Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Skin rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin rolling is a process of releasing these knots so that the physical skin can flow efficiently over the body. The technique uses the thumb and fingers to pull the skin away from the body. Then, keeping a continuous forward motion with the thumb, the skin is gently rolled in a uniform direction to separate it from any muscles that may be stuck.

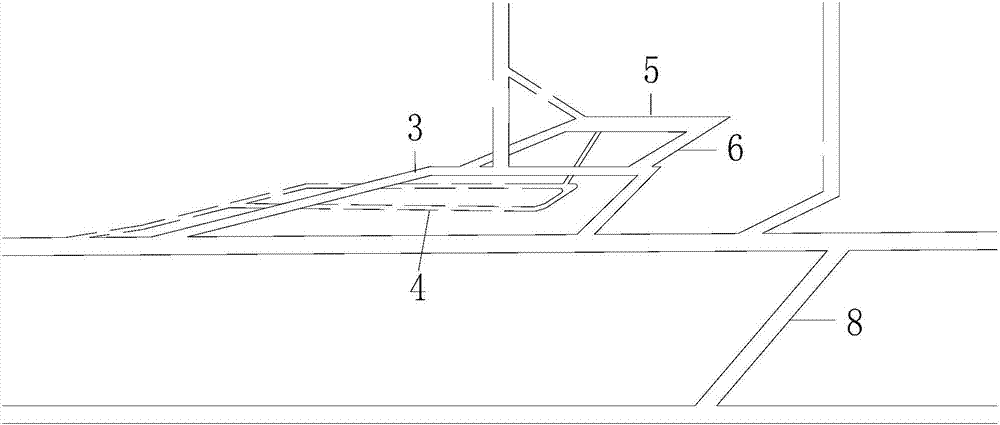

Construction method for underground city based on abandoned mine

InactiveCN107119710AIncrease profitRealize the development of energy conservation and environmental protectionArtificial islandsUnderwater structuresElectricityFire protection

The invention discloses a construction method for an underground city based on an abandoned mine. The construction method comprises the steps that a pier stud filling method is adopted to recycle industrial square protective coal pillars to form a construction space of the underground city; treatments of skin rolling and beautifying, anchoring and shotcreting and pier-stud-filling reinforced supporting are connected on main roadways and surrounding chambers, and then decoration construction is conducted on the main roadways and the surrounding chambers to form underground business streets; and return-air-shaft protective coal pillars at two sides are recycled through the pier stud filling method to form a regular building space, therefore, the 'one-core, double-city, double-axis and multi-area' construction layout and a main body frame of the underground city are formed, moreover, the whole underground city is equipped with systems of electrical power, ventilation, garbage collection, domestic water, air conditioner, communication, traffic, fire protection and the like, and then self-sufficiency of water, electricity, air and heat of the underground city is achieved. According to the construction method for the underground city based on the abandoned mine, the characters of the abandoned mine are utilized to develop the underground building space, the purposes of enhancing the use ratio of land resources, protecting the environment, relieving the ground traffic pressure and the like are achieved, and optimization of mine resource utilization is achieved.

Owner:CHINA UNIV OF MINING & TECH

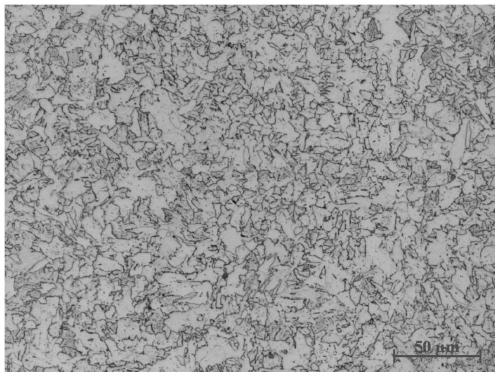

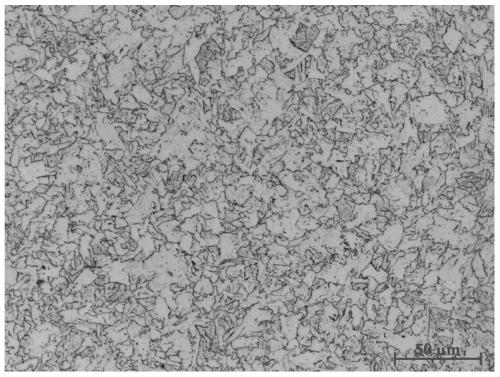

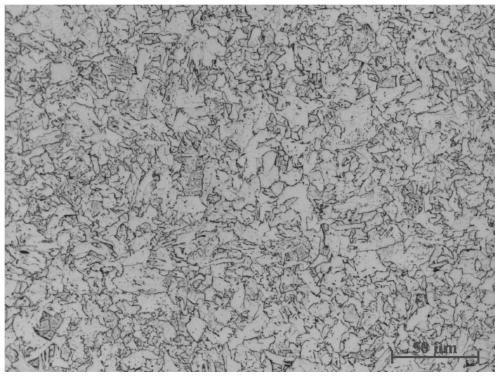

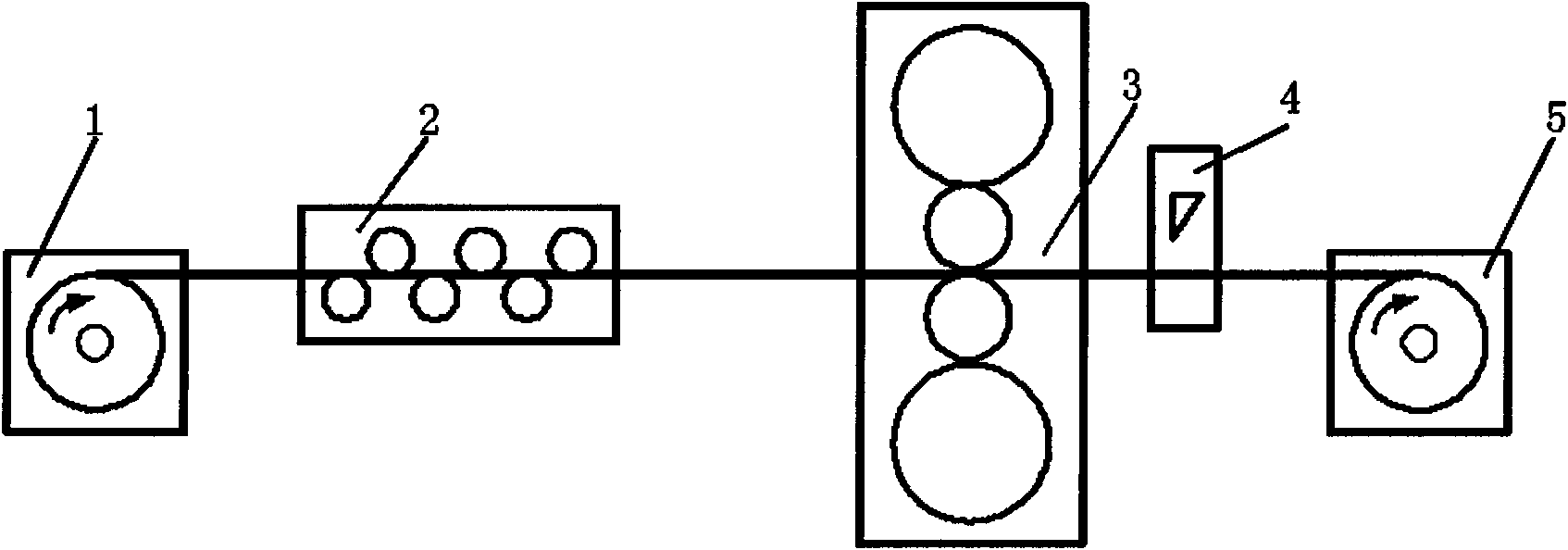

High-efficiency non-oriented silicon steel and preparation method thereof

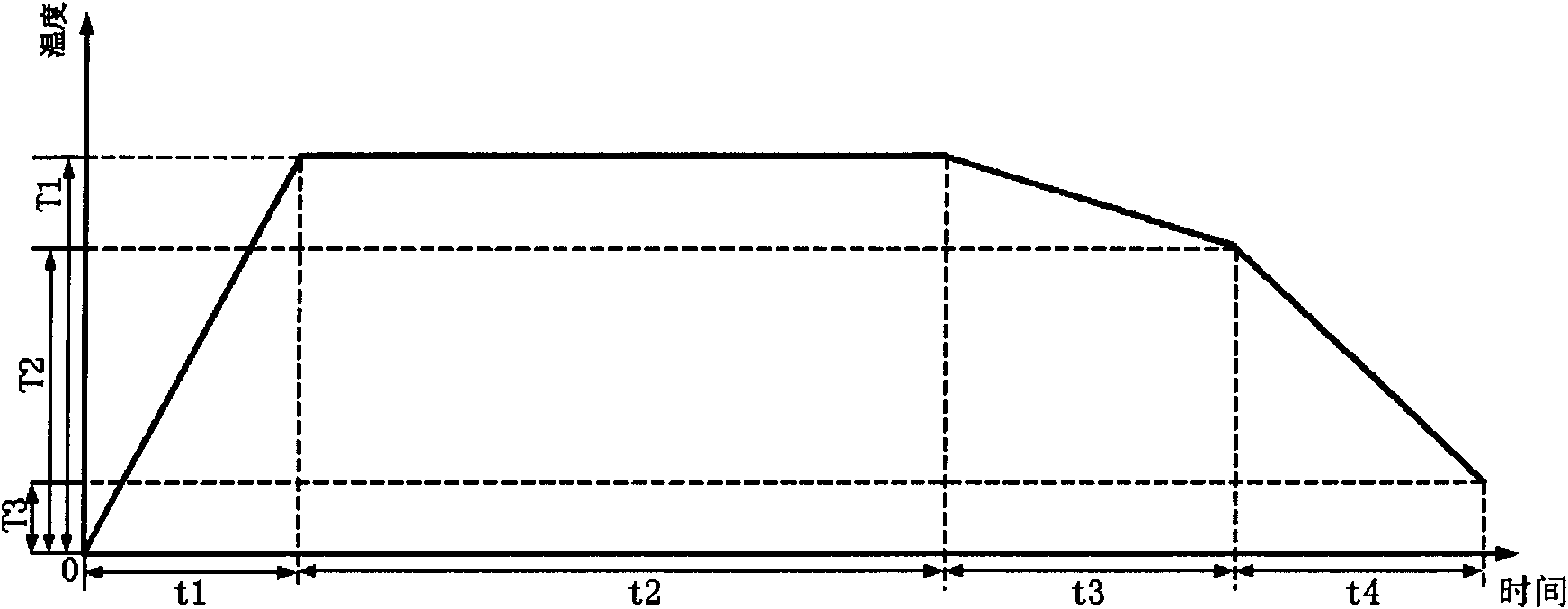

InactiveCN110042310AReduce iron lossReduce the risk of belt breakageIncreasing energy efficiencySteelmakingChemical composition

The invention discloses high-efficiency non-oriented silicon steel and a preparation method thereof. The high-efficiency non-oriented silicon steel comprises the chemical components in percentage by mass of at most 0.005% of C, 1.0-2.0% of Si, 0.2-0.8% of Als, 0.25-0.8% of Mn, 0.01-0.05% of Sn, at most 0.02% of P, at most 0.0040% of S, at most 0.0020% of N, at most 0.0020% of Nb, at most 0.0020% of V, at most 0.0020% of Ti and the rest of Fe and unavoidable impurities. The high-efficiency non-oriented silicon steel and the preparation method have the advantages that by the strict component control in steelmaking, the impurity elements meeting the target requirement is ensured; by hot skin rolling, high temperature normalizing, induction heating before cold rolling, annealing and rapid warming and a low temperature long-time insulation process, the high-efficiency non-oriented silicon steel is obtained; and the iron loss of a finished product is P1.5 / 50<=3.2W / kg, and magnetic inductionis B50>=1.73T.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

Production method of 440MPa-grade thin gauge hot-rolling pickling automobile sheet

