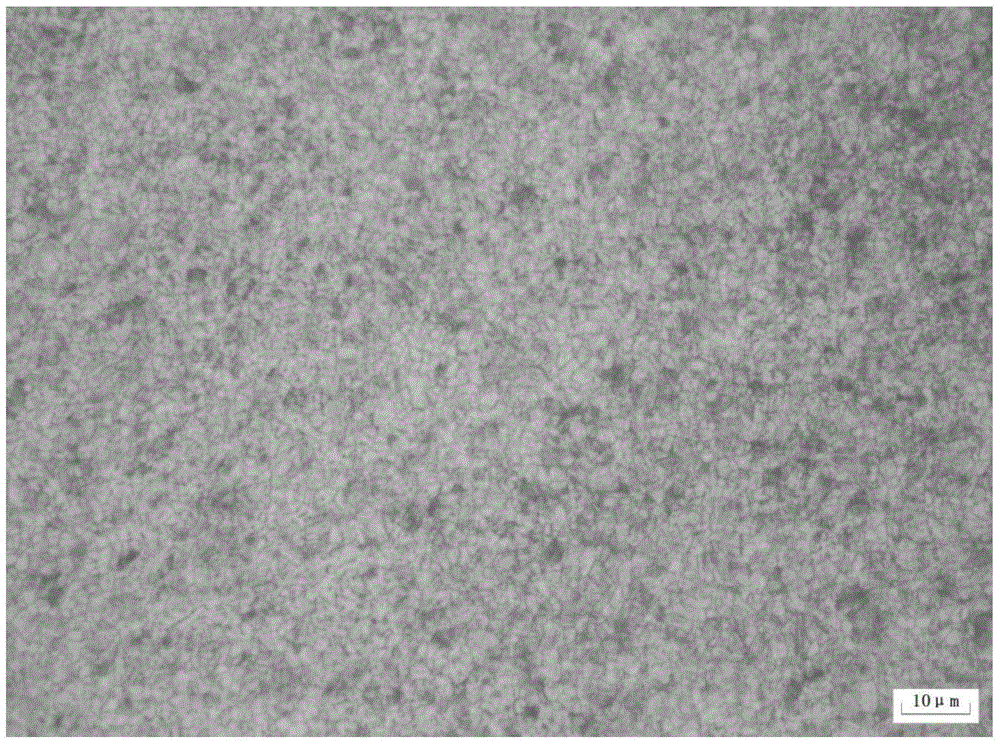

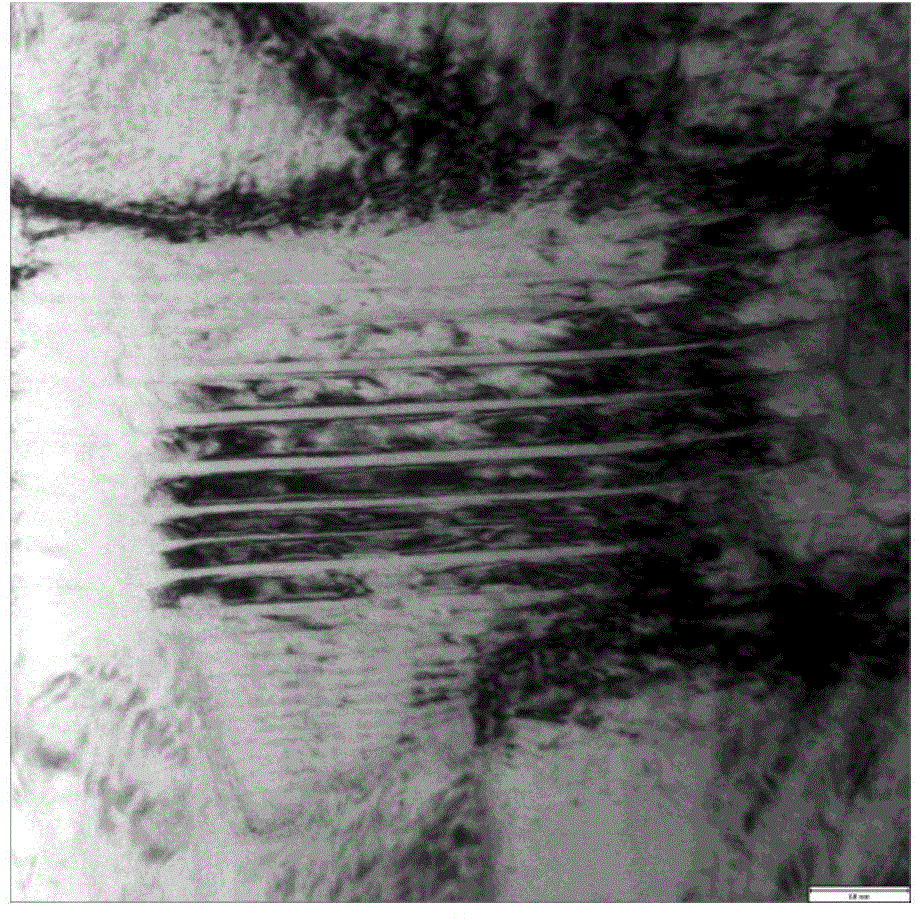

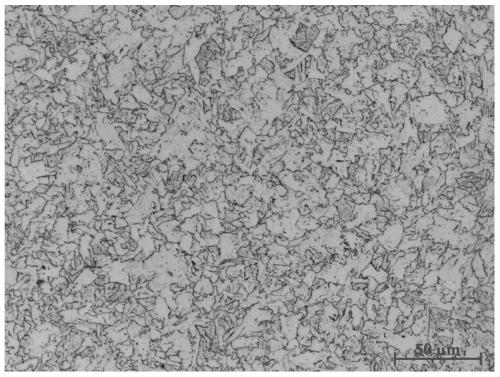

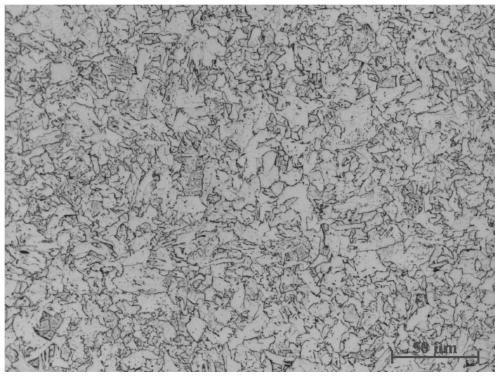

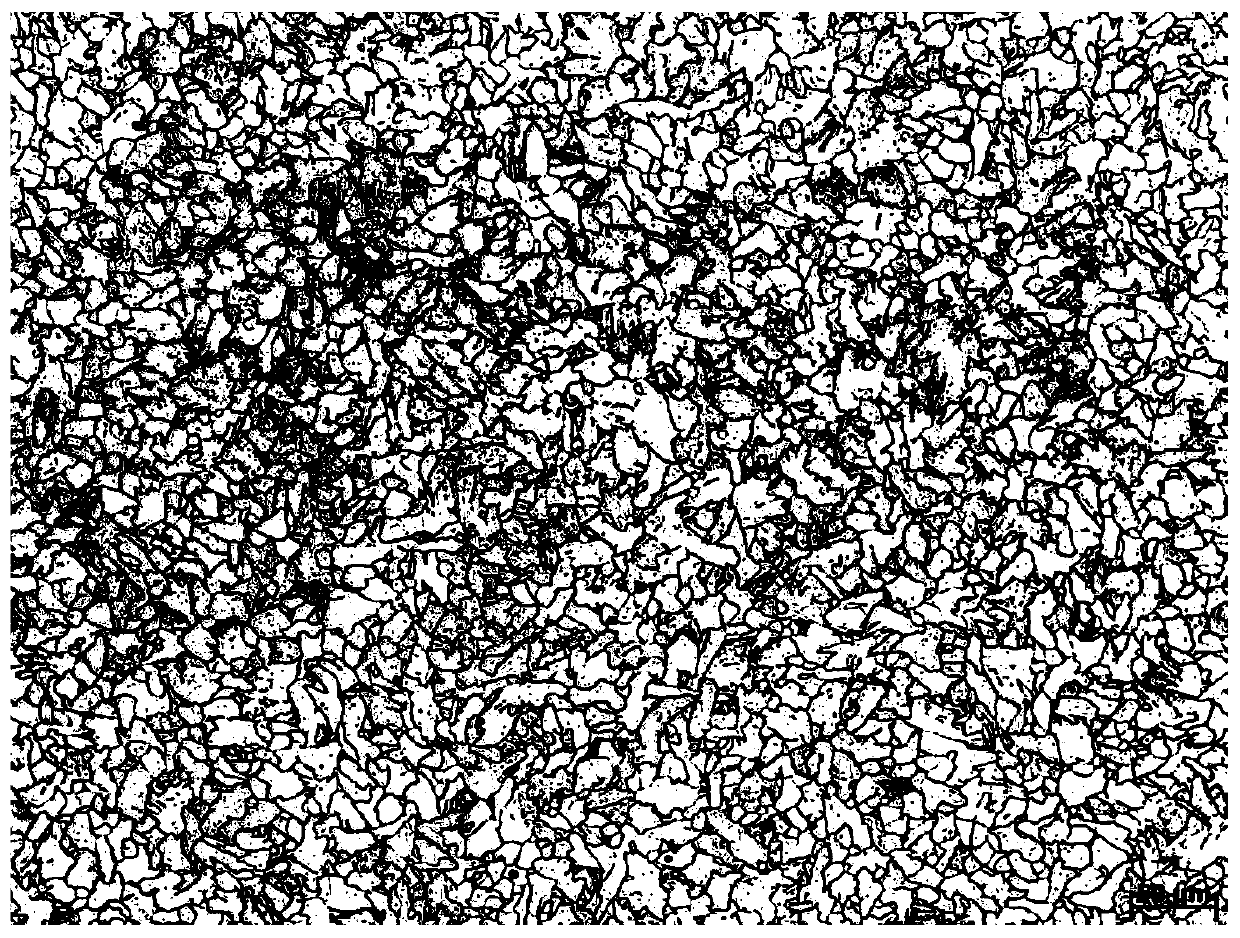

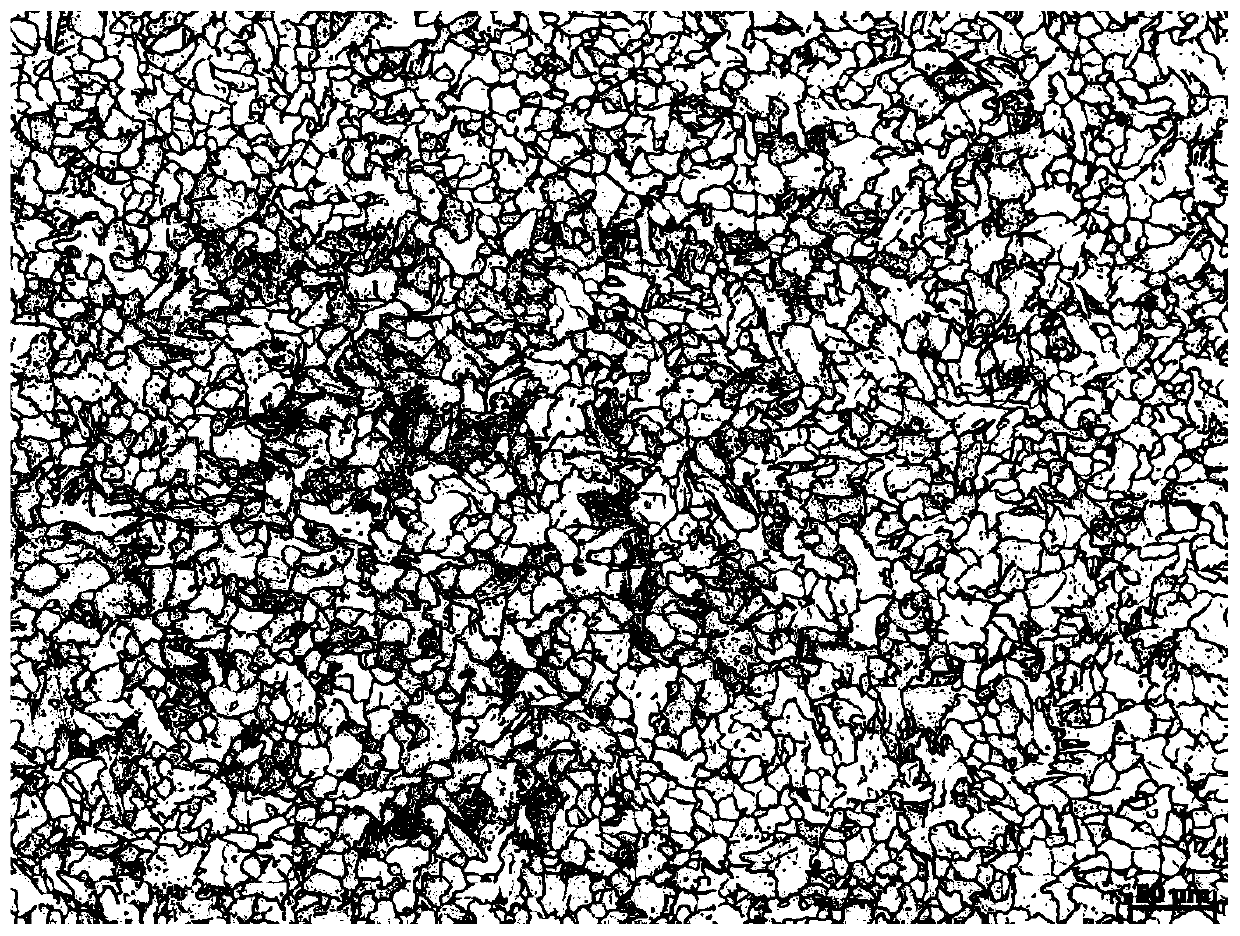

Titanium alloy with easily refined grains and preparing method thereof

ActiveCN104946928ABreak through limitationsReduce process control difficulty and manufacturing costCrystalliteChemical composition

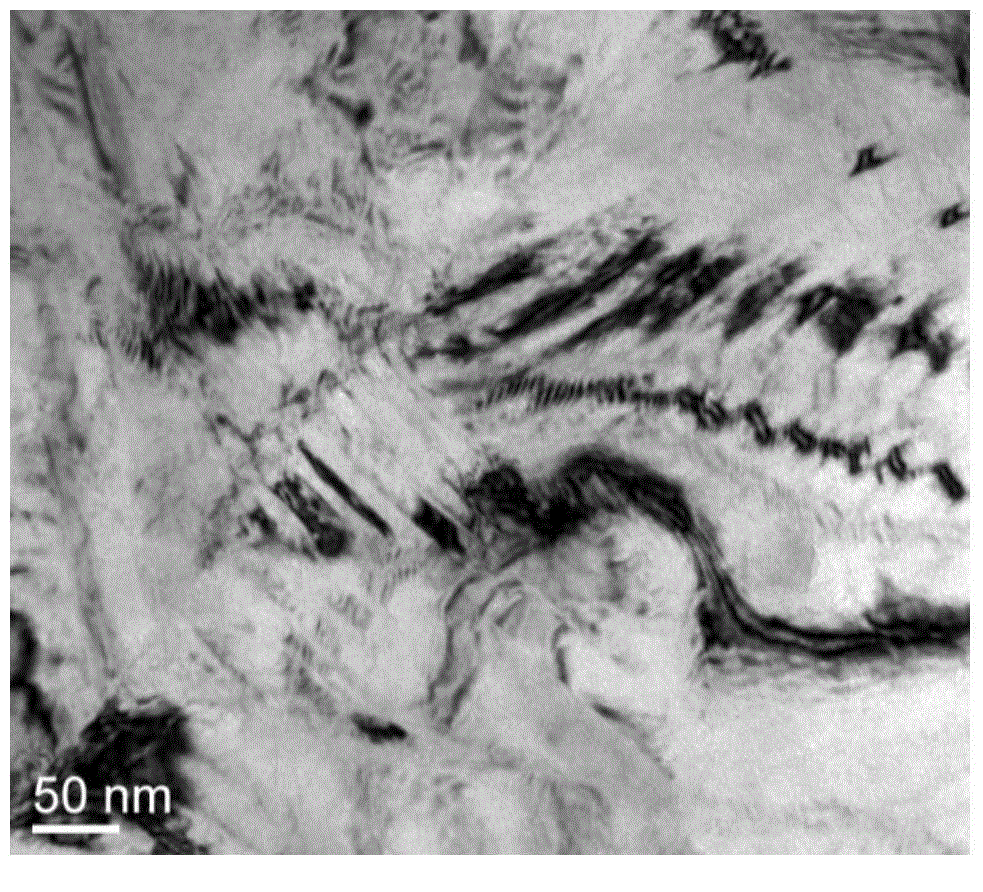

The invention discloses a titanium alloy and a preparing method thereof, the titanium alloy comprises chemical components in percent by weight: 33wt%-40wt% of Nb, 0.3wt%-0.5wt% of O and the balance of Ti; or the alloy comprises the components in percentage by weight: 33wt%-40wt% of Nb, 0.3wt%-0.5wt% of O, one or more of following element groups: 0-3wt% of V, 0-1wt% of Mo, 0-3wt% of Al, 0-3wt% of Sn and 0-4wt% of Zr and the balance of Ti. Components of the alloy in the invention are optimally designed, low-stacking fault energy large-sized ultra-fine grain / nanocrystalline titanium alloy can be obtained by smelting, thermal processing and cold processing, the titanium alloy has excellent match of strength and plasticity, the preparing method breaks through limitation of preparing of a titanium alloy nano-material in the prior art, processing control difficulty and manufacturing cost are reduced, the production efficiency is improved and the titanium alloy and preparing method have a broad application prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

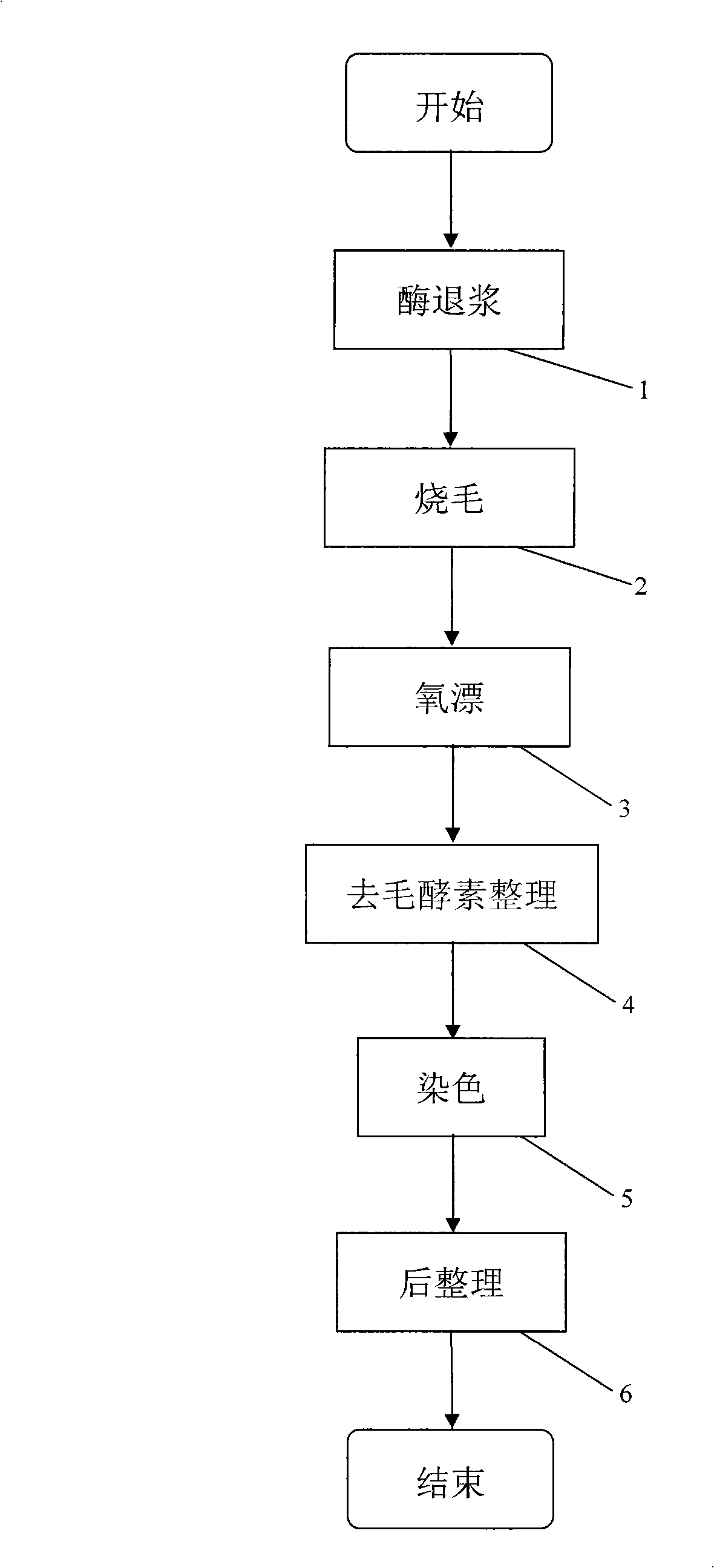

Dyeing and finishing process for bamboo fibre

The present invention discloses a bamboo fiber dyeing and finishing process, which sequentially comprises the prodedures as follows: enzyme desizing, singeing, oxide bleaching, de-fleecing and enzyme finishing, dyeing, after finishing and other procedures. A bleaching unit machine is used for the enzyme desizing and oxide bleaching, thus simplifying the process flow and saving the energy. The unwooling and enzyme finishing after the oxide bleaching increases the color and luster of the product; in addition, the normal-temperature and pressure jig dyeing avoids the over-tension of the fabrics and the phenomena of end breaking and scratches and reliably ensures the product quality. The amount of peroxide is controlled to be 3.5g / L without adjusting pH value, thus reducing the process control difficulty.

