Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Skin sample" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

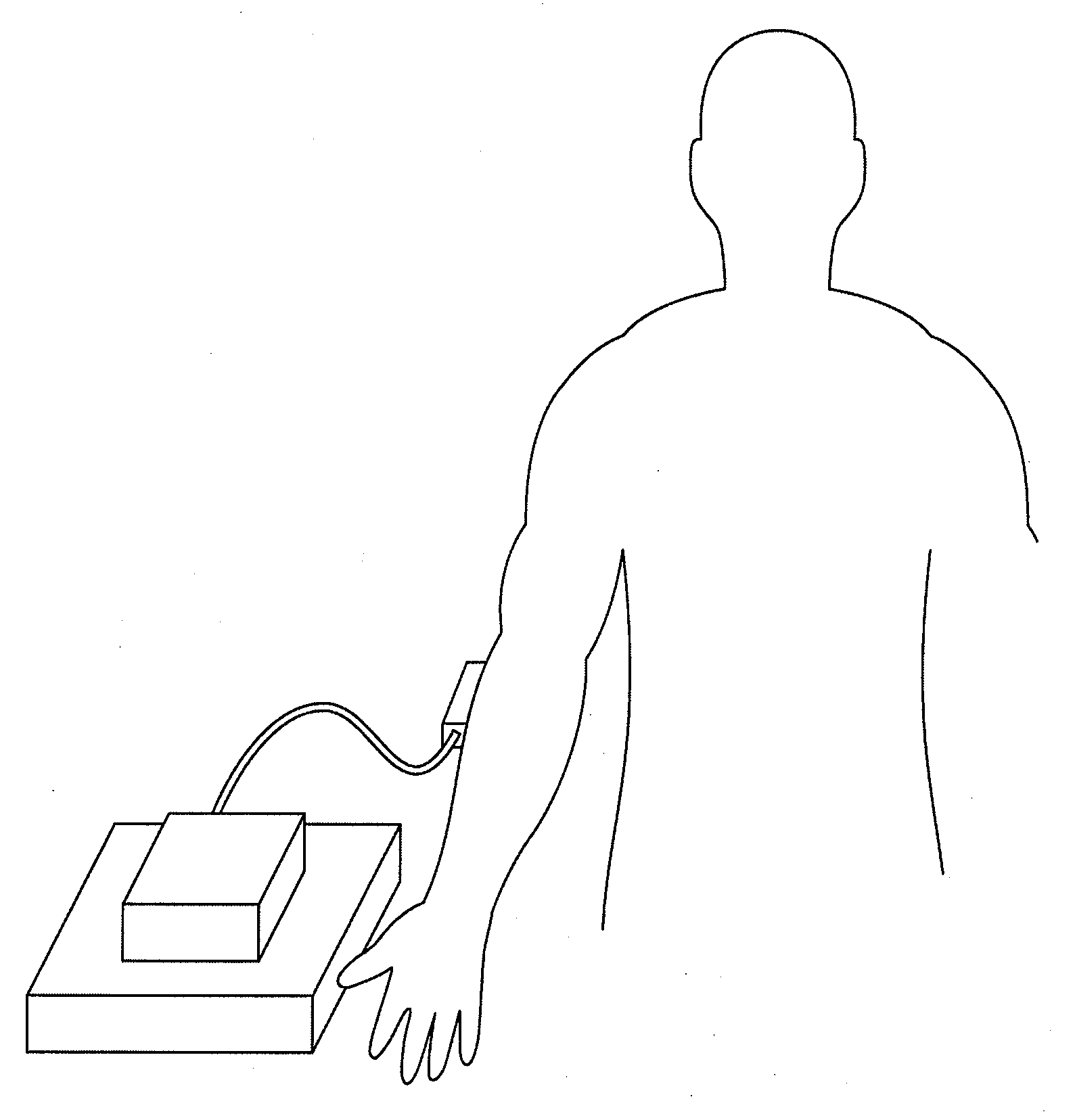

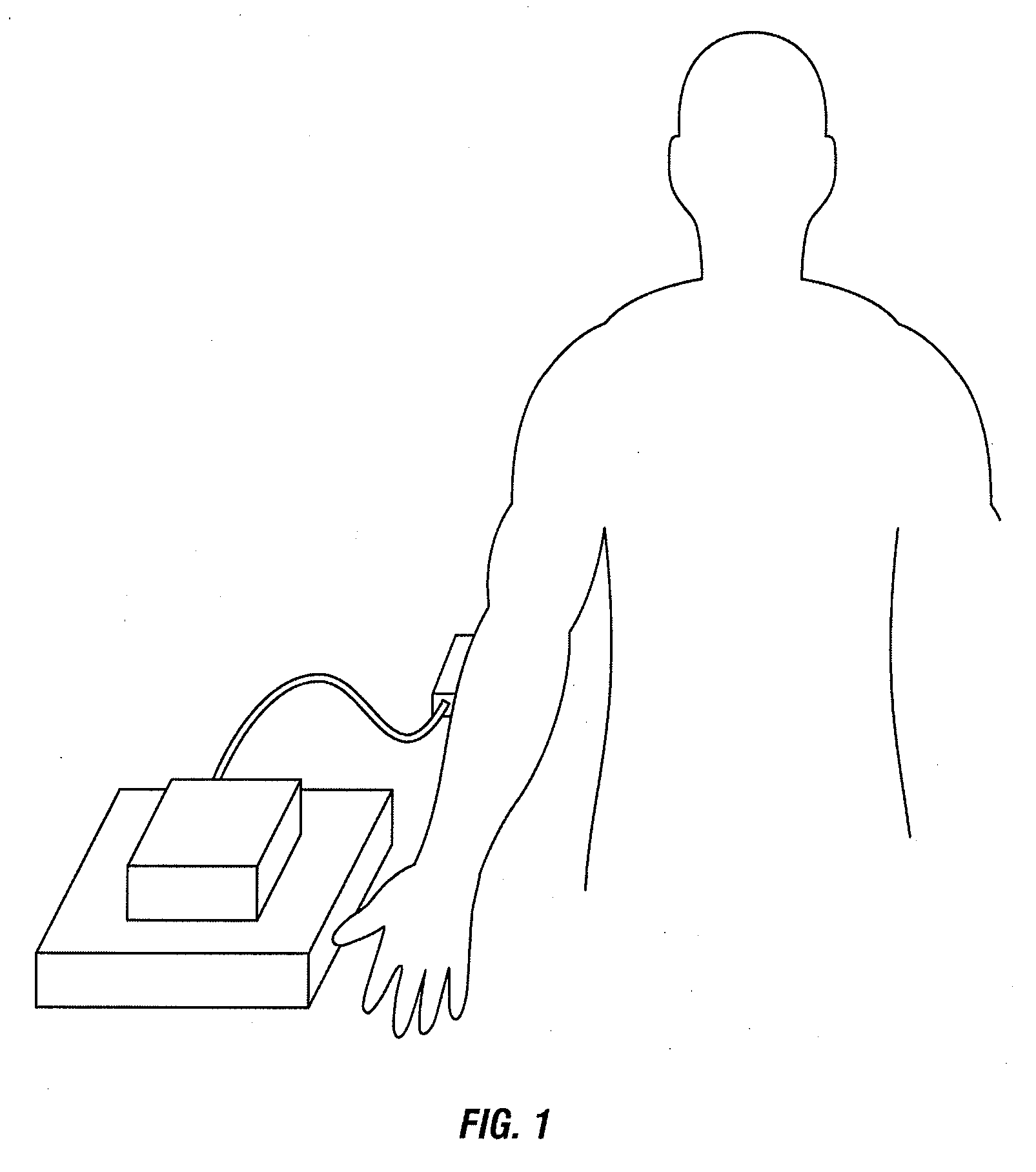

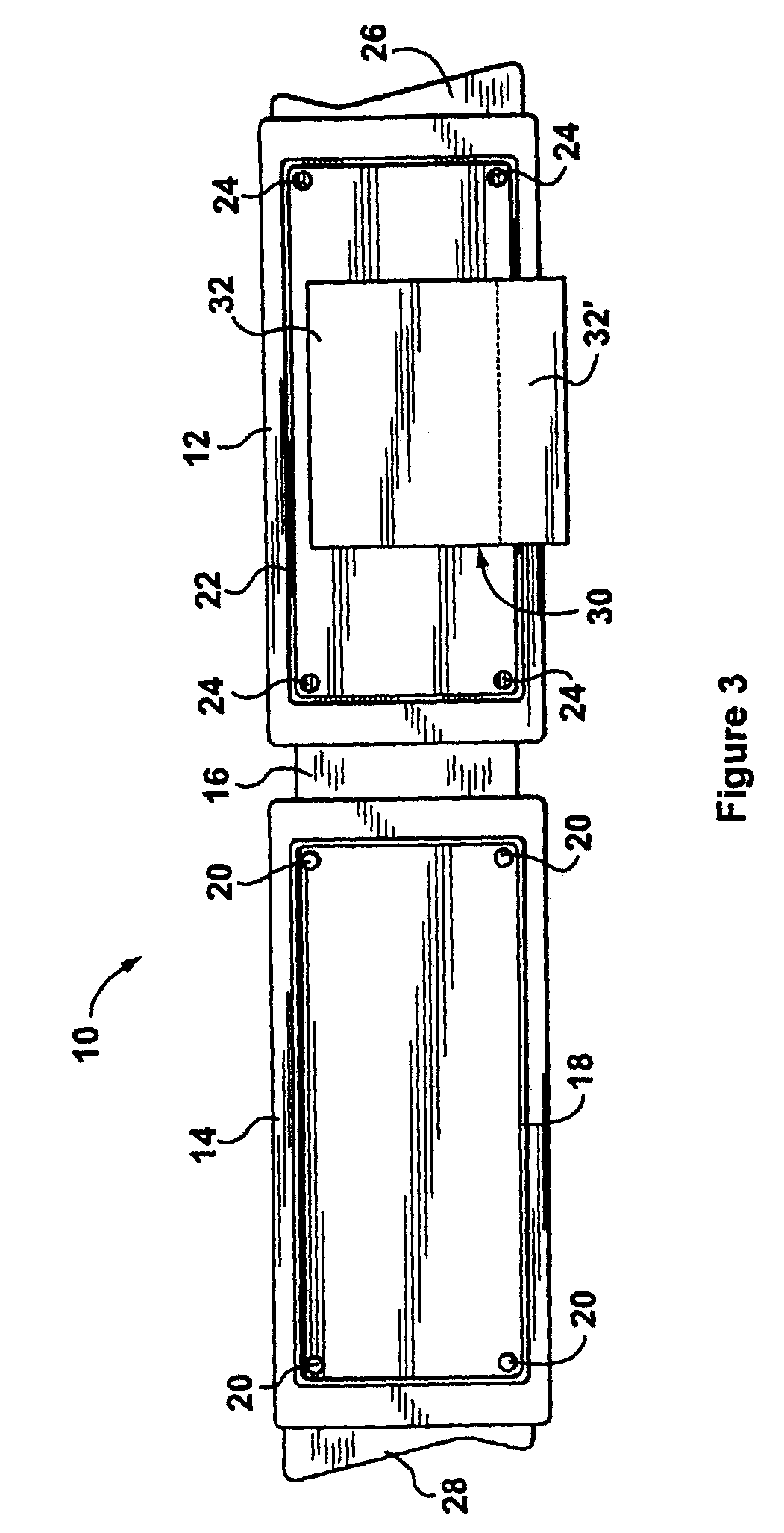

Method and apparatus for coupling a channeled sample probe to tissue

ActiveUS8504128B2Good optical performanceError minimizationMedical devicesMaterial analysis by optical meansAnalyteThin layer

Sampling is controlled in order to enhance analyte concentration estimation derived from noninvasive sampling. More particularly, sampling is controlled using controlled fluid delivery to a region between a tip of a sample probe and a tissue measurement site. The controlled fluid delivery enhances coverage of a skin sample site with the thin layer of fluid. Delivery of contact fluid is controlled in terms of spatial delivery, volume, thickness, distribution, temperature, and / or pressure.