The invention discloses a production method of a 440MPa-grade thin gauge hot-rolling pickling automobile sheet. The hot-rolling pickling automobile sheet is prepared from the chemical element components in percentage by weight: C is 0.07-0.09, Si is less than or equal to 0.05, Mn is 1.00-1.20, P is less than or equal to 0.020, S is less than or equal to 0.020, Nb is 0.010-0.020, Als is 0.030-0.050, Ti is 0.010-0.030, N is less than or equal to 0.008, and the balances are Fe and unavoidable impurities. The preparation method sequentially includes the following steps of liquid iron pre-desulfuration processing, converter steel-making, steel ladle LF refining, continuous casting, casting blank heating, rough rolling, finish rolling, laminar flow cooling, high temperature coiling, skin rolling, pickling, rinsing, oil coating and coiling. According to the production method, the measures of low temperature heating, the rough rolling, high pressure dephosphorization before the finish rolling,dephosphorization before the rough rolling and between the finish rolling passes, and corrosion inhibitor adding in the pickling are adopted, and the surface quality of a steel coil is improved; andthe reduction rate of the finish rolling, the finishing rolling temperature, coiling temperature precision control and high temperature coiling are adopted, stability of a steel coil general rolling technology is ensured, and the strip shape quality and the performance general volume stability of the steel coil are improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

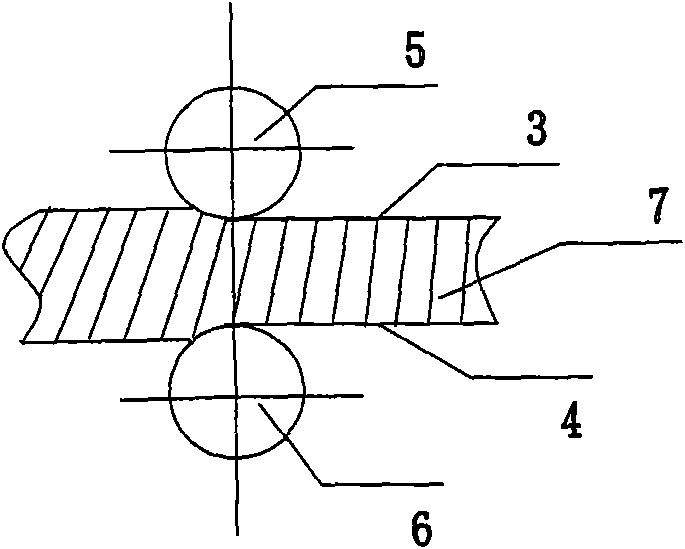

Processing method for printing circuit board semi-PTH groove

InactiveCN105555060AAvoid defectsEliminate the risk of sheddingPrinted element electric connection formationTinningMilling cutter

The invention provides a processing method for printing a circuit board semi-PTH groove. The processing method is characterized in that the processing method comprises the following steps of: a, forming a groove on a circuit board (7) in a continuously drilling mode by adopting a drilling pin or in a milling mode by a milling cutter; b, plating copper to the inner wall of the groove; c, plating a layer of tinning protection film (3) outside the copper layer of a copper plated area (2); d, drilling out a copper cutting hole (4) by a drilling bit with O serving as a center; e, removing a millable area (5) from a cutting line (6) so as to form the semi-PTH groove (1) with the tinning protection film (3); and f, adopting a tin stripping mode to remove the tinning protection film (3) in the semi-PTH groove (1). According to the invention, residual burr defects after routine processing are overcome, a copper skin rolling phenomenon is prevented, the risk of copper skin falling is eliminated, and the product quality is improved.

Owner:DALIAN CHONGDA CIRCUIT

Method for machining hot-dipped galvanized steel sheet having two faces with different types of spangles

ActiveCN101554702AHelps to chooseSave zinc raw materialHot-dipping/immersion processesRolling equipment maintainenceSkin rollingSurface structure

The invention relates to a method for machining a hot-dipped galvanized steel sheet having two faces with different types of spangles, belonging to the technical field for machining hot-dipped galvanized steel sheet. The method comprises the steps of rolling a base plate, washing, annealing, zinc boiler galvanizing and skin rolling. The method is characterized in that the surfaces of an upper working roll and a lower working roll for rolling the base plate in the step of rolling are processed in a way of roughening so that the surfaces of the upper working roll and the lower working roll are respectively form a roughened surface structure; the roughened surface structure on the upper working roll is different from the roughened surface structure on the lower working roll; when the upper working roll and the lower working roll with the roughened surface structures roll the base plate, the two faces of the base plate are respectively form the roughened surface structure of the base plate, wherein, the roughened surface structure of the base plate formed at one face of the base plate is different from the roughened surface structure of the base plate formed at the other face of the base plate. The method is good for saving zinc raw materials and reducing cost for manufacturers and is helpful for users to elect according to use and request.

Owner:CHANGSHU HUAYE STEEL STRIP

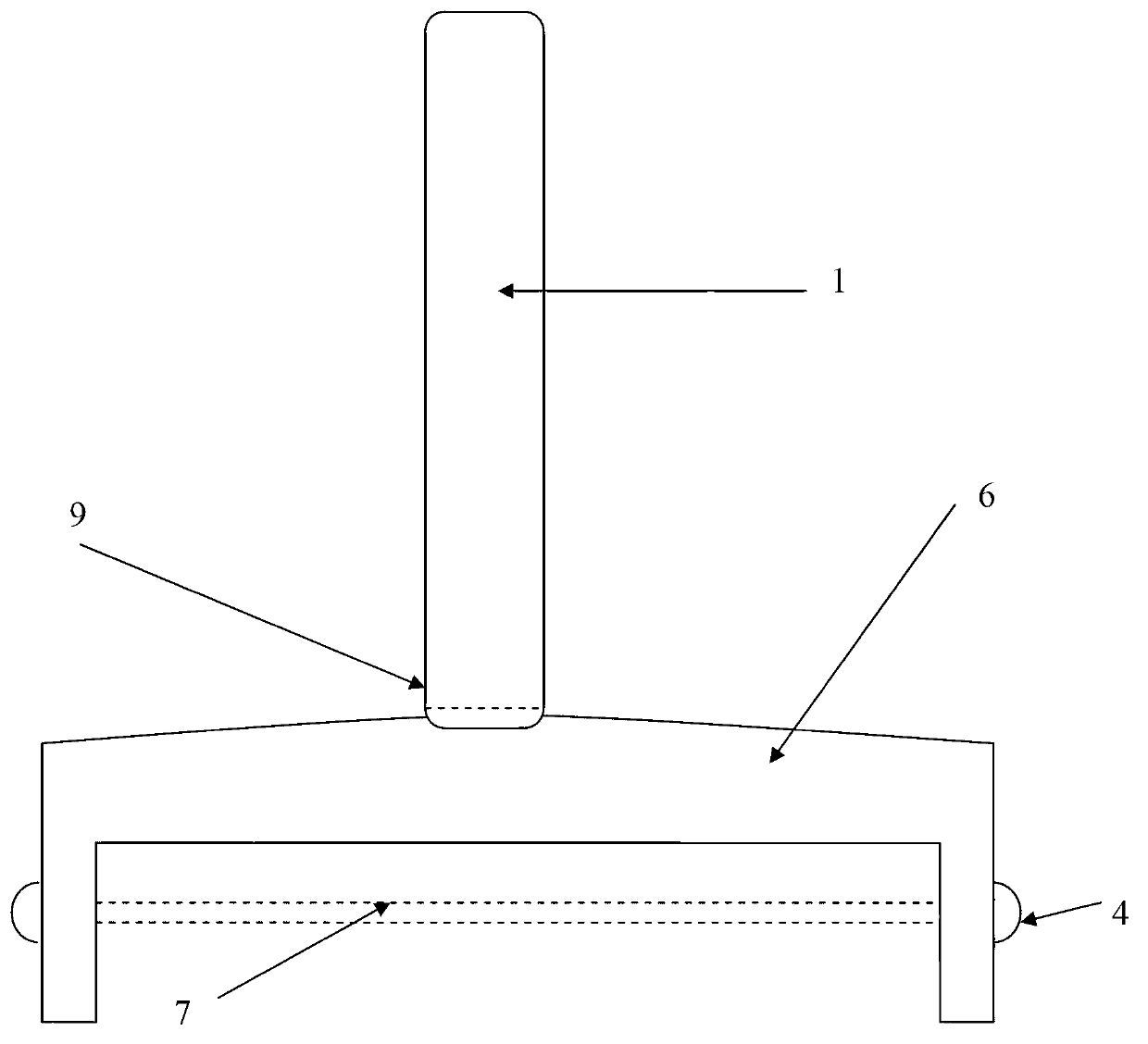

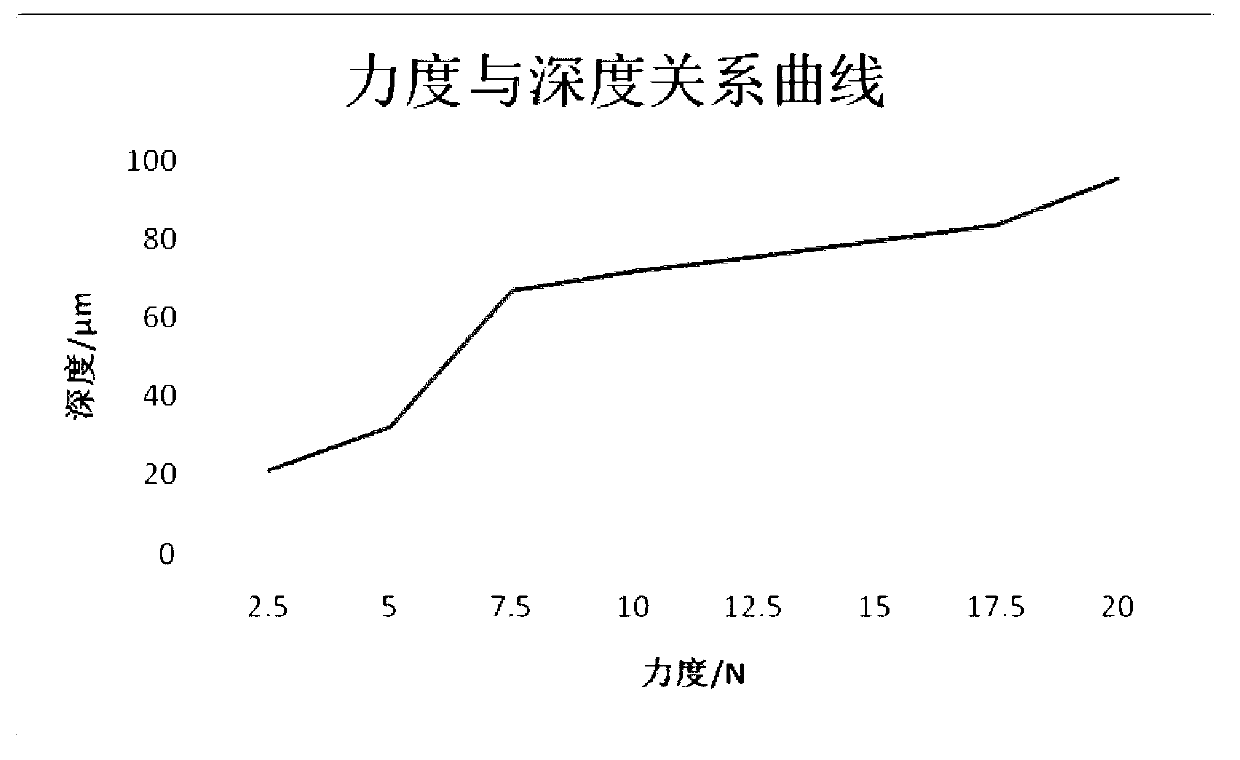

Skin rolling needle

InactiveCN103120826ASimple structureEasy to operateMicroneedlesMedical devicesControlled releaseSide effect

The invention relates to a painless skin rolling needle used for fast cutaneous penetration or cosmetic products. A handle and a support of the fixing frame of the device are movably connected in a multidirectional sliding or multi-angle moving embedded mode, a rolling wheel seat is a hollow column cylinder, transdermal drug delivery, transdermal absorption and controlled-release system are improved, large numbers of micro pipelines can be formed through the rolling needle in a short time, medicines, the cosmetic products and the like are directly penetrated through epidermal cells, an epidermal wound is micro and is fast healed, and possibilities of bacterial infection are remarkably lowered. Skin hardening and cell shrinkage cannot be caused, an epidermal tissue also cannot become thin, and the skin rolling needle can be used for multiple times and further can be used for scalp massage to stimulate hairs to grow. The skin rolling needle is simple in preparation process, low in cost and side effect, obvious in effect, good in controllability, convenient to use, strong in practicality, capable of being directly used for daily life, suitable for large-scale production and commercial application in medical and cosmetic industries, and remarkable in benefit. In addition, a user can master the skin rolling needle through simple training.