Owner:浙江誉华集团湖州印染有限公司

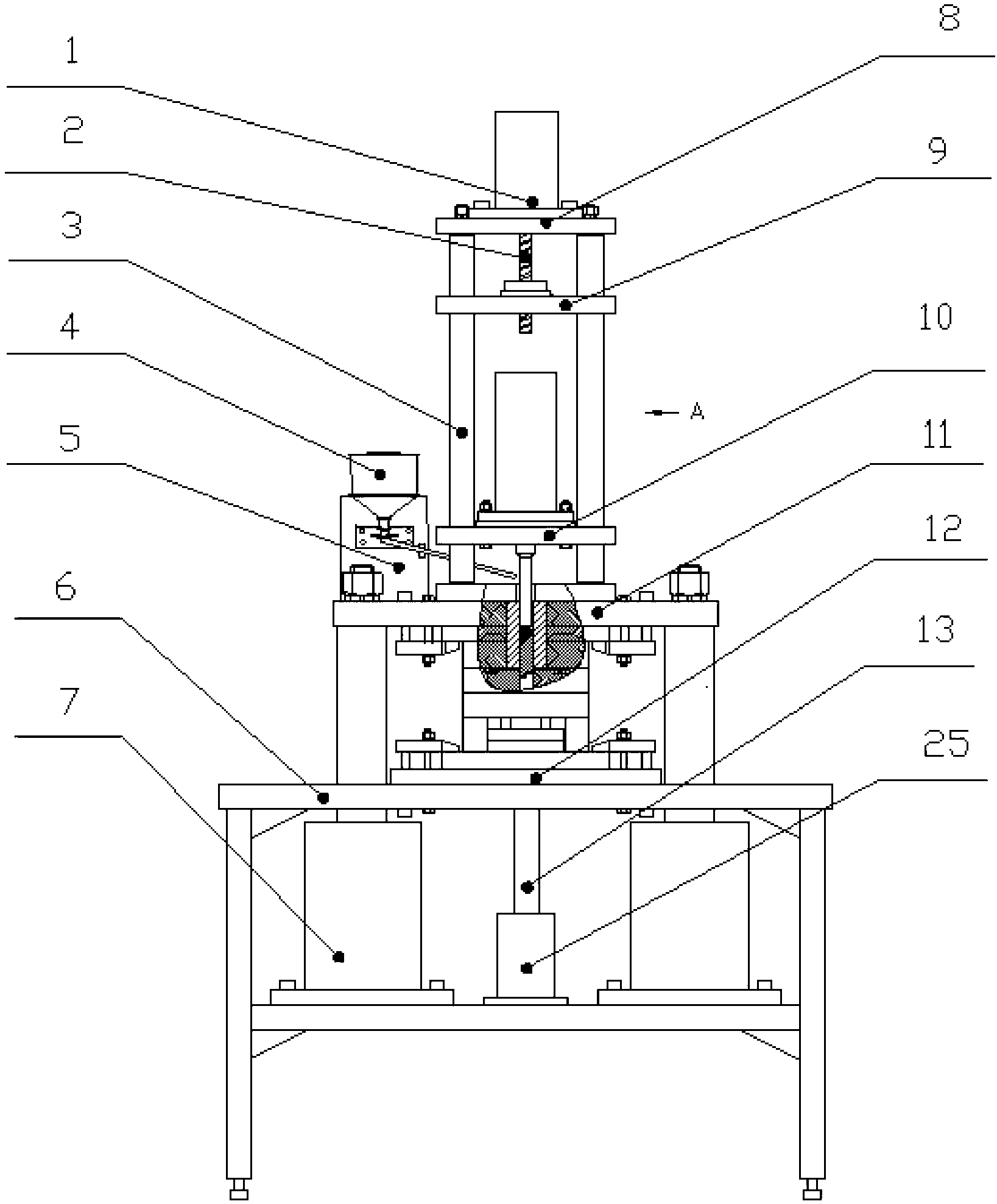

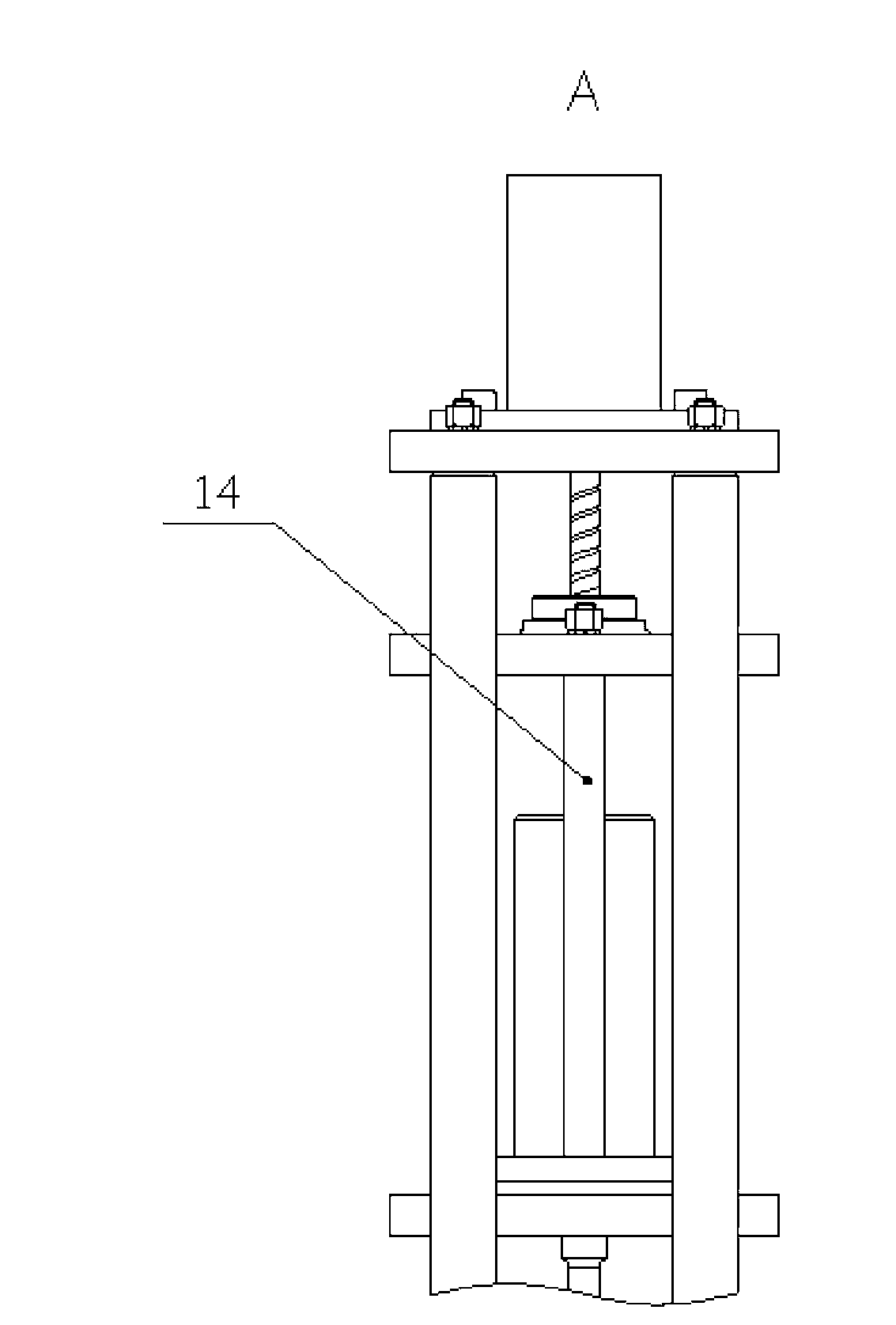

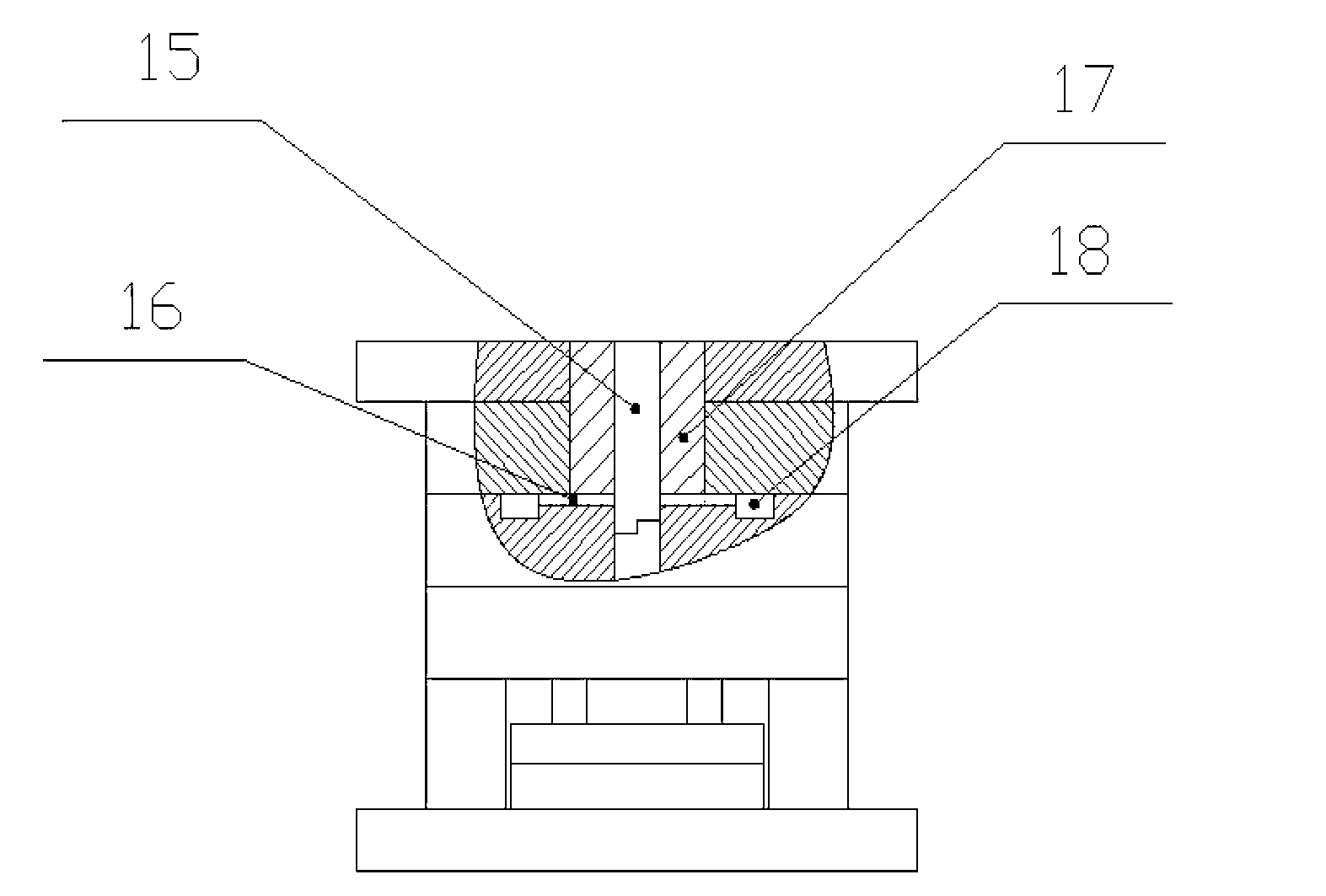

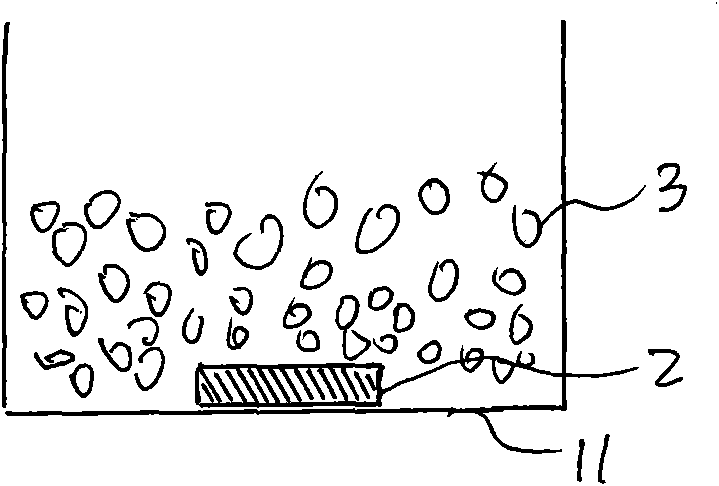

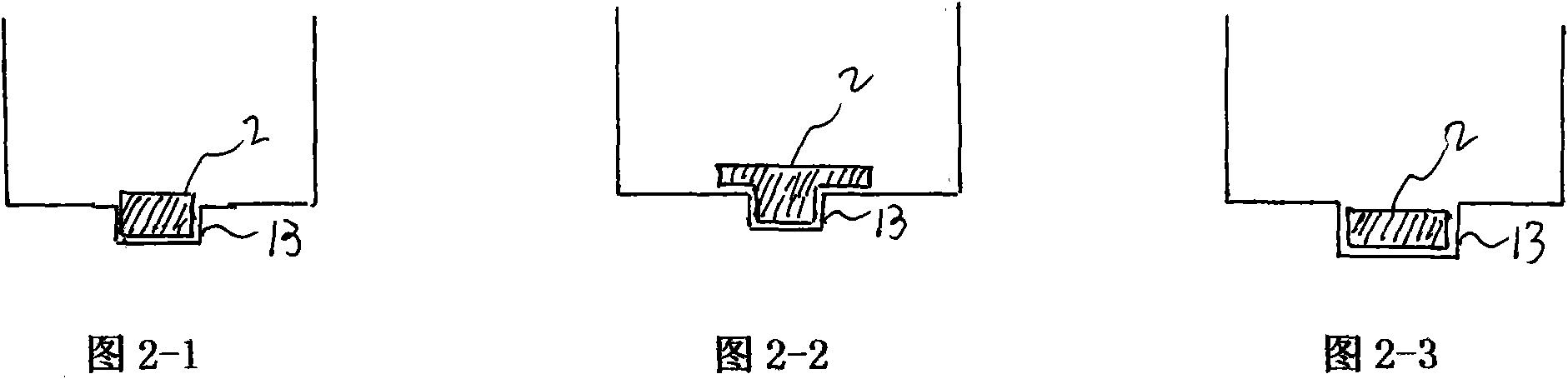

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

The invention discloses a screw-free ultrasonic microinjection molding device for a molten and plasticized polymer and a molding method. An injection part comprises an injection motor, a lead screw, an injection push plate and a connecting rod; an ultrasonic vibration system comprises an ultrasonic generator, an energy converter, an amplitude-change pole and a tool head; an injection module is provided with a plasticizing hole, a sub-runner and a mould cavity; a feeding system comprises a hopper and a support; and a mould closing and ejecting system comprises a mould closing hydraulic cylinder, an ejecting hydraulic cylinder, an upper mould fixing plate, a lower mould fixing plate and an ejector rod. A solid polymer is molten into a liquid under the action of frication thermogenesis and viscoelasticity thermogenesis applied into the polymer particle process through ultrasonic vibration, and meanwhile, ultrasonic waves play a cavitation role in the polymer liquid, so that the apparent viscosity is reduced, the phenomenon of short shot or insufficient filling in the machining process is overcome, the injection molding of a small plastic device can be well realized, the energy consumption is reduced, the difficulty in controlling the process is lowered, the economic efficiency of the device is increased, and the production cost is reduced.

Owner:CENT SOUTH UNIV

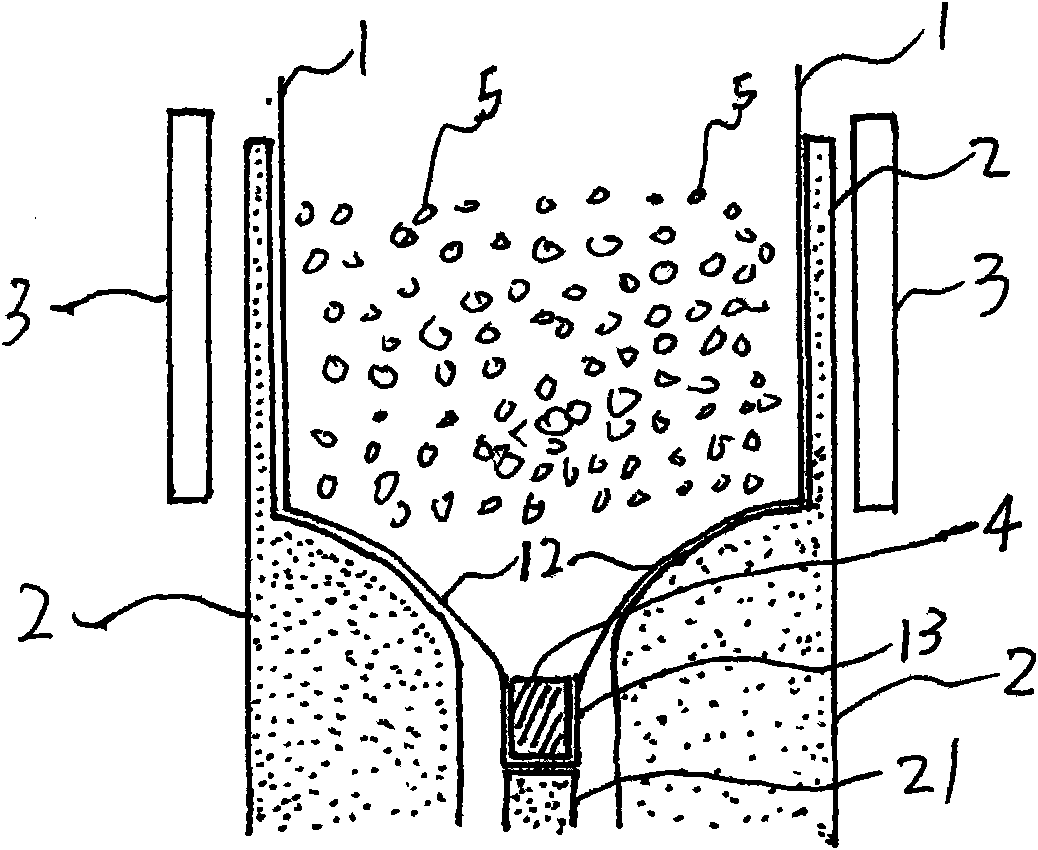

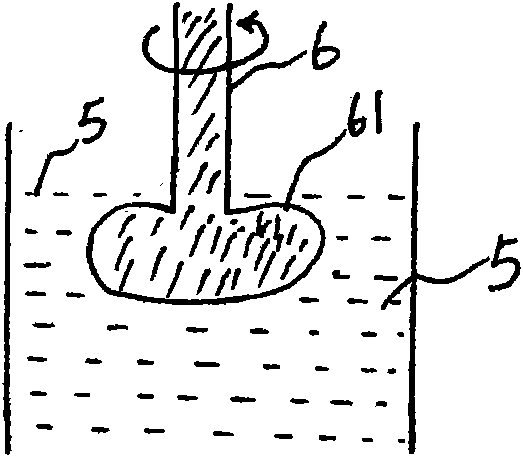

Method for casting crystal by seed crystal induction

InactiveCN102312279AImprove photoelectric efficiencyLow costFrom frozen solutionsSeed crystalDirectional solidification

The invention relates to a crystal material with a bigger size, which is manufactured by using a seed crystal induction vertical directional solidification casting method, in particular to a polycrystal or monocrystal material suitable for photoelectric application, such as silicon or silicon germanium. A traditional seed crystal used for casting a silicon crystal has a bigger size and higher consumption, thus, the invention provides a seed crystal with a smaller size and lower consumption, a method of casting a polycrystal or a monocrystal with the bigger size by using the seed crystal and the directional solidification method, the crystal material obtained by adopting the method, including a semiconductor crystal, and an application of the seed crystal in manufacturing semiconductor devices.