Owner:GLT ACQUISITION

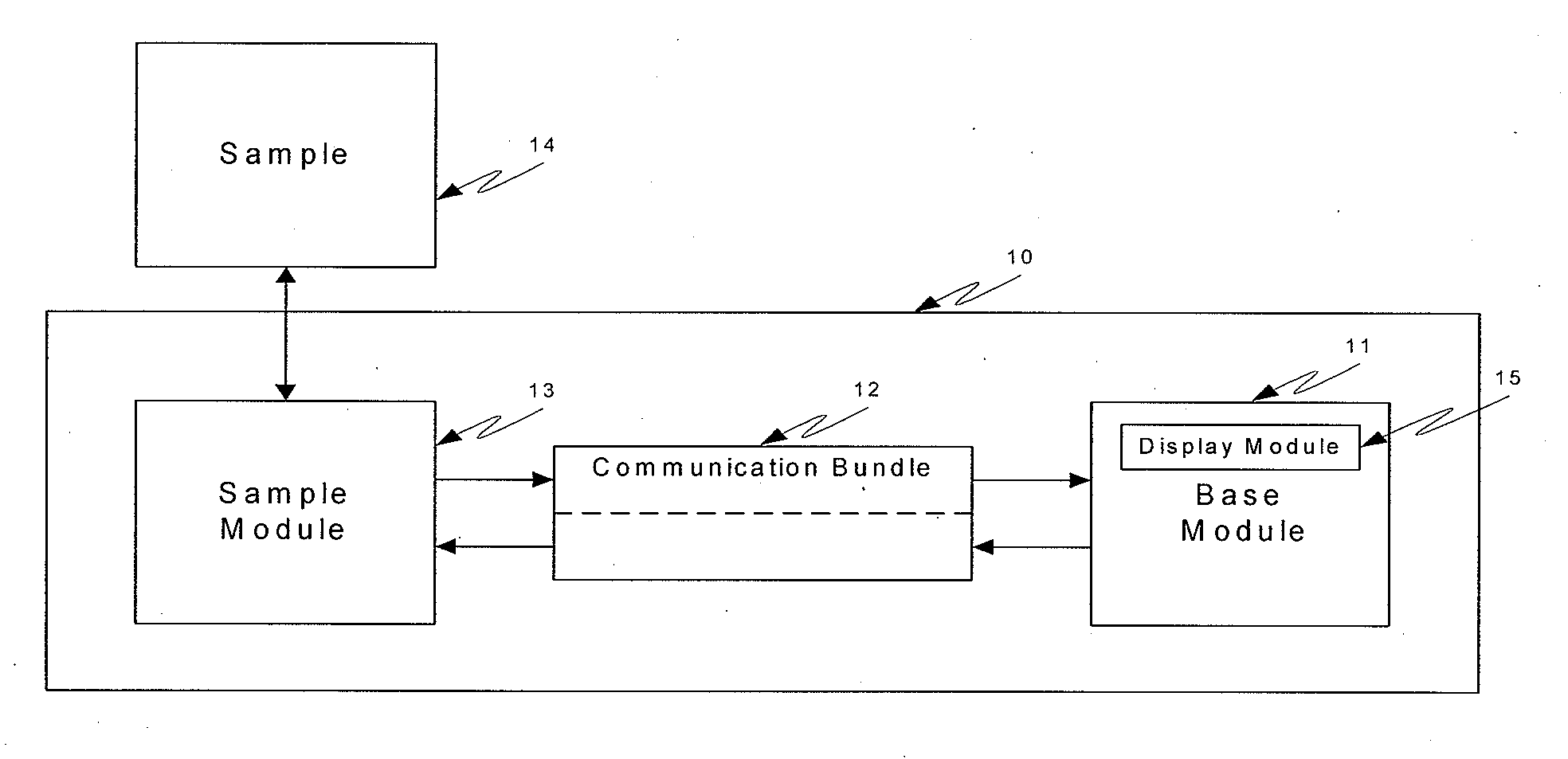

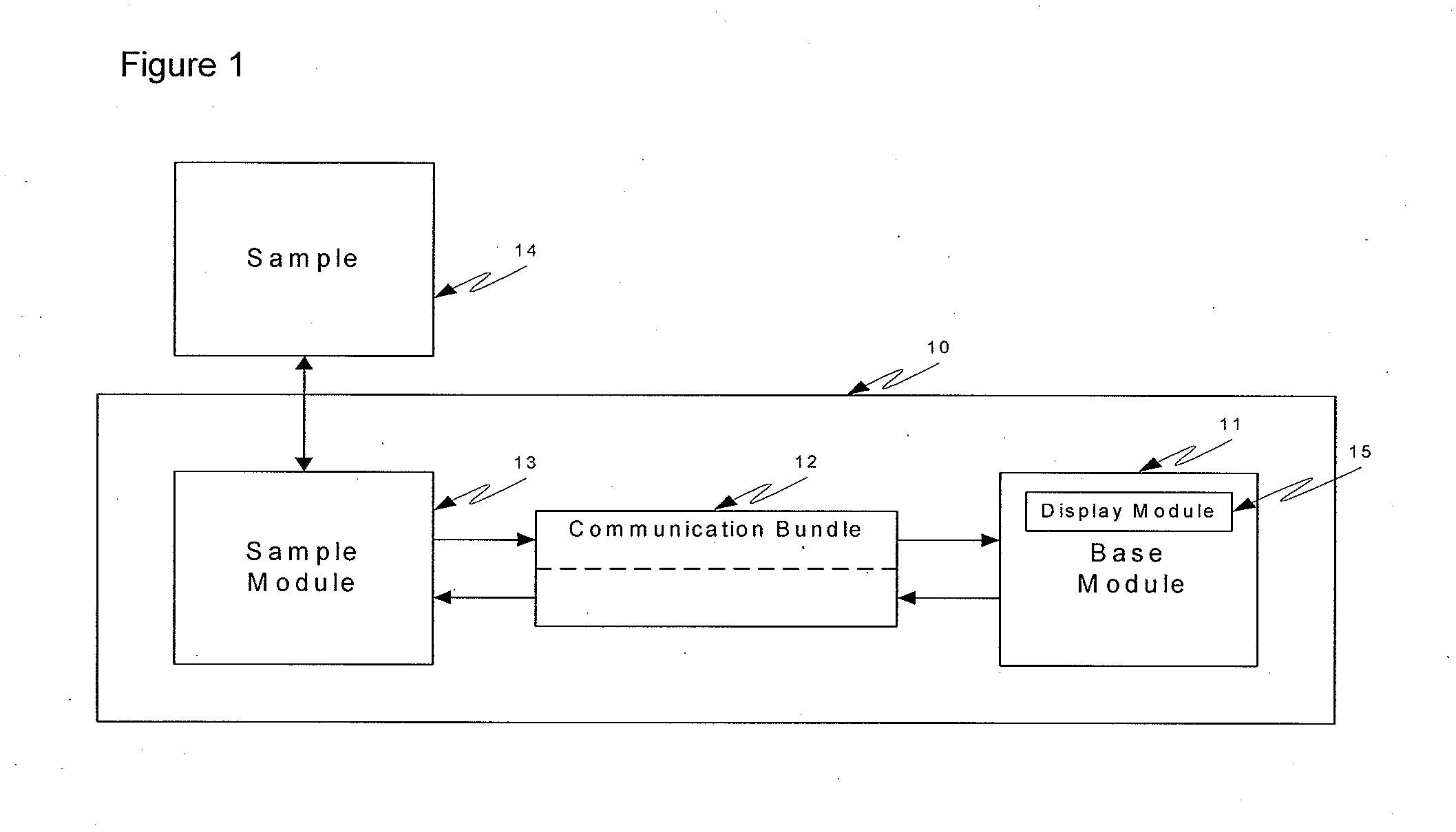

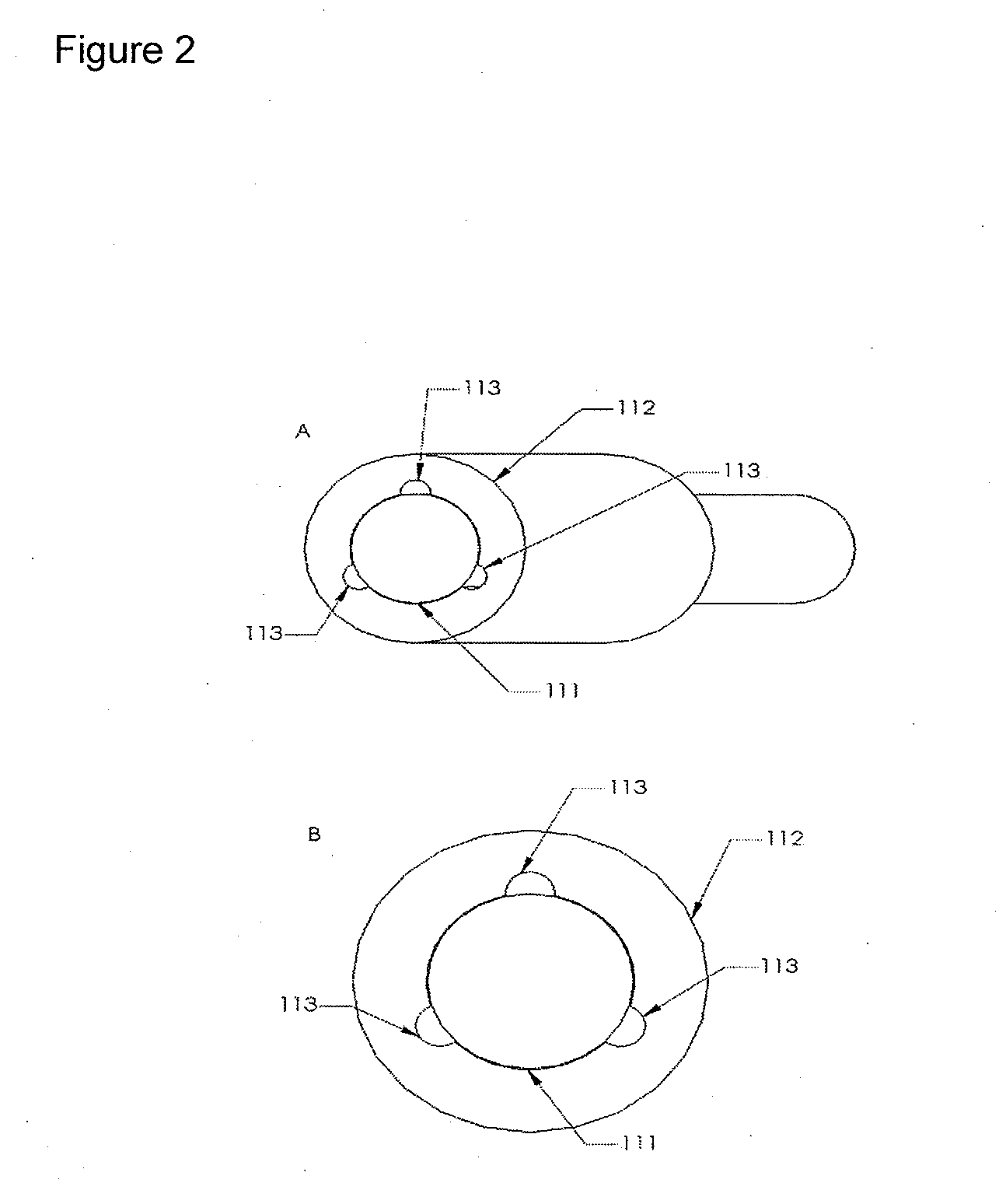

Method and apparatus for controlling positioning of a noninvasive analyzer sample probe

Owner:GLT ACQUISITION

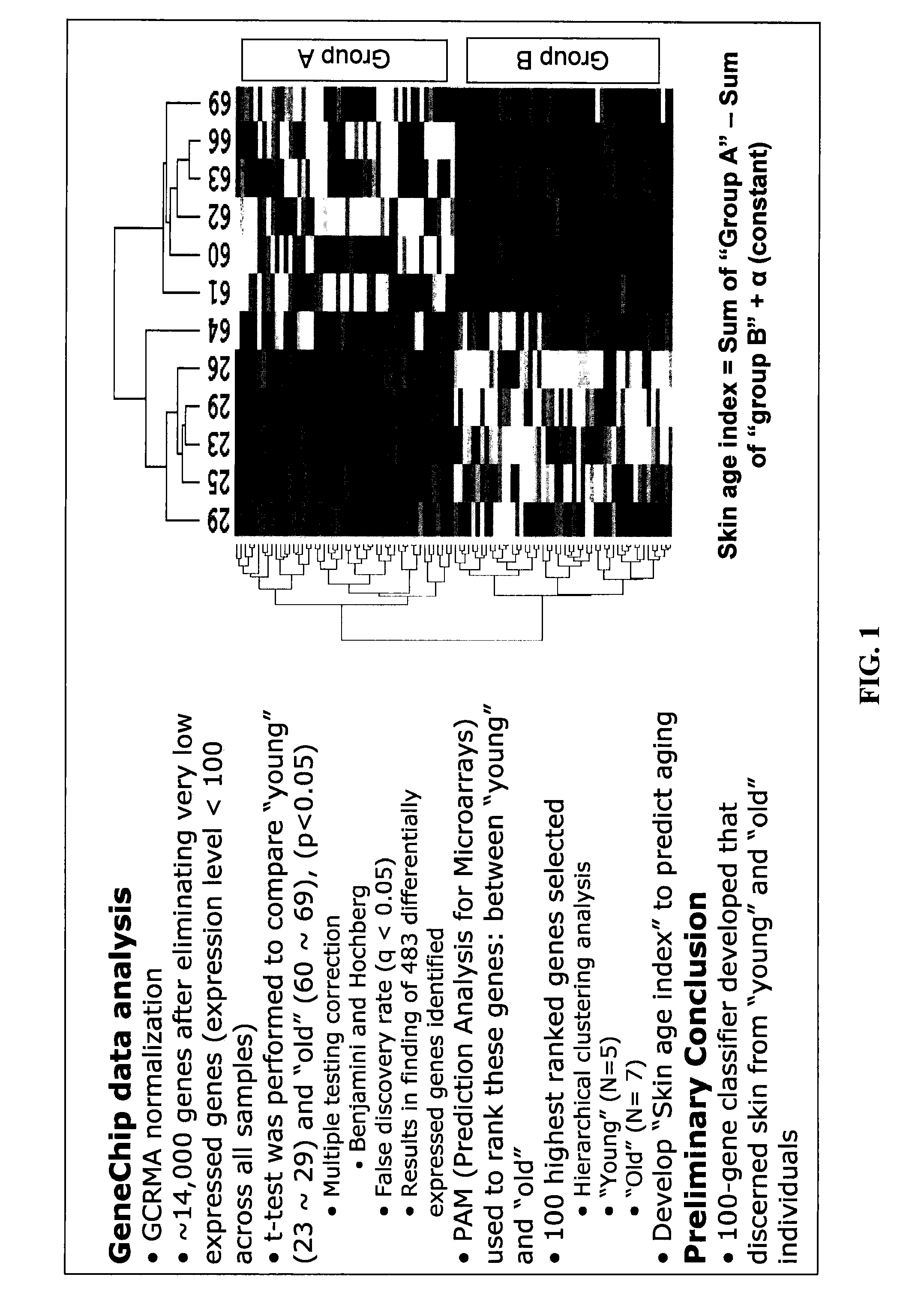

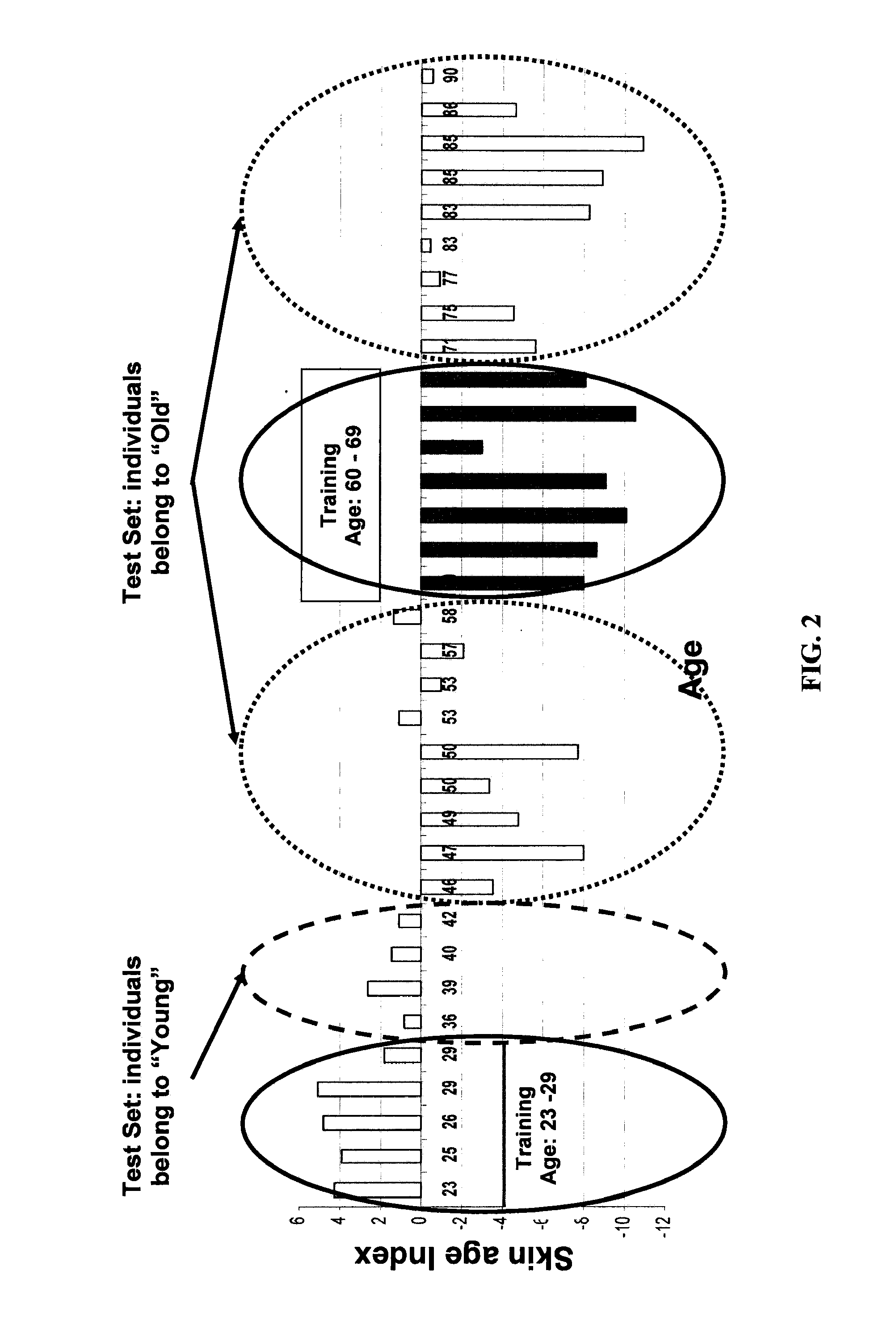

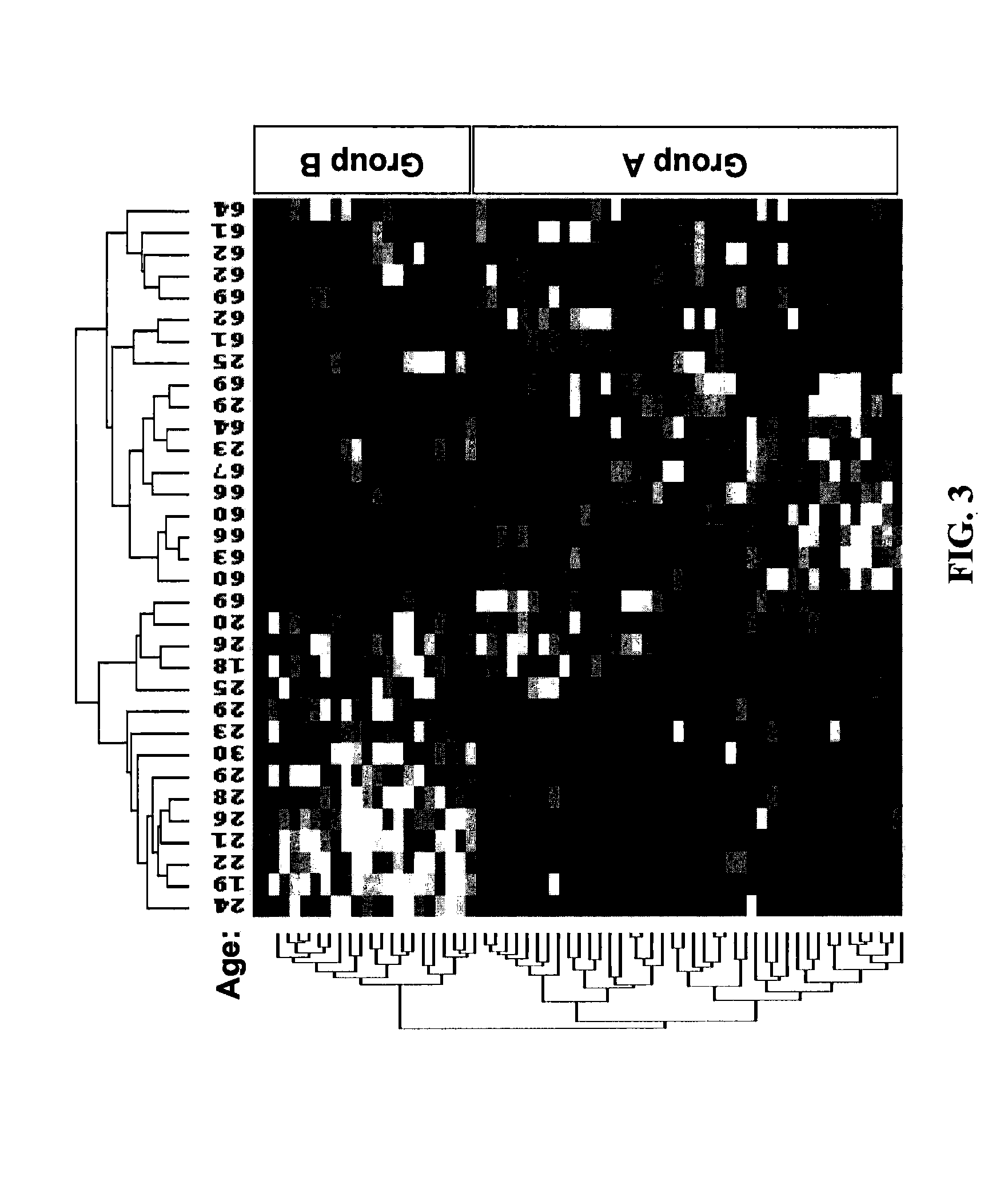

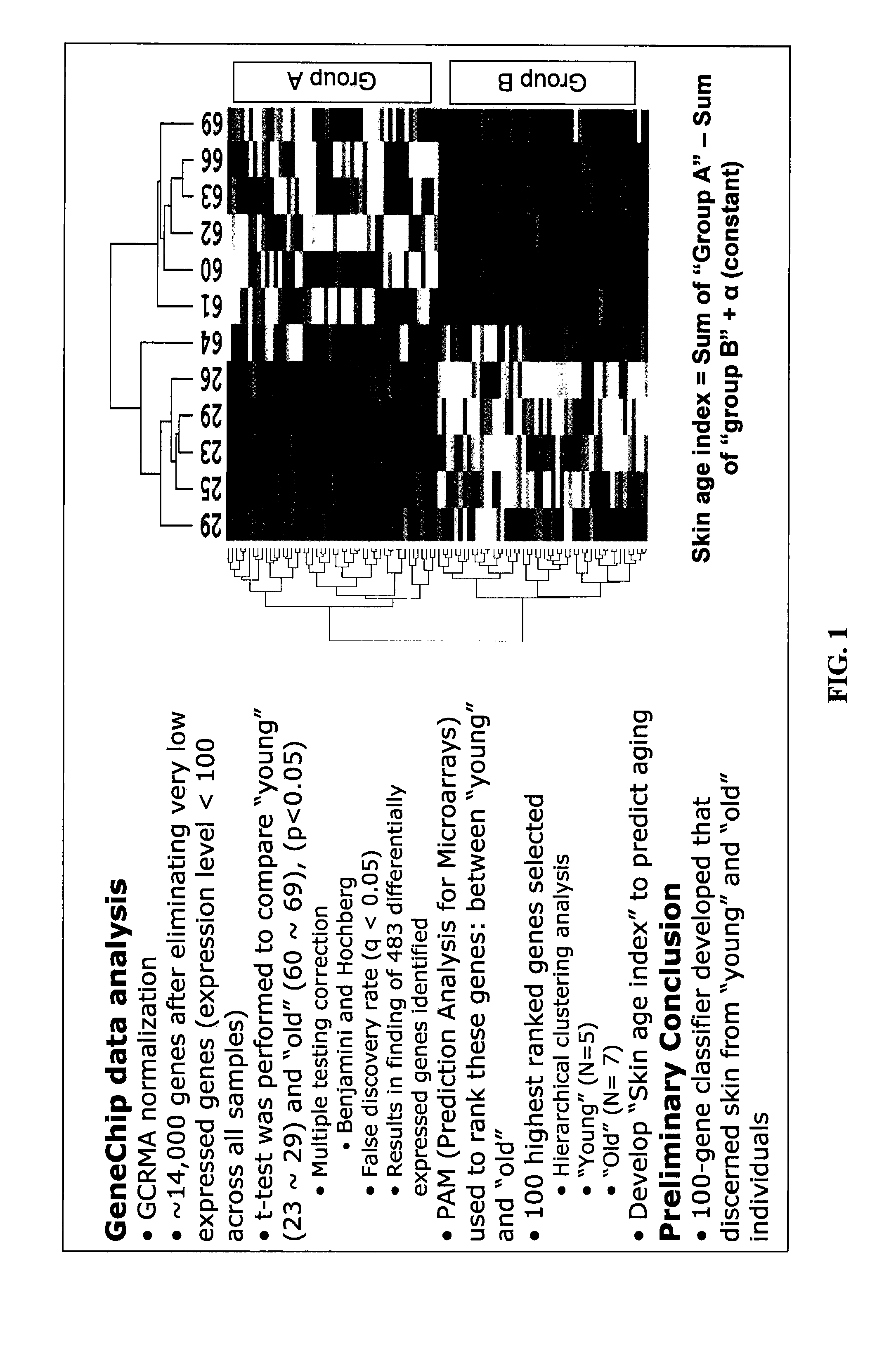

Determining Age Ranges of Skin Samples

InactiveUS20100086501A1Ensure adequate isolationReducing and increasing expression of geneCosmetic preparationsCompound screeningProtein profilingProtein molecules

The present invention provides methods for characterizing a skin sample of a subject as belonging to an age range by analyzing nucleic acid or protein molecules obtained from the subject. The methods include analyzing expression or mutations in epidermal samples, of one or more skin markers. The methods can include the use of a microarray to analyze gene or protein profiles from a sample and compare them with a known skin age index. Therapeutic and cosmetic formulations are also provided herein.