Owner:上海百华生物科技有限公司

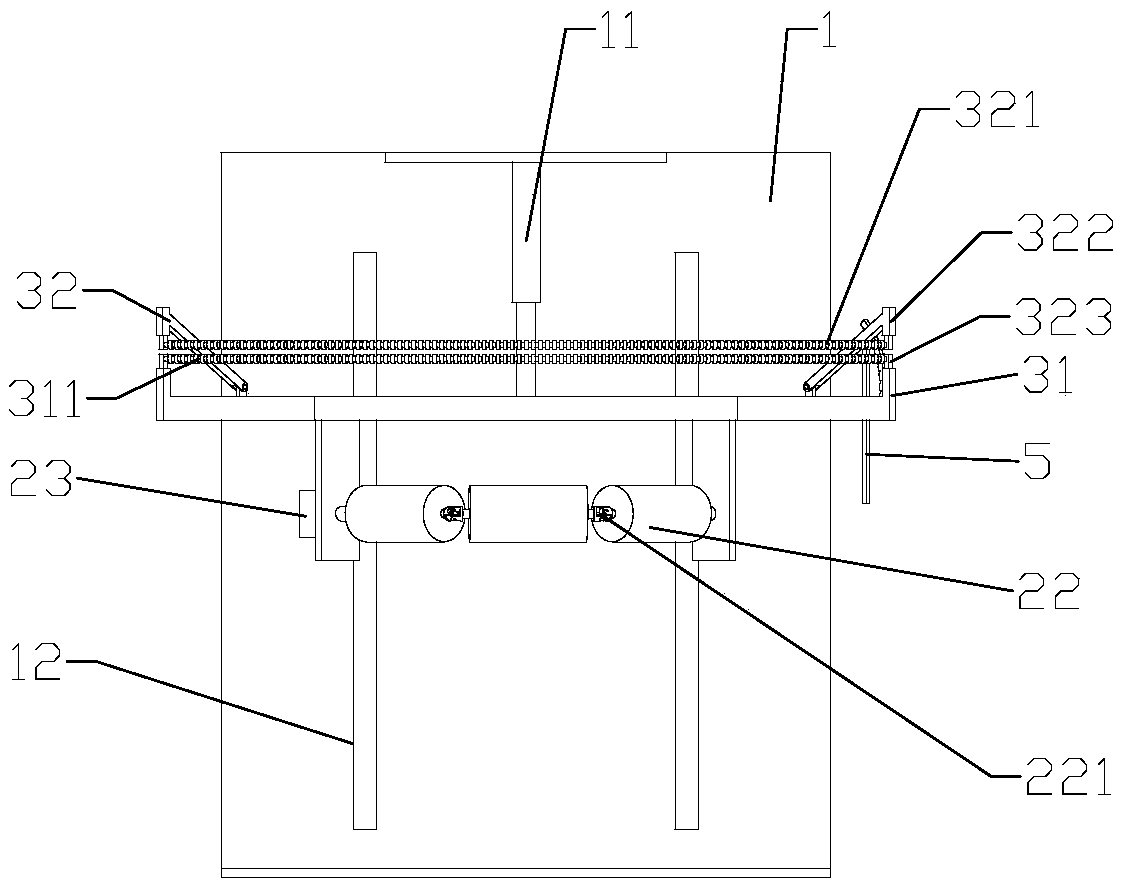

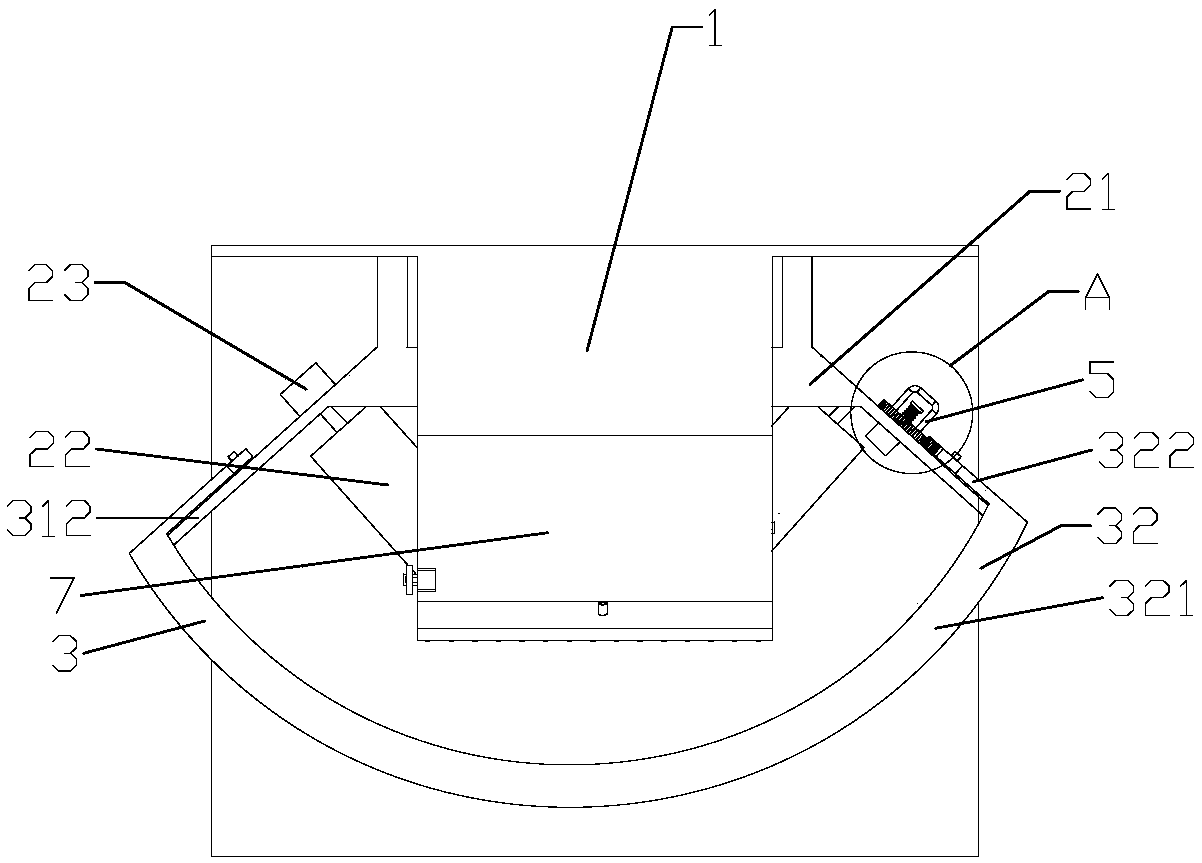

Skin pulling device for slaughtering

ActiveCN109122789AReduce manual involvementPlay a buffer roleSkinning instrumentsSkin rollingEngineering

The invention discloses a skin pulling device for slaughtering. The skin pulling device comprises an operating table, a skin rolling device and a lifting cylinder, wherein an arc-shaped skin expandingdevice is arranged on the supporting frame, the skin expanding device comprises a supporting portion, a compressing portion and a fixing device, the supporting portion comprises a supporting rod andconnecting rods I arranged on both ends of the supporting rod and connected with the supporting frame, the compressing portion comprises a compressing rod and connecting rods II arranged on both endsof the compressing rod and hinged with the connecting rods I, the compressing rods correspond to the supporting rods in the vertical direction, and the compressing rods are arranged above the supporting rods; the fixing device is arranged at the right ends of the connecting rods I and the connecting rods II, and is used for fixing the connecting rods II rotated to certain positions. The skin pulling device can realize the effect of simultaneous downward tearing and pulling on the same horizontal plane, and is even in skin pulling without manual trimming and peeling.

Owner:内蒙古草原福美食品有限公司

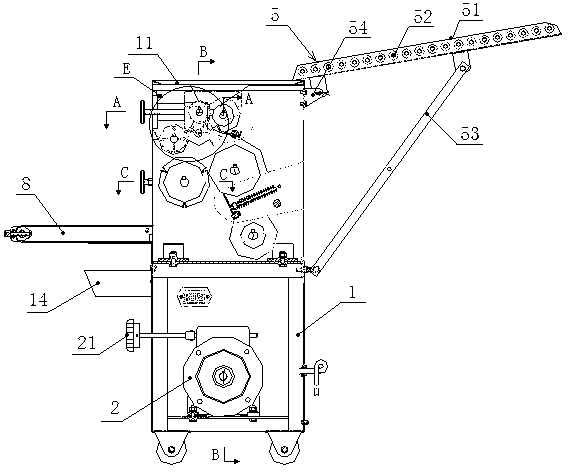

Baked wheat cake wrapper forming machine and processing method

ActiveCN103315013AReduce labor intensityRealize one machine continuous productionDough processingSkin rollingContinuous production

The invention discloses a baked wheat cake wrapper forming machine and a processing method. The baked wheat cake wrapper forming machine comprises a stand and a speed regulation speed reducer, wherein the speed regulation speed reducer is arranged at the lower part of the stand; a flour pressing part and a shaping part are arranged at the upper part of the stand; a flour receiving disc is arranged below the flour pressing part; a flour smoothing dustpan combination is arranged above the shaping part; a forming part is arranged below the shaping part; a conveyer belt combination is arranged below the forming part; an excess material receiving disc is arranged below the conveyer belt combination; a flour introducing disc is arranged above the flour pressing part and the shaping part. The baked wheat cake wrapper forming machine simulates the principle of manual skin rolling and integrates wrapper shaping, forming and conveying into a whole. By utilizing the baked wheat cake wrapper forming machine, continuous production with one machine can be realized, the production speed and the thickness of the wrapper can be regulated, the surface of the pressed wrapper is smooth, the shape and the size are consistent, the number of operators is reduced, the efficiency is improved, the labor intensity of the operators is alleviated, and the baked wheat cake wrapper forming machine is beneficial to industrial production of pasta processing.

Owner:SHANDONG YINYING COOKING MACHINERY

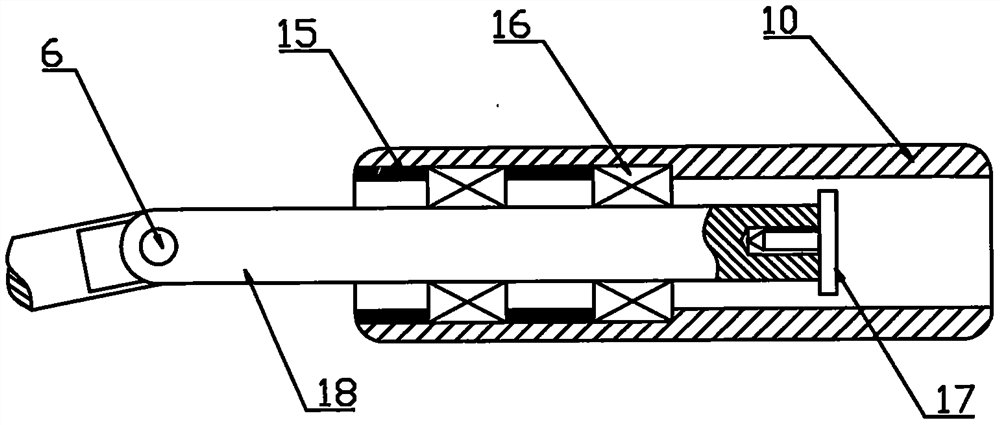

High-frequency massage roller

InactiveCN107198649AIncrease elasticityImprove beauty effectElectrotherapyRoller massageSkin contactSkin surface

The invention relates to a massage roller utilizing high-frequency waves. Skin is massaged by two rotation rollers in a rolling mode, a reference power supply and a high-frequency wave power supply active reference electrode and a therapeutic electrode are provided, and the rotation rollers enable the interior of the body to generate deep heat in the skin contact rolling massage process; according to rolling massage, the partial massage function is achieved, the high-frequency wave therapeutic function can also be brought into play, the lipolysis effect is achieved, the skin elasticity effect is enhanced, the beautifying effect is further enhanced, the high-frequency wave therapeutic effect is more conveniently and efficiently achieved, a safety switch is arranged on the power supply on the condition that the two rotation rollers make contact with the skin and apply pressure when the reference value is exceeded, the power supplied to the rotation rollers can be cut off through the safety switch even if the mistake that the rotation rollers get away from the back is made from the beginning of the surface of the skin, and by means of the high-frequency massage rollers, the burning danger caused by sparks or excessive deep heat can be avoided.