Owner:赵钧永

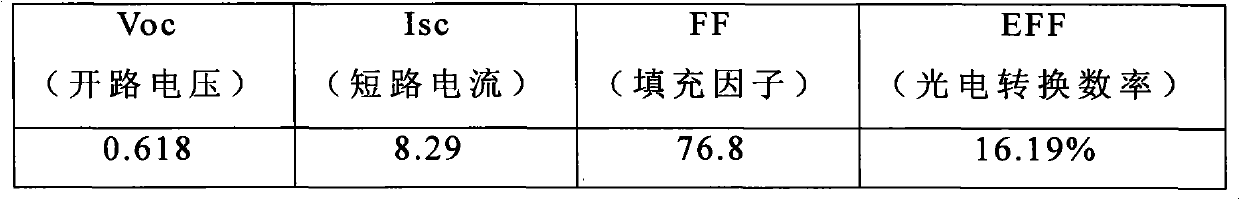

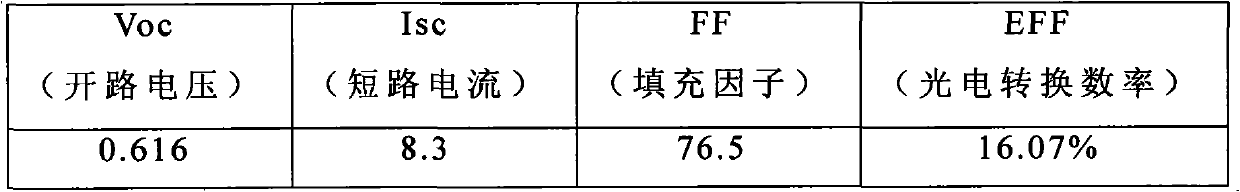

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502AAvoid uneven diffusionReduce uneven diffusionFinal product manufactureSemiconductor devicesNitrogen atmosphereNitrogen gas

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute; (2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and discharging out of a boat. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

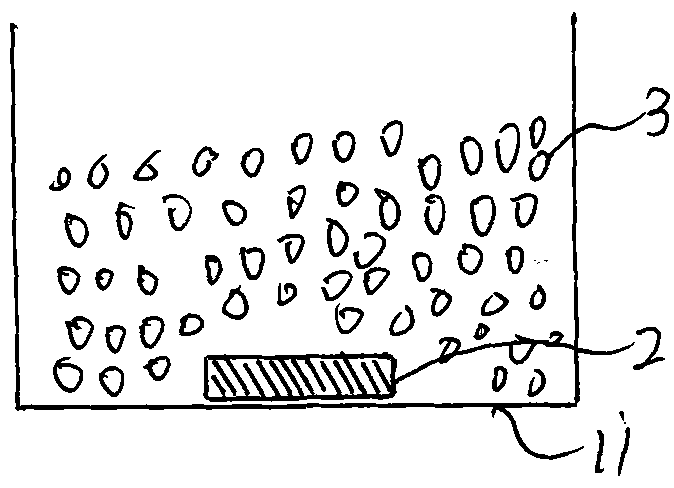

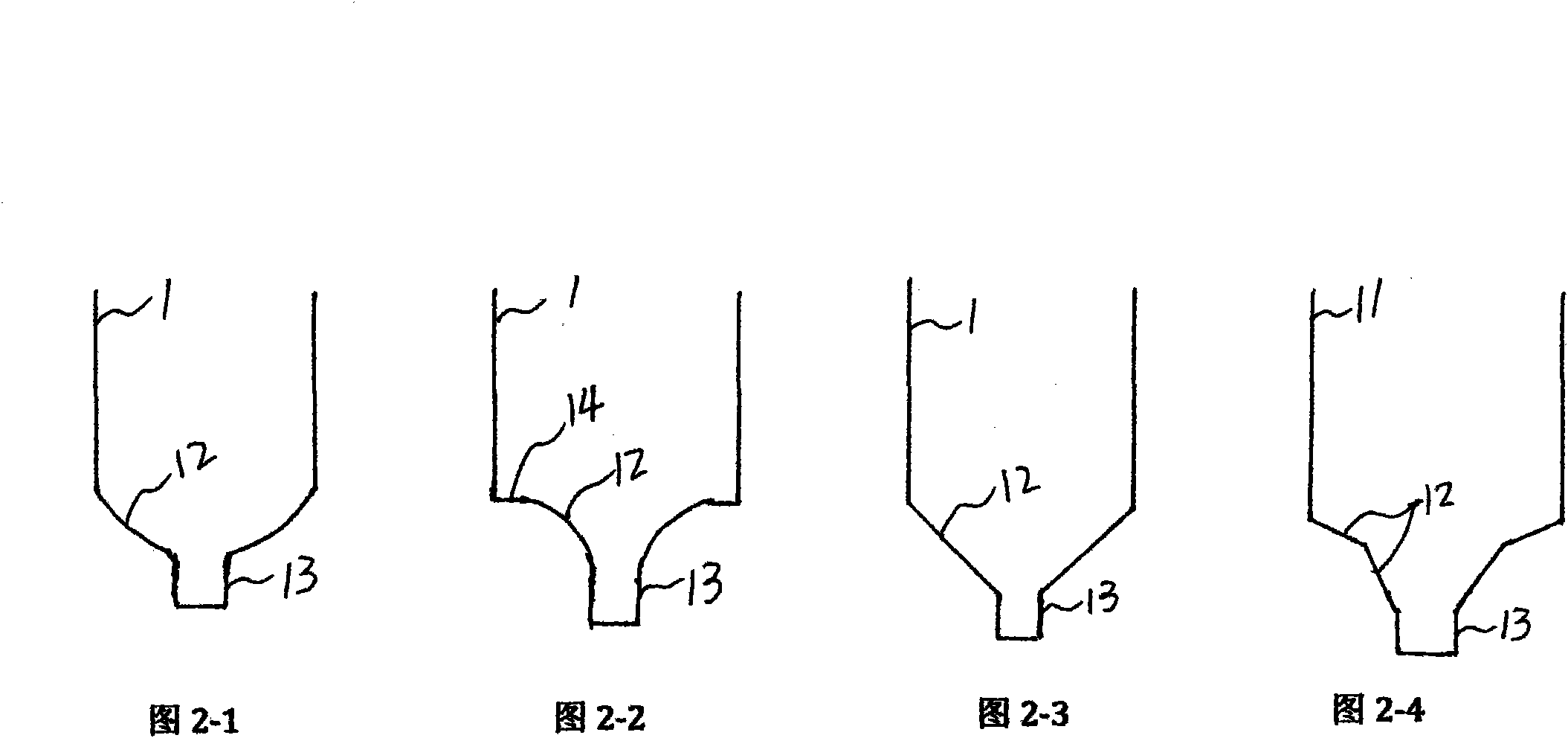

Crystal material containing seed crystal and manufacturing method and manufacturing device thereof

InactiveCN102312281ALow costImprove photoelectric efficiencyFrom frozen solutionsCrystal orientationDirectional solidification

The invention generally relates to a vertical directional solidification casting method using seed crystal induction, which is used for manufacturing a crystal material with a reserved crystal orientation and comprises a polycrystal material and a monocrystal material. When a traditional method for casting the crystal by using the seed crystal induction is used for producing the crystal with a bigger size, the problems that the seed crystal consumption is high, a mixed crystal is easy to generate, the internal stress is high, the monocrystal material is hard to obtain or the expected quality requirement is hard to reach and the like exist. The problems are solved by the invention through providing a gradually-changed crystal growth area of which the horizontal cross section is gradually increased, thereby, a good crystal growth effect is obtained, and the obtained cast monocrystal or polycrystal material, such as silicon or silicon germanium, has fewer defects, high quality and a good performance, and is especially suitable for the application of the semiconductor field and the photovoltaic field.

Owner:赵钧永

Hot-rolled deep-punched pickled plate for automobile structures and production method thereof

InactiveCN102719754AImprove deep drawing performanceReduce the difficulty of process controlChemical compositionPunching

The invention relates to a hot-rolled deep-punched pickled plate for automobile structures and a production method thereof. The hot-rolled deep-punched pickled plate for the automobile structures comprises the components in percentage by weight: 0.02-0.05% of C, not more than 0.05% of Si, 0.10-0.30% of Mn, 0.40-0.60% of Cr, 0.01-0.02% of Ti, not more than 0.15% of P, not more than 0.008% of S, 0.02-0.07% of Als, and the balance of Fe and inevitable impurities. The production method of the hot-rolled deep-punched pickled plate for the automobile structures comprises the step of: controlling the chemical components in the steel, the hot rolling process, the pickling process and other parameters to manufacture the hot-rolled deep-punched pickling plate for the automobile structures. The hot-rolled deep-punched pickled plate for the automobile structures has the characteristic of excellent deep punching performance; and the production method of the hot-rolled deep-punched pickled plate for the automobile structures has the advantages of low difficulty in process control, strong operability, simple method, low cost and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Production method of 440MPa-grade thin gauge hot-rolling pickling automobile sheet

The invention discloses a production method of a 440MPa-grade thin gauge hot-rolling pickling automobile sheet. The hot-rolling pickling automobile sheet is prepared from the chemical element components in percentage by weight: C is 0.07-0.09, Si is less than or equal to 0.05, Mn is 1.00-1.20, P is less than or equal to 0.020, S is less than or equal to 0.020, Nb is 0.010-0.020, Als is 0.030-0.050, Ti is 0.010-0.030, N is less than or equal to 0.008, and the balances are Fe and unavoidable impurities. The preparation method sequentially includes the following steps of liquid iron pre-desulfuration processing, converter steel-making, steel ladle LF refining, continuous casting, casting blank heating, rough rolling, finish rolling, laminar flow cooling, high temperature coiling, skin rolling, pickling, rinsing, oil coating and coiling. According to the production method, the measures of low temperature heating, the rough rolling, high pressure dephosphorization before the finish rolling,dephosphorization before the rough rolling and between the finish rolling passes, and corrosion inhibitor adding in the pickling are adopted, and the surface quality of a steel coil is improved; andthe reduction rate of the finish rolling, the finishing rolling temperature, coiling temperature precision control and high temperature coiling are adopted, stability of a steel coil general rolling technology is ensured, and the strip shape quality and the performance general volume stability of the steel coil are improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

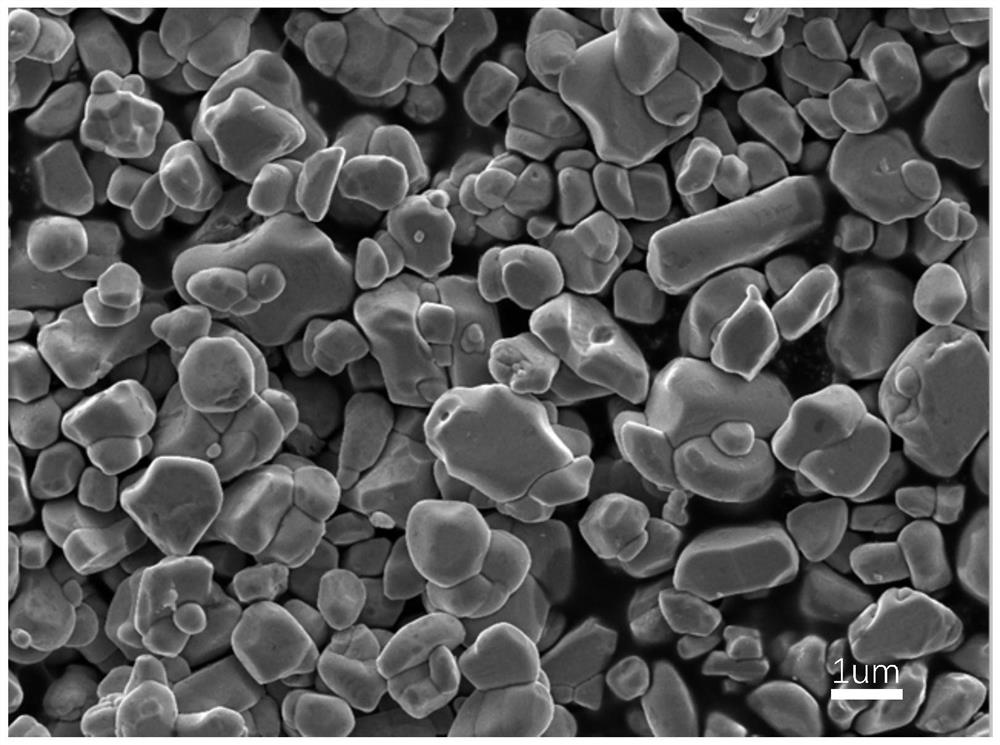

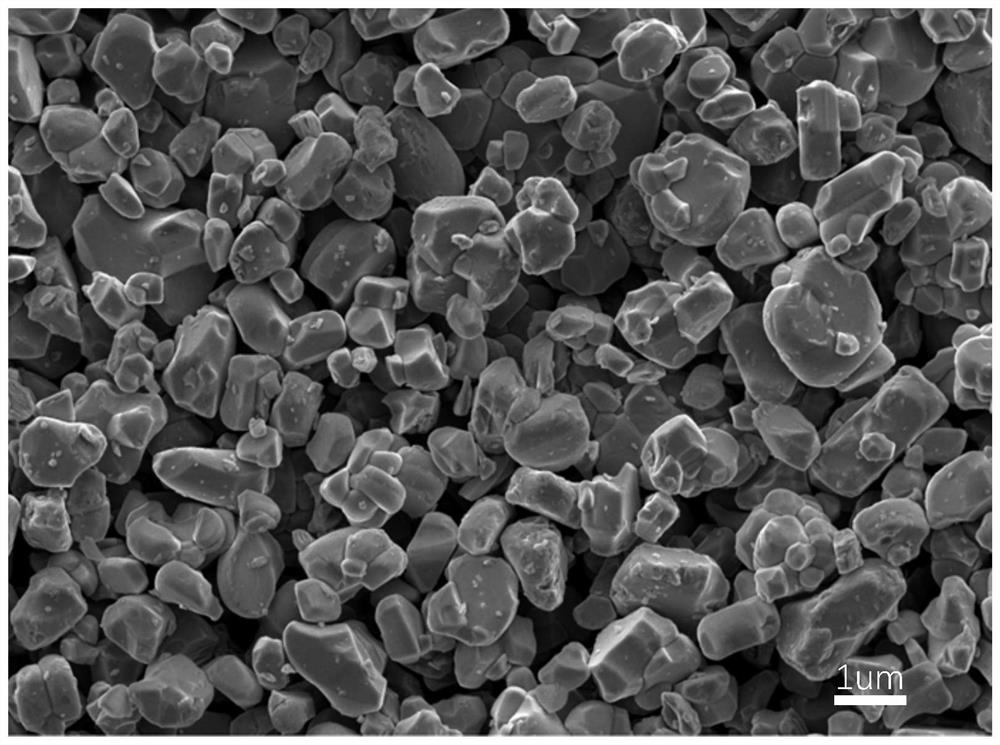

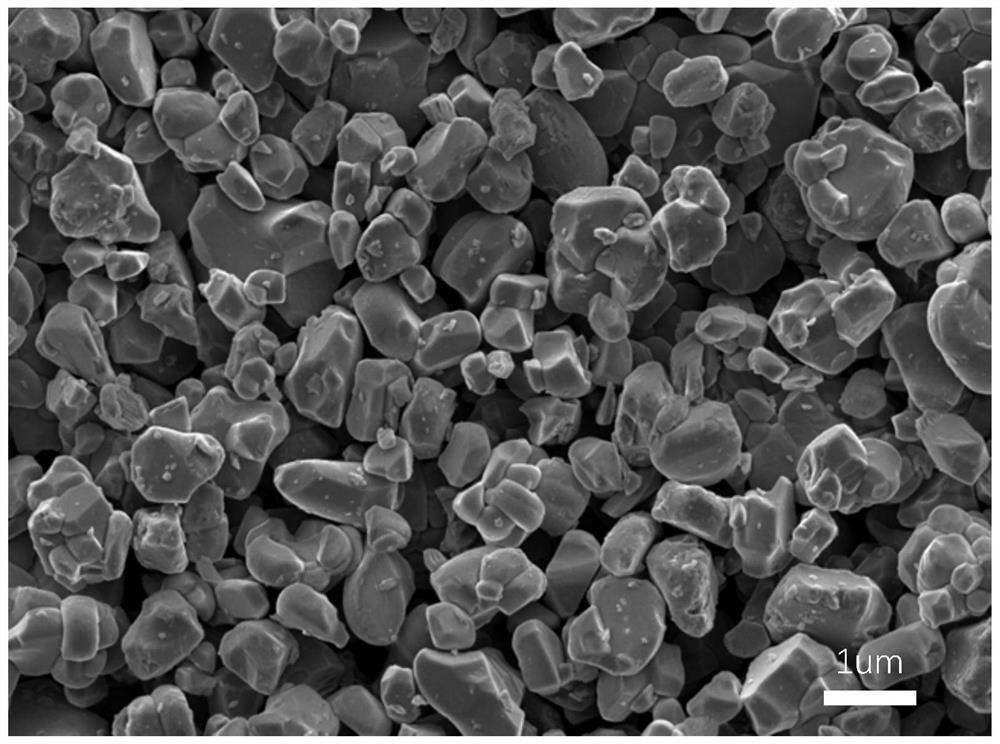

Preparation method of single-crystal-morphology lithium ion battery positive electrode material

ActiveCN113036095AReduce processingProcess environmental protectionCell electrodesSecondary cellsSingle crystalSlurry

The invention discloses a preparation method of a single-crystal-morphology lithium ion battery positive electrode material. The preparation method comprises the following steps: (1) adding a metal salt solution and a sodium hydroxide solution into a reaction kettle, and carrying out a co-precipitation reaction to prepare precursor slurry; (2) mixing a precursor slurry with a lithium source and a doping agent by a wet method, and performing spray drying to obtain a precursor mixture; (3) performing primary sintering on the precursor mixture to obtain a primary sintering product; and (4) washing the primary sintering product with water, mixing the washed product with a coating agent, and carrying out secondary sintering to obtain the single-crystal-morphology lithium ion battery positive electrode material. In the preparation method, the precursor slurry is prepared by adopting an ammonia-free process, particles formed by stacking a plurality of fine particles are formed, the specific surface area of the precursor is very large and is greater than 100m < 2 > / g, and the precursor with an ultrahigh specific surface area is easier to form a single-crystal positive electrode material with uniformly dispersed primary particles after being sintered, so that development of the capacity is facilitated.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