Owner:DERMTECH INT

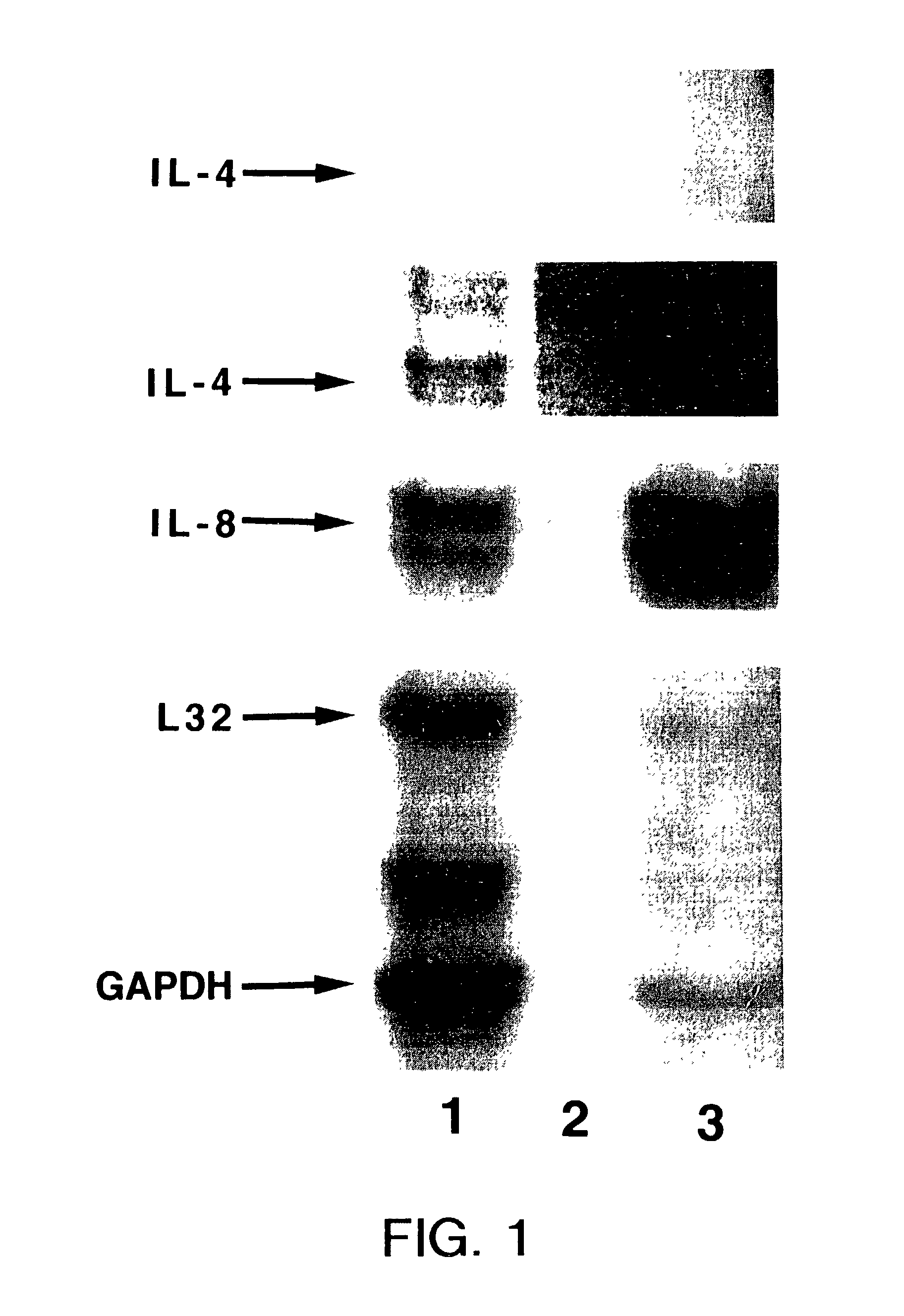

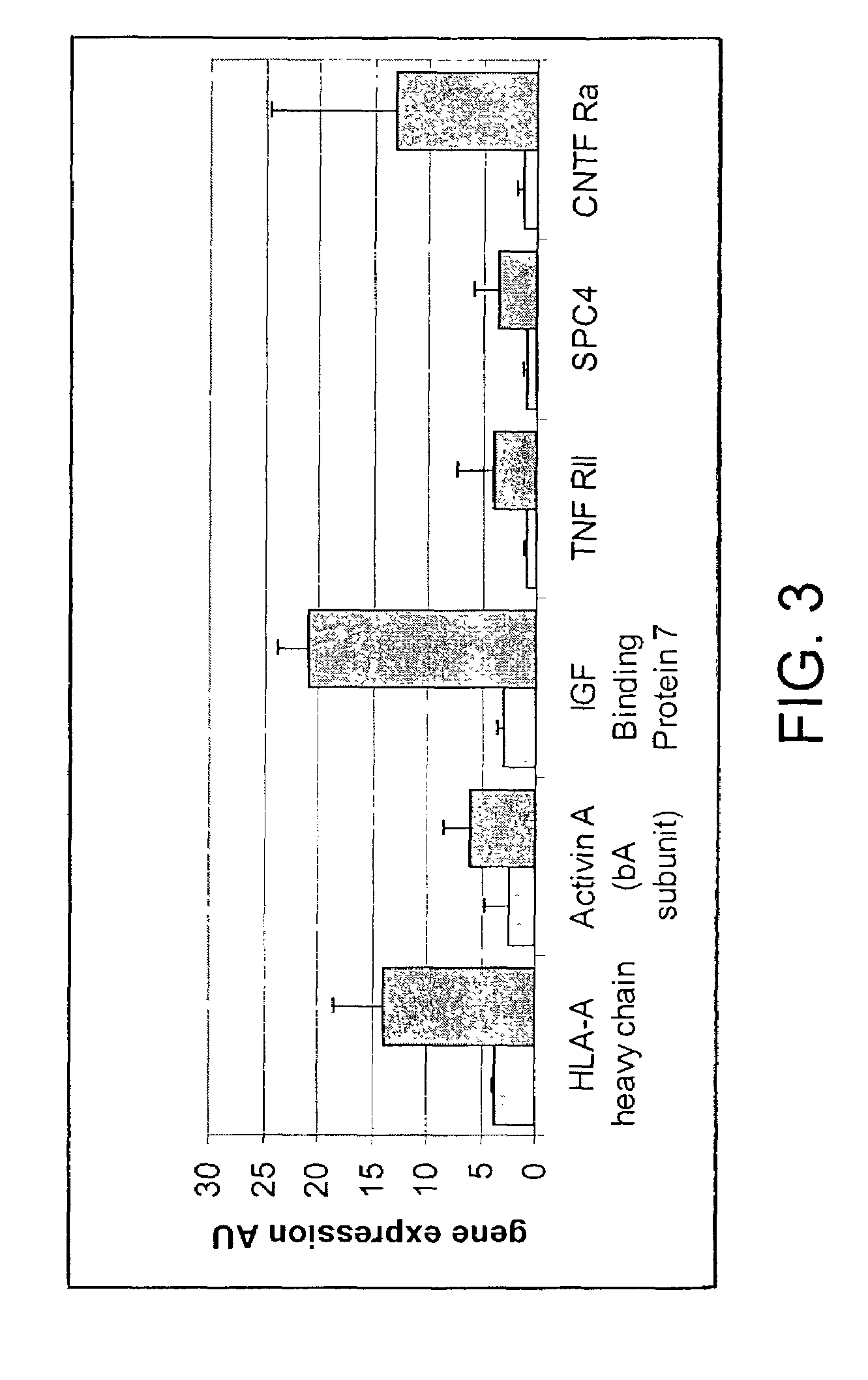

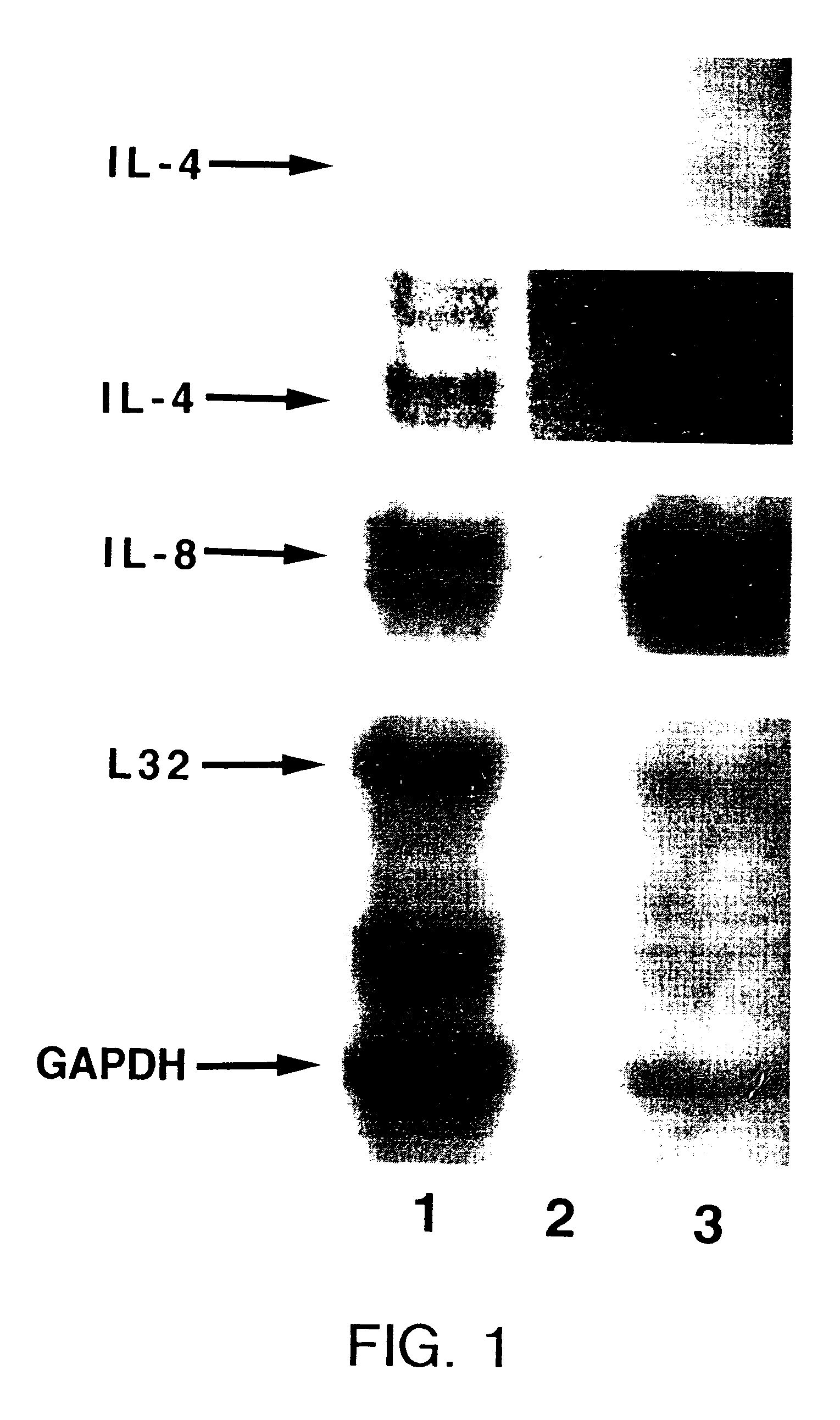

Method for detection of melanoma

The present invention provides non-invasive methods for detecting, monitoring, staging, and diagnosing malignant melanoma in a skin sample of a subject. The methods include analyzing expression in skin sample of one or more melanoma skin markers. The melanoma skin markers include IL-1 RI, endothelin-2, ephrin-A5, IGF Binding Protein 7, HLA-A0202 heavy chain, Activin A (βA subunit), TNF RII, SPC4, and CNTF Rα. The skin sample can include nucleic acids, and can be a human skin sample from a lesion suspected of being melanoma.

Owner:DERMTECH INT

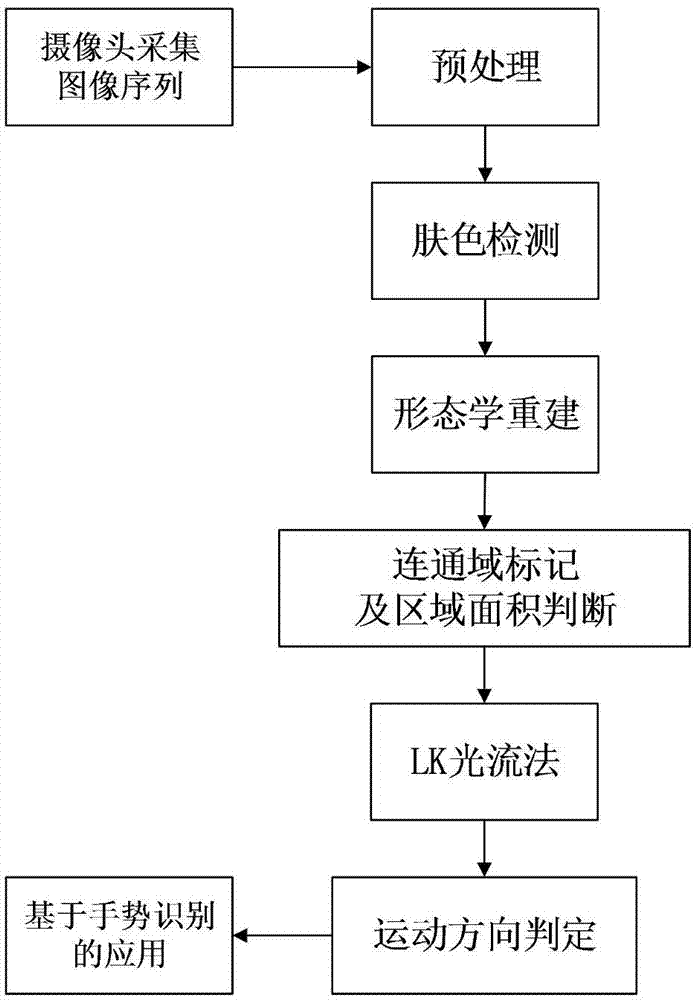

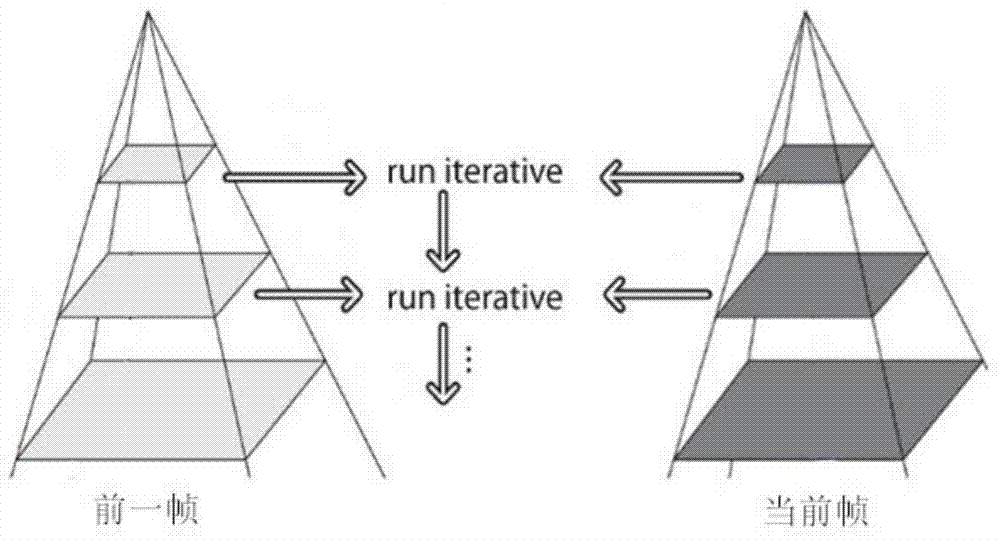

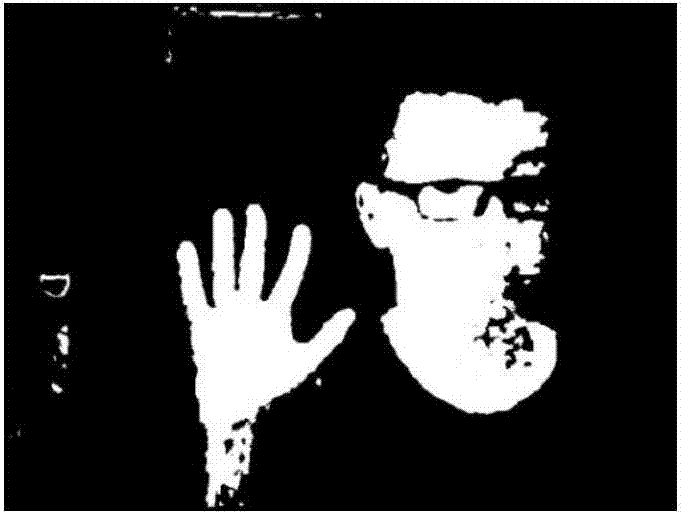

Optical flow-based gesture motion direction recognition method

InactiveCN104331151AInput/output for user-computer interactionImage analysisGraphicsImage resolution

The invention discloses an optical flow-based gesture motion direction recognition method. The method comprises the following steps of acquiring an image sequence on the front of a computer by using a common camera with video graphics array resolution, and preprocessing the image sequence; distributing skin samples in an approximately elliptical area in a CbCr plane in a concentrated way, and determining whether to accord with skin colors according to a fact whether a pixel point falls in the elliptical area in the CbCr plane; performing morphological reconstruction on binary images subjected to skin color detection, and adopting closed operation in morphology; marking each white connected region, calculating an area of each white connected region, arraying white connected regions from large to small, and reserving three largest connected regions; reducing the resolution of the images, and acquiring an optical flow motion vector in a skin color area by using a pyramid LK optical flow method; judging the direction of the optical flow motion vector; judging the direction once every other two frames, and giving a result if directions are consistent twice; after a user is familiar with and masters the gesture motion operation rule, moving the gesture in the upper, lower, left and right directions before the camera. According to the method, real-time interaction can be completed, and the gesture motion direction recognition accuracy can be higher than 95 percent.