Owner:韩成镐

High-speed skin cutting machine

The invention provides a high-speed skin cutting machine which comprises a base component, a skin cutting component and a pressure component. The base component comprises two opposite side plates, a support plate 3 for holding a skin sample is arranged between the two side plates, and lower roller holes and upper roller grooves are arranged on the two side plates. The skin cutting component comprises an upper roller 17 and a lower roller 19 which reversely rotate through two engaged gears 8, a blade 9 is arranged on the surface of the upper roller 17, and the upper roller 17 can vertically move along the upper roller grooves. The pressure component comprises two pressing blocks, springs are arranged in the two pressing blocks, and spring pressing rods are arranged at the bottoms of the two springs and used for contacting with two ends of the upper roller 17. The distance between the upper roller 17 and the lower roller 19 can be automatically and slightly adjusted according to the thickness of the skin sample in the use process of the high-speed skin cutting machine, and the problem that an existing skin rolling machine cannot cut off a skin sample is effectively solved.

Owner:BYD CO LTD

Method for eliminating defect of strip shape of hot-rolled high-strength steel

ActiveCN101670372BMeet end-use requirementsHigh-precision shape qualityBell type furnacesProfile control deviceSkin rollingInternal stress

The invention relates to a method for eliminating a defect of strip shape of hot-rolled high-strength steel. The technological combination of skin rolling, batch annealing and roll straightening is introduced into a process for the plate rolling of the hot-rolled high-strength steel with a specification range of 3-18.4mm multiplied by 900-1800mm (thickness multiplied by width) and a yield strength not less than 600MPa, so as to eliminate an internal stress of the hot-rolled high-strength steel, obviously improve the shape quality, and enable a user to obtain good shape stability, which is capable of meeting the strict requirement of the user that the flatness is less than or equal to 2mm / m.

Owner:SHOUGANG CORPORATION

Method of producing high-yield pattern-free galvanized sheet with yield strength of being 410MP or above

InactiveCN109371321ASolve sizeSolve the shapeHot-dipping/immersion processesAcid washingSkin rolling

The invention discloses a method of producing a high-yield pattern-free galvanized sheet with the yield strength of being 410MP or above. According to the method, on the basis of galvanized raw material components of the ESP (endless strip production) sheet billet full endless rolling technology and the rolling technology design, continuous acid-washing galvanization is conducted, induction furnace heating is conducted, the skin rolling technology is adopted, drawing straightening operation is conducted, and therefore production of the galvanized pattern-free product is achieved, specifically,the specification of the product ranges from 0.8mm to 4.0mm, and the yield strength of the product is larger than 410MPA. The product has the high dimensional accuracy and the good performance stability, the purpose that hot-rolled products partially replace cold-rolled products in the high-yield pattern-free galvanized products is achieved, compared with the cost of cold-rolling galvanization, the cost of hot-rolling galvanization can be reduced by 500-600 yuan per ton, the technological process is shortened, energy is saved, and the cost is reduced.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

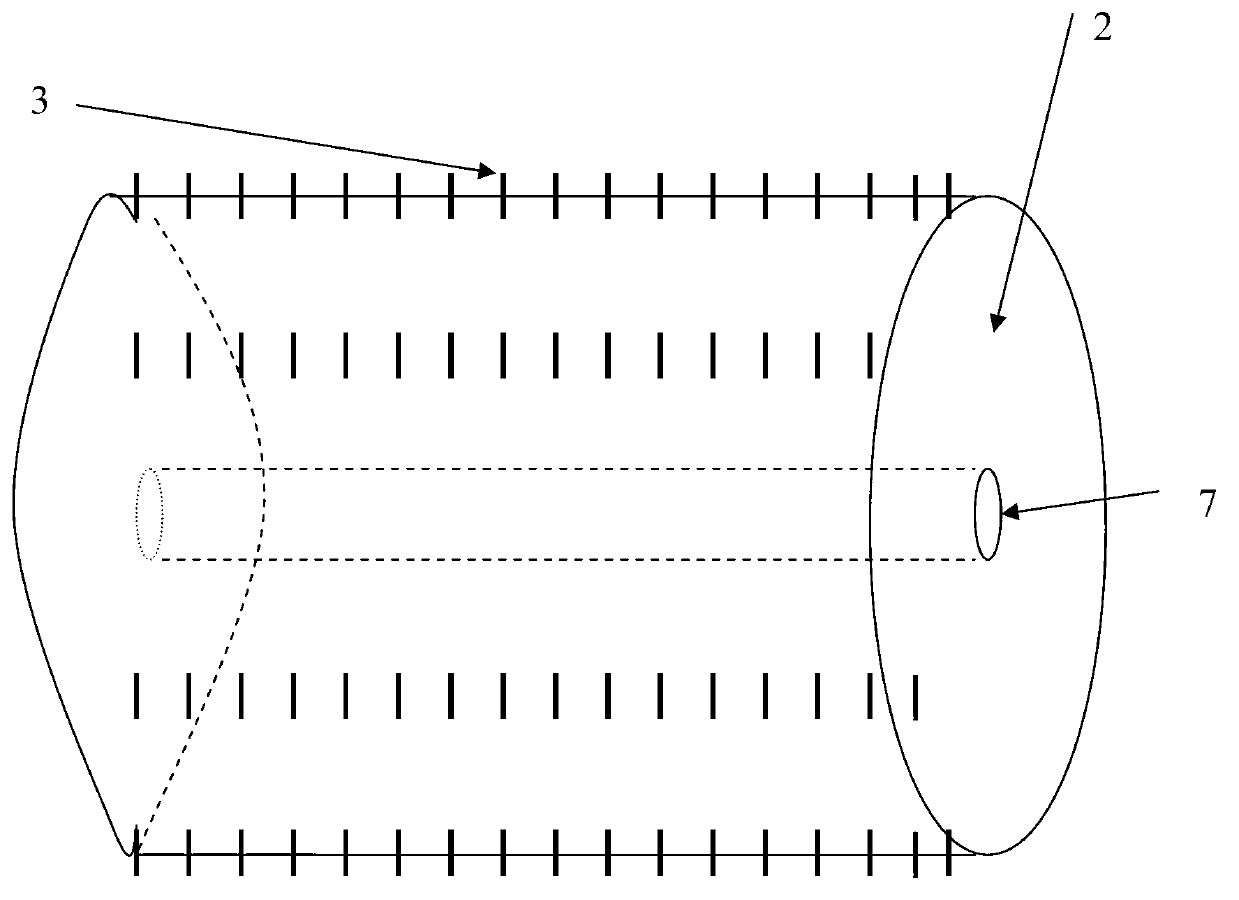

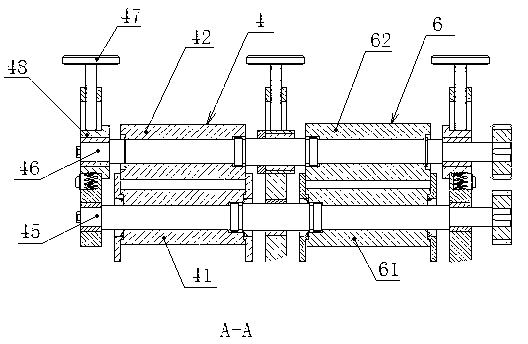

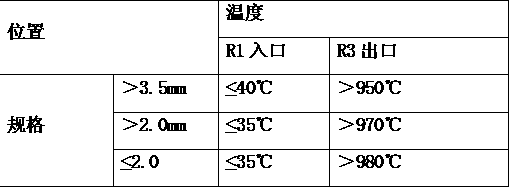

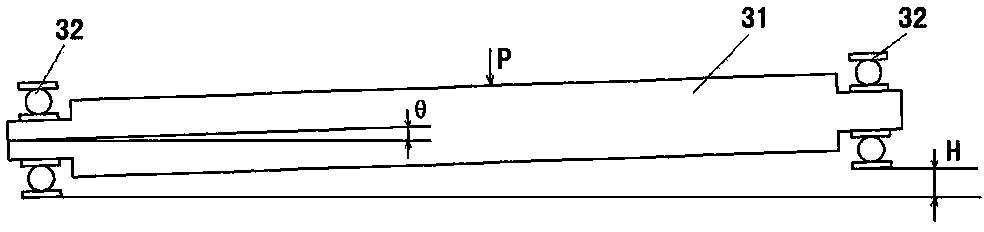

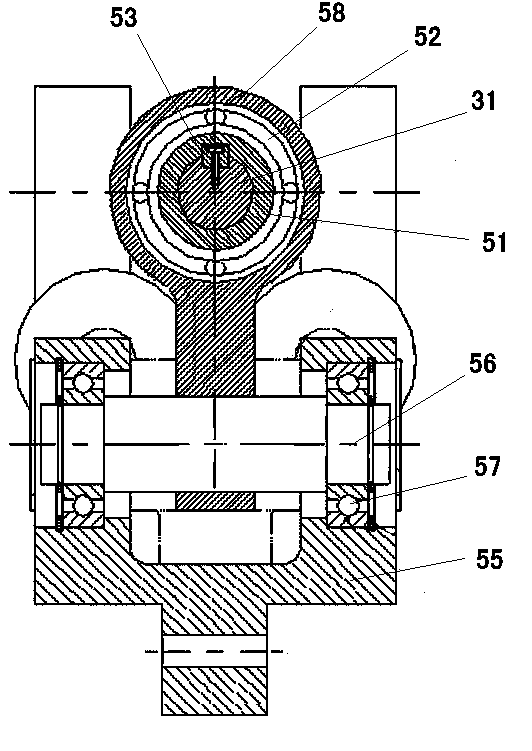

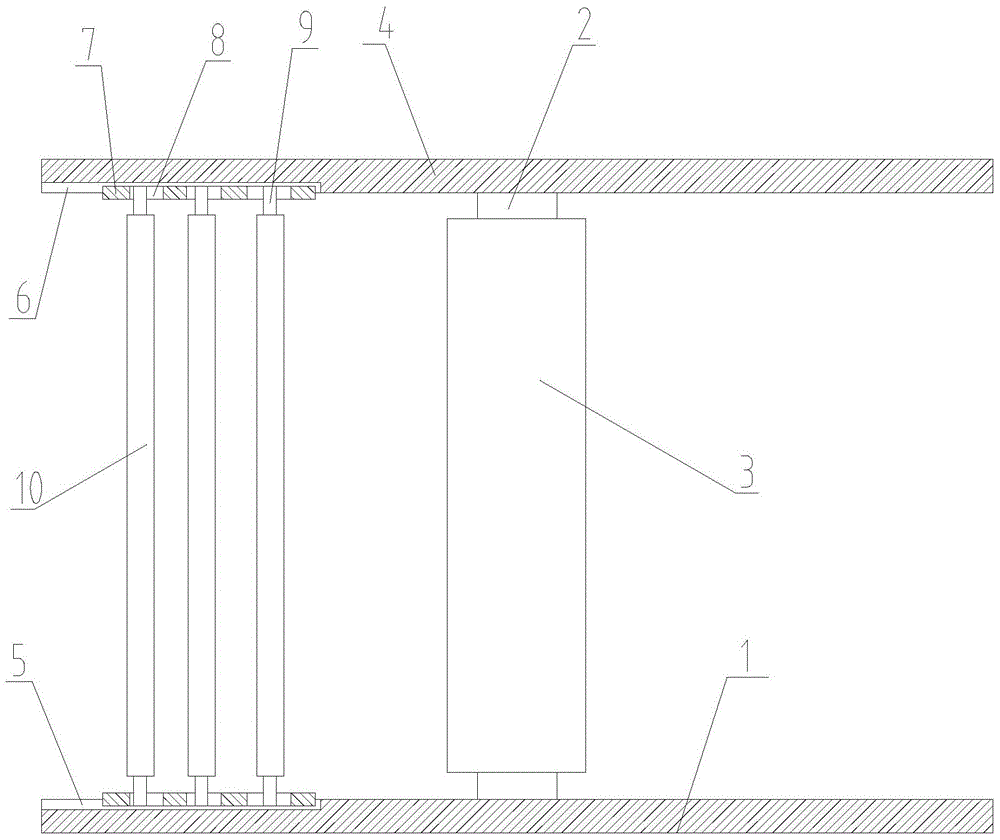

Self-adaptive skin rolling supporting structure

InactiveCN103879567ASatisfy the requirement of thickness difference in the width directionEasy to adjustAircraft assemblyPositioning apparatusSkin rollingHeight difference