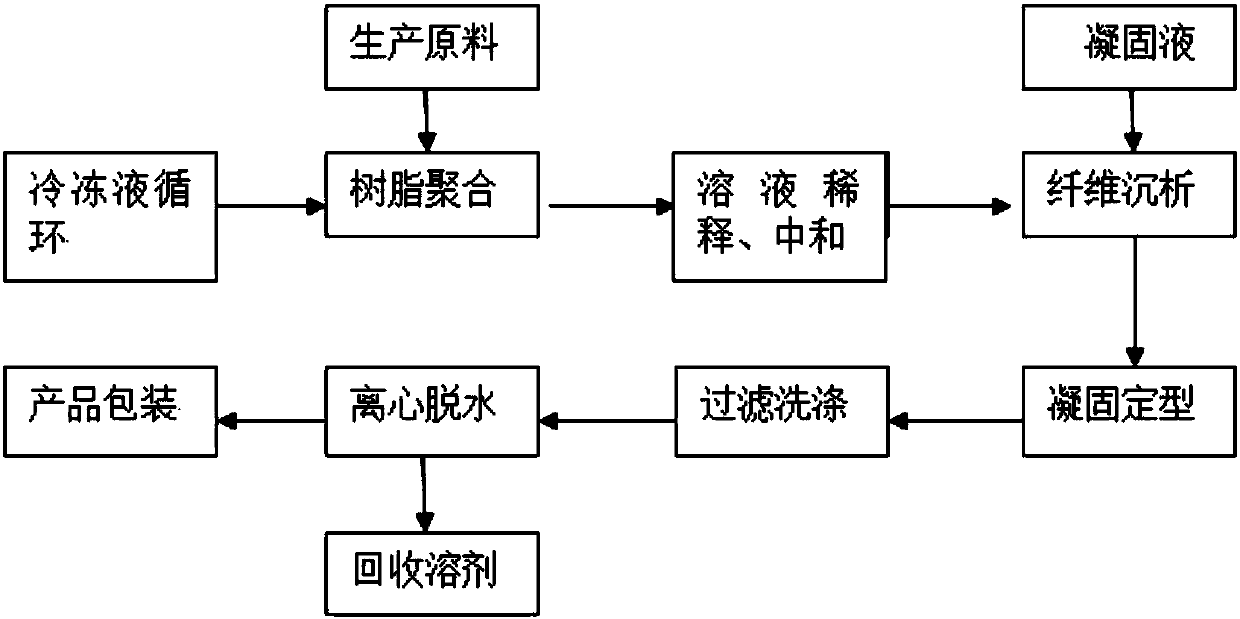

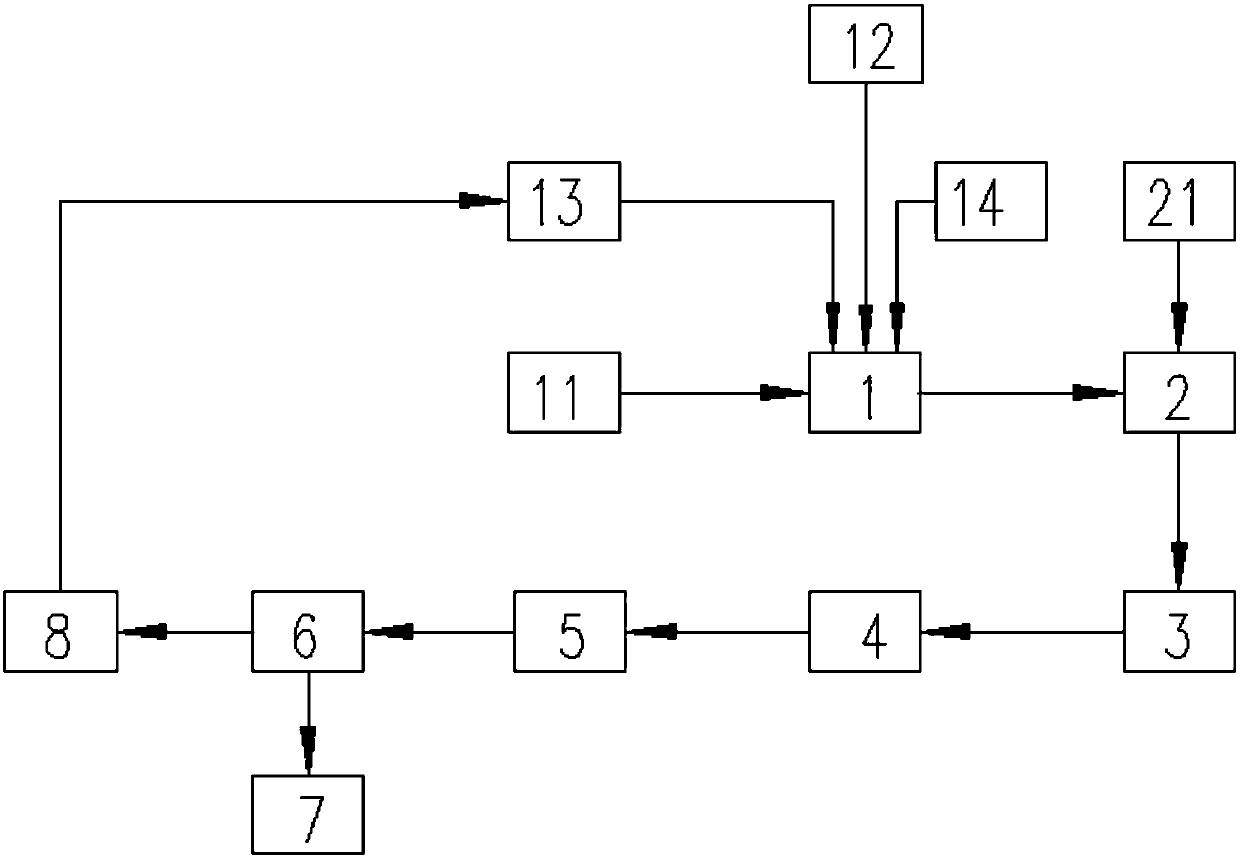

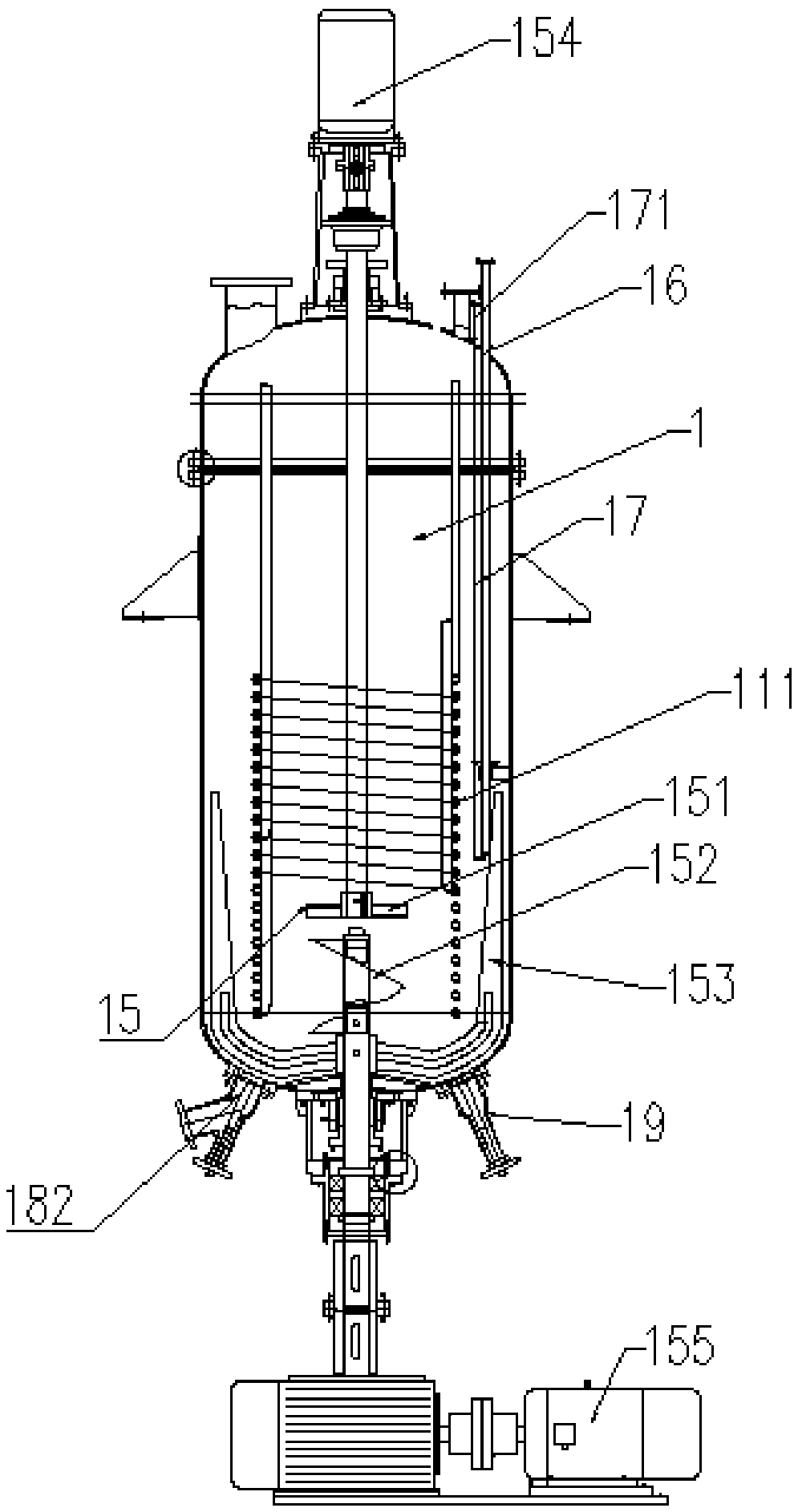

Method for producing aramid fiber fibrid

InactiveCN107814927AChange regularitySlow down aggregationMonocomponent copolyamides artificial filamentPolymer sciencePerformance index

The invention relates to a method for producing aramid fiber fibrid and belongs to the technical field of macromolecules. The method for producing the aramid fiber fibrid, provided by the invention, comprises the following steps: (1) dissolving m-phenylenediamine and p-phenylenediamine in a polar organic solvent under the protection of an inert gas atmosphere, so as to obtain a stock solution; (2)cooling the temperature of the stock solution to -8 DEG C to -12 DEG C, adding m-phthaloyl chloride for a polymerization reaction, adding a polar organic solvent for dilution when the reduced viscosity is 1,000 to 1,500, and terminating the reaction, so as to obtain a polymer solution; (3) subjecting the polymer solution to diluting, neutralizing, settling out, curing, filtering, washing and dewatering, thereby obtaining the aramid fiber fibrid. According to the method, the molecular weight size and distribution thereof of resin are easily controlled, and the product performance index of thearamid fiber fibrid can also be adjusted in view of the requirements of different application fields.

Owner:菲博(郁南)纤维新材料科技有限公司

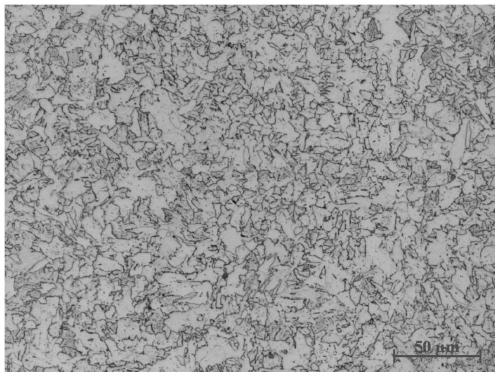

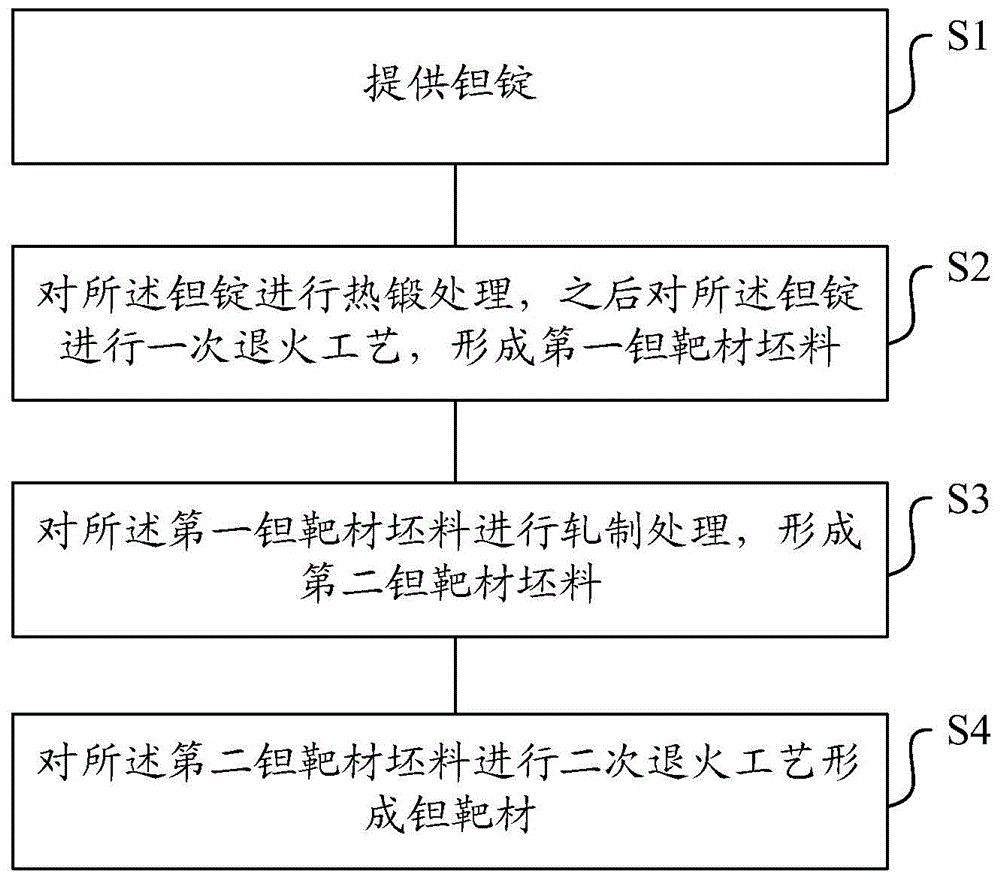

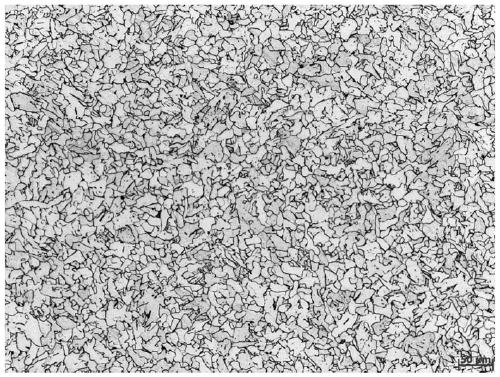

Method for manufacturing tantalum target material

ActiveCN104419901ASimple internal structureStress reliefVacuum evaporation coatingSputtering coatingIngotTantalum

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

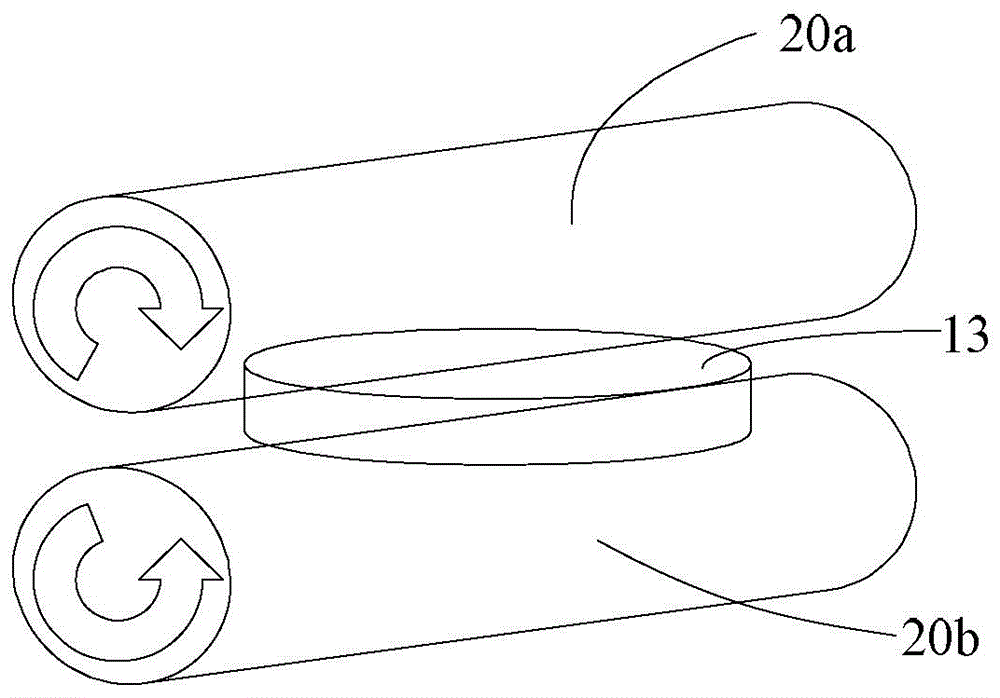

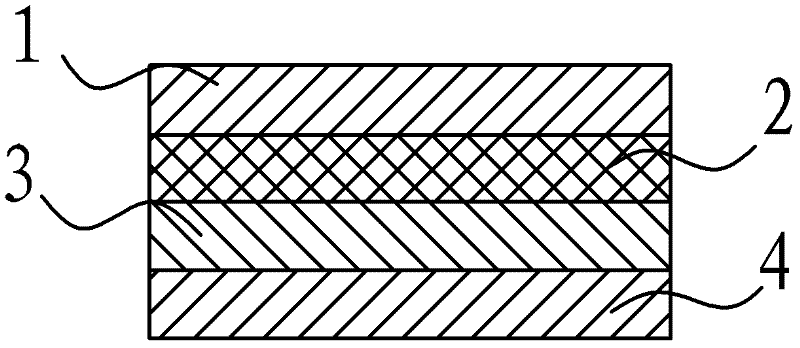

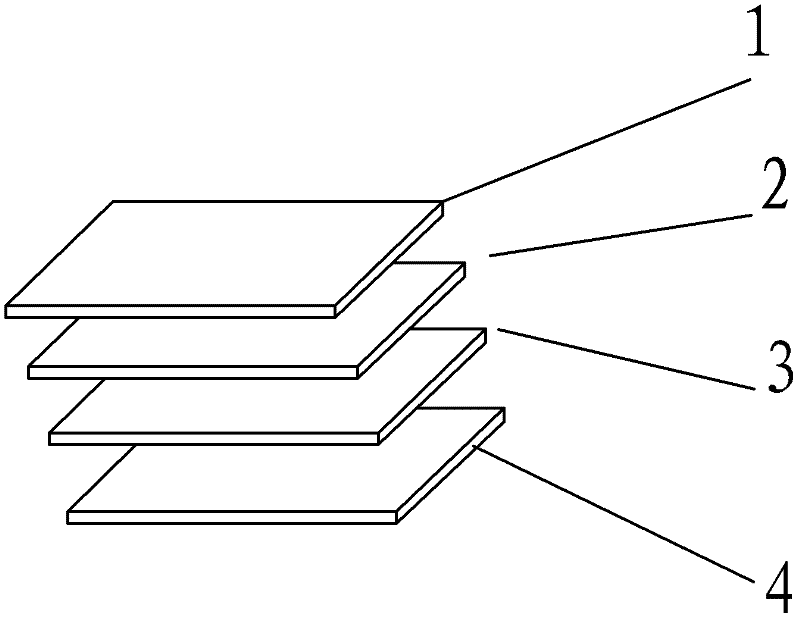

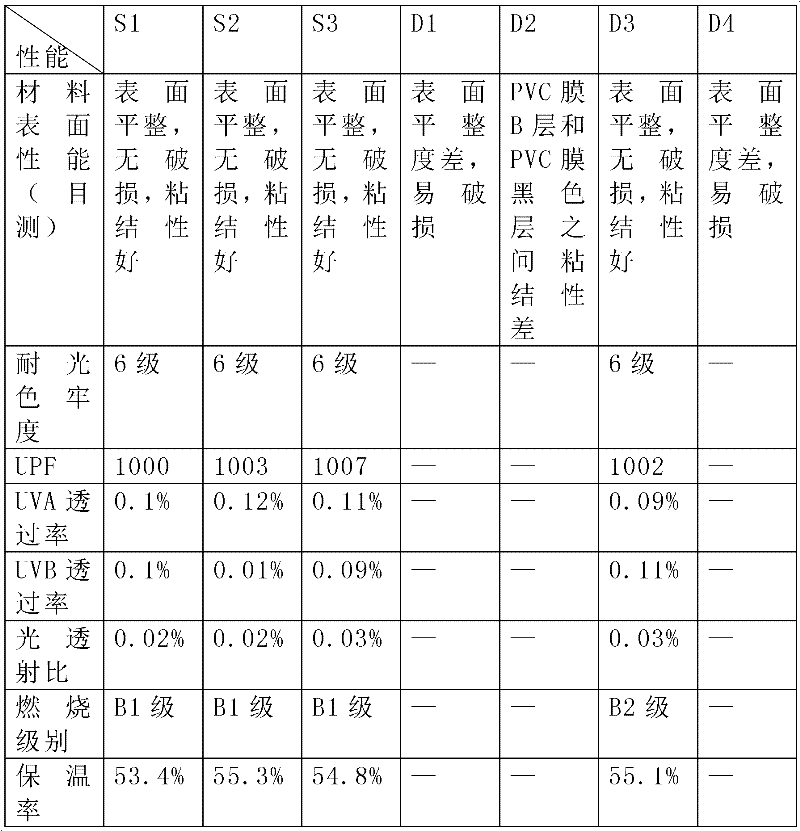

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

ActiveCN102555352AWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

The invention provides a glass fiber / PVC (polyvinyl chloride) composite membrane material. The glass fiber / PVC composite membrane material comprises a first PVC membrane layer, a second PVC membrane layer, a glass fiber base fabric layer and a third PVC membrane layer from bottom to top in sequence, wherein the second PVC membrane layer is a black PVC membrane layer. The invention also provides a preparation method for the glass fiber / PVC composite membrane material. The glass fiber / PVC composite membrane material provided by the invention has good shading and thermal insulation performances on the premise of ensuring good comprehensive color fastness and combustion performances. The preparation method for the glass fiber / PVC composite membrane material, provided by the invention, is simplified in the process and easy to perform.

