Manufacturing method and application of glazed tempered/semi-tempered U-shaped glass

A production method and semi-tempered technology, applied in the direction of coating, etc., can solve the problems of poor sound insulation, thermal insulation and shading, and achieve the effects of outstanding decorative effect, stable color and wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

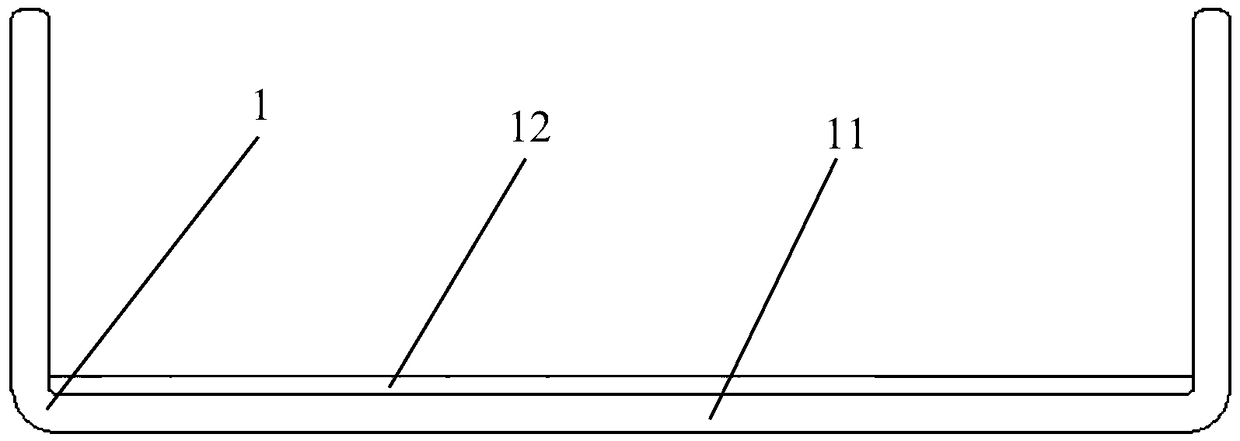

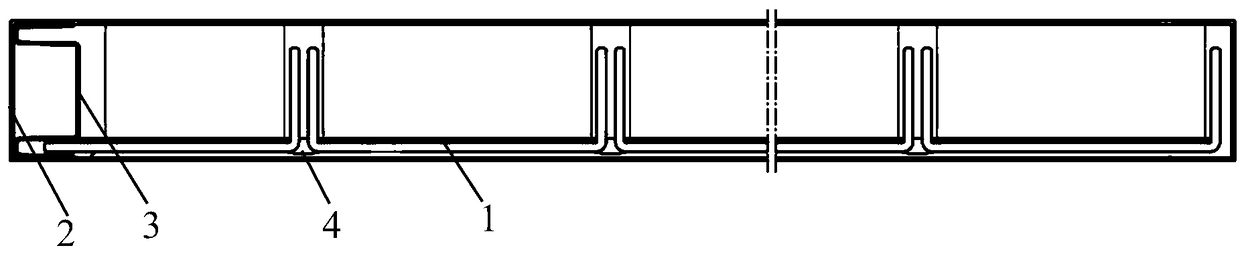

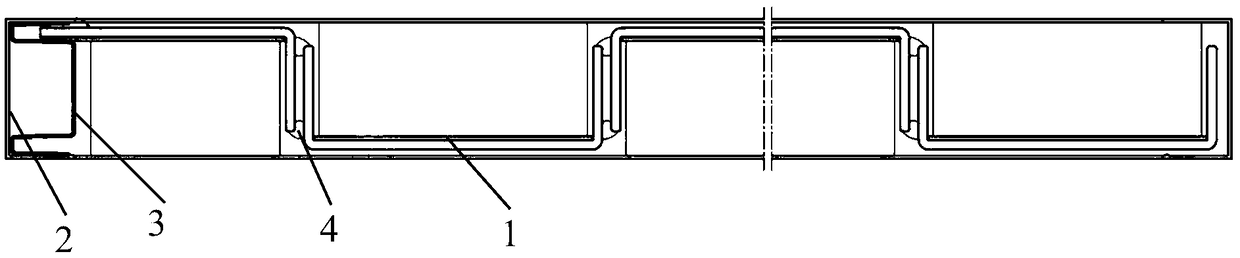

[0054] Step 1: Select the inorganic glaze 12 and the U-shaped glass 11 with a thickness of 5-10 mm, first place the U-shaped glass 1 on the cleaning rack, and use a sponge brush dipped in cleaning solution to evenly scrub the surface of the U-shaped glass 11 for 2 minutes. Then use clear water to rinse the glass surface until the surface of the U-shaped glass 11 is free of stains and then stop;

[0055] Step 2: drying the glass cleaned in step 1 with hot air, and glazing as soon as possible after the U-shaped glass 11 is dried, so as to avoid secondary pollution of the U-shaped glass 11;

[0056] Step 3: Evenly print or spray the inorganic glaze 12 in step 1 on the web of the U-shaped glass 11, and dry the inorganic glaze 12 after spraying, at a temperature of 650°C for 10 minutes, Stop until the inorganic glaze 12 is completely dry to obtain a U-shaped glass 11 coated with the inorganic glaze 12;

[0057] Step 4: The U-shaped glass 11 coated with inorganic glaze 12 obtained ...

Embodiment 2

[0060] Step 1: Select the inorganic glaze 12 and the U-shaped glass 11 with a thickness of 5-10mm, first place the U-shaped glass 1 on the cleaning rack, and use a sponge brush dipped in cleaning solution to evenly scrub the surface of the U-shaped glass 11 for 2.3 minutes , and then use clean water to rinse the glass surface until the surface of the U-shaped glass 11 is free of stains and stop;

[0061] Step 2: drying the glass cleaned in step 1 with hot air, and glazing as soon as possible after the U-shaped glass 11 is dried, so as to avoid secondary pollution of the U-shaped glass 11;

[0062] Step 3: Evenly print or spray the inorganic glaze 12 in step 1 on the web of the U-shaped glass 11. After the inorganic glaze 12 is sprayed, dry it for 8 minutes at a temperature of 670°C. Stop until the inorganic glaze 12 is completely dry to obtain a U-shaped glass 11 coated with the inorganic glaze 12;

[0063] Step 4: The U-shaped glass 11 coated with inorganic glaze 12 obtained...

Embodiment 3

[0066] Step 1: Select the inorganic glaze 12 and the U-shaped glass 11 with a thickness of 5-10mm, first place the U-shaped glass 1 on the cleaning rack, and use a sponge brush dipped in cleaning solution to evenly scrub the surface of the U-shaped glass 11 for 2.5 minutes , and then use clean water to rinse the glass surface until the surface of the U-shaped glass 11 is free of stains and stop;

[0067] Step 2: drying the glass cleaned in step 1 with hot air, and glazing as soon as possible after the U-shaped glass 11 is dried, so as to avoid secondary pollution of the U-shaped glass 11;

[0068] Step 3: Evenly print or spray the inorganic glaze 12 in step 1 on the web of the U-shaped glass 11, and dry the inorganic glaze 12 after spraying, and dry it at a temperature of 700°C for 7 minutes. Stop until the inorganic glaze 12 is completely dry to obtain a U-shaped glass 11 coated with the inorganic glaze 12;

[0069] Step 4: The U-shaped glass 11 coated with inorganic glaze 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com