The invention provides a self-adaptive skin rolling supporting structure and aims at solving the problem that skin of a skin riveting supporting shaft structure cannot horizontally move smoothly due to the fact that a bearing can be possibly jammed and a supporting shaft cannot roll along with horizontal moving of the skin in the prior art. The self-adaptive skin rolling supporting structure comprises a supporting shaft, a left supporting component and a right supporting component, and the left supporting component and the right supporting component are mounted at two ends of the supporting shaft respectively. The self-adaptive skin rolling supporting structure has the advantages that height difference H of two axial ends of the supporting shaft can be adjusted conveniently to meet requirements on thickness difference of the skin in the width direction, the upper surface of the supporting shaft is ensured to be a horizontal plane after the skin is placed on the supporting shaft, and the supporting shaft is ensured to be capable of smoothly rolling along with horizontal moving of the skin, and the self-adaptive skin rolling supporting structure is simple in structure and low in cost.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

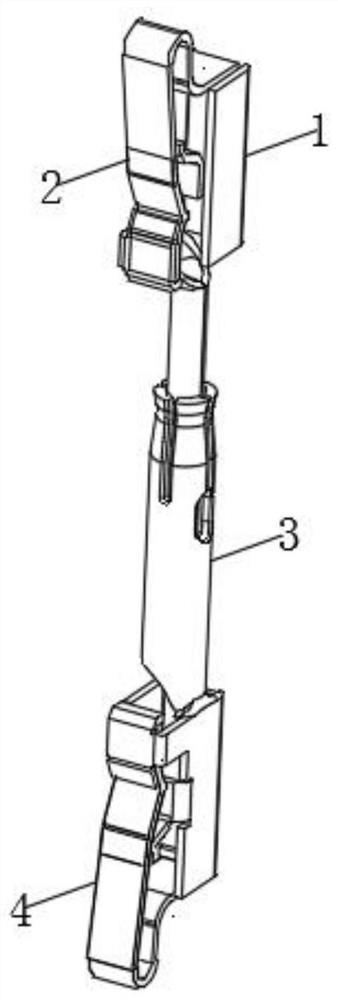

Caliper-type grabbing device for collecting skin tissue fluid

PendingCN110693535AFetch to achieveAchieve pressureSurgeryVaccination/ovulation diagnosticsDiseaseTissue fluid

The invention provides a caliper-type grabbing device for collecting a skin tissue fluid. The device consists of a slave roller, a disposable silicone sleeve, a return steel, an adjusting handle, fixed threads, a rail window, a cavity rail, a bullet hole, an elastic wire, a spring, an elastic seat, a fixing hole, a rotating sleeve, a main roller and a skin rolling handle. The device is designed byusing the caliper projectile principle and the rolling principle of a twisting roller, so that the operation force is controllable and adjustable. The friction force between the skin and the roller is utilized to make the grabbing effect obvious. Especially for patients with infectious diseases, the operator does not directly contact with the skin of the patient during operation and executes theoperation by different hands during tissue scraping, thus being safe and reliable. By the device of the invention, the disadvantages and deficiencies existing in the bare-hand collection of tissue fluids in the prior art are solved; the grabbing, pressing and fixing of corresponding movable skins can be completely realized; the gap of lack of relevant medical devices in related fields is also filled; and auxiliary devices are provided for the collection and extraction of skin tissue fluids of patients.

Owner:浙江省皮肤病防治研究所

Soybean milkTofu skin rolling device

PendingCN109007056ARealize continuous rollingSimple structureCheese manufactureFood scienceSkin rollingEngineering

The invention discloses a soybean milktofu skin rolling device. The soybean milktofu skin rolling device comprises a frame body, wherein the frame body is provided with a conveying component, the conveying component is provided with a suspension component, the suspension component is rotatably arranged on the conveying component. The suspension component is connected with a driving component, andthe driving component is fixedly arranged on the frame body. The frame body is further provided with a rolling pallet, the rolling pallet is arranged under the suspension component. The soybean milktofu skin is suspended on the suspension component, the suspension component is driven to rotate by the driving component, and the soybean milktofu skin is rolled on the rolling pallet. The soybean milktofu skin rolling device provided by the invention has the advantages of simple structure and ingenious design, and continuous rolling of the soybean milktofu skin can be achieved, thus the productionefficiency is improved greatly. At the same time, the soybean milktofu skin rolling device provided by the invention is highly automatic, and does not need manual participation in the rolling, thereby avoiding the risk of workers being burned.

Owner:北京香豆豆食品有限公司

Method for producing high magnetic induction oriented silicon steel strip through batch nitriding

The invention relates to a production method of high magnetic induction oriented silicon steel. The method comprises the following steps: smelting, performing continuous casting, heating a casting billet, performing hot rolling, normalizing, performing cold rolling, and decarburizing; performing heat preservation or cooling batch nitriding; naturally cooling to the room temperature; and performing final high temperature annealing, coating a tensile stress coating, stretching and performing skin rolling for standby. Compared with the prior art, for the 0.27mm high magnetic induction oriented silicon steel product, the average iron loss P1.7 / 50 is reduced from 0.955W / kg to no more than 0.940W / kg and the average magnetic induction B800 is increased from 1.898T to no less than 1.905T; and forthe 0.23mm high magnetic induction oriented silicon steel product, the average iron loss P1.7 / 50 is reduced from 0.885W / kg to no more than 0.860W / kg and the average magnetic induction B800 is increased from 1.895T to no less than 1.903T.

Owner:武汉钢铁有限公司

Processing technology of leather product

ActiveCN107338336ANo damageGood flexibility and wear resistanceLeather clicking/perforating/clickingPre-tanning chemical treatmentSurface cleaningWear resistant

The invention belongs to the technical field of leather products, and particularly relates to a processing technology of a leather product. The processing technology comprises the following specific steps of A1, skin selection; A2, first soaking; A3, meat removal; A4, secondary soaking; A5, first lime soaking; A6, hair removal; A7, secondary lime soaking; A8, skin planing; A9, surface cleaning; A10, lime removal; A11, cleaning; A12, airing; A13, first skin smoking; A14, first skin covering; A15, secondary skin smoking; A16, medicinal herb decocting; A17, liquid medicine applying; A18, secondary skin covering; A19, third skin smoking; A20, melanterite coating; A21, oil coating; A22, splitting; A23, first skin rolling; A24, third skin covering; A25, secondary skin rolling; A26, skin spreading; A27, trimming; and A28, numbering and warehousing. Under the premise that no chemical raw material is added, the prepared leather has breathable and waterproof characteristics, and is wear-resistant and tough.

Owner:汪孝凌

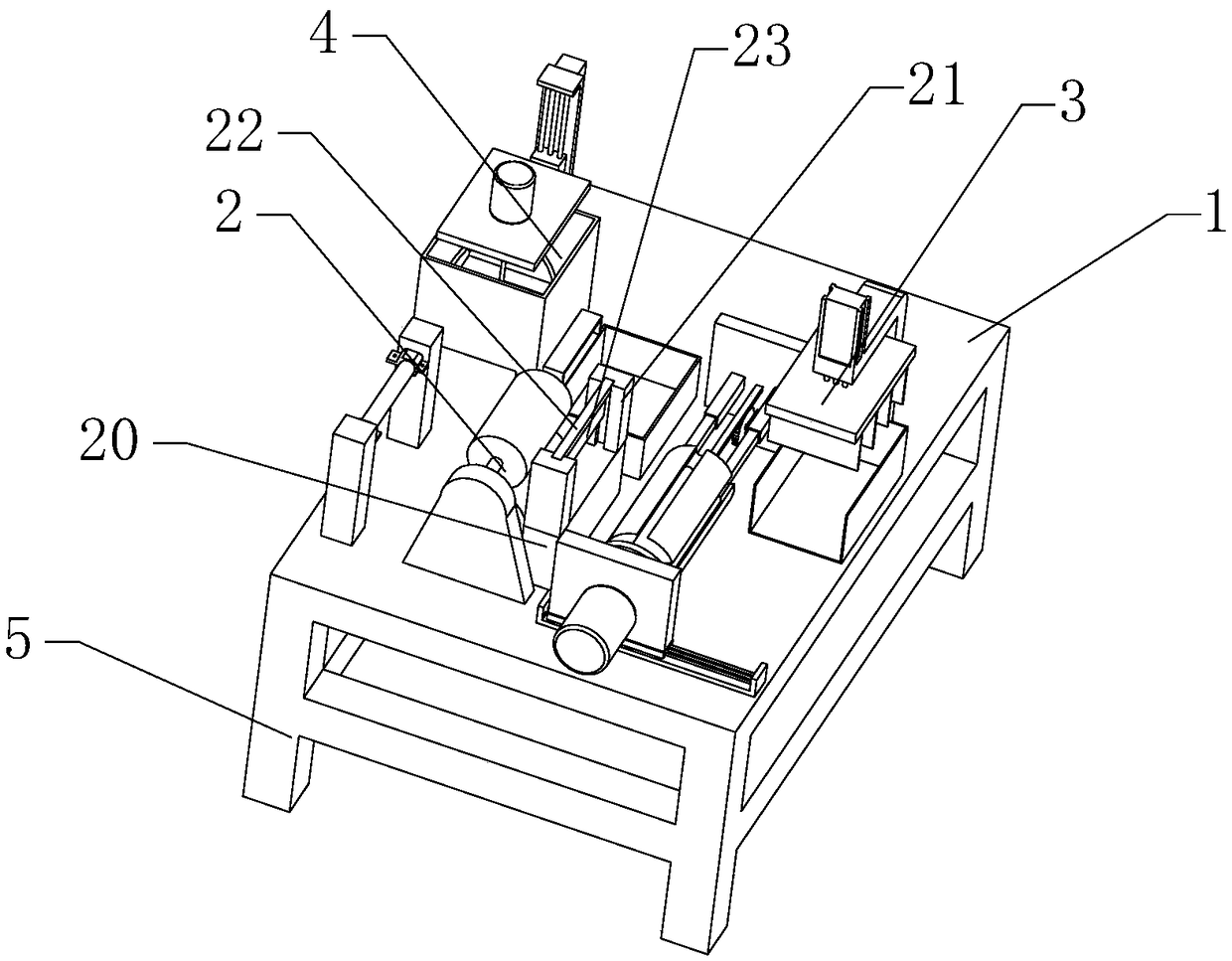

Stuffing formula for five-fragrant rolls in South Fujian, rolling device and automatic rolling method

ActiveCN109380666AImprove processing efficiencyPlay a supporting roleFood coatingAutomatic processingSkin rolling

The invention relates to the field of automatic processing device for five-fragrant rolls, in particular, relates to a stuffing formula for five-fragrant rolls in South Fujian, and also discloses a rolling device for the five-fragrant rolls in South Fujian, wherein the rolling device includes a worktable, a bean curd skin guiding assembly, a meat stuffing filling assembly, a slitting assembly anda material blending assembly. The bottom of the worktable is provided with a plurality of support leg frames; the bean curd skin guiding assembly is located in the middle of the front end of the worktable; two sides of the soybean curd skin guiding assembly are provided with a raw material rack and a clipping assembly respectively. The meat stuffing filling assembly includes a skin rolling mechanism and a meat stuffing filling mechanism. The skin rolling mechanism is arranged on the side part of the clipping assembly. The meat stuffing filling mechanism is arranged on one side, far away from the front end of the worktable, of the skin rolling mechanism. The slitting assembly and the material blending assembly are arranged on both sides of the meat stuffing filling mechanism respectively, and the side part of the material blending assembly is also fixedly provided with a meat stuffing storage box. The invention further discloses an automatic rolling method of the five-fragrant rolls inSouth Fujian. The device improves the processing efficiency of the five-fragrant rolls in South Fujian.