Owner:NINGBO XIANFENG NEW MATERIAL

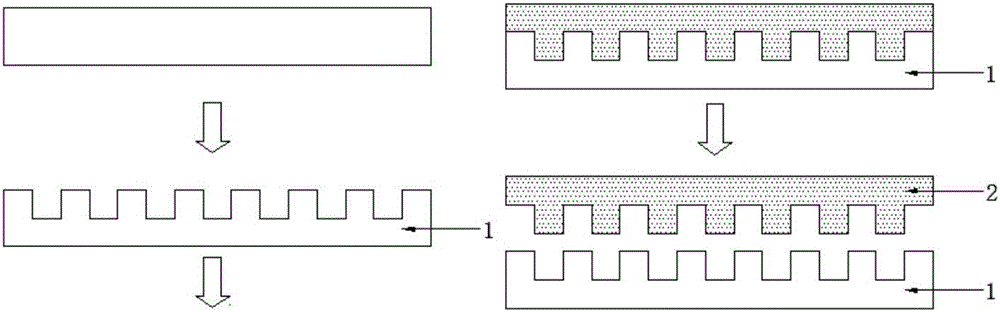

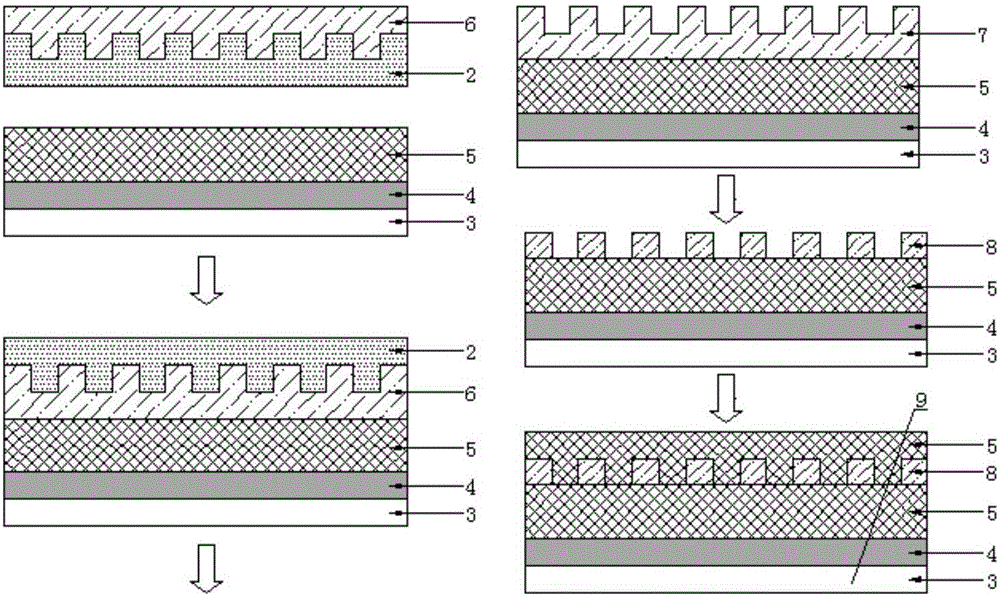

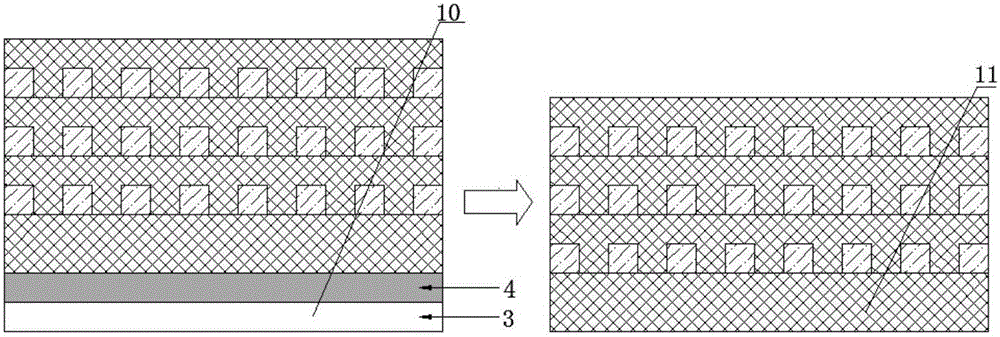

Method for manufacturing force responsive photonic crystal materials based on inverse compressing nano-forming technology

ActiveCN106226846ASimple processShort preparation cycleOptical elementsPhotonic crystal structureElectron-beam lithography

The invention discloses a method for manufacturing force responsive photonic crystal materials based on inverse compressing nano-forming technology. Electron beam lithography technology and reactive ion etch technology are employed. A nanometer magnitude pattern is etched on a rigid template to serve as a mother template according to preset photonic crystal structure parameters. An elastic polymer soft template with an inverse nanometer magnitude pattern can be made and serves as a secondary template. With highly elastic gel as filling material and visco-elastic polymer as moulding material, the pattern on the mother template is copied on to the visco-elastic polymer in a high fidelity way through inverse compressing, so as to produce nanometer magnitude and structure-controllable force responsive photonic crystal. Compared with the prior art, the method has the advantages of simple process, short flow, easily controlled technological parameters, repeatedly usable templates, high product precision level, stable and reliable product quality and low cost.

Owner:SHANDONG UNIV OF SCI & TECH

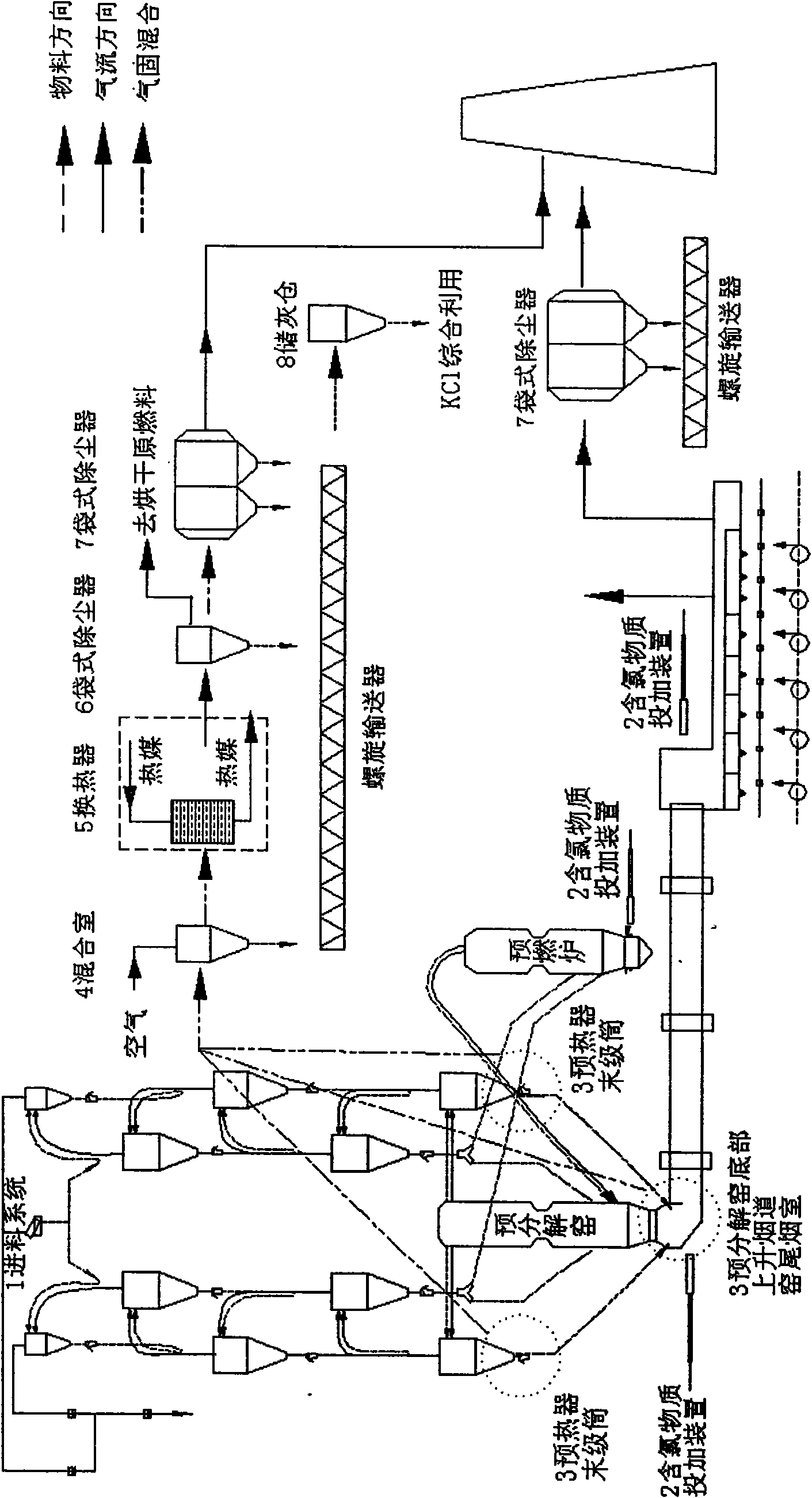

Method for producing low alkali cement by using high alkali raw materials

ActiveCN101607796ASolve environmental problems such as land occupationEfficient removalAlkali metal chloridesDecompositionCement kiln

The invention provides a method for producing low alkali cement by using high alkali raw materials, which includes the steps of: putting the raw material limestone with alkali equivalent about 0.80% into a dry cement rotary kiln through a normal channel for putting the raw material into the kiln; adding chlorine-containing substances into the rotary kiln at the locations of a kiln head, a kiln head fuel burner, a flue chamber at kiln tail end, a pre-decomposition kiln or a pre-burning furnace; opening holes at the positions of the bottom part of the pre-decomposition kiln, an ascending flue channel, the flue chamber at kiln tail end or the tail grade cylinder of a pre-heater and inducting the chlorine-containing smoke gas enriched in the positions into a smoke dust collection system and collecting the smoke dust in the smoke gas. The smoke dust collection system comprises a mixing room. The method for producing low alkali cement by using high alkali raw materials uses the special property that alkali metal ions, chloride ions and sulfate ions mutually affect the melting point temperature under the high temperature coexistence condition, adds the chlorine-containing substances during the production process, and leads the chlorine in wastes to be reacted with the alkali in the raw materials by controlling the proportion between the alkali metal ions, chloride ions and sulfate ions entering the cement kiln, thereby achieving the double effects of reducing the alkali in the cement and processing high-chlorine wastes.

Owner:广灵金隅水泥有限公司

Refined processing method of apocynum venetum fiber

ActiveCN106435760AImprove qualityImprove degumming effectHeating/cooling textile fabricsLiquid/gas/vapor fibres/slivers/rovings treatmentElectricityApocynum venetum

The invention discloses a refined processing method of apocynum venetum fiber. The refined processing method comprises steps as follows: wetting activation of apocynum venetum bast, beating into cakes and caging, directional catalytic oxidation, chemical degumming and postprocessing, wherein after the apocynum venetum bast is subjected to wetting activation with organic amine solvents, lignin, pectin and hemicellulose are subjected to the directional catalytic oxidation with a ferrite solution and an activator. A series of technological means including wetting activation processing, the directional catalytic oxidation and the like are organically combined, so that the refined processing method of the apocynum venetum fiber has the characteristics that the degumming effect is good, and a finished apocynum venetum fiber product is good in fineness, length, strength and other indexes, excellent in quality, good in spinnability and the like; besides, the consumption of chemicals during processing is low, the environmental protection pressure is low, and the technology is simple to control; the consumption of utilities such as water, electricity, gas and the like is low, the efficiency is high, and the refined processing method is applicable to industrial production.

Owner:山东恒丰新型纱线及面料创新中心有限公司

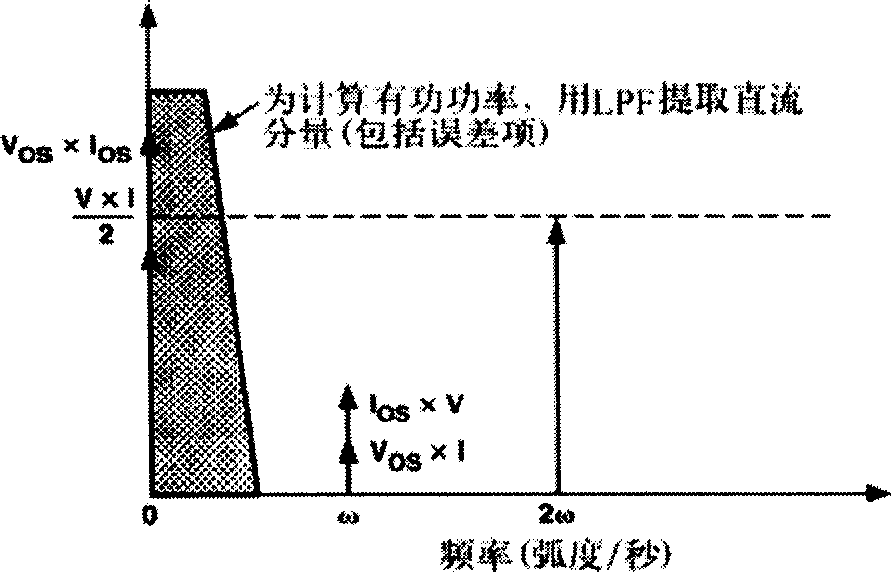

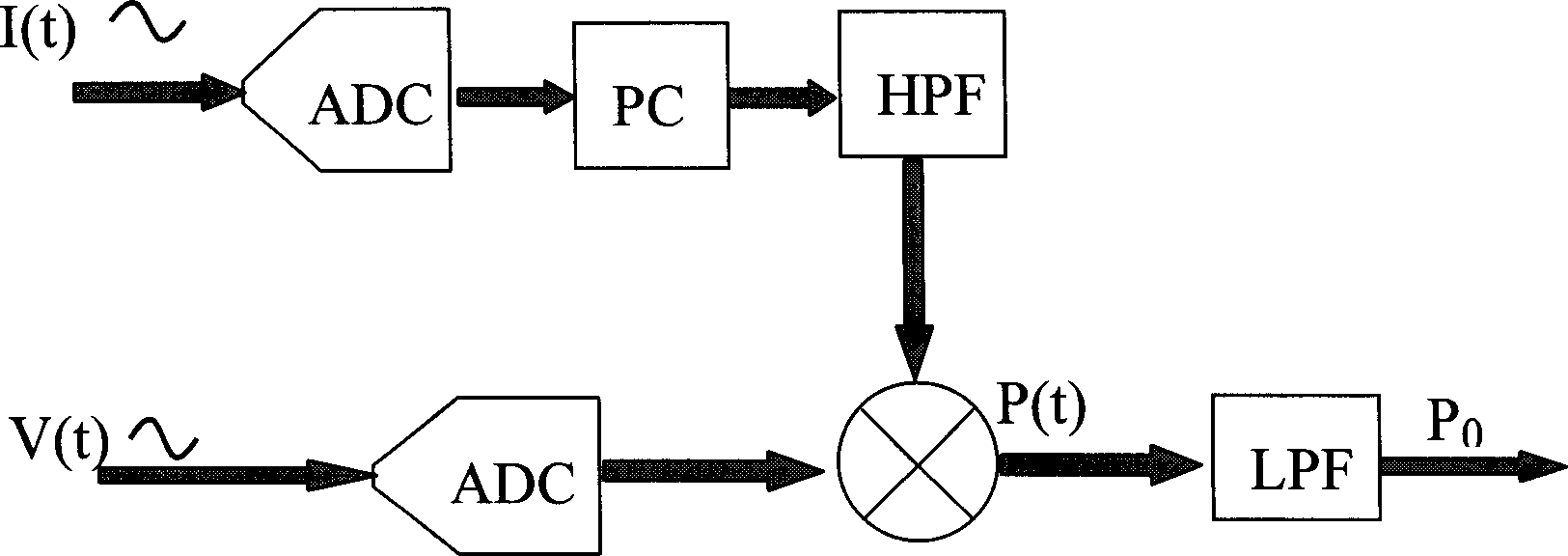

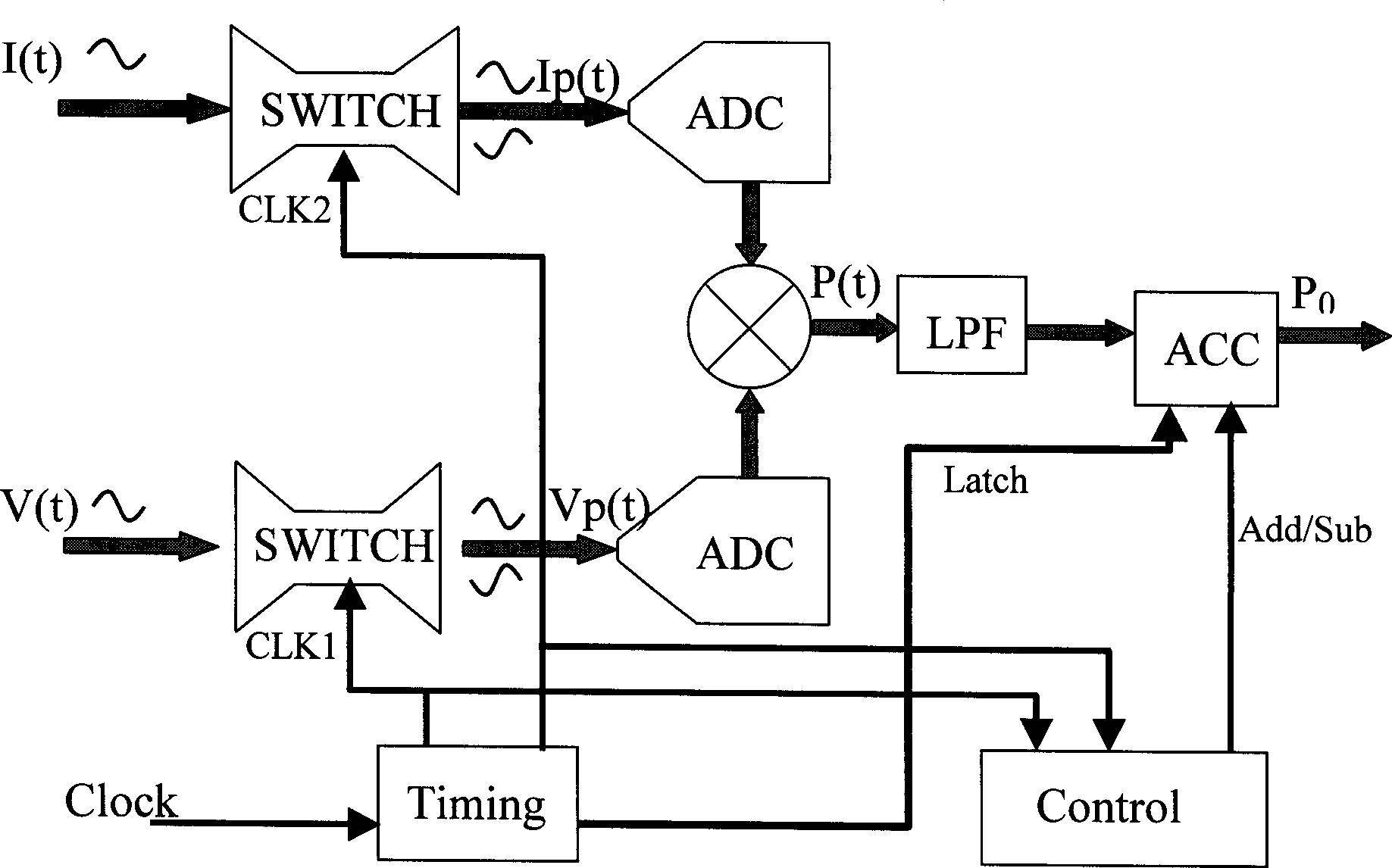

Automatic eliminating method for self d.c. component in power metering system

InactiveCN1439883AReduce complexityReduce the difficulty of process controlPower measurement by digital techniquePower measurement by current/voltageObservational errorEffective power