Owner:COMMUNICATION UNIVERSITY OF CHINA

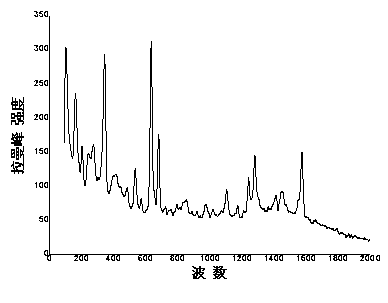

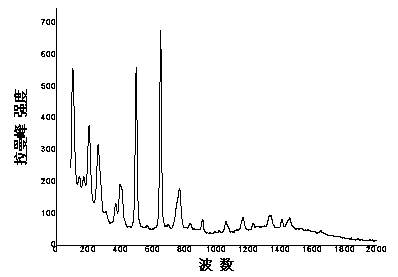

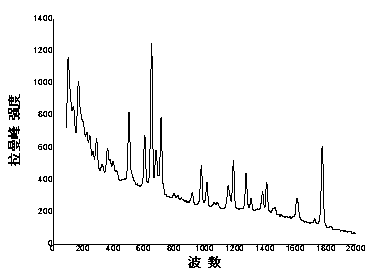

SERS (Surface Enhanced Raman Spectroscopy) detection method for pesticide residues in fruits

InactiveCN103472051AQuick Qualitative AnalysisEasy to operatePreparing sample for investigationRaman scatteringFood safetySurface-enhanced Raman spectroscopy

The invention relates to an SERS (Surface Enhanced Raman Spectroscopy) detection method for pesticide residues in fruits, belonging to the technical field of food safety detection. The method comprises the following steps: step 1, acquiring fruit skin samples, and extracting a sample solution; step 2, preparing a silver sol solution; step 3, preparing a sodium chloride solution; step 4, mixing the sample solution in the step 1, the silver sol solution in the step 2 and the sodium chloride solution in the step 3 to form a sample to be detected, and uniformly mixing on a vibration instrument; step 5, dripping the mixed sample to be detected on a glass slide, naturally drying, and carrying out a Raman spectrum test to obtain an SERS spectrum of the sample to be detected; step 6, comparing the SERS spectrum of the sample to be detected obtained in the step 5 with a standard pesticide SERS spectrum, and determining whether the sample contains a corresponding pesticide or not. The method is efficient and rapid, is low in detection cost, and can be widely applied to the field of food safety detection.

Owner:EAST CHINA JIAOTONG UNIVERSITY

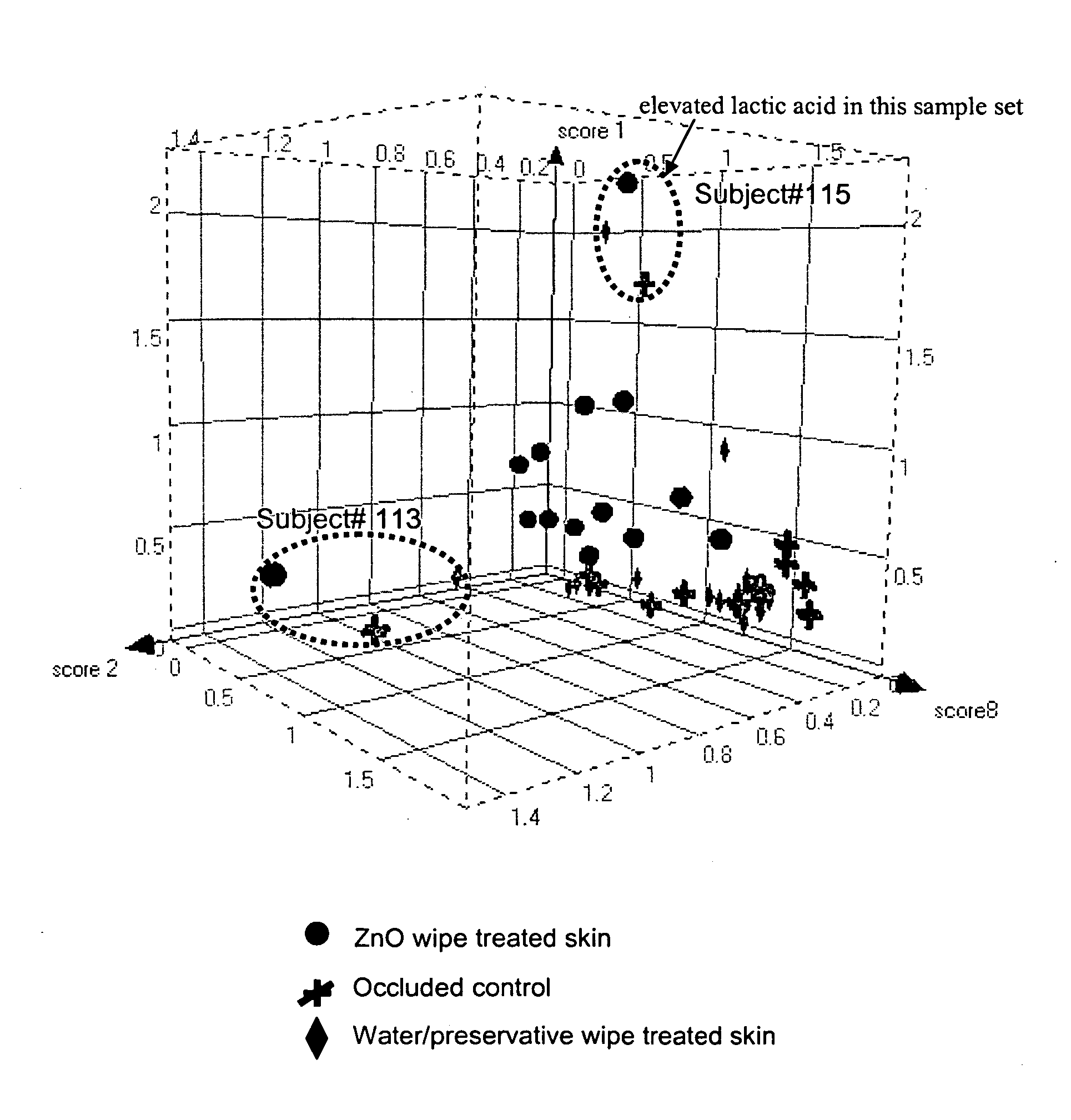

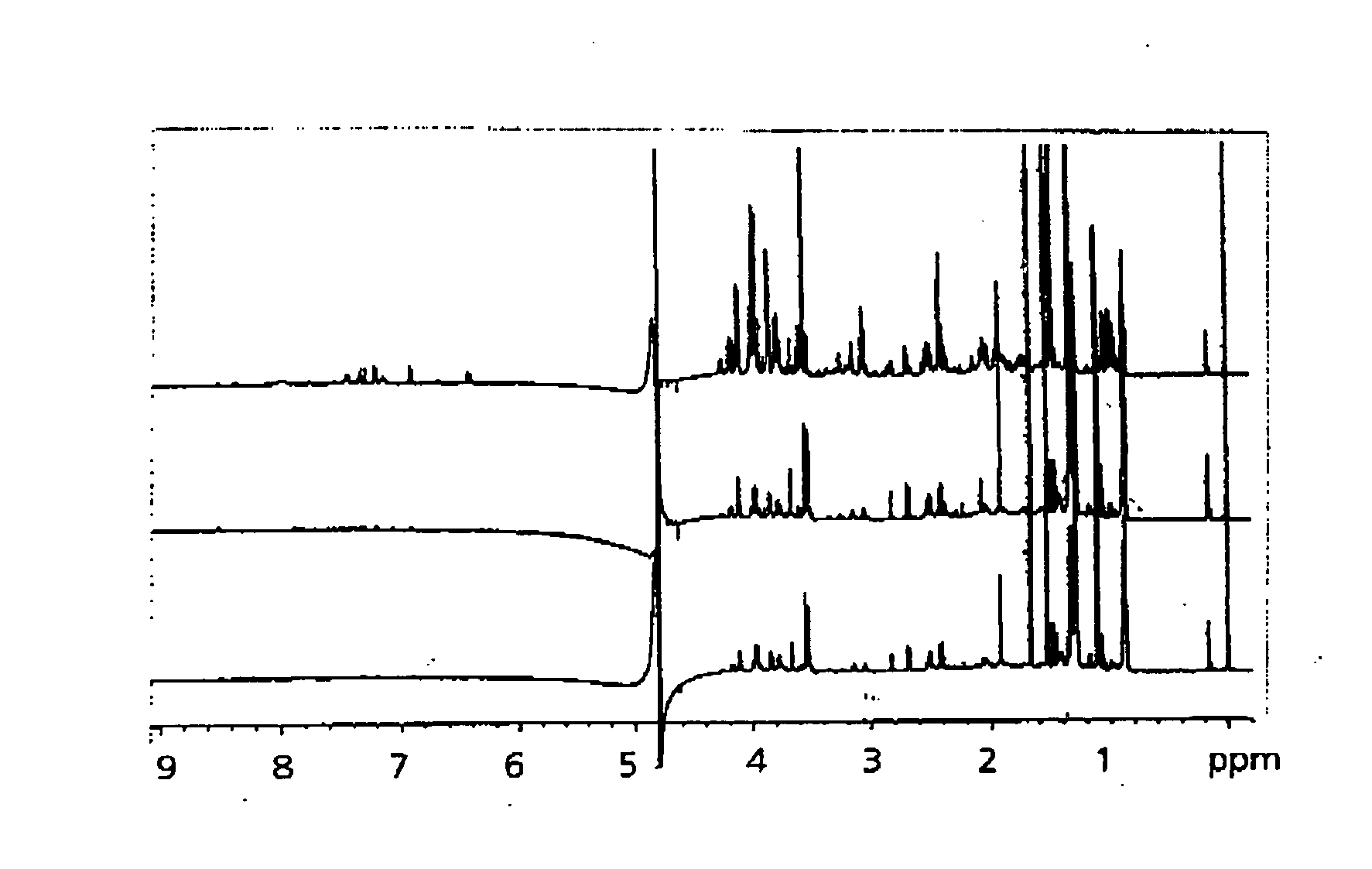

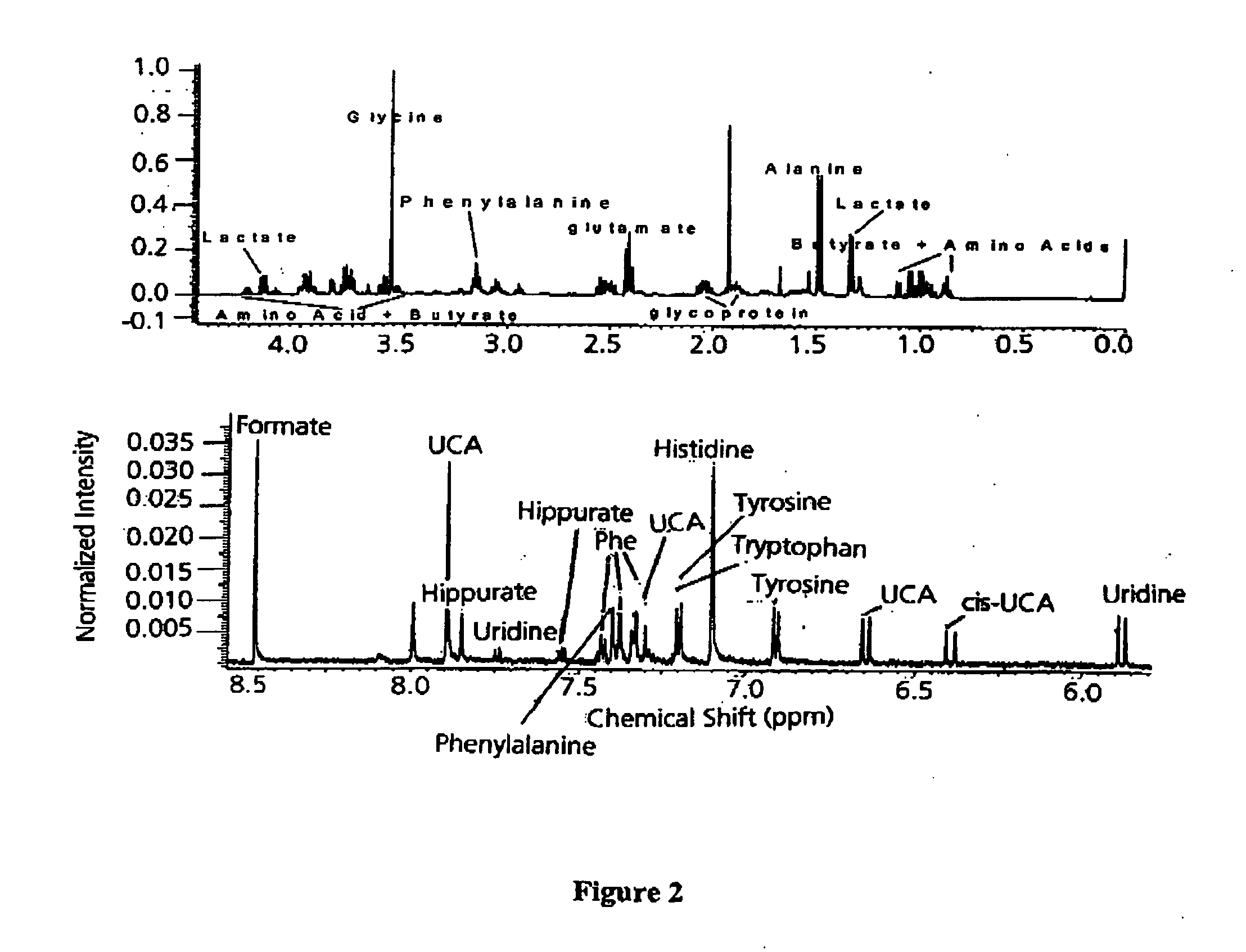

Metabonomic methods to assess health of skin

InactiveUS20070224696A1Lower Level RequirementsReduce variationMagnetic measurementsBiological testingSkin treatmentsOrganism

The present invention relates to methods of assessing the health of skin. Biomarkers are used to evaluate skin samples. Using metabonomics approaches, samples taken from different skin sites or at different times during a treatment are used to diagnose skin conditions or to appraise various skin treatments for efficacy.