Owner:FUJIAN YAMING FOOD

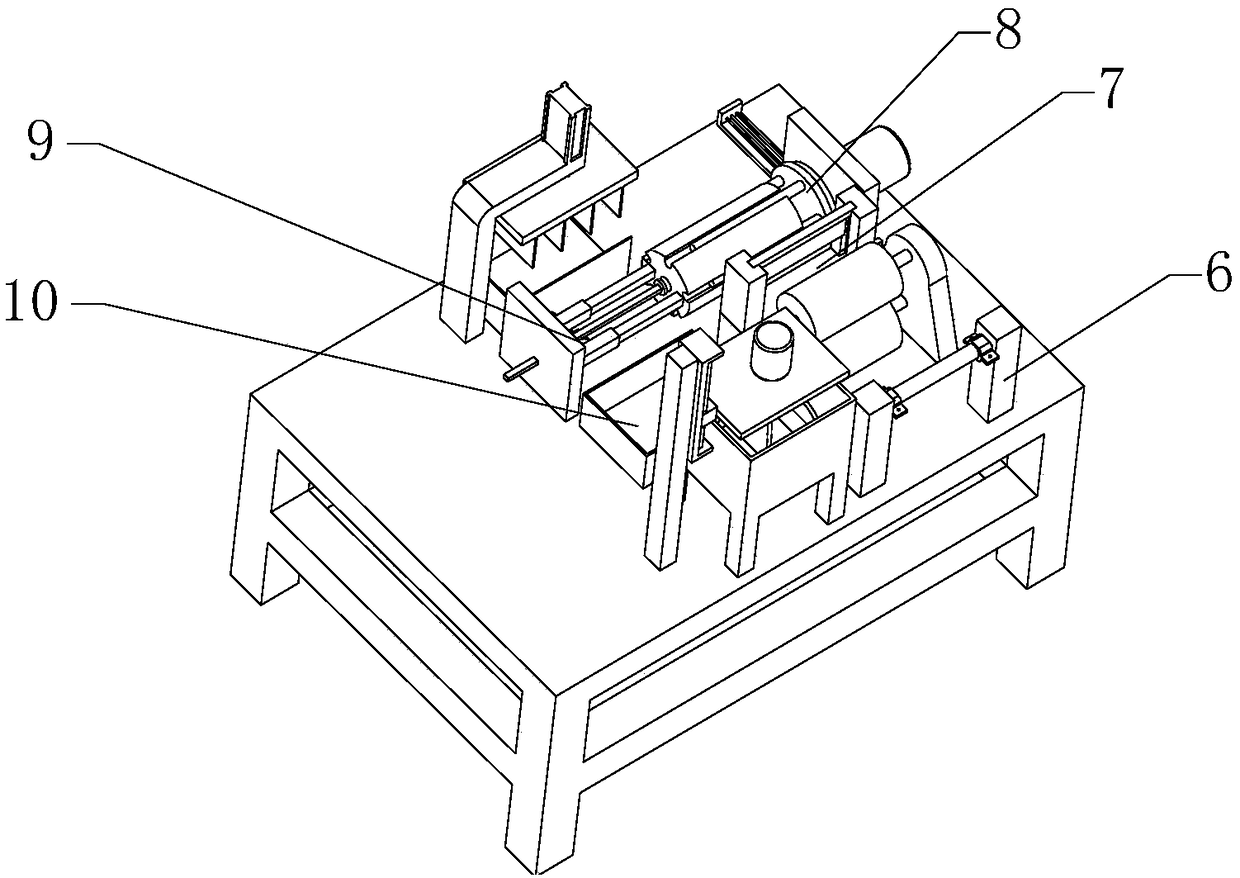

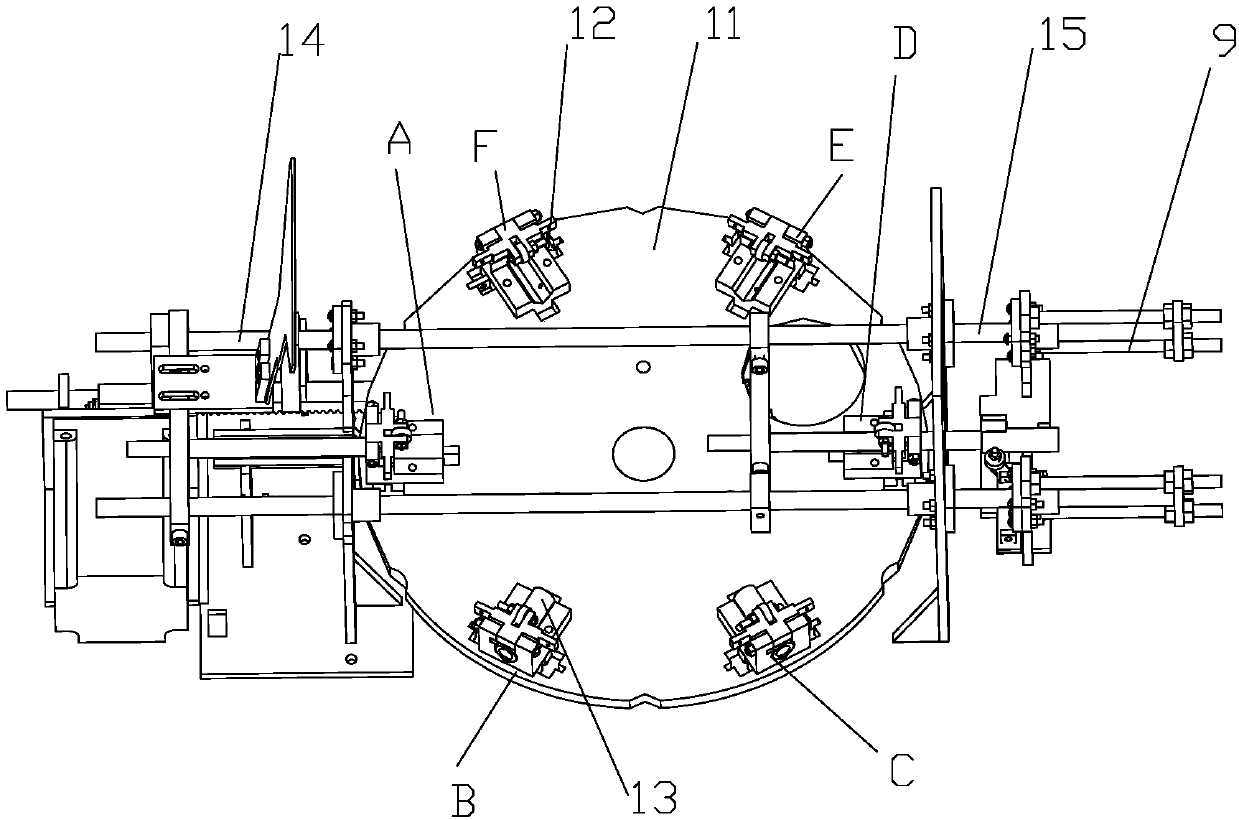

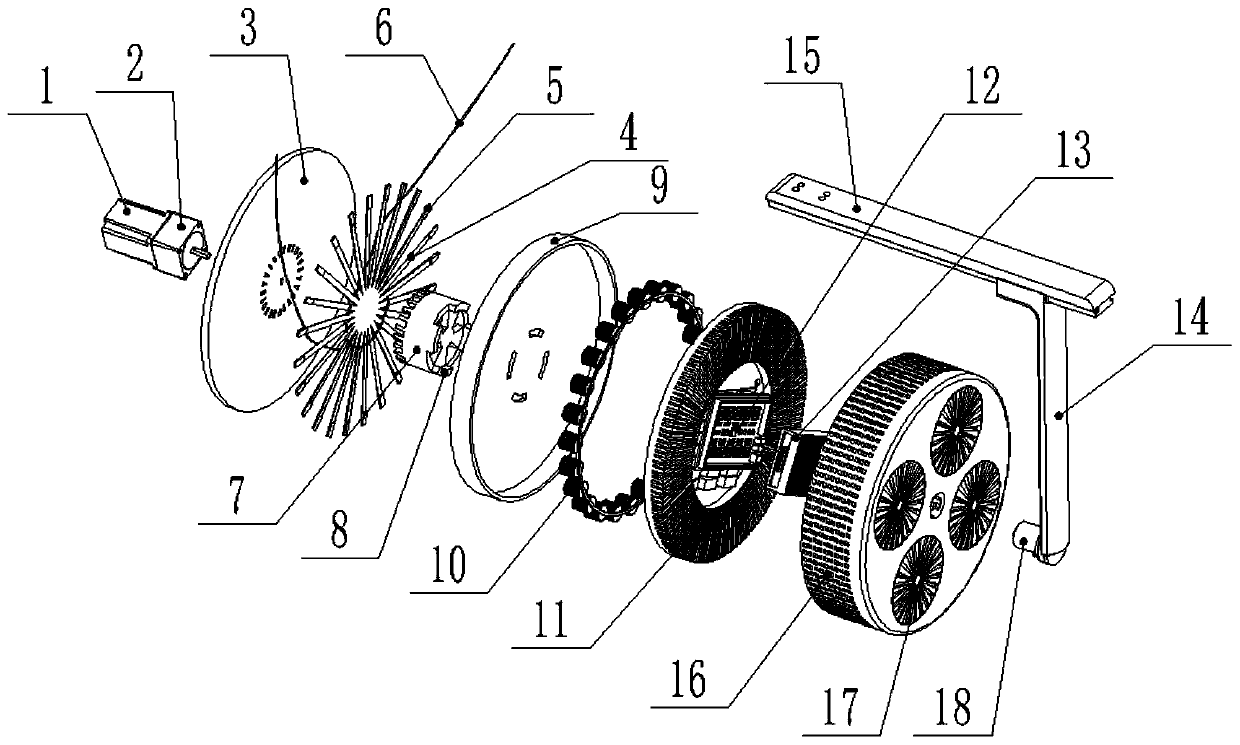

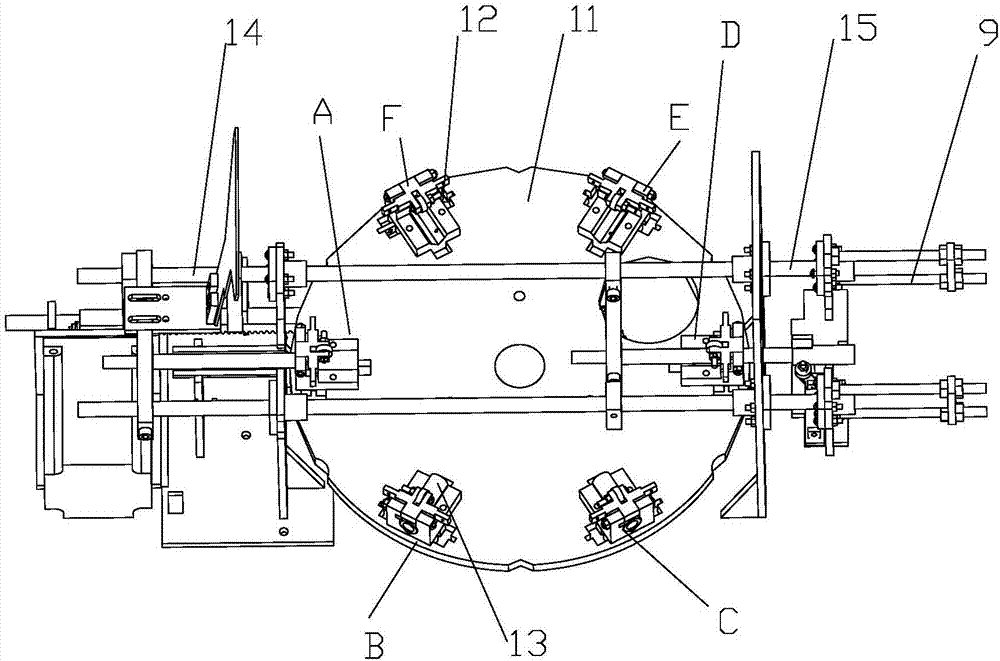

Carousel type sheepskin tearing machine

ActiveCN105994564AHigh efficiencyHigh degree of automationSkinning instrumentsElectric machineSkin rolling

The invention discloses a carousel type sheepskin tearing machine, belonging to the technical field of sheepskin tearing machines. The sheepskin tearing machine comprises a rotary rack, wherein a variable-frequency gear motor for driving the rotary rack to rotate is arranged at the top of the rotary rack; a rotation mechanism penetrates in the middle of the rotary rack; at least two guide pillars are uniformly distributed and fixed on the peripheral edge of the rotary rack; each guide pillar is in slip connection with a sliding block; a servo motor is fixed on one side of the sliding block; a rotor of the servo motor is connected with a skin rolling mechanism; the sliding block is also fixedly connected with an air cylinder; and the air cylinder is fixed on the rotary rack and connected with a pneumatic control valve group for controlling the air cylinder to move up and down. According to the invention, through the compound motion of rotation of the skin rolling mechanism and lifting of the sliding block, the sheepskin is torn from the sheep body; and the carousel type sheepskin tearing machine has the advantages of being stable and reliable in skin tearing during work, easiness in operation, convenience in adjustment, low labor intensity, high automation degree, high speed and the like.

Owner:福瑞珂食品设备(济宁)有限公司

Manufacturing method for fireworks

The invention discloses a manufacturing method for fireworks. The manufacturing method comprises the steps that step 1: a prior step: the fireworks are fed, drilled and assembled with detonators, andthen the fireworks provided with the detonators are pushed out through a material pushing mechanism; step 2: a fireworks conveying step; step 3: a skin attaching step; at a skin attaching station, outer skins which are cut and are glued are arranged on two skin rolling rollers; the fireworks provided with the detonators are placed on the outer skins by a pneumatic finger; the two skin rolling rollers rotate to coil and attach the outer skin on the fireworks; and step 4: a finished-product discharging step, namely after skin attaching is finished, one skin rolling roller translates outwards, sothat a fireworks barrel subjected to skin attaching falls into a material receiving basket below. By adopting the manufacturing method for the fireworks, automatic drilling, detonator assembling andskin attaching can be realized; the automation degree is high; and production efficiency is high.

Owner:浏阳市金富太出口烟花制造有限公司

Making method for peony steamed dumplings

InactiveCN105249179AFully reflect the medicinalFully reflect the value of health careFood scienceProduction chainSkin rolling

Owner:HENAN LUOYANG RED PEONY IND RES & DEV CO LTD

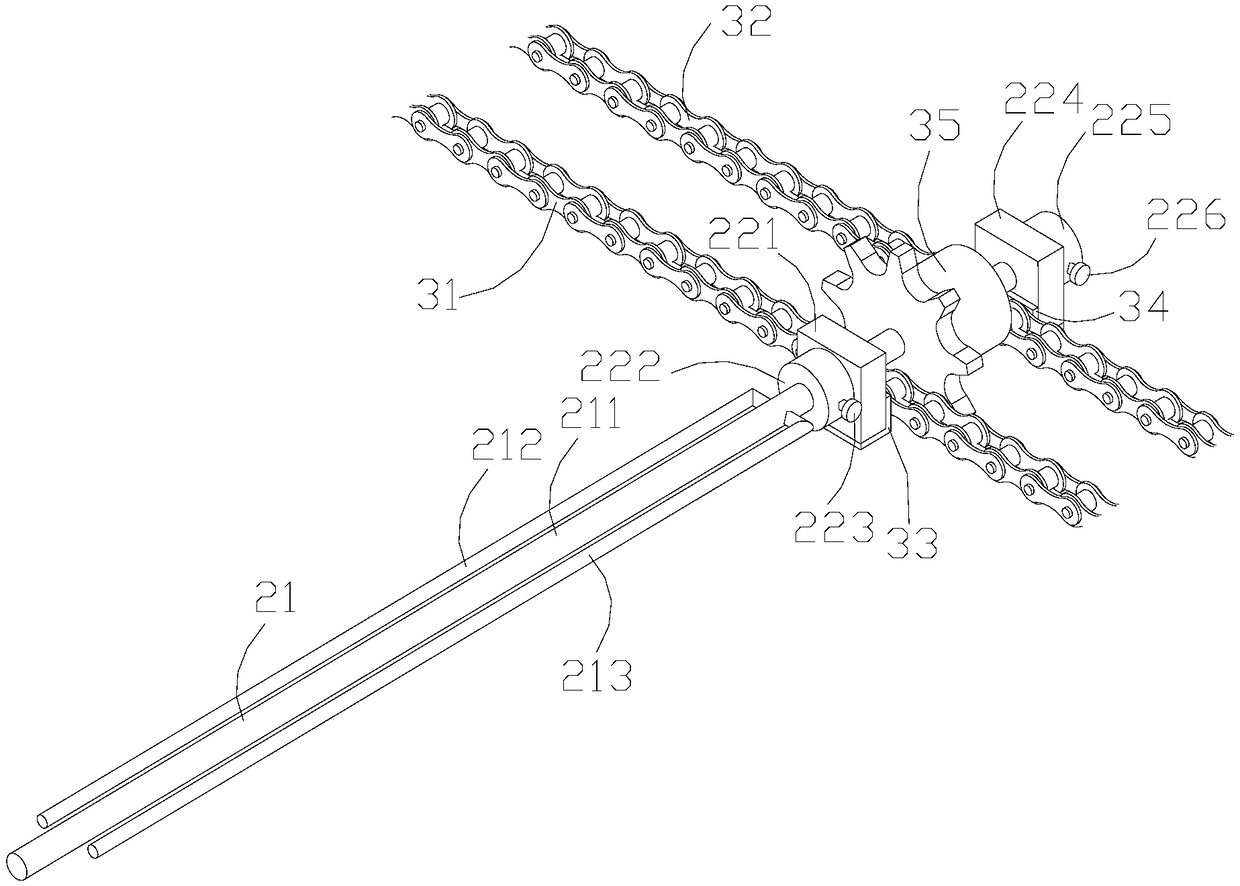

Multifunctional skin pulling machine

ActiveCN109315470AReduce manual involvementWrangling fastSkinning instrumentsUniversal jointElectric machinery

The invention discloses a multifunctional skin pulling machine. The multifunctional skin pulling machine comprises an operating table, a skin rolling device and a lifting air cylinder, the skin rolling device comprises a supporting frame, rollers and a motor device, the top end of the supporting frame is connected with the operating table through the lifting air cylinder, the three rollers are arranged on the supporting frame and connected through universal joints, each roller is connected with a skin pulling chain, an arc-shaped skin supporting device is arranged above the rollers and comprises a supporting part, a pressing part and a fixing device, and the fixing device comprises a fixing end, a mobile end and a rotating shaft for connecting the fixing end and the mobile end. The multifunctional skin pulling machine is simple in structure and capable of realizing synchronous tearing and pulling on the same horizontal plane, skin pulling is uniform, few staff participate, cleaning isconducted in advance, and efficiency is high.

Owner:诸暨市佳航机械有限公司

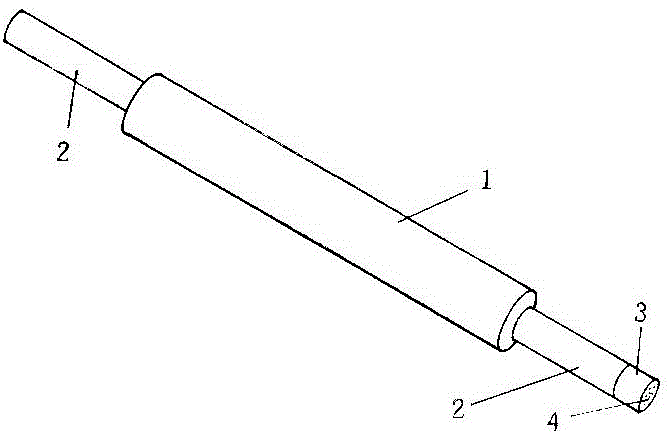

Cooperatively used dry flour loading rolling pin

InactiveCN105638810AEasy to roll doughDough-sheeters/rolling-machines/rolling-pinsSkin rollingEngineering

The present invention provides a cooperatively used dry flour loading rolling pin. The rolling pin for dough rolling has a hollow core noodle rolling main body. A hand rolling handle is arranged at both ends, a sealed cover communicating with the internal core is arranged at one end of the rolling handle end, and a plurality of flour outlets are distributed on the end surface of the sealed cover. When the rolling pin is used, dry flour can be loaded into the hollow core. When the dough skin is rolled, the flour can be sprinkled to the outside of the dough skin via the various outlets, so that it is more convenient for dough skin rolling.

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

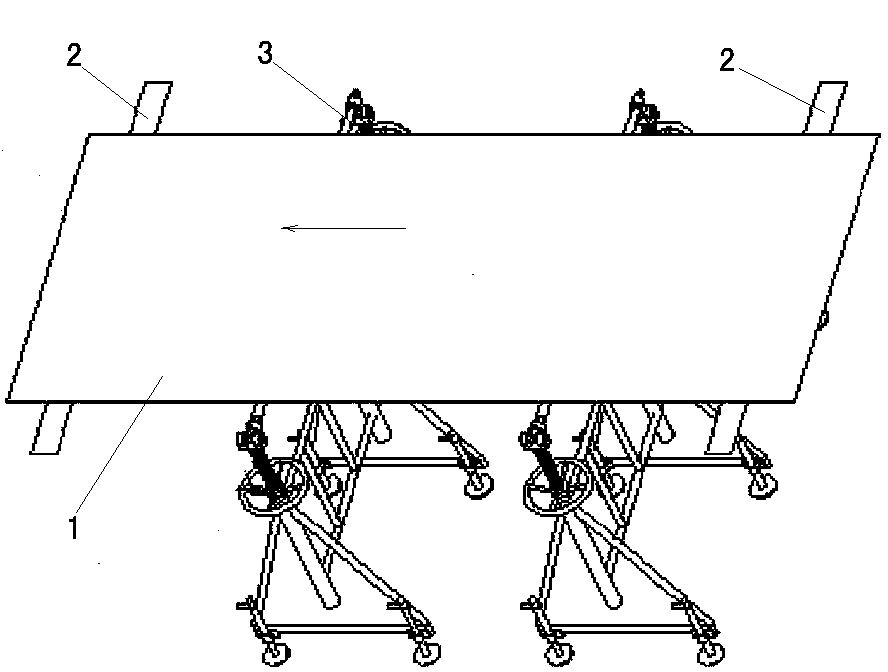

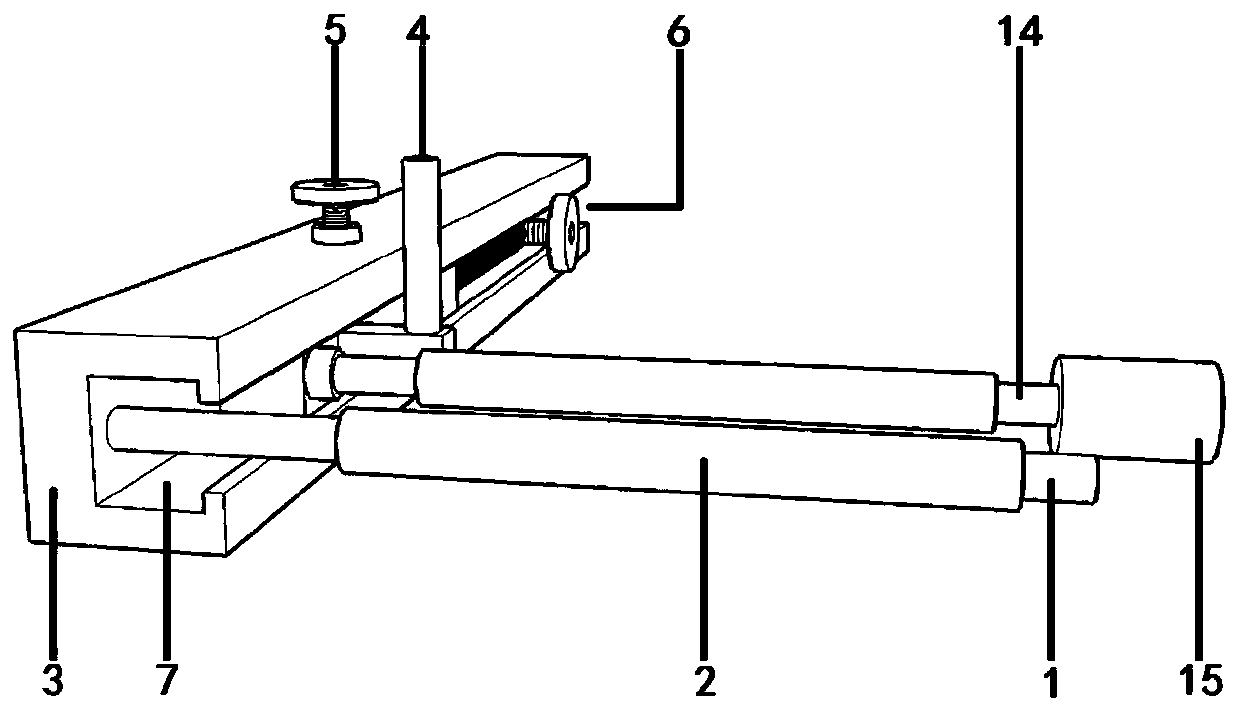

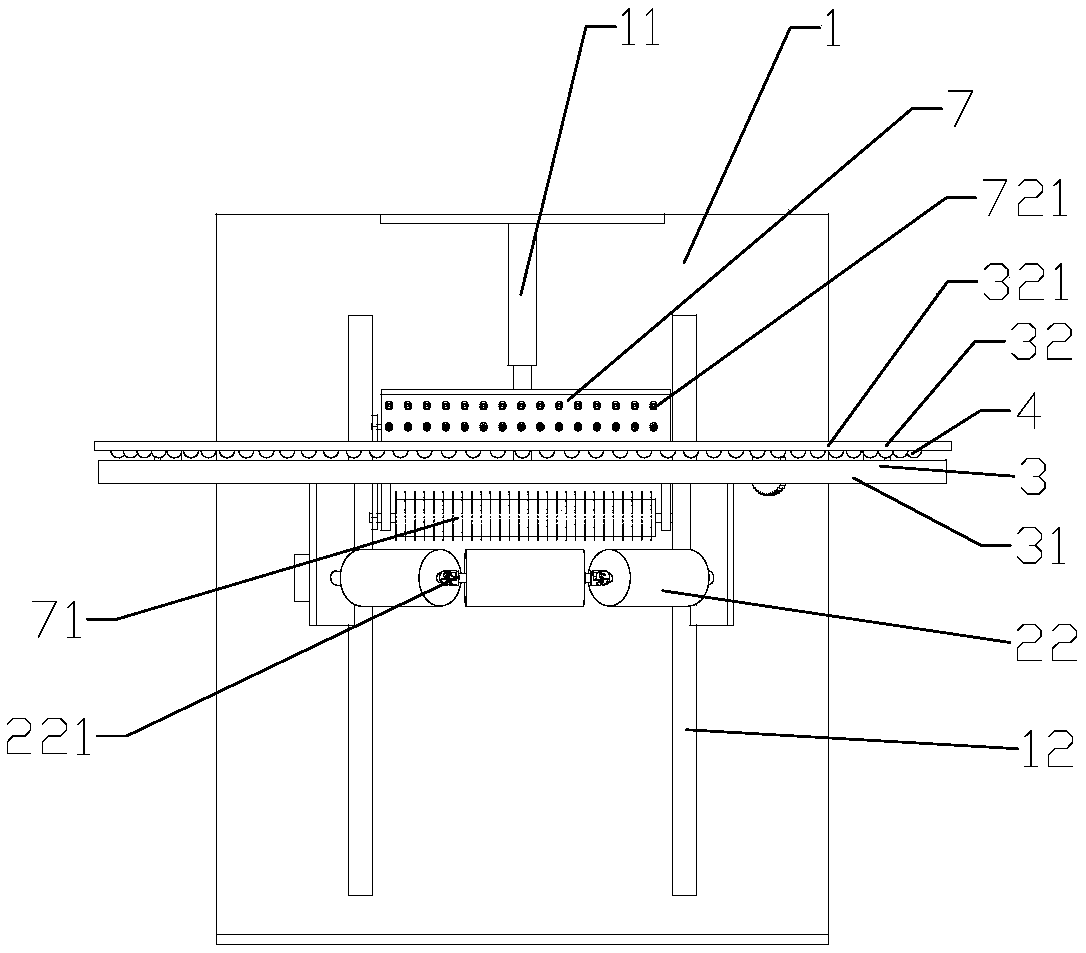

A lever labor-saving skin rolling device

ActiveCN111374157BPlay the role of repeated rollingMeet the requirements of hand-rolled doughDough-sheeters/rolling-machines/rolling-pinsSkin rollingEngineering

The invention discloses a lever and labor-saving skin rolling device, comprising a panel (1), a slide plate (3), a handle (7), a card seat (8), a fixing frame (11), a dough rolling device, a fixing device and a guiding device; The panel (1) is a rectangular wooden board, and a guide device is installed on the fixing device on one side of the guide device. The corresponding member of the guide device is connected with the slide plate (3), and the connection point is fixed in the height direction. 8) It is stuck on the corresponding components of the dough rolling device, the front end of the slide plate (3) is made with a handle (7), push the handle (7) back and forth by hand and apply a small pressure downward, so that the dough rolling device can be moved downward. When a large pressure is generated, the slide plate (3) drives the deck (8) and the rolling device to roll back and forth on the panel (1), so that the pre-prepared small dough can be rolled and pressed into a finished dough.

Owner:NANJING YONGWEI TECH CO LTD

Bean gluten forming stick delivery table

ActiveCN105775679BAchieve the effect of automatic deliveryHigh degree of mechanizationConveyor partsSkin rollingGluten

The invention belongs to the field of soybean gluten making equipment, and particularly discloses a transporting table for soybean curd sheet shaping rods. The transporting table comprises machine frames, a conveying chain, and transmission parts for driving the conveying chain, wherein a supporting device for supporting the soybean gluten shaping rods is arranged on the conveying chain and comprises supporting blocks fixed on the conveying chain, and a supporting tank for supporting the soybean gluten shaping rods is formed in each of the supporting blocks; the transporting table also comprises a beancurd skin rolling device for driving the soybean gluten shaping rods to roll, and the beancurd skin rolling device is positioned at a discharge end of the conveying chain. Compared with a conventional operation manner, the transporting table has the advantages that in the scheme, the operation of manually rotating the soybean gluten shaping rods to roll beancurd skin is performed by a mechanical structure rather than manual work, so that the mechanized degree is further increased, and the bean gluten shaping efficiency is improved.

Owner:邳州市鑫盛创业投资有限公司

Stamping-mode heavy-load ferrule module elastic sheet type skin rolling contact pin

PendingCN111952756AReduce manufacturing costImprove conductivityCoupling contact membersSkin rollingEngineering

The invention provides a stamping mode heavy load insertion core module elastic sheet type skin rolling pin which comprises a male skin rolling pin and a female skin rolling pin, the male skin rollingpin is inserted into the upper end of the female skin rolling pin, a first elastic sheet is clamped in the male skin rolling pin, a second elastic sheet is clamped in the female skin rolling pin, andthe male skin rolling pin comprises a first shell. A first positioning plate extends out of one end of the first shell, a first limiting plate extends out of the lower portion of the first positioning plate at one end of the first shell, an inserting rod is connected to the lower end of the first shell, the first elastic piece comprises a U-shaped plate, a connecting plate is arranged at one endof the U-shaped plate, and an inserting plate is connected to the lower end of the U-shaped plate. According to the stamping-mode heavy-load insertion core module elastic piece type skin rolling insertion pin, the production cost of the insertion pin is reduced, efficient batch production can be achieved, the material utilization rate is high, the assembly steps are simple, the insertion pin is tough, resistant to abrasion and better in conductivity, and the performance technical requirements of use can be met.

Owner:WEILE ELECTRIC SHANGHAI CO LTD

Semi-automatic bamboo weaving machine

The invention discloses a semi-automatic bamboo weaving machine. A stepping motor is connected with a shape template, a bamboo skin framework is placed on a thin bamboo strip fixing ring, and one end of the thin bamboo strip fixing ring is inserted into a groove of the shape template; iron sheets are arranged at the end part of the bamboo skin framework, two weaving thin bamboo strips are wound on the bamboo skin framework, and a transmission key at the other end of the thin bamboo strip fixing ring is inserted into the groove of a suction shape shell; an electromagnet, an electromagnet cooling fin, a control module and a power module are sequentially arranged inside the suction shape shell, one end of a collecting ring is connected with a sliding guide rail through a sliding wire arranging pipe, the two weaving thin bamboo strips penetrate through adjusting frames and are wound on bamboo skin rolling discs respectively, and a spraying softener is placed on each bamboo skin rolling disc. According to the semi-automatic bamboo weaving machine, most of the repeated weaving process of disc-shaped bamboo weaving products can be completed under the assistance of manpower, the semi-automatic bamboo weaving machine can also complete a small-part weaving process of the bamboo weaving products such as a large part of round bottom and an oval bottom, and one person can control multiple machines, so that the production cost of the bamboo weaving process is greatly reduced.

Owner:曹风帆

Sheet metal bending and rolling device

The invention relates to a metal plate bending and pipe rolling device. The metal plate bending and pipe rolling device comprises a package skin rolling section, a middle conveying section, a pipe rolling section, a welding deburring section and a tail cutting section. The metal plate bending and pipe rolling device has the advantages that the design is reasonable, the device is simple to operate and is practical, the power is reduced, the energy is saved, the roundness of the rolled metal pipes is better, the forming speed is fast and stable, the rolled pipes are perfect, the strength is high and the burrs are fewer.

Owner:安徽鹏远金属制品股份有限公司

Skin rolling-up and sticking method for fireworks

The invention discloses a skin rolling-up and sticking method for fireworks. The skin rolling-up and sticking method comprises the steps that 1, skin rolling-up and sticking are conducted, specifically, on a skin rolling-up and sticking station, cut and glued outer skins are placed on two skin-rolling rollers through a suction cup, a finger is started to place the fireworks subjected to firing line inserting on the outer skins, and the two skin-rolling rollers rotate to stick the outer skins on the fireworks in a rolling mode; and 2, finished product discharging is conducted, specifically, after skin rolling-up and sticking, one of the skin-rolling rollers outwards moves transversely, and thus firework tubes subjected to skin rolling-up and sticking fall into a receiving basket on the lower portion. According to the skin rolling-up and sticking method for the fireworks, automatic gluing and skin rolling-up and sticking can be achieved, the automation degree is high, and the productionefficiency is high.

Owner:浏阳市城东三力烟花制造有限公司

A kind of processing technology of leather products

ActiveCN107338336BNo damageGood flexibility and wear resistanceLeather clicking/perforating/clickingPre-tanning chemical treatmentBiotechnologySurface cleaning

The invention belongs to the technical field of leather products, and particularly relates to a processing technology of a leather product. The processing technology comprises the following specific steps of A1, skin selection; A2, first soaking; A3, meat removal; A4, secondary soaking; A5, first lime soaking; A6, hair removal; A7, secondary lime soaking; A8, skin planing; A9, surface cleaning; A10, lime removal; A11, cleaning; A12, airing; A13, first skin smoking; A14, first skin covering; A15, secondary skin smoking; A16, medicinal herb decocting; A17, liquid medicine applying; A18, secondary skin covering; A19, third skin smoking; A20, melanterite coating; A21, oil coating; A22, splitting; A23, first skin rolling; A24, third skin covering; A25, secondary skin rolling; A26, skin spreading; A27, trimming; and A28, numbering and warehousing. Under the premise that no chemical raw material is added, the prepared leather has breathable and waterproof characteristics, and is wear-resistant and tough.

Owner:汪孝凌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com