A technique for automatically eliminating the self DC component of system in power metering features that a very simple and effective circuit structure is used to automatically elimitate the measuring error caused by input misadjustment, and in turn the false power caused by internet DC component (misadjustment). If the input signal has a DC component, it can be used to calculate active power.

Owner:VIMICRO CORP

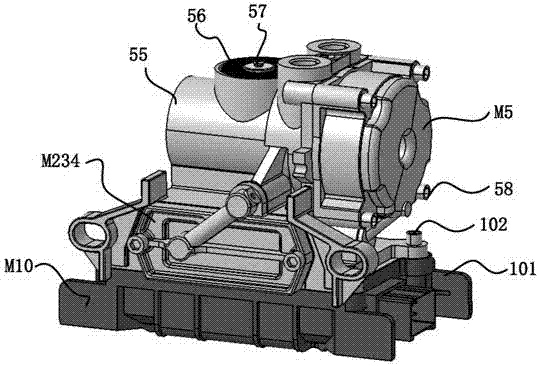

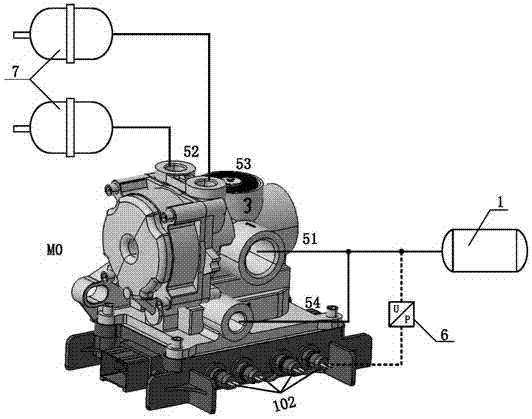

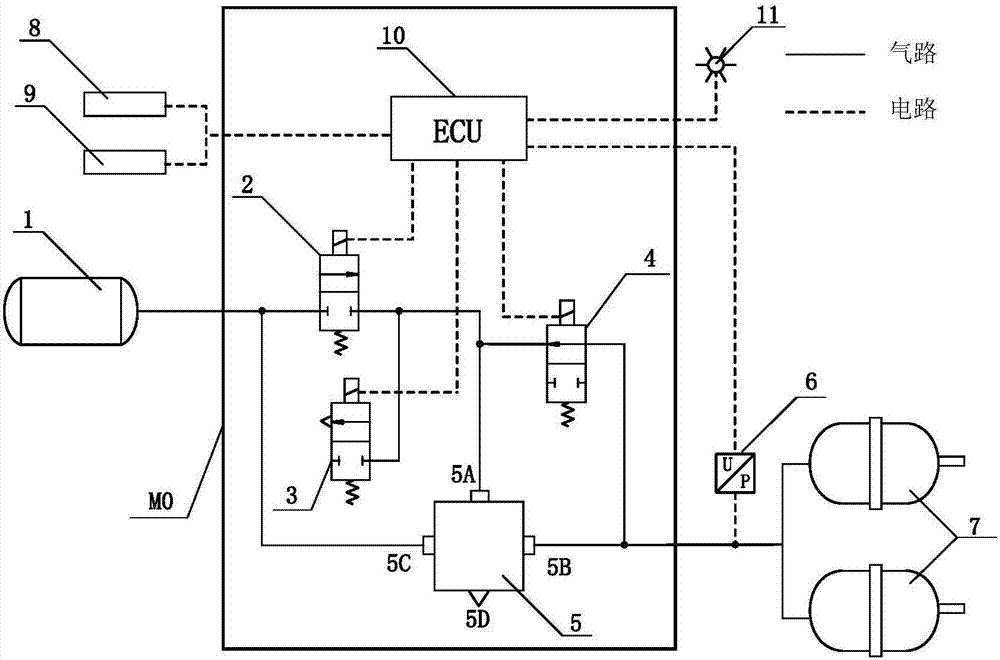

Pneumatic electronic parking brake integrated valve

PendingCN107215327AReduce in quantitySave installation spaceBraking action transmissionApplication and release valvesRelay valveSolenoid valve

The invention discloses a pneumatic electronic parking brake integrated valve which is used for connecting with an air storage tank and a parking brake air chamber. The integrated valve comprises a relay valve assembly (M5), a solenoid valve assembly (M234), a parking brake controller assembly (M10), an upper shell (55) and a lower shell (101), the relay valve assembly (M5) comprises a relay valve (5), the solenoid valve assembly (M234) comprises a first solenoid valve (2), a second solenoid valve (3) and a third solenoid valve (4), the parking brake controller assembly (M10) comprises a parking brake controller (10), the upper shell (55) is detachably and fixedly connected with the lower shell (101), the solenoid valve assembly (M234) is adjacent to the relay valve assembly (M5), the mounting surface of the solenoid valve assembly (M234) is mutually perpendicular to that of the relay valve assembly (M5), both the solenoid valve assembly (M234) and the relay valve assembly (M5) are arranged in the upper shell (55), and the parking brake controller assembly (M10) is arranged at the bottom of the integrated valve and mounted in the lower shell (101). According to the integrated valve, the parking brake controller, three solenoid valves and the relay valve are effectively integrated, pipeline connection is simplified, manufacturing and assembling of components are simplified, and the integrated valve is compact in structure, low in cost and reliable in performance.

Owner:NANJING UNIV OF SCI & TECH

Environment-friendly leather finishing agent and preparing method thereof

InactiveCN105820693ADropping step is omittedChemically activeCoatingsLeather surface finishingCross-linkZinc

The invention discloses an environment-friendly leather finishing agent and a preparing method thereof, and belongs to the technical field of leather processing. The leather finishing agent is prepared from, by weight, 15-40% of ethyl acrylate, 1-8% of acrylic acid, 3-10% of an emulsifying agent, 0.2-0.8% of an initiating agent, 2-8% of a cross-linking agent and the balance water. Compared with the prior art, the step of adding the initiating agent and monomers dropwise is omitted in the preparing method, and the preparing method has the advantages of being low in technical control difficulty, high in maneuverability, simple, low in cost and the like. Zinc oxide is used for replacing acrylamide derivative to serve as the cross-linking agent, zero emission of formaldehyde is achieved, and the prepared leather finishing agent has excellent ductility.

Owner:安徽百益鞋业有限公司

Production method for hot rolling acid pickling automobile plate

The invention discloses a production method for a hot rolling acid pickling automobile plate. The hot rolling acid pickling automobile plate comprises chemical elements including, by weight, 0.02-0.04% of C, smaller than or equal to 0.05% of Si, 0.20%-0.30% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S, 0.010%-0.020% of Nb, 0.030-0.050% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable impurities. The preparing method for the hot rolling acid pickling automobile plate sequentially includes the following steps of molten iron pre-desulfuration treatment, converter steelmaking, steel ladle LF refining, continuous casting, casting blank heating, rough rolling, finish rolling, laminar cooling, high-temperature coiling, flattening,acid pickling, rinsing, oil smearing and coiling. By means of the production method for the low-carbon, low-manganese and low-silicon component design is adopted, the carton equivalent is reduced onone hand, and the steel plate welding performance is improved; on the other hand, ferrous silicate which is hardly subjected to acid pickling is prevented from being formed on the surface of a steel plate in the hot rolling process, and the surface quality of the steel plate is improved; a proper amount of Nb alloys are added, so that the strengthening effect of the Nb alloys is sufficiently achieved, and low-cost component design is achieved; and high-temperature coiling is adopted, the laminar cooling control difficulty is lowered, the steel roll through roll technology is stability, and thesteel roll plate shape quality and the through roll performance stability are improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

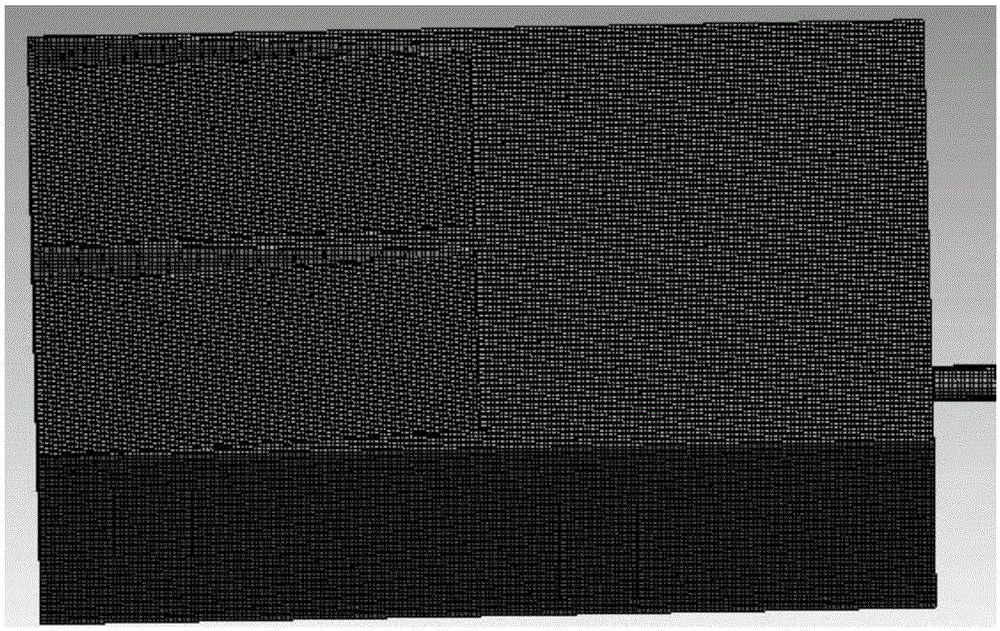

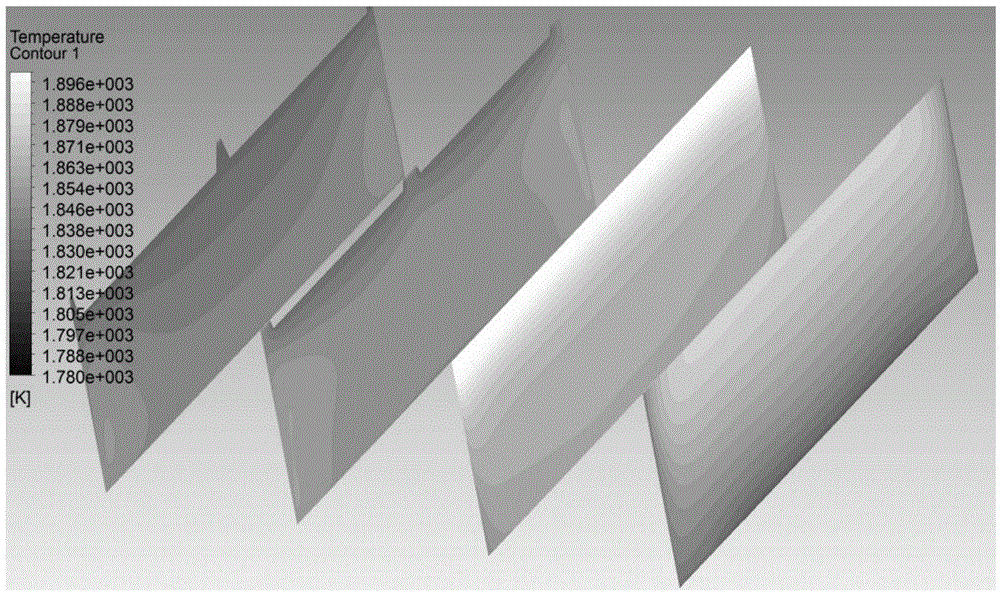

Electric glass melting furnace work simulating method and application thereof

ActiveCN105574280AReduce manufacturing costImprove temperature fieldSpecial data processing applicationsLiquid temperatureLiquid surfaces

The invention discloses an electric glass melting furnace work simulating method and application thereof. The electric glass melting furnace work simulating method is based on a fluent software, and comprises the following steps: establishing a glass liquid geometric model, dividing grids, and drawing an obvious boundary between an electrode surface and a nearby adjacent insulating fire-resistant material area so as to add an electric field module; according to actual production situations, setting boundary conditions, and adding voltage boundary conditions to the electrode surface; simulating a temperature field, a flow field and an electric field of glass liquid to obtain glass liquid temperature field distribution, space flame temperature field distribution and speed field distribution conditions of different areas in the furnace; adopting a gabled temperature schedule as initial glass liquid surface temperature distribution, so as to obtain a final curve according to simulation coupling and curve coupling, and importing the final curve using a user-defined function for calculating; measuring a conductivity curve, a viscosity curve and heat conductivity coefficients, which change along with temperature, of the glass liquid in advance, and importing the conductivity curve, the viscosity curve and the heat conductivity coefficients into a model using the user-defined function. According to the electric glass melting furnace work simulating method and the application thereof, the working principle of the electric glass melting furnace is analyzed at a low cost.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

Preparation method of force responsiveness nanometer magnitude photonic crystal materials

ActiveCN106226847ASimple processShort preparation cycleOptical elementsPhotonic crystal structureCurrent technology

The present invention discloses a preparation method of force responsiveness nanometer magnitude photonic crystal materials. Through adoption of the electron beam lithography technology and the reactive ion etch technology, a rigid template with a nanometer magnitude pattern is etched and taken as a filling template according to photonic crystal structure parameters designed in advance, high-elastic gel with good mechanical property is taken as matrix materials, and a visco-elastic polymer is taken as filling materials; and through the mode of the filling template, the photonic crystal pattern designed in advance in the high fidelity mode is transferred into the visco-elastic polymer, and the nanometer magnitude and structure controllable photonic crystal materials with force responsiveness are prepared through spin coating, stacking and the like. Compared to the current technology, the preparation method of force responsiveness nanometer magnitude photonic crystal materials is simple in technology and short in flow, technology parameters are easy to control, the template can be reused, the precision of products is high in level, the quality is stable and reliable, and the cost is low, etc.