Owner:THE PROCTER & GAMBLE COMPANY

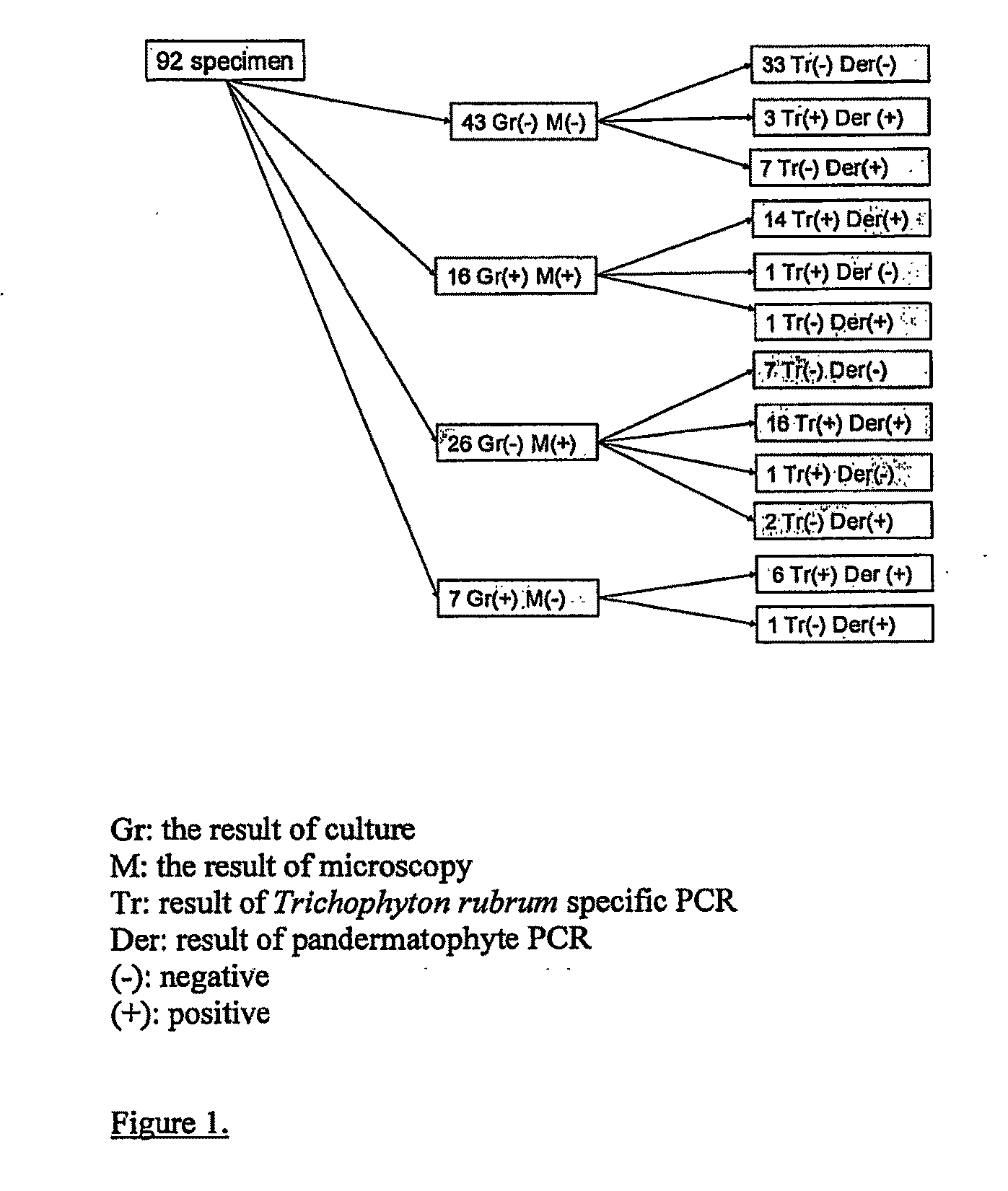

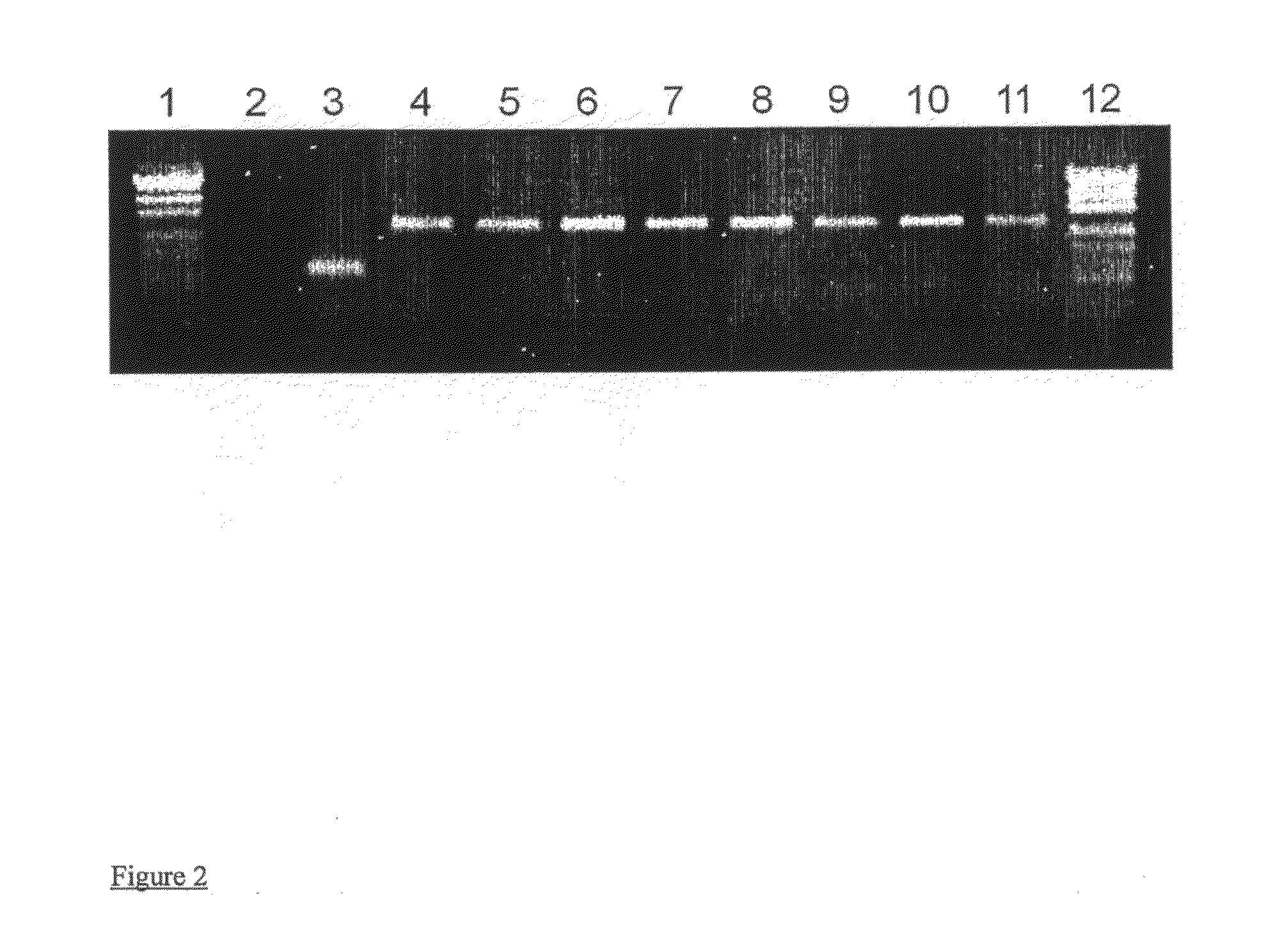

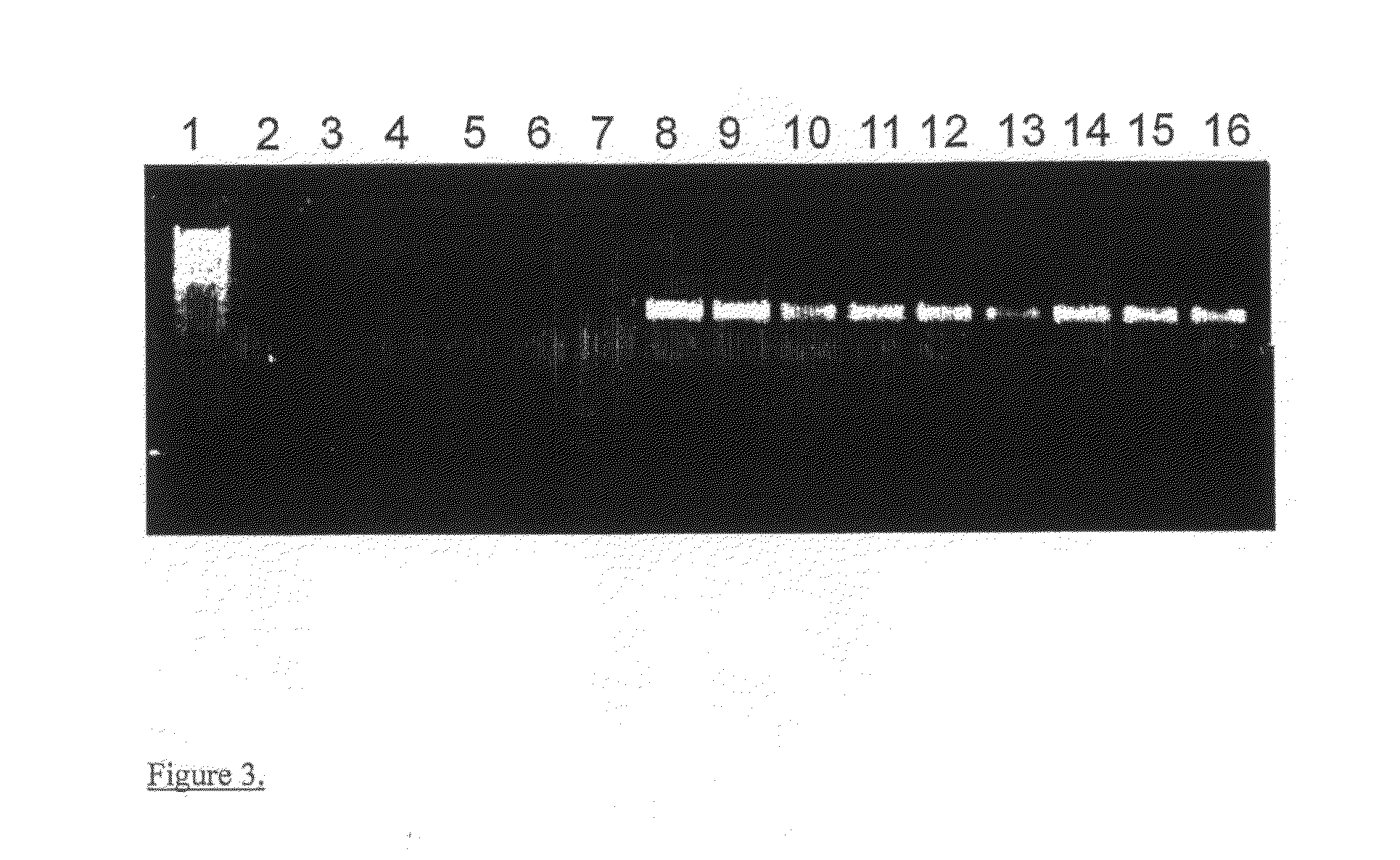

PCR diagnostics of dermatophytes and other pathogenic fungi

InactiveUS20100311041A1Sugar derivativesMicrobiological testing/measurementFungal microorganismsSkin specimen

Dermatophytes which belong to one of the three genera Epidermophyton, Trichophyton and Microsporum are the main cause of fungal infections of skin, hair and nails. Traditional diagnostic procedures consist of microscopy and culture, but due to the slow growth rate of dermatophytes typically two to four weeks are needed before a final diagnosis is obtained. The present invention is a rapid DNA extraction method extracting nucleic acids from fungi (e.g. dermatophytes and other pathogenic fungi) which can be performed from directly on hair, nail or skin specimens from humans, from naturally or experimentally infected animals or from cultured fungal colonies for the use in PCR amplification and detection assays. The present invention also includes specific primer sets for detection of any dermatophyte and for species specific detection of Trichophyton rubrum and Epidermophyton floccosum by PCR and a kit for diagnosing fungal infections.

