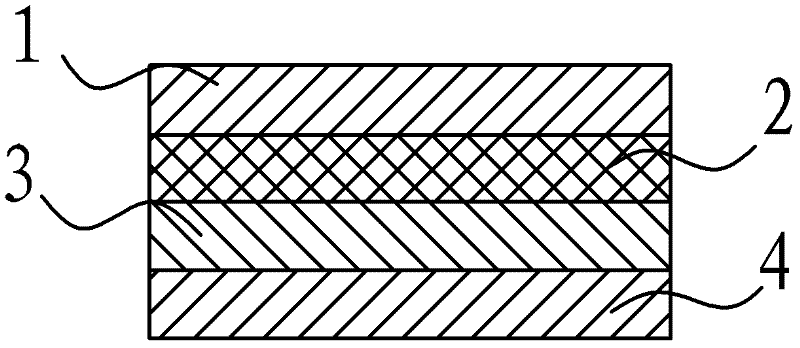

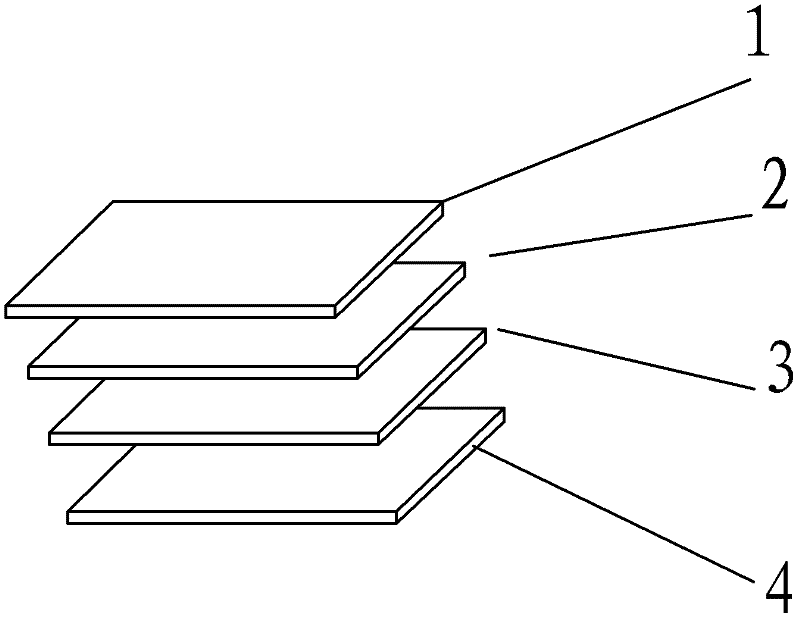

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

A technology of glass fiber and composite film, applied in glass/slag layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of surface PVC film thickness, surface smoothness difficult to control, high process requirements, light It is difficult to control the transmittance, etc., to achieve good adhesion, ensure the quality of the cloth surface, and the effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

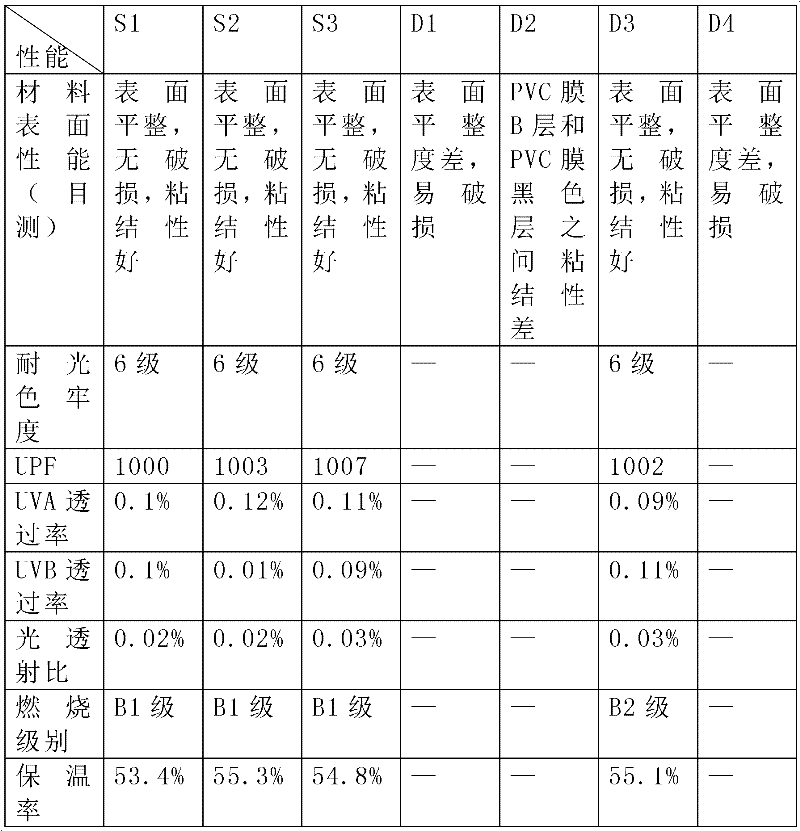

Embodiment 1

[0045] 100 parts of PVC resin, 3.5 parts of stabilizer, 25 parts of plasticizer, 20 parts of flame retardant (the contents of antimony trioxide and phosphate flame retardant are 4 parts and 16 parts respectively), 18 parts of adhesive modified After the additive and the required color pigment are mixed evenly, they are kneaded in an internal mixer to a molten and plasticized state, transported to a calender, pressed, extended and cooled to form a PVC film B layer with a thickness of 0.08mm and a thickness of 0.08mm The black layer of PVC film, the pigment used in the black layer of PVC film is black pigment. After mixing 100 parts of PVC resin, 3.5 parts of stabilizer, 25 parts of plasticizer, 20 parts of flame retardant (the contents of antimony trioxide and phosphate flame retardant are 4 parts and 16 parts respectively) and pigments, the Knead in an internal mixer to a molten and plasticized state, transport to a calender, press, extend and cool to form a layer A of PVC fil...

Embodiment 2

[0050] The glass fiber / PVC composite membrane material S2 of the present embodiment is prepared in the same steps as in Example 1, the difference is that in step (1), 100 parts of PVC resin, 3.5 parts of stabilizer, 30 parts of plasticizer, 18 parts of flame retardant (the contents of antimony trioxide and phosphoric acid ester flame retardant are 6 parts and 12 parts respectively, after 18 parts of adhesion modifier and required color pigment are mixed evenly, knead in the internal mixer to Molten state, after cooling, roll into the calender, press and stretch to form PVC film B layer, PVC film black layer, the pigment used in the PVC film black layer is black pigment.

Embodiment 3

[0052] The glass fiber / PVC composite membrane material S3 of this embodiment is prepared by the same steps as in Example 1, the difference is that: in step (2), the bonding temperature is 140 ° C, and the bonding pressure is 0.4 MPa; step (4) ), the lamination temperature is 175°C, and the lamination pressure is 0.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com