Owner:SHANDONG UNIV OF SCI & TECH

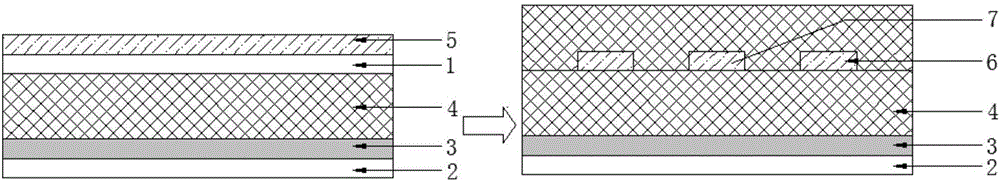

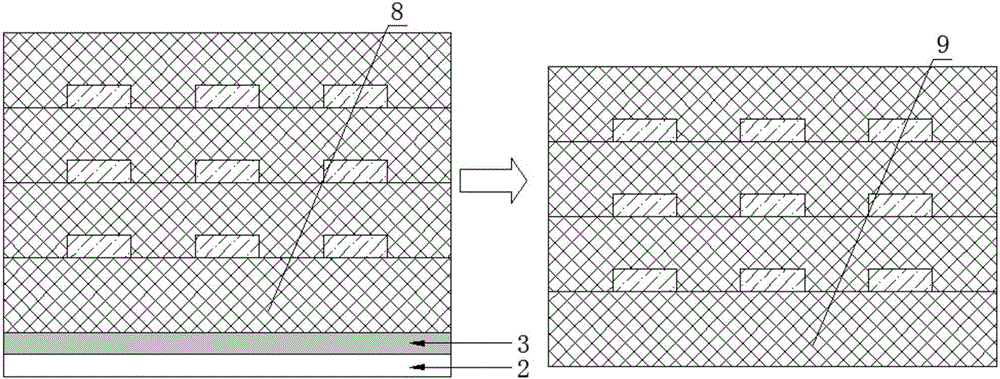

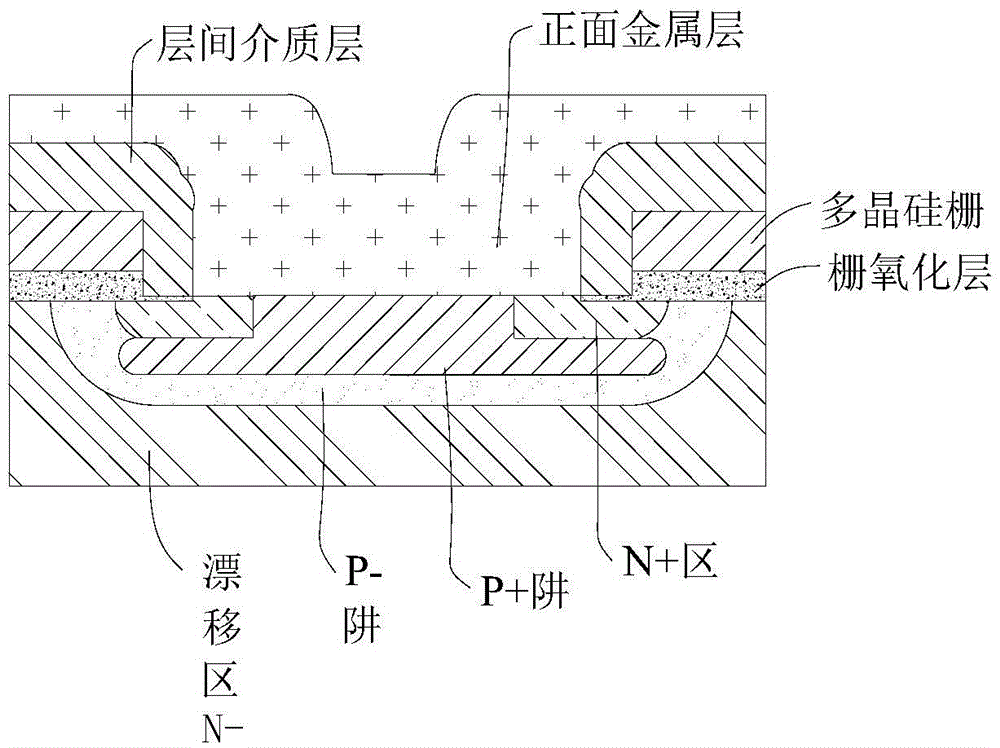

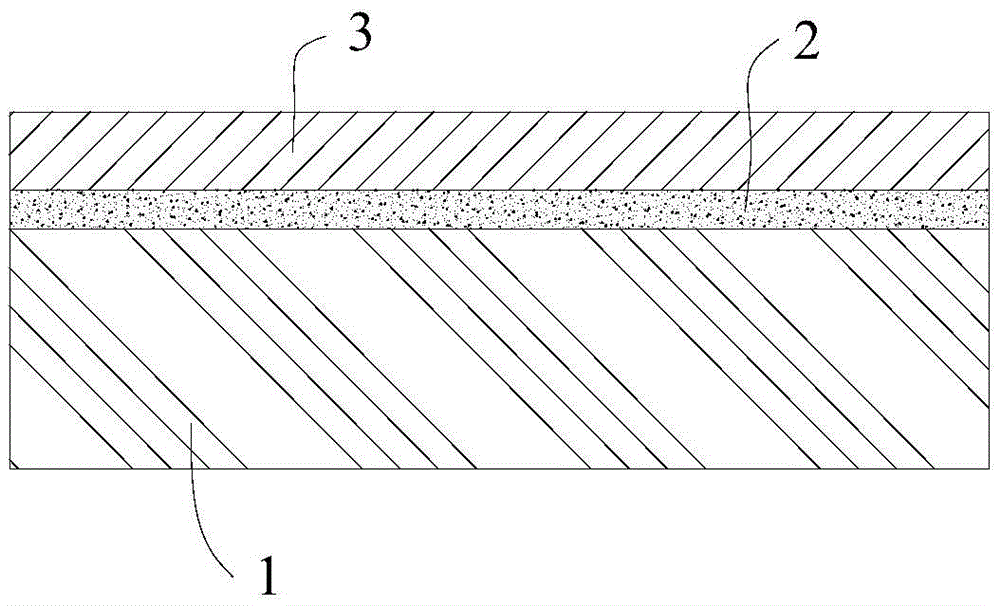

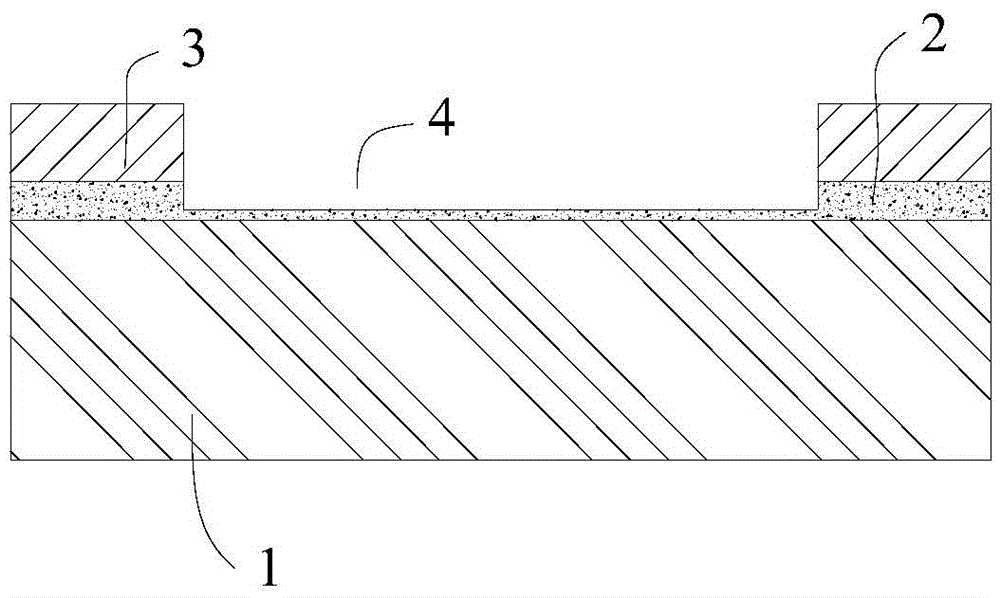

Power semiconductor device and preparation method thereof

InactiveCN106783606AAvoid Lithography Rework RatesImprove parameter stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesIon implantationPolycrystalline silicon

The invention provides a power semiconductor device and a preparation method thereof. The method comprises the steps of forming a gate oxidation layer, and depositing a polycrystalline silicon gate; performing first etching treatment; performing first ion injection treatment; performing second ion injection treatment; forming a thermal oxidation layer; performing third ion injection treatment; depositing an interlayer dielectric layer; performing second etching treatment; and sputtering front-surface metal. According to the preparation method of the power semiconductor device, provided by an embodiment of the invention, general photoetching selective injection is replaced with a thermal oxidation layer self-alignment process and contact etching, so that the process steps can be effectively reduced, the process control difficulty can be lowered, the P+ and N+ photoetching rework rates and the parameter fluctuation and deviation caused by the P+ photoetching alignment and N+ photoetching alignment problems are avoided, the device parameter stability is improved, and the product yield is increased.

Owner:BYD CO LTD

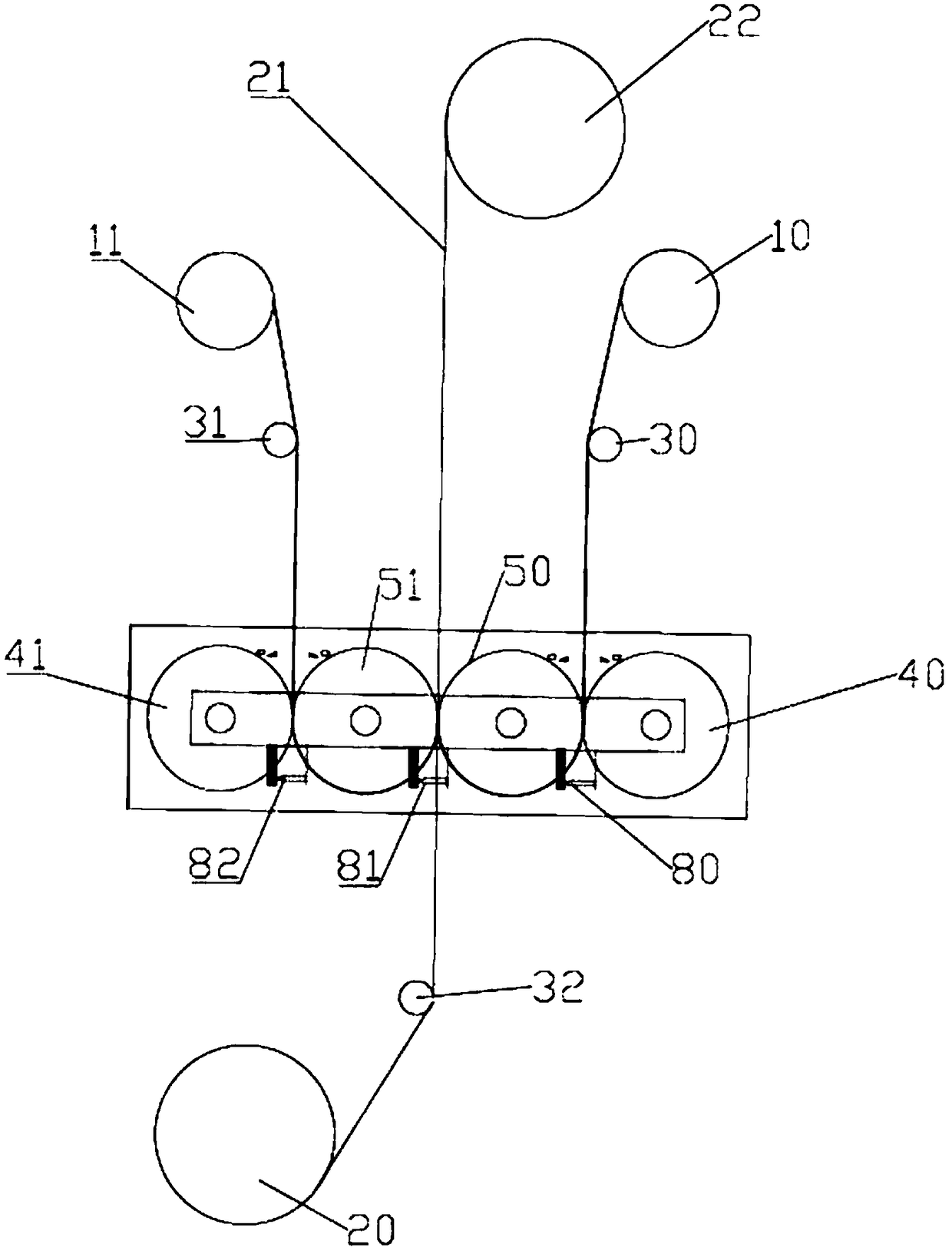

Method for supplementing lithium to negative pole piece

ActiveCN108899468AHigh thickness accuracyEasy to operateElectrode rolling/calenderingSecondary cellsLithiumPole piece

The invention relates to a method for supplementing lithium to a negative pole piece. The method comprises the following specific steps: arranging a first calendering roll, a first composite roll, a second composite roll and a second calendering roll which are adjacently arranged in sequence, and coating silicon oil on roll surfaces of the first calendering roll, the first composite roll, the second composite roll and the second calendering roll; respectively unwinding two lithium strips to enter a gap between the first calendering roll and the first composite roll and a gap between the secondcalendering roll and the second composite roll, carrying out calendering to cause the lithium strips to be attached to the roll surfaces of the first composite roll and the second composite roll; unwinding the negative pole piece to enter a gap between the first composite roll and the second composite roll, and carrying out transfer printing on the lithium strip from the roll surfaces of the first composite roll and the second composite roll to the negative pole piece so as to obtain the lithium-supplemented negative pole piece. The method has the beneficial effects that base strips do not need to be adopted for protecting the lithium strips, so that the operation process of the traditional production process is greatly simplified, the process control difficulty is greatly reduced, the production cost is saved, and meanwhile the thickness accuracy of calendered lithium foils is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

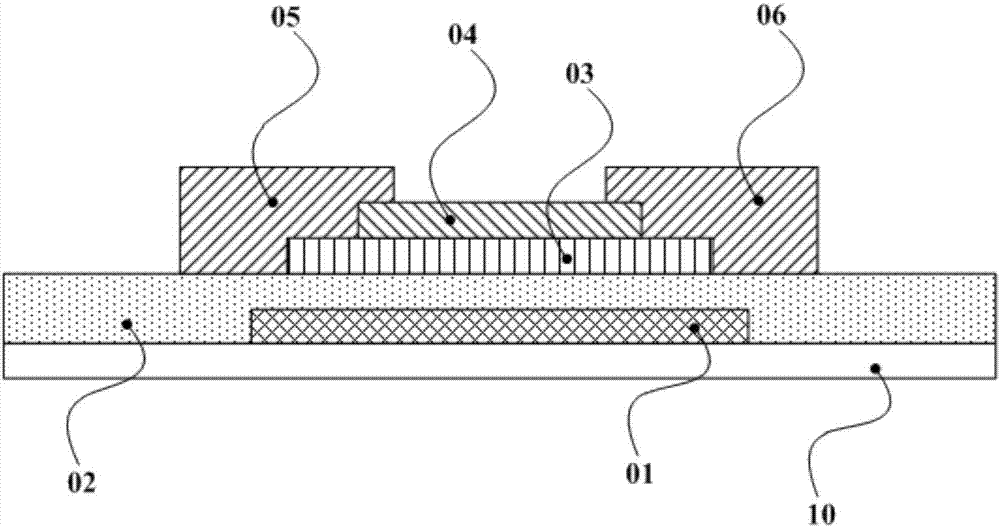

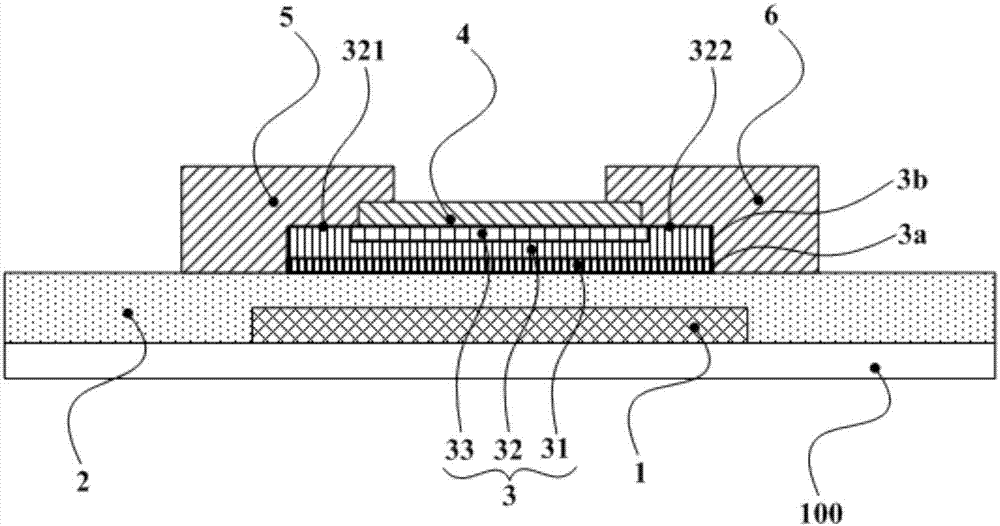

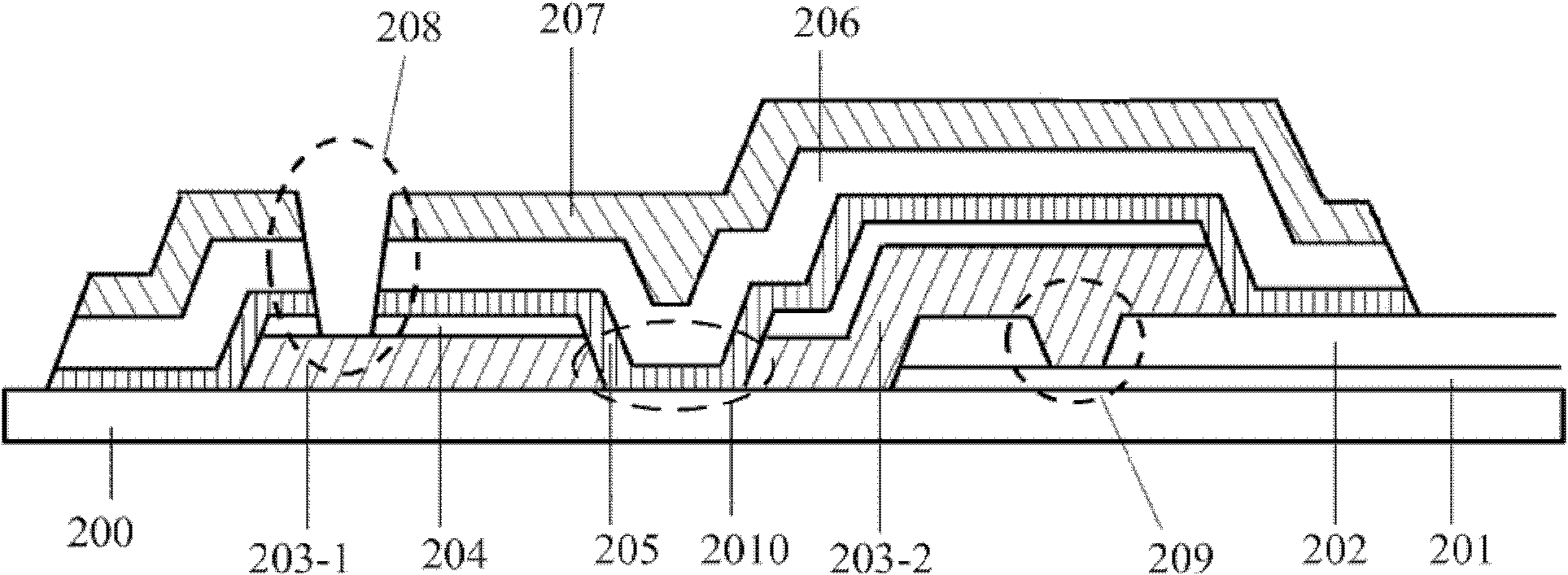

Display substrate, display device and manufacturing method of display substrate

ActiveCN107316897AImprove performanceImprove product qualityTransistorSemiconductor/solid-state device manufacturingDisplay deviceBottom gate

The invention discloses a display substrate, a display device and a manufacturing method of the display substrate so as to improve the performance of a thin film transistor and improve the product quality of the display device. The display substrate comprises a substrate and a bottom-gate type thin film transistor arranged on the substrate, wherein the thin film transistor comprises an active layer, an etching blocking layer, a source electrode and a drain electrode, wherein the active layer comprises a first concentration layer, a second concentration layer and a third concentration layer, the carrier concentrations of the first concentration layer, the second concentration layer and the third concentration are decreased in sequence in the direction away from the substrate, the second concentration layer comprises a first connecting part connected with the source electrode and a second connecting part connected with the drain electrode, and the third concentration layer is exposed out of the first connecting part and the second connecting part; the etching blocking layer is arranged on the side, away from the substrate, of the active layer, and does not exceed the edge of the third concentration layer; and the source electrode and the drain electrode are arranged on the side, away from the substrate, of the etching blocking layer, and are connected with the first connecting part and the second connecting part respectively.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

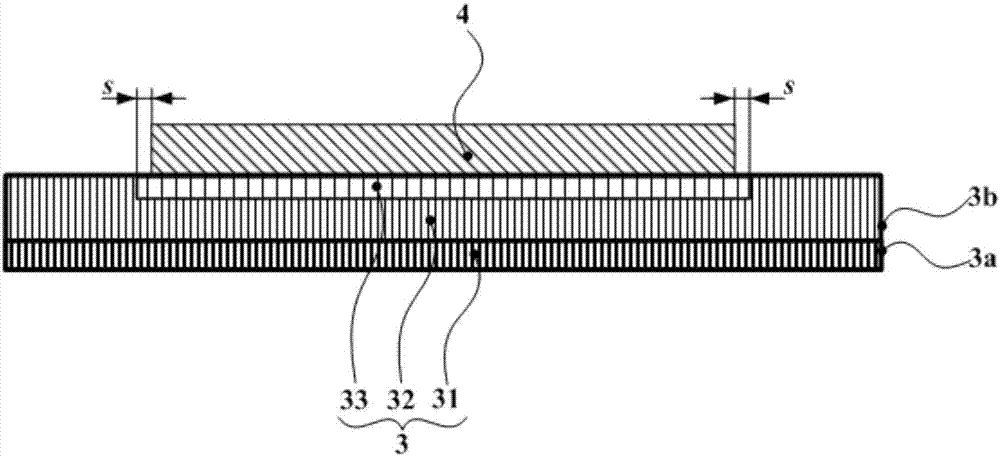

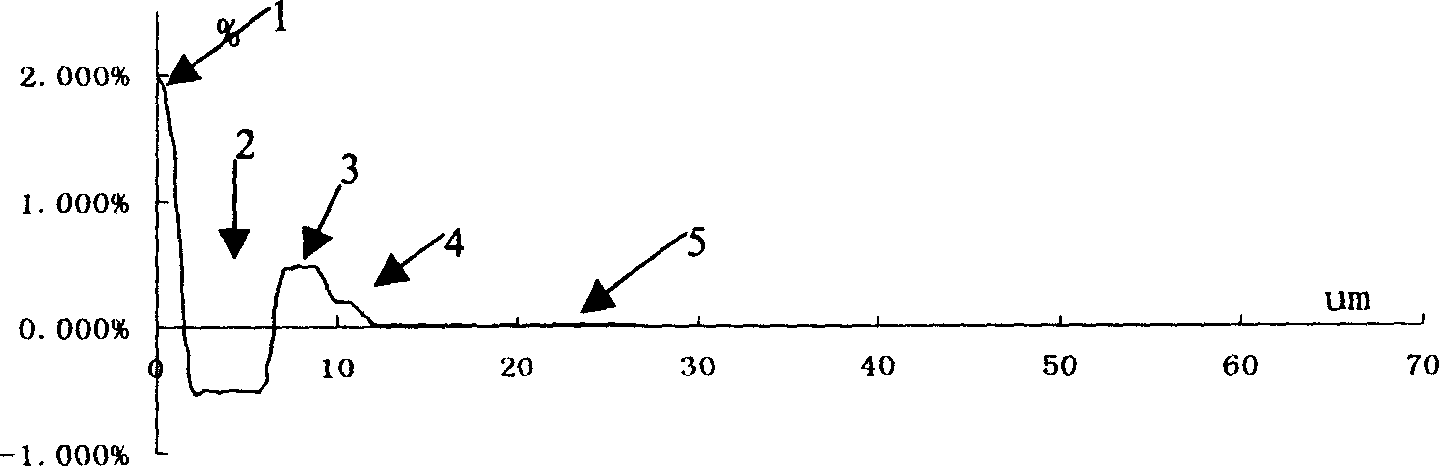

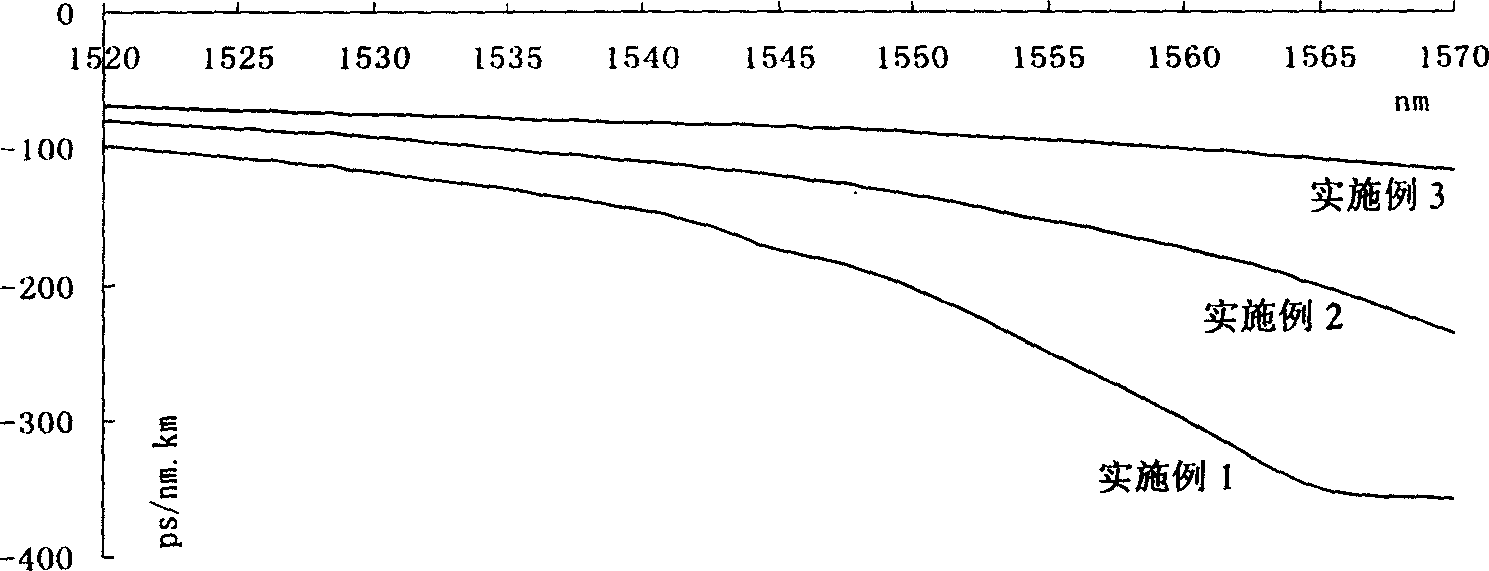

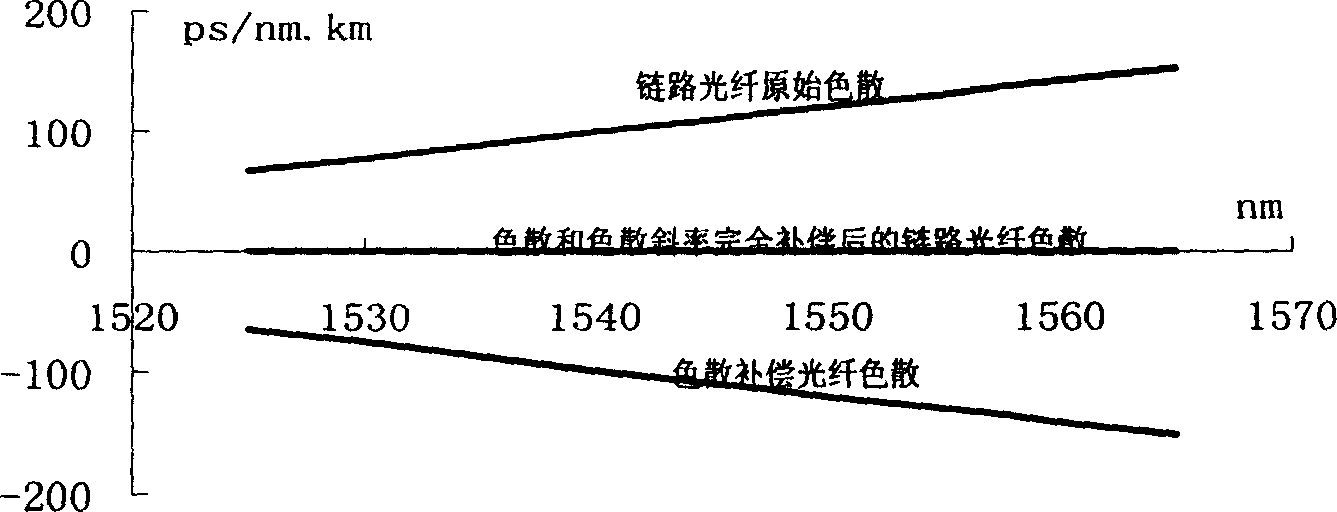

Dispersion compensation optical fibre

ActiveCN1609640AHigh relative dispersion slope RDS valueLarge negative dispersionOptical light guides

The present invention relates to one kind chromatic dispersion compensating fiber with negative chromatic dispersion and negative chromatic dispersion slope in C band optical communication window. The fiber includes fiber core and cladding of SiO2, and features that its fiber core includes at least four layers, of which the first layer has positive relative refractive index difference, the middle layer has negative relative refractive index difference and the maximum difference between relative refractive index differences of the first layer and the middle layer not lower than 2.45 %. The present invention can obtain relatively high negative chromatic dispersion and negative chromatic dispersion slope, high RDS value and wide RDS range, low attenuation and low PMD value, and can meet various compensation requirement of G.655.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

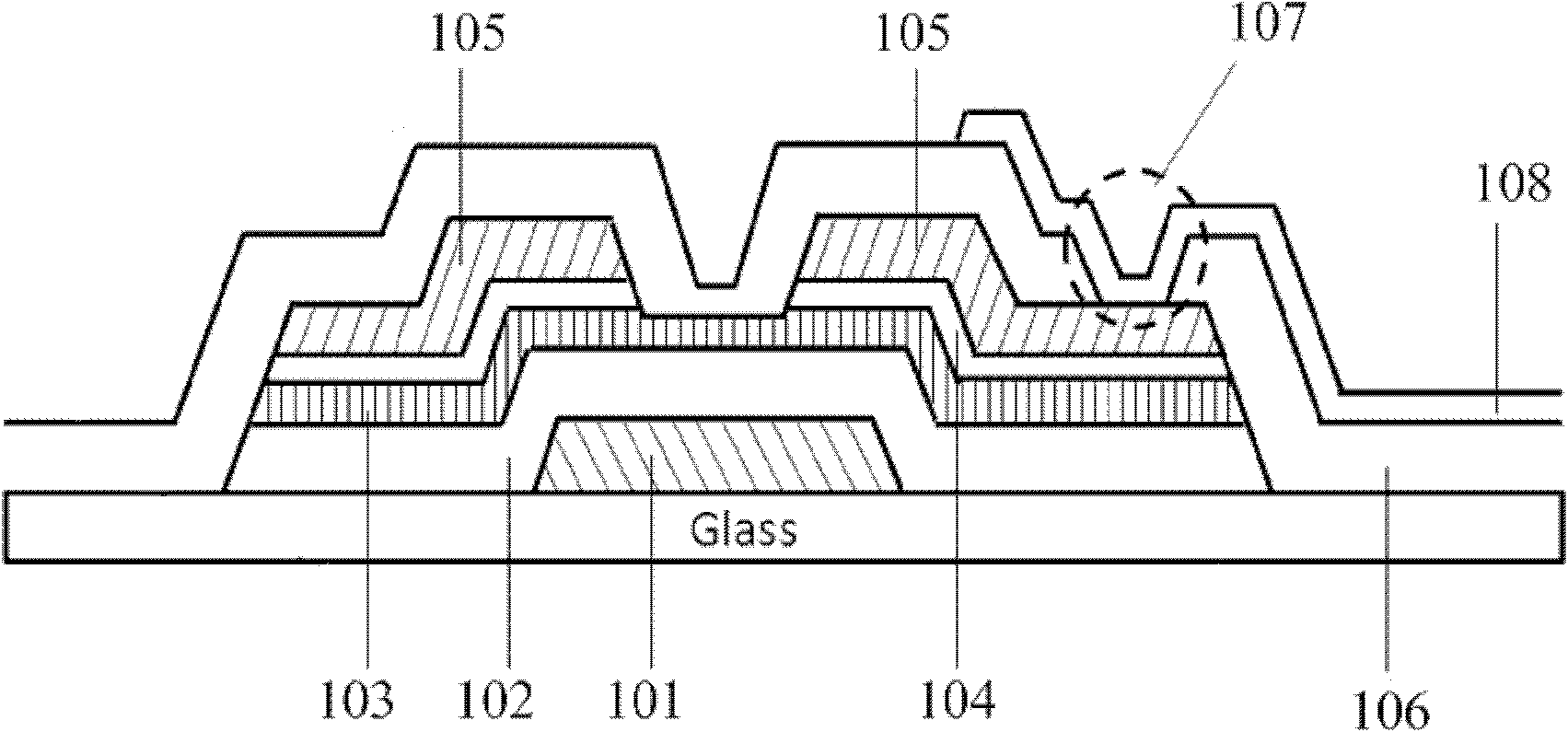

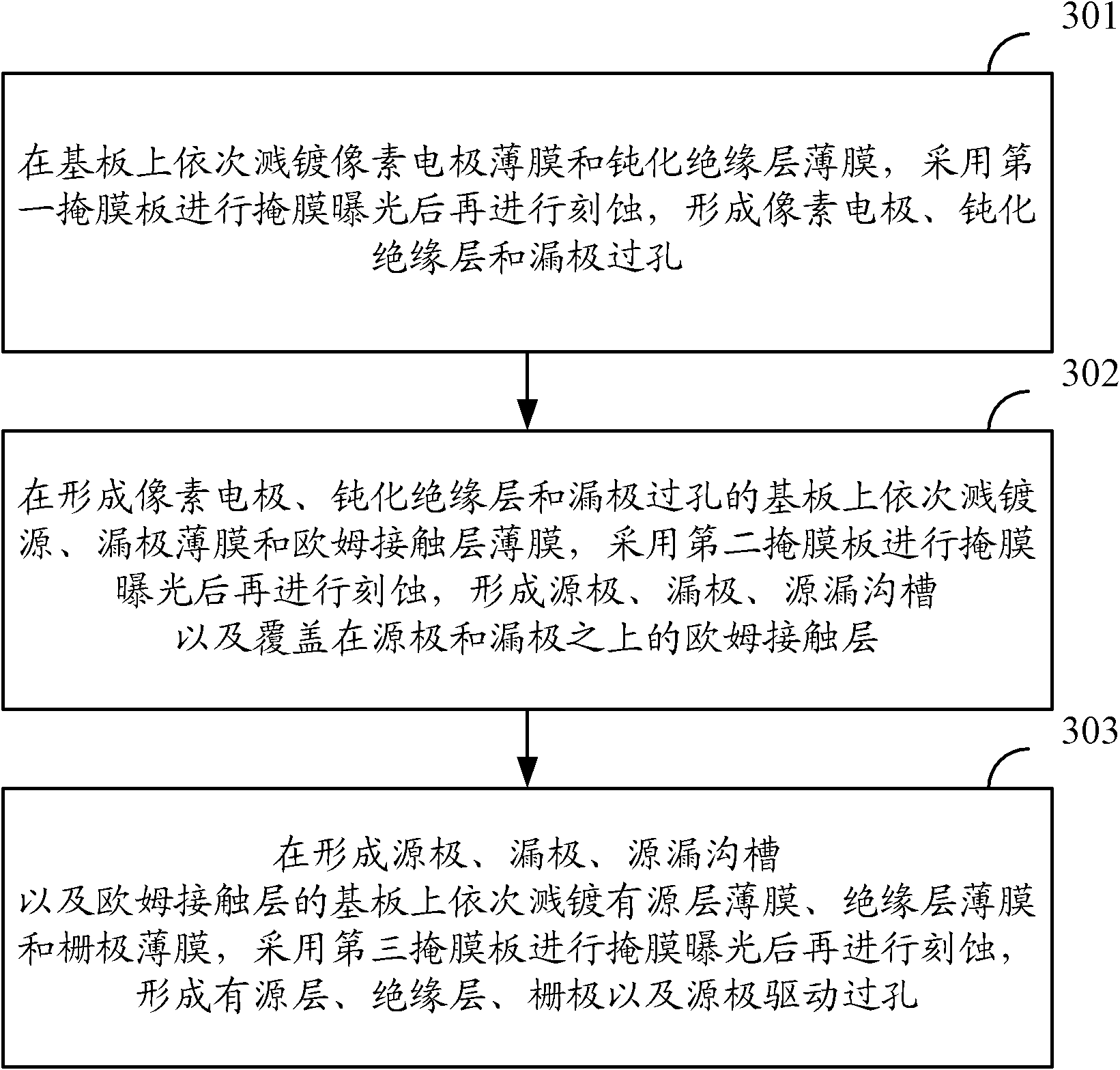

Pixel structure of thin film transistor liquid crystal display and manufacturing method thereof

ActiveCN102646713AReduce exposureImprove yield rateTransistorSolid-state devicesLiquid-crystal displayInsulation layer

The invention discloses a pixel structure of a thin film transistor liquid crystal display and a manufacturing method thereof, which aim to reduce the number of mask, simplify process flow and save cost. The method comprises the following steps of sputtering a pixel electrode film and a passivation insulating layer film on a substrate in sequence; performing mask exposure by using a first mask plate and then etching the first mask plate to form a pixel electrode, passivation insulating layer and drain electrode through hole; and then sputtering source, drain electrode films and an ohmic contact layer film in sequence; performing mask exposure by using a second mask plate and etching the second mask plate to form a source electrode, a drain electrode, a source-drain channel and an ohmic contact layer covering on the source electrode and the drain electrode; and then sputtering an active layer film, an insulation layer film and a grid electrode film in sequence; performing mask exposure by using a third mask plate and etching the third mask plate to form an active layer, an insulation layer, a grid electrode and a source electrode driving hole. The invention synchronously discloses the pixel structure of the thin film transistor liquid crystal display.

Owner:BOE TECH GRP CO LTD +1

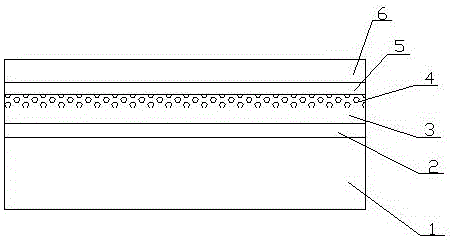

Low-cadmium CIGS-based thin-film solar cell and manufacturing method thereof

InactiveCN105118883AImprove conversion efficiencyReduced CdS layer thicknessFinal product manufacturePhotovoltaic energy generationPhysicsThin membrane

The invention provides a low-cadmium CIGS-based thin-film solar cell and a manufacturing method thereof. The thin-film solar cell sequentially comprises a substrate, a back electrode, a CIGS absorption layer, a CdS layer and an upper electrode from the bottom up. Cu atoms on the surface of the CIGS absorption layer are partially replaced by Cd atoms to form a surface modified layer. The thickness of the CdS layer ranges from 20nm to 35nm. The manufacturing method comprises the following steps of (a) depositing the back electrode on the substrate; (b) depositing the CIGS absorption layer on the back electrode; (c) depositing the CdS layer on the CIGS absorption layer; and (d) depositing the upper electrode on the surface of the CdS layer. In the step c, an operation for modifying the surface of the CIGS surface is performed before the CdS layer is deposited. While the overall high CIGS cell conversion efficiency is kept, the thickness of the CdS layer is greatly lowered. The Cd content of a whole cell module is greatly reduced.

Owner:蔡淼鑫

Preparation method of titanium dioxide-polyaniline composite corrosion-resistant coating

ActiveCN105111925AShort processSimple process controlAnti-corrosive paintsTitanium dioxidePolyaniline compositeCopper

The invention discloses a preparation method of a titanium dioxide-polyaniline composite corrosion-resistant coating. According to the preparation method, the steps of preparing nanometer titanium dioxide, synthesizing titanium dioxide-polyaniline, coating the surface of a metal plate with the titanium dioxide-polyaniline, and the like are synchronously carried out in a hydrothermal reaction kettle, and are completed through one step. The technical problem in the prior art that nanometer titanium dioxide is easy to agglomerate in a mixed solution system comprising the nanometer titanium dioxide and polyaniline is solved well, the technological process is greatly shortened, and the process control difficulty is reduced; besides, the step of heating and drying the composite coating required in the prior art is eliminated, and a series of technical problems that a coating easily cracks due to organic matter volatilization to further influence the combination firmness between the composite coating and a metal matrix, and the like are solved. The preparation method has the characteristics of being short in technological process, simple to control, stable and reliable in product quality, and the like, and the titanium dioxide-polyaniline composite corrosion-resistant coating prepared is suitable for being used as cathodic protection of copper, steel or stainless steel base material.

Owner:SHANDONG UNIV OF SCI & TECH

Refining processing method for apocynum venetum fiber

ActiveCN106319642AImprove qualityImprove degumming effectFibre treatment to obtain bast fibreElectricityApocynum venetum

The invention discloses a refining processing method for an apocynum venetum fiber. The method comprises the steps of infiltrating and activating apocynum venetum bast; performing steam explosion activating treatment; caking and putting into a cage; performing directional catalytic oxidizing; chemically degumming and post-processing. Organic amine is adopted for infiltrating and activating and steam explosion activating treatment is performed, and then a ferrite solution and an activating agent are adopted for performing directional catalytic oxidization on lignin and hemicellulose; through the organic combination of a series of technical methods, such as, infiltration and activation, steam explosion, degumming and directional catalytic oxidization, the production method provided by the invention has the characteristics of good degumming effect, excellent indexes including finish fineness, length, strength and the like of the acquired apocynum venetum fiber, high quality, excellent spinning property, and the like; the chemical consumption is low; the environment-friendly pressure is low; the technical control is simple; the consumption of the public works, such as water, electricity and gas, is low, the efficiency is high and the method is suitable for industrial production.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com