Owner:STATENS SERUM INST

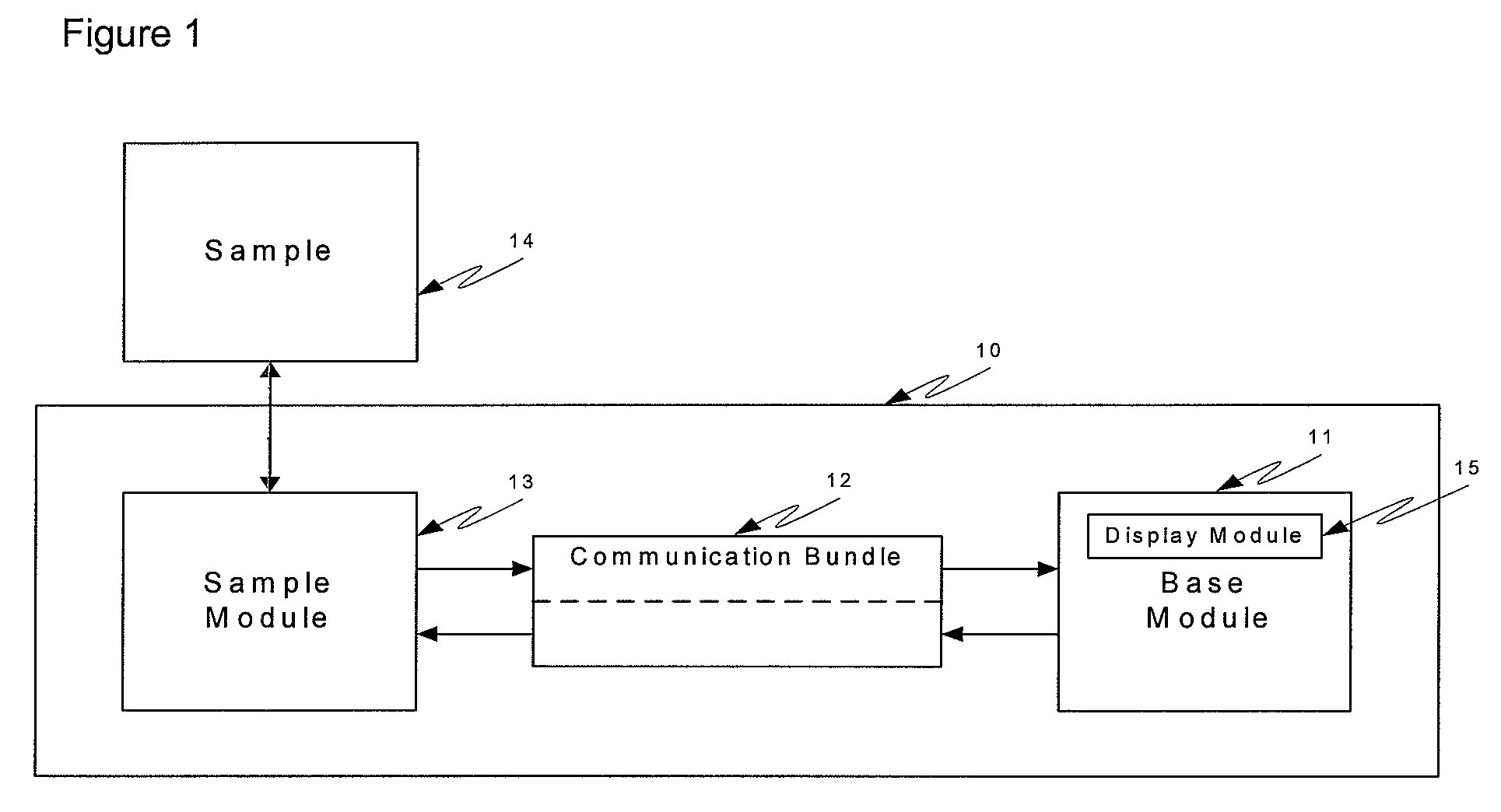

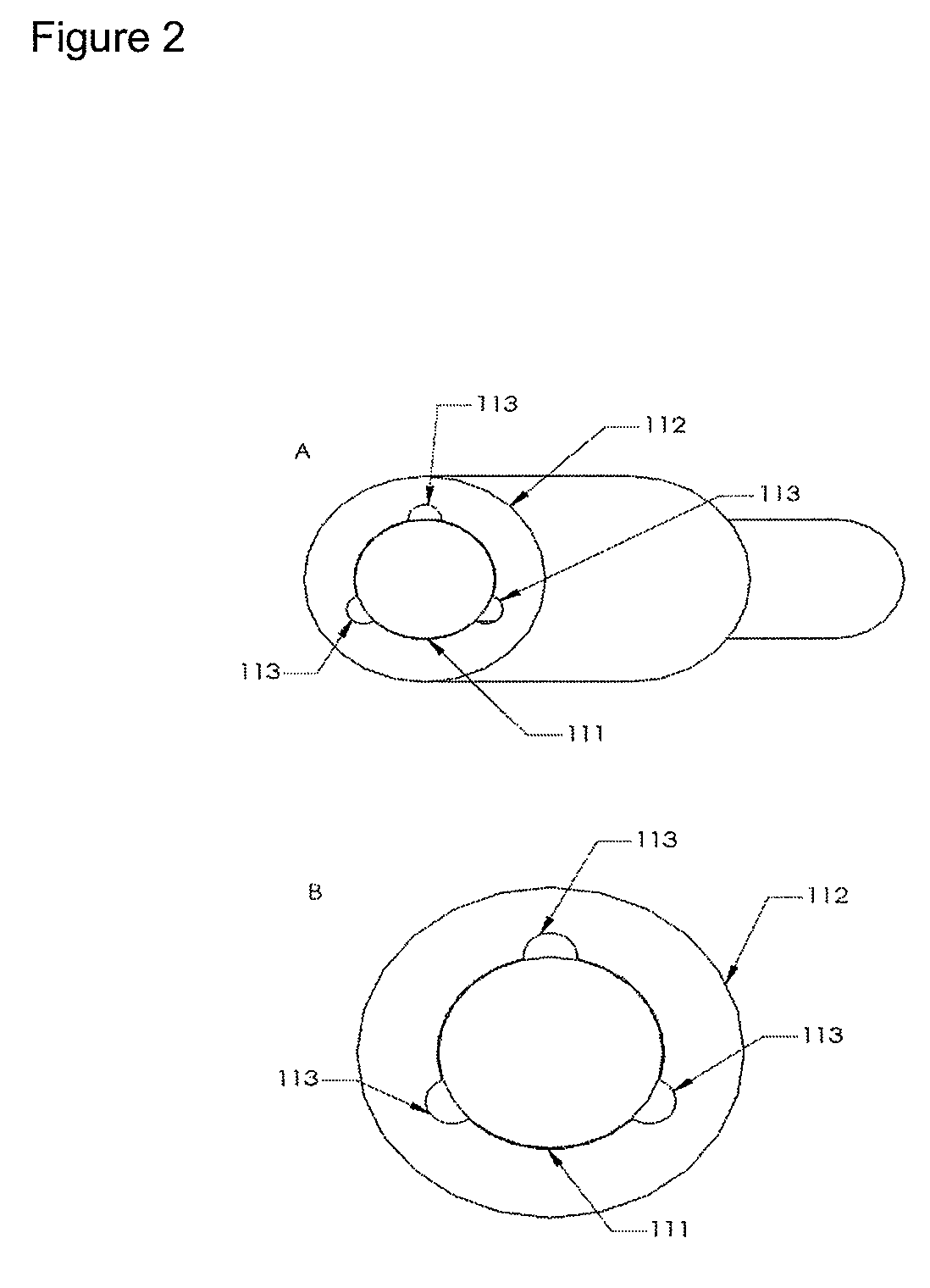

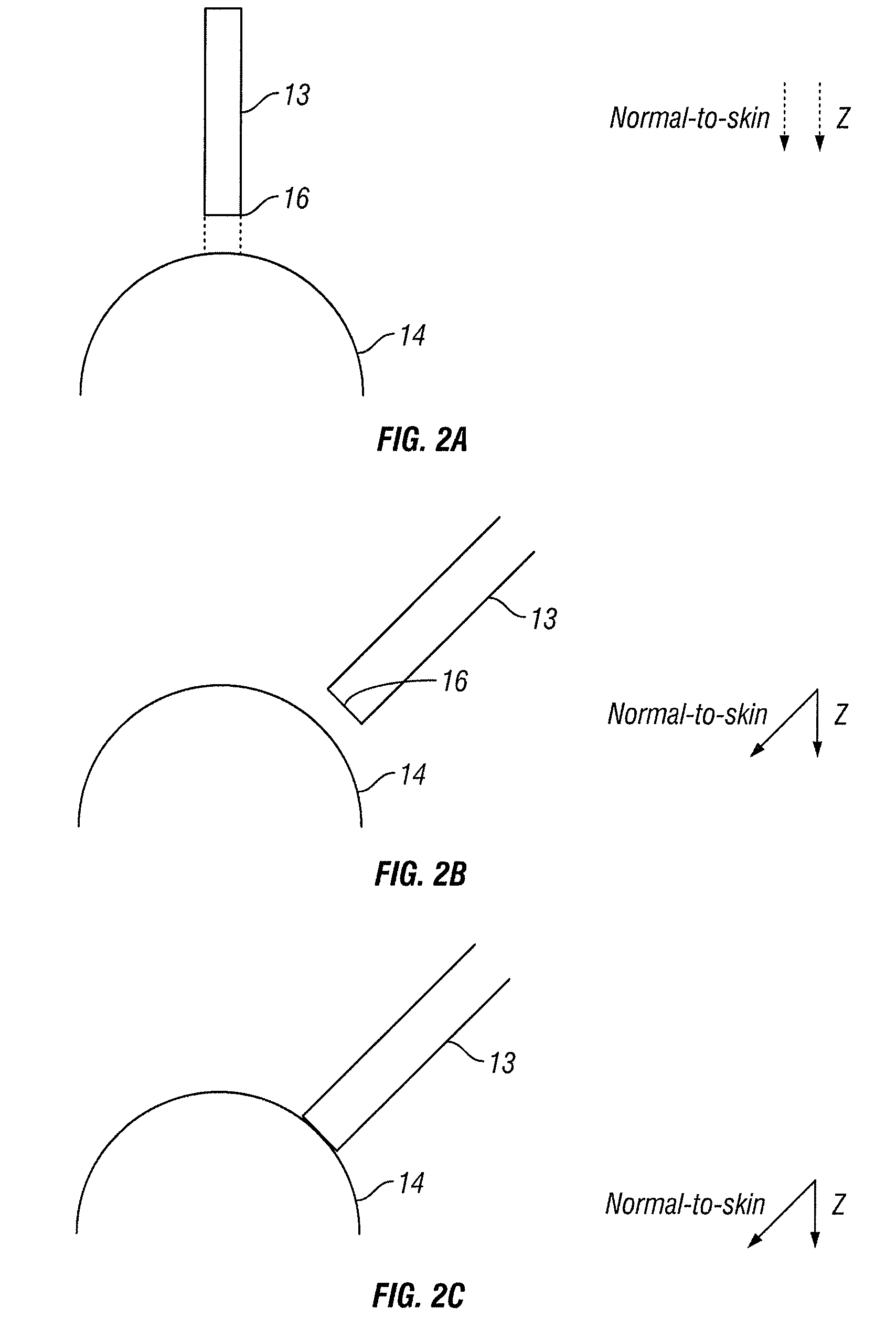

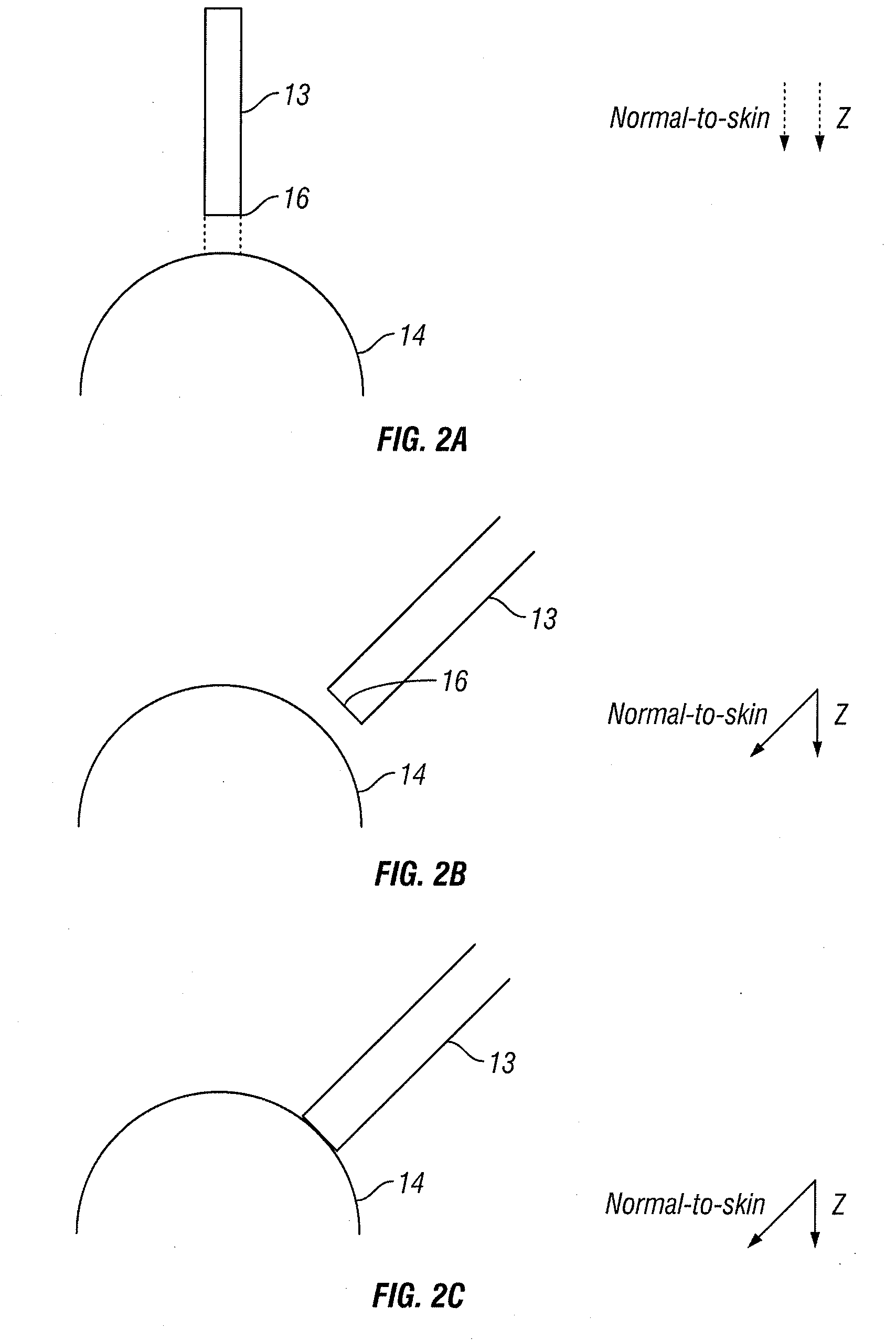

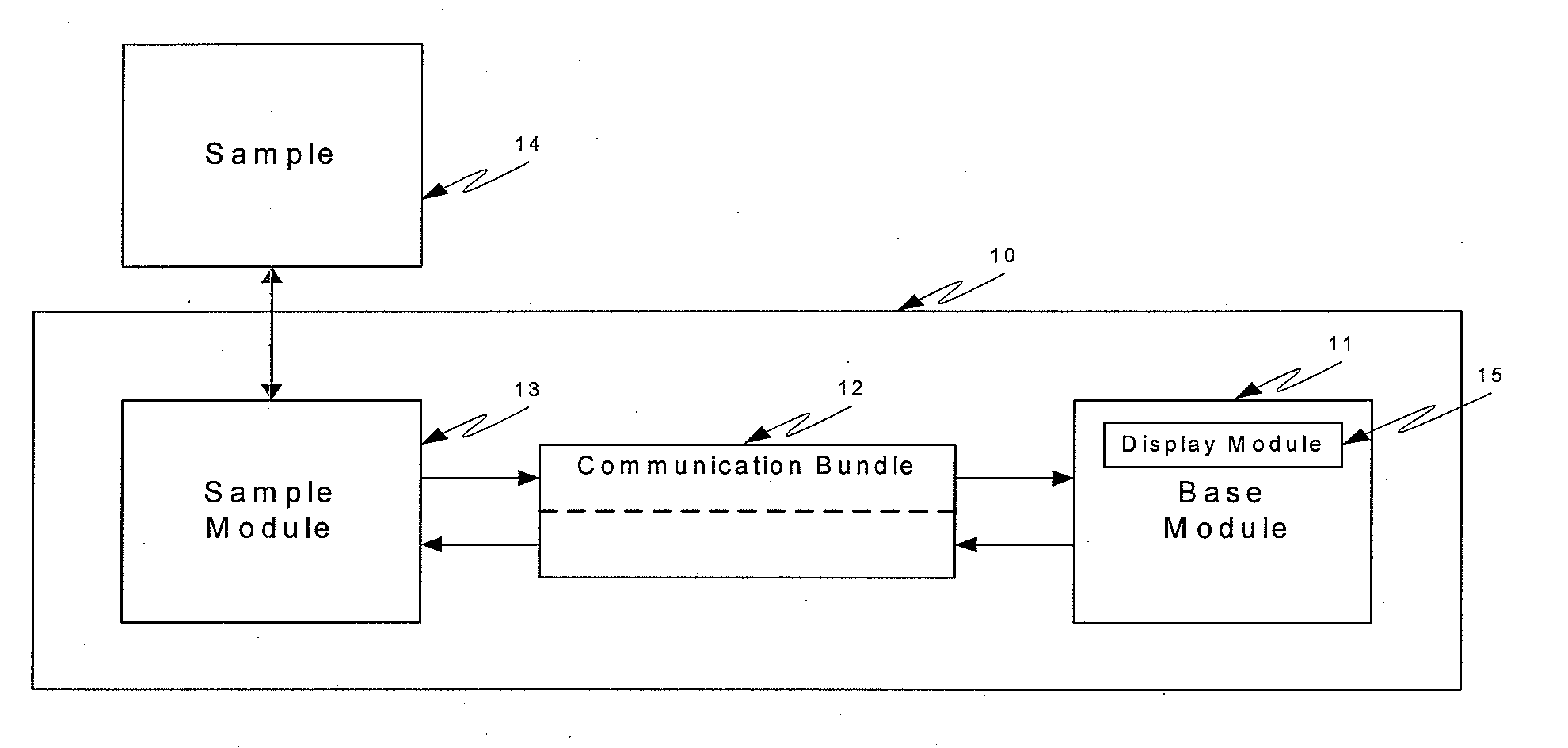

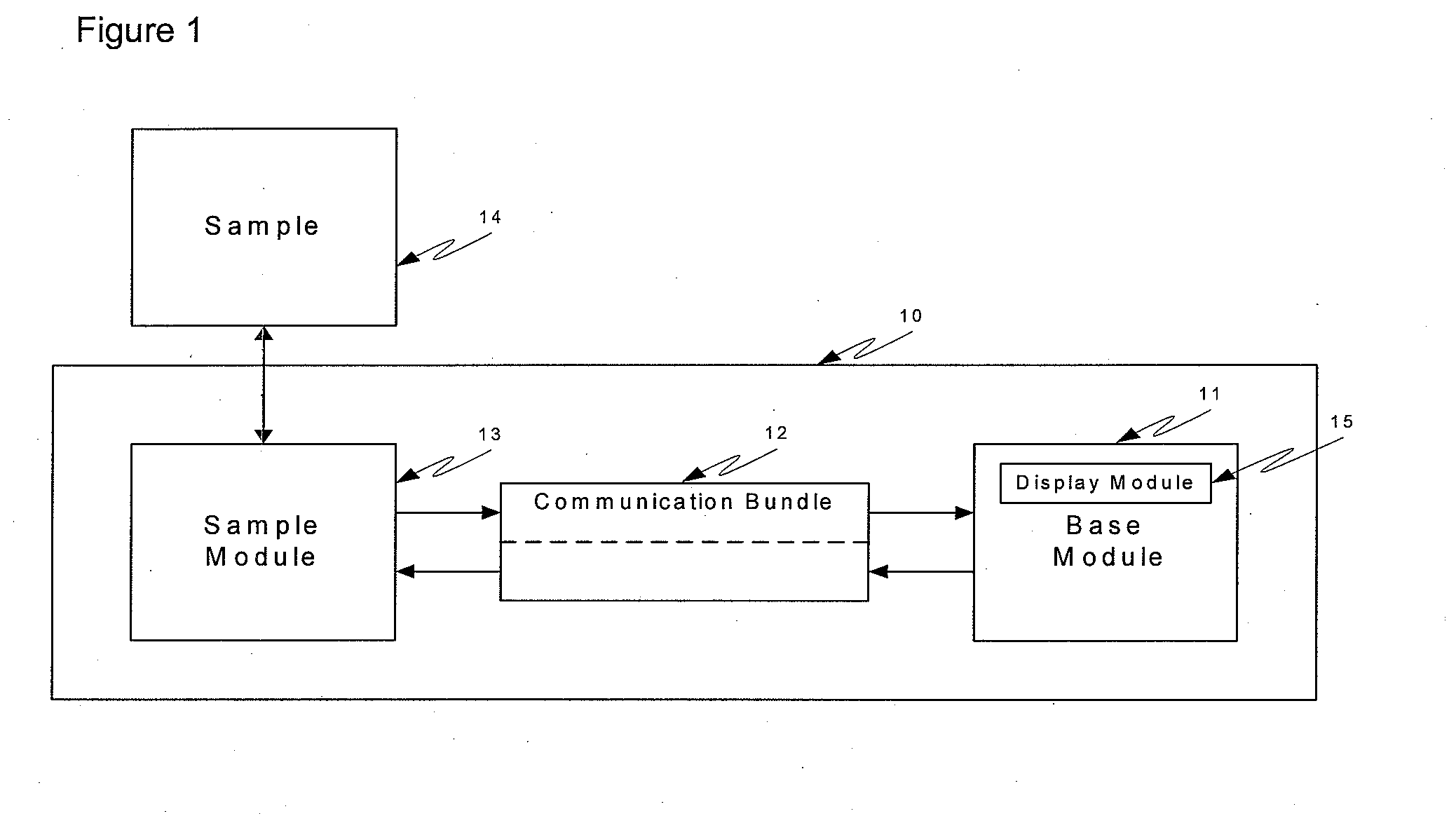

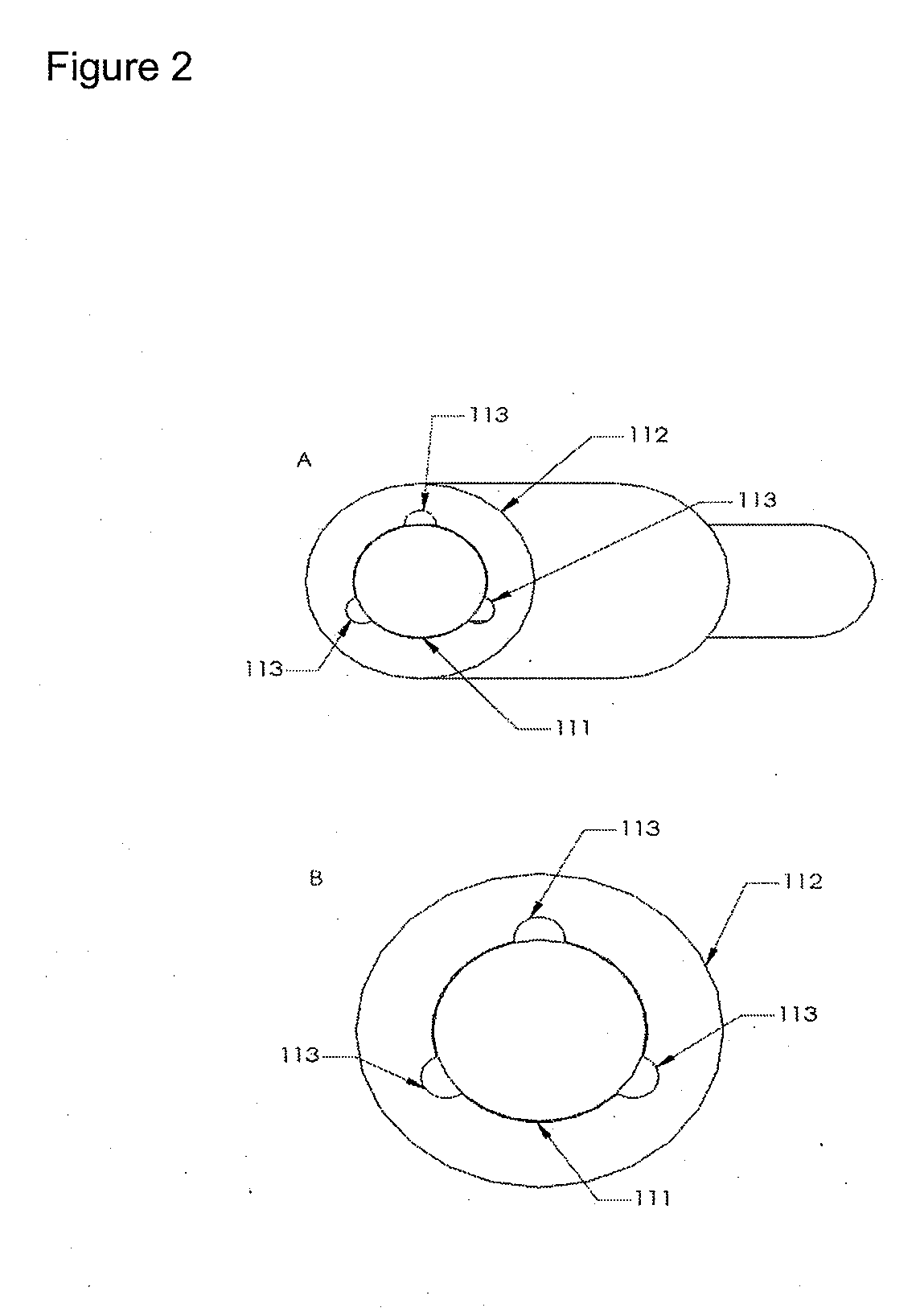

Method and apparatus for controlling positioning of a noninvasive analyzer sample probe

The invention relates generally to a probe interface method and apparatus for use in conjunction with an optical based noninvasive analyzer. More particularly, an algorithm controls a sample probe position and attitude relative to a skin sample site before and / or during sampling. For example, a sample probe head of a sample module is controlled by an algorithm along the normal-to-skin-axis. Preferably, the sample probe head is positioned in terms of 3-D location in the x-, y-, and z-axes and is attitude orientated in terms of pitch, yaw, and roll. Further, attitude of the probe head is preferably orientated prior to contact of the sample probe head with the tissue sample using indicators, such as non-contact distance feedback from capacitance sensor, contacting or non-contacting optical sensors, and / or contact electrical sensors.

Owner:GLT ACQUISITION

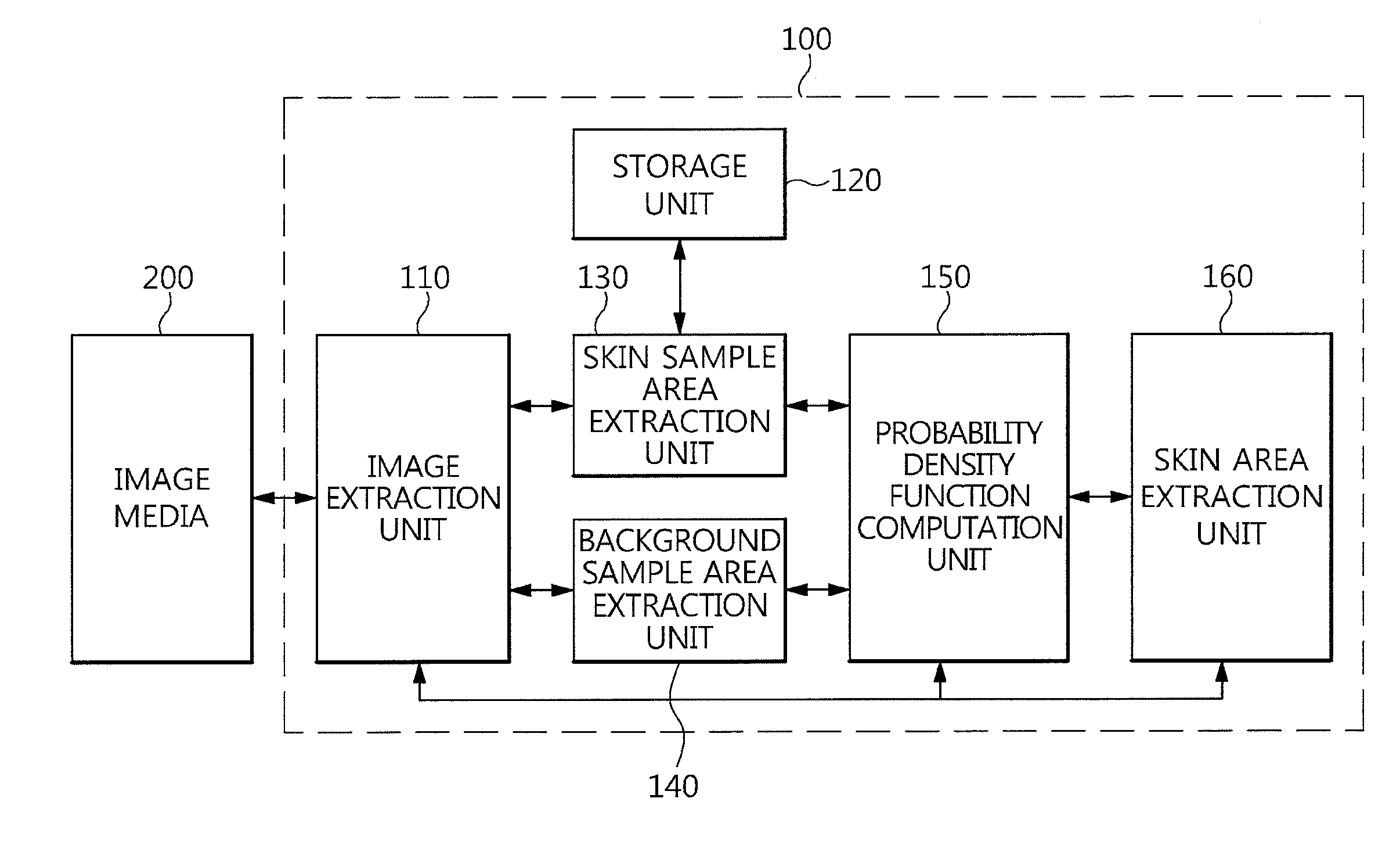

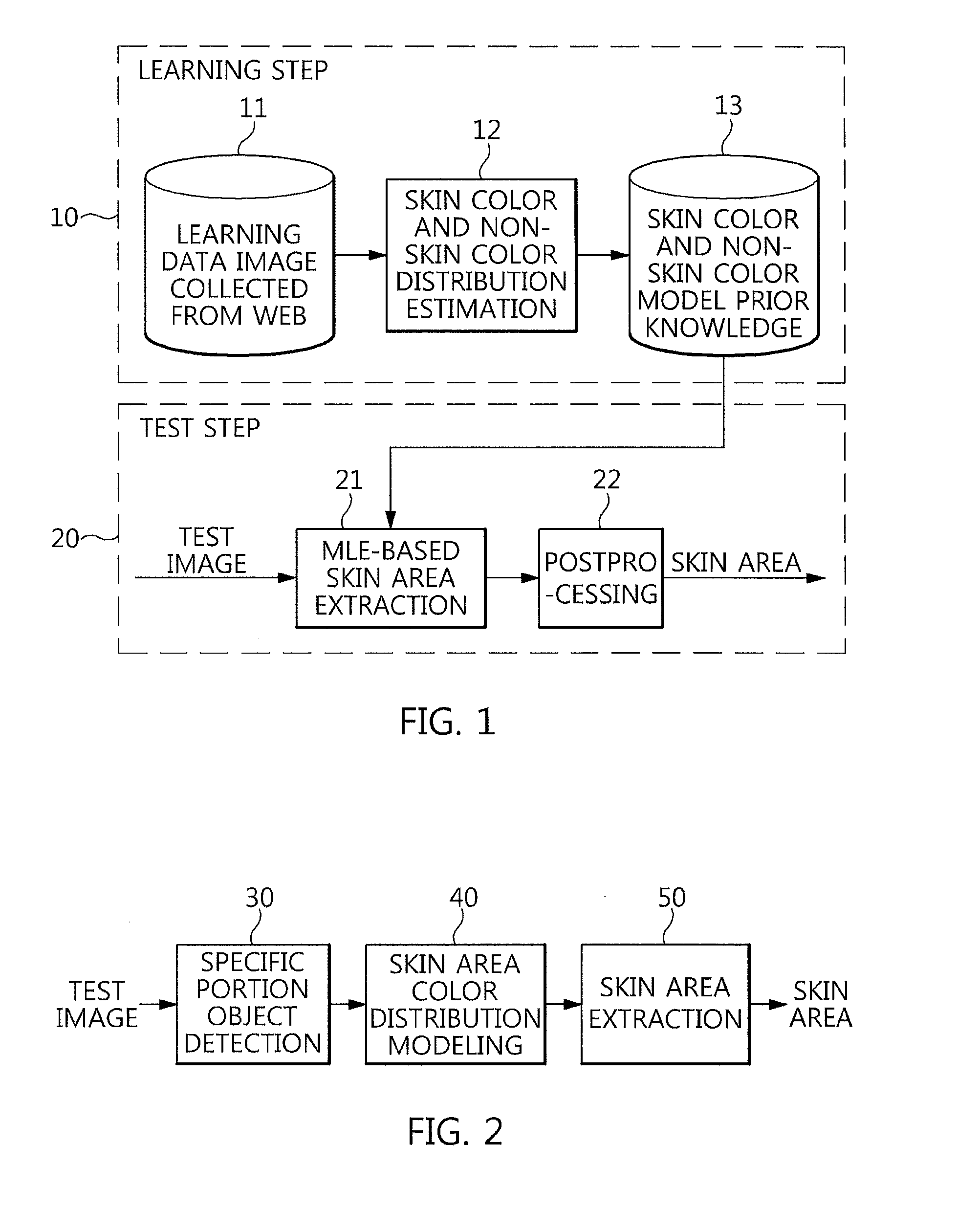

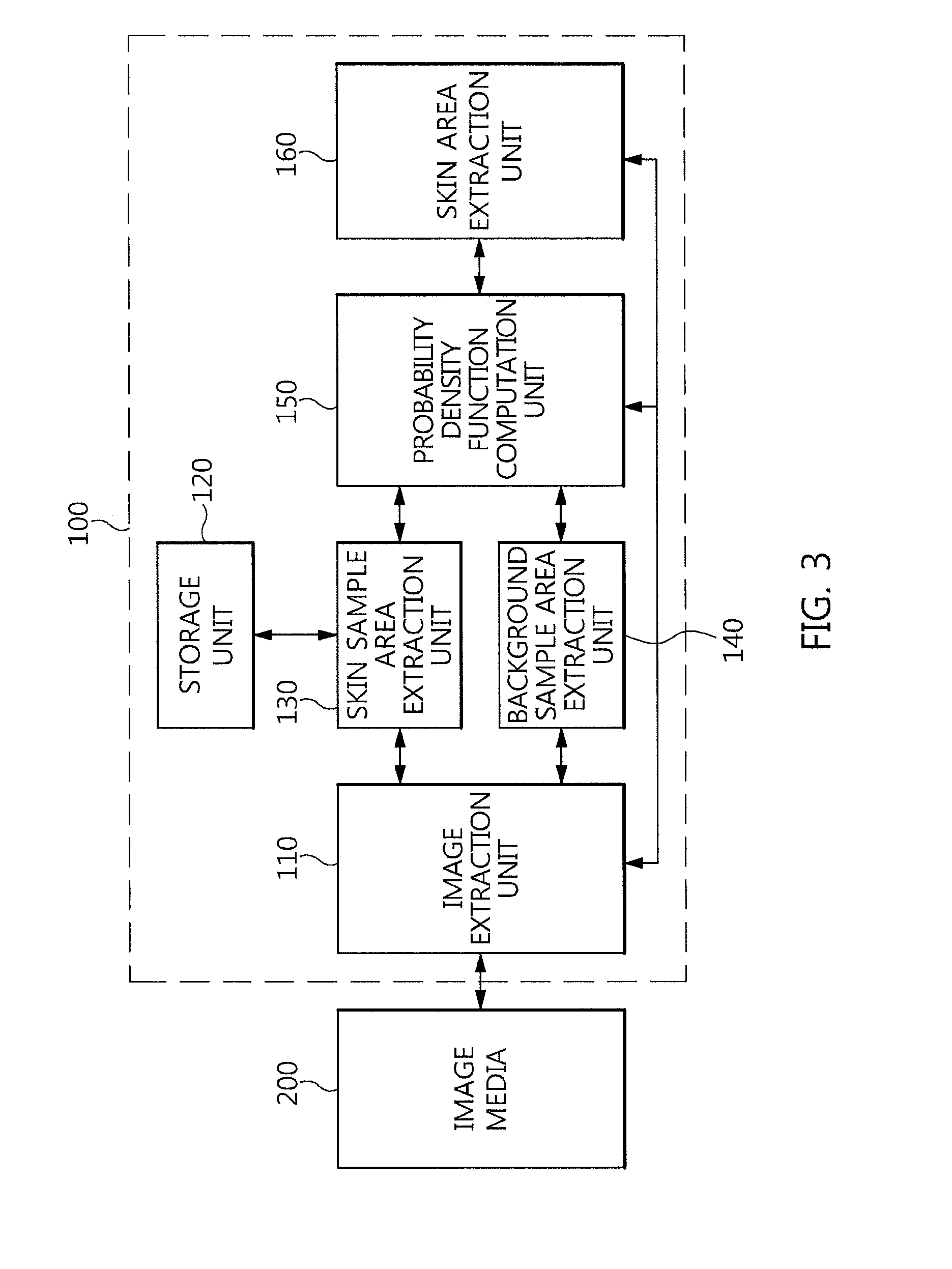

Apparatus and method for extracting skin area to block harmful content image

InactiveUS20150125074A1Component can be removedMinimizing false positive rateImage enhancementImage analysisImage extractionPattern recognition

Disclosed are an apparatus and method for extracting a skin area to block a harmful image. The apparatus includes an image extraction unit, a skin sample area extraction unit, a background sample area extraction unit, a probability density function computation unit, and a skin area extraction unit. The image extraction unit extracts an image from image media. The skin sample area extraction unit extracts a skin sample area of the image based on prior information. The background sample area extraction unit extracts a background sample area of the image based on the prior information. The probability density function computation unit calculates the probability density functions of the skin sample area and the background sample area. The skin area extraction unit extracts a skin area from the image based on the probability density function of the skin sample area and the probability density function of the background sample area.

Owner:ELECTRONICS & TELECOMM RES INST

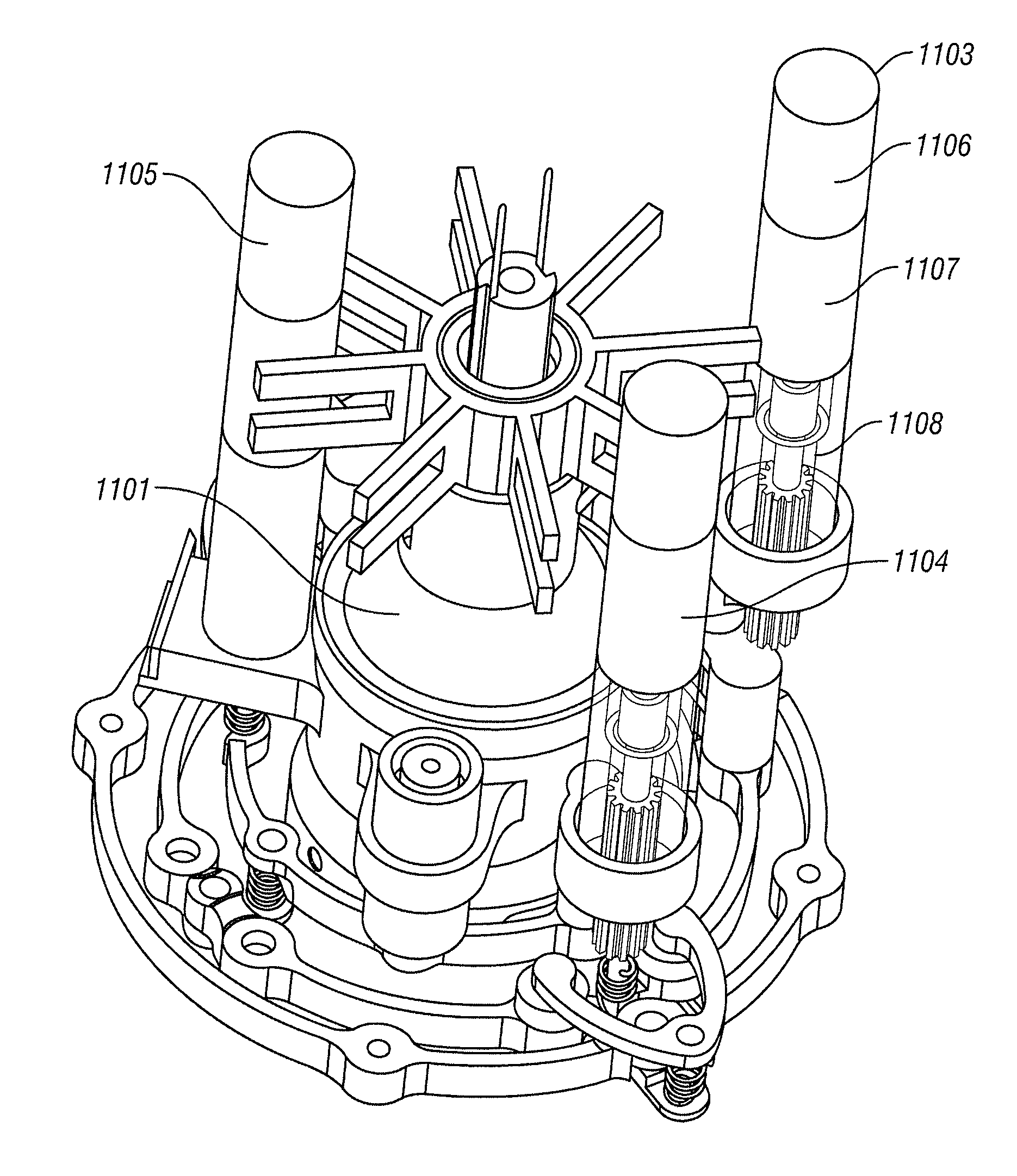

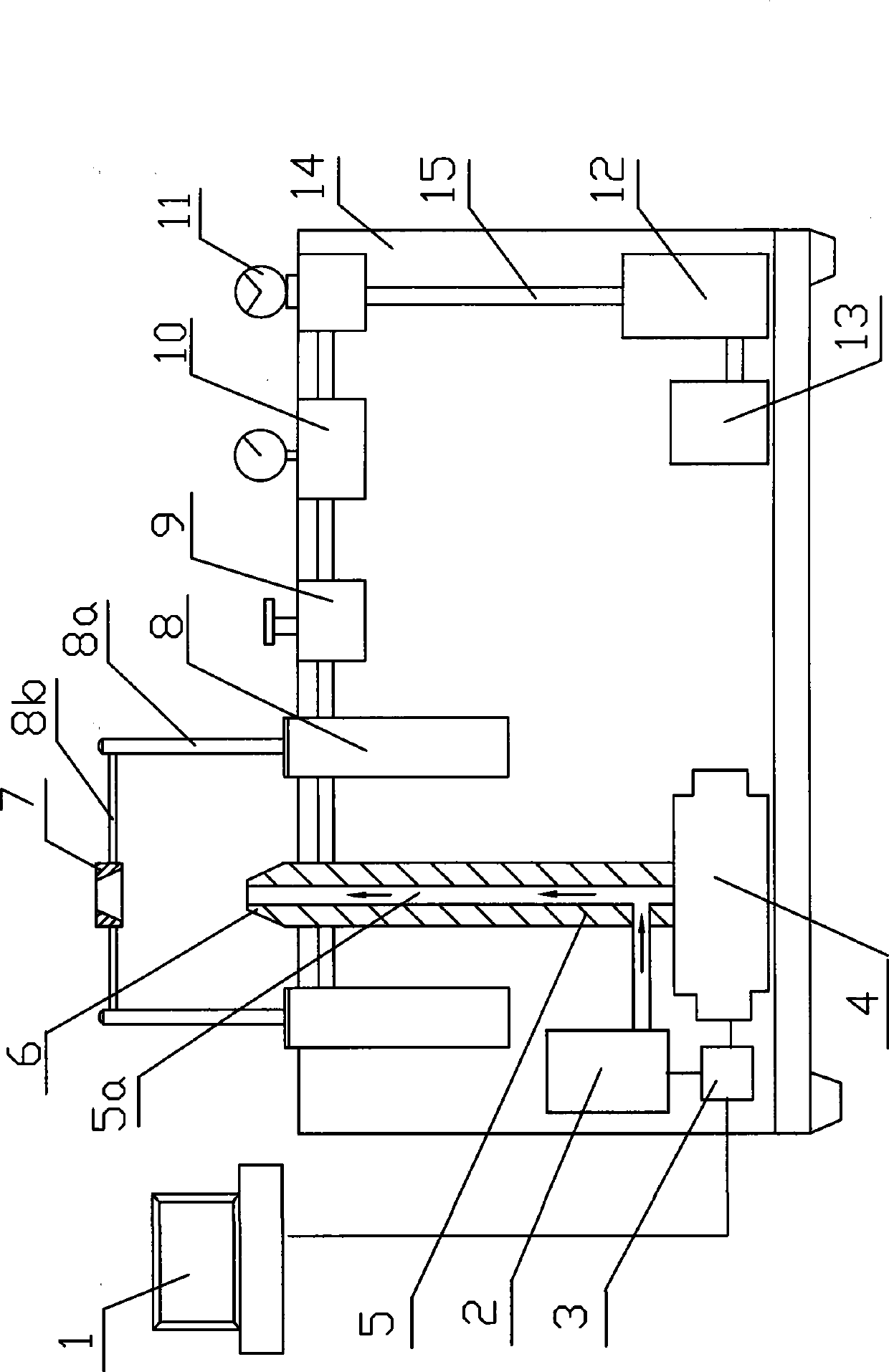

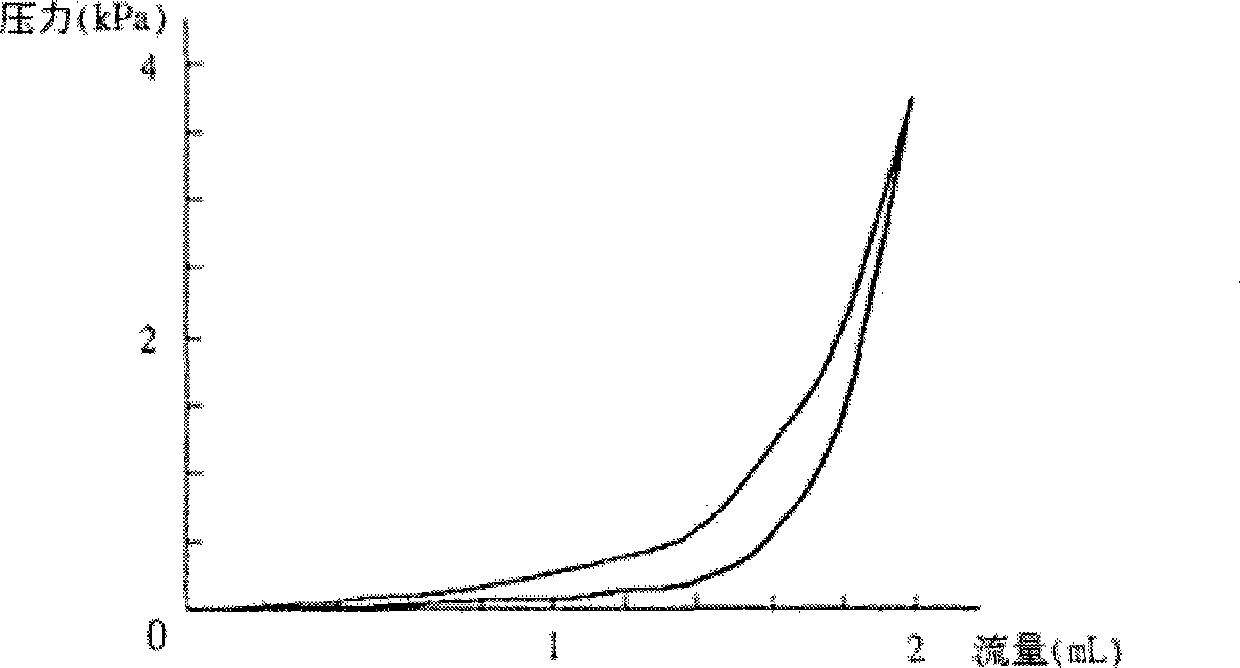

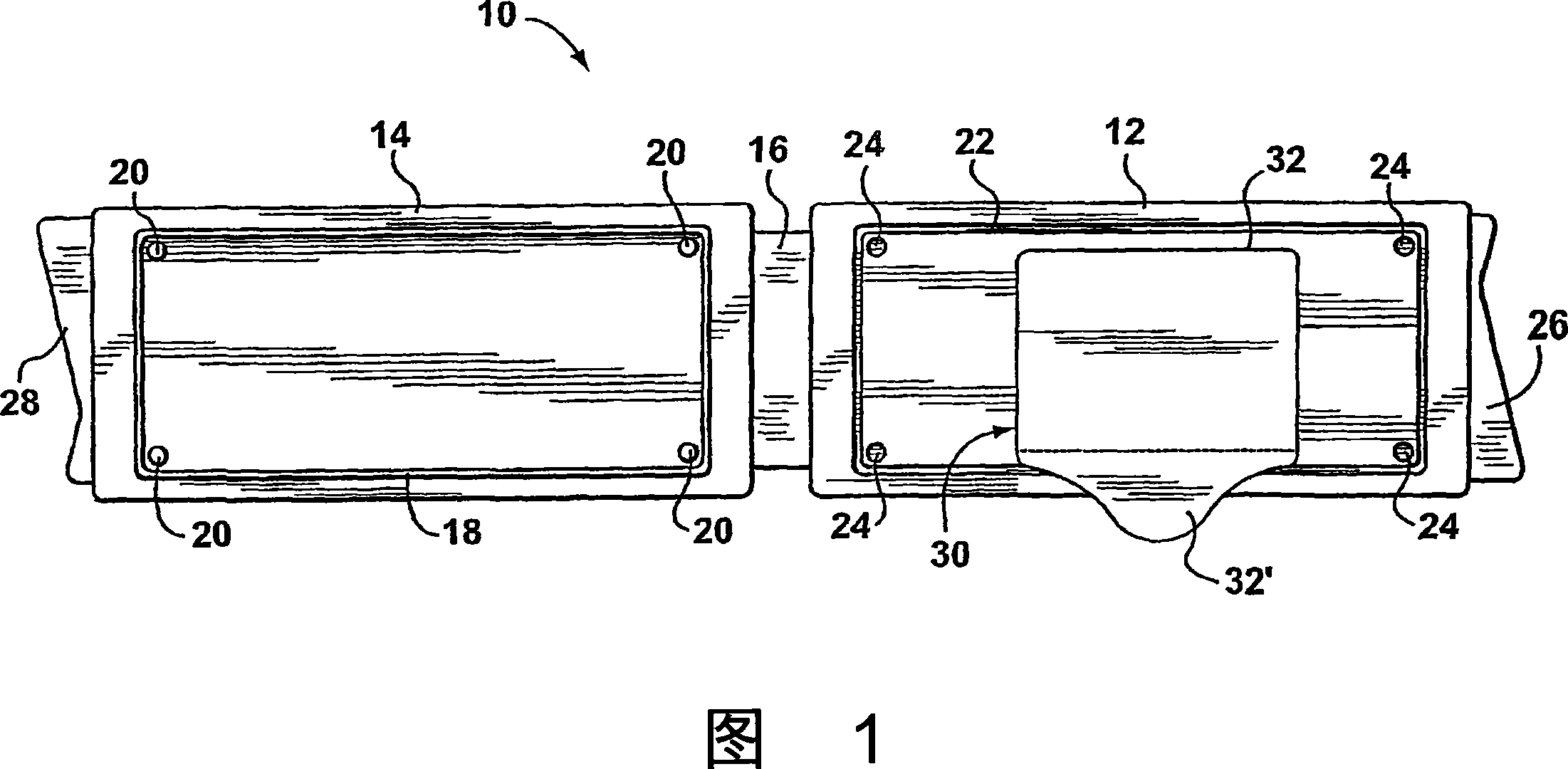

Biomechanics test device for skin soft tissue and its liquid loading test method

InactiveCN101487778ANo slippageNo pinching phenomenon will occurMaterial strength using tensile/compressive forcesPumpsHuman bodyBiomechanics

The invention discloses a biomechanics test device for soft tissues of skin and a liquid loading test method. The biomechanics test device consists of a computer, a metering pump for driving liquid, a device provided with a liquid storage cavity and used for supporting a skin sample, a pressure sensor, a data acquisition card, a pressing sleeve for fixing the sample, a cylinder, a control valve, a pressure reducing valve and a pressure gauge, can carry out biomechanics test under the state that the soft tissue sample of the skin is similar to physiological environment of human body, and ensures that the pressure for clamping the soft tissue sample of the skin is moderate and the test is more accurate. The method for carrying out liquid loading test by adopting the biomechanics test device can obtain load and deformation state of the soft tissue sample of the skin through variation of pressure of loading liquid and flow volume, so as to obtain various biomechanics indexes of the soft tissue sample of the skin.

Owner:INST OF FIELD OPERATION SURGERY NO 3 MILITARY MEDICL UNIV PLA

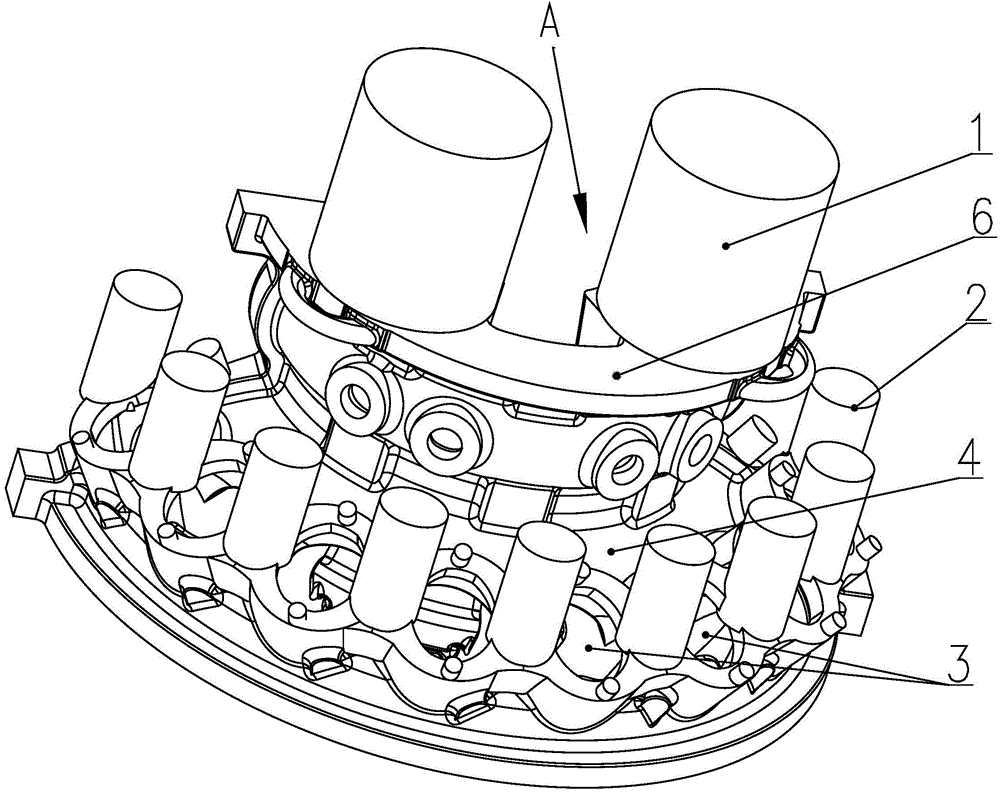

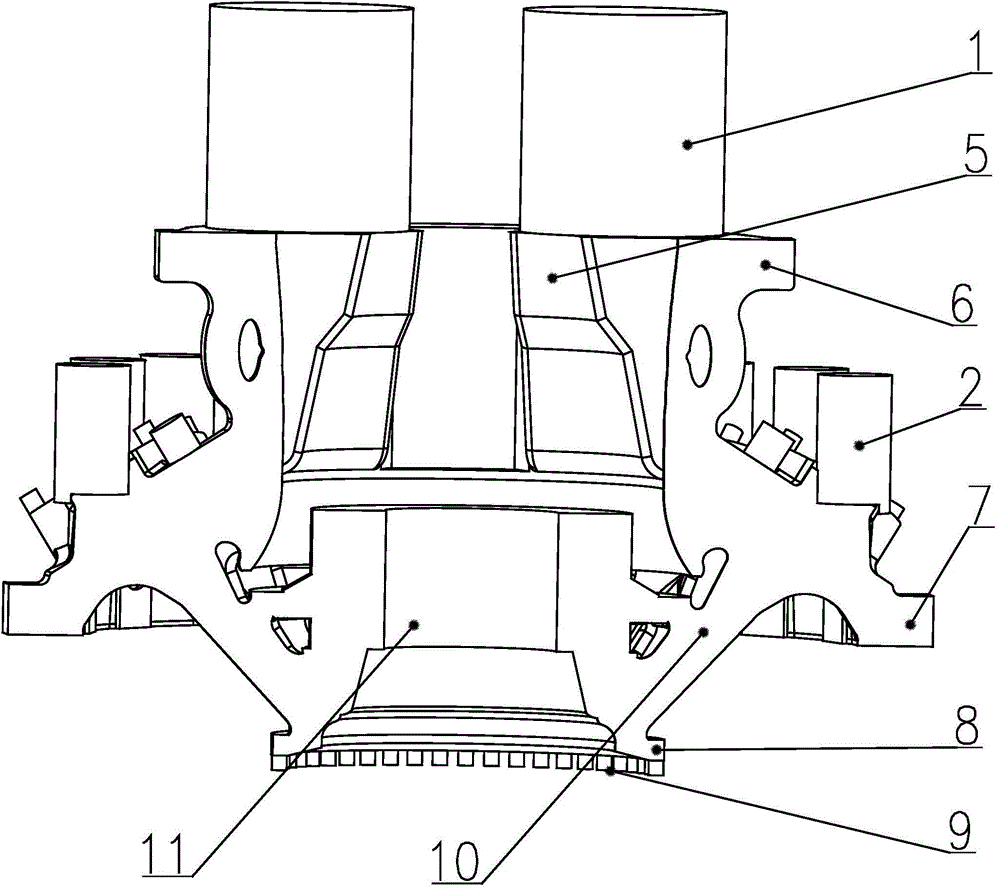

Heavy type gas turbine compressor exhaust cylinder casting process

ActiveCN104907499AReduce the chance of deformationQuality improvementFoundry mouldsFoundry coresEngineeringCylinder block

The present invention discloses a heavy type gas turbine compressor exhaust cylinder casting process, in order to fully feed the casting solidification process, a cylinder body is vertically poured, an annular open riser is placed on the upper part of the cylinder body, a plurality of annular blind risers are placed on a sector, a chiller and a patch are simultaneously assembled for feeding the casting; a wood-type skin sample is used for shaping to ensure a precision casting size; an alkaline phenolic resin sand is used as back sand, chrome ore sand is used as a surface sand, and the air permeability and deformability of the sand mold surface can be increased; an open-type water nozzle is used for pouring, the chance of casting distortion can be reduced, and the casting quality is improved. Compared with the prior art, the beneficial effects are that: the technical problems of the defects of being complex in structure, large in volume, uneven in partial casting wall thickness, difficult to feed, easy to deform, easy to loosen, crack and deform, and the like of a heavy type gas turbine compressor exhaust cylinder steel casting part can be effectively solved.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

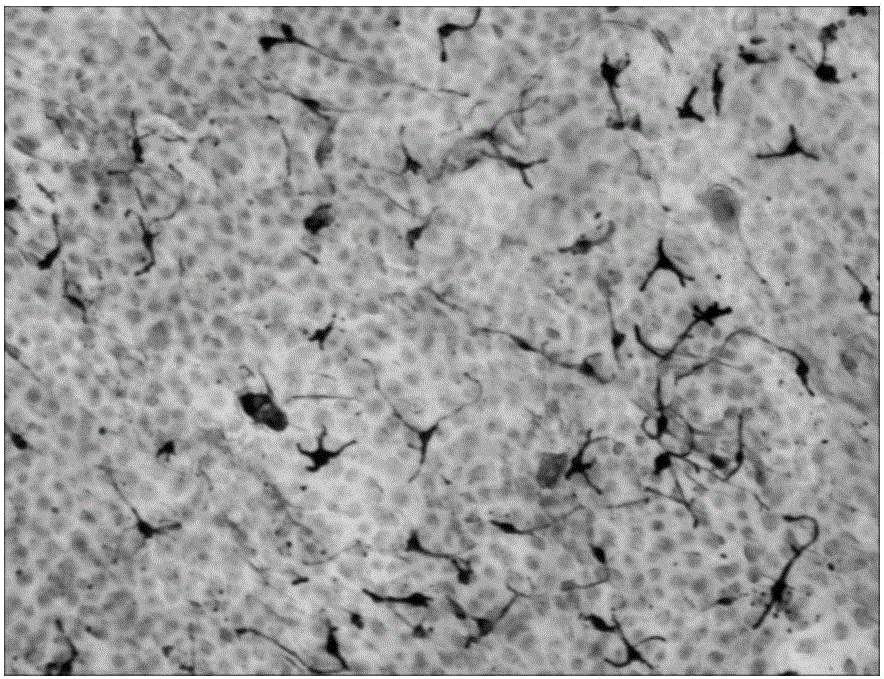

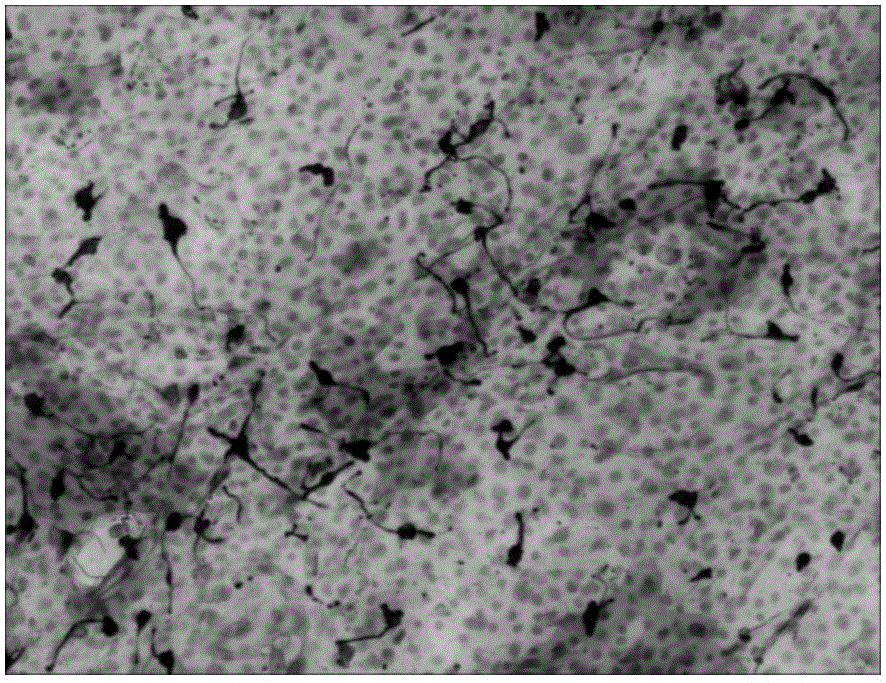

Mixed cultