Production method of 440MPa-grade thin gauge hot-rolling pickling automobile sheet

A technology of hot-rolled pickling and production methods, which is applied in metal rolling and other directions, can solve the unfavorable automobile weight loss, surface quality, plate shape quality and coil performance stability that cannot meet the requirements of continuous batch stable stamping of auto parts , pickling plate thickness and other issues, to achieve the effect of less difficulty in process control, low cost, and stable roll-through performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

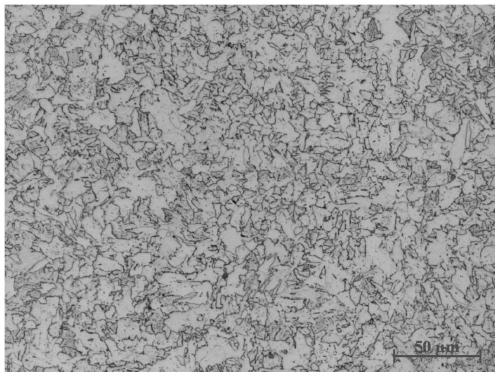

Embodiment 1

[0054] 1) In terms of weight percentage, the chemical composition of the billet is: C: 0.078, Si: 0.02, Mn: 1.12, P: 0.015, S: 0.009, Nb: 0.014, Als: 0.037, Ti: 0.021, N: 0.006, and The amount is Fe and unavoidable impurities. Its production process is: hot metal pre-desulfurization treatment → converter steelmaking → ladle LF refining → continuous casting;

[0055] The hot metal is desulfurized. After desulfurization, the sulfur content is lower than 0.008%, and the end point C of the converter is controlled at 0.06-0.08%. During the refining process, Al and Mn are adjusted in place and Nb and Ti are alloyed. After refining, calcium treatment is performed and soft stirring is performed for 10 minutes. , post-continuous casting, crystallizer liquid level fluctuations are controlled within ±2mm, slab thickness 220±2mm; slab heating→6-pass rough rolling→7-pass finish rolling→laminar cooling→coiling→levelling→pickling → Oiling → Finished product. After the steel billet is heate...

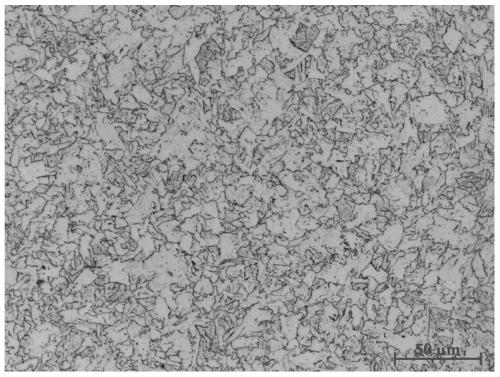

Embodiment 2

[0061] 1) In terms of weight percentage, the chemical composition of the billet is: C: 0.082, Si: 0.04, Mn: 1.16, P: 0.016, S: 0.012, Nb: 0.014, Als: 0.041, Ti: 0.015, N: 0.003, and The amount is Fe and unavoidable impurities. The production process is: pre-desulfurization treatment of molten iron → converter steelmaking → ladle LF refining → continuous casting; desulfurization of molten iron, after desulfurization, the sulfur content is lower than 0.008%, the end point C of the converter is controlled at 0.06-0.08%, Al, Mn After the adjustment is in place, carry out Nb and Ti alloying. After refining, carry out calcium treatment, and softly stir for 10 minutes, and then continue casting. The fluctuation of the crystallizer liquid level is controlled within ± 2mm, and the thickness of the slab is 220 ± 2mm; the slab is heated → 6 passes Sub-rough rolling → 7-pass finish rolling → laminar cooling → coiling → leveling → pickling → oiling → finished product. After the steel bill...

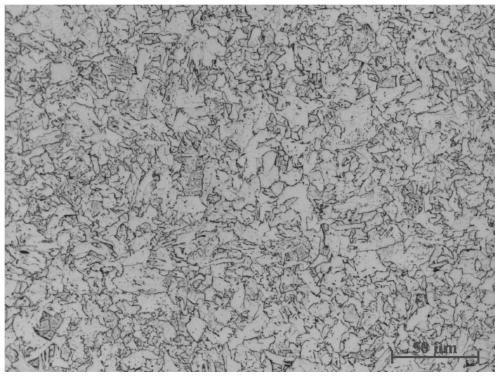

Embodiment 3

[0066] 1) In terms of weight percentage, the chemical composition of the billet is: C: 0.074, Si: 0.04, Mn: 1.05, P: 0.010, S: 0.011, Nb: 0.017, Als: 0.042, Ti: 0.025, N: 0.005, and The amount is Fe and unavoidable impurities. Its production process is: hot metal pre-desulfurization treatment → converter steelmaking → ladle LF refining → continuous casting;

[0067]The hot metal is desulfurized. After desulfurization, the sulfur content is lower than 0.008%, and the end point C of the converter is controlled at 0.06-0.08%. During the refining process, Al and Mn are adjusted in place and Nb and Ti are alloyed. After refining, calcium treatment is performed and soft stirring is performed for 10 minutes. , post-continuous casting, crystallizer liquid level fluctuations are controlled within ±2mm, slab thickness 220±2mm; slab heating→6-pass rough rolling→7-pass finish rolling→laminar cooling→coiling→levelling→pickling → Oiling → Finished product. After the steel billet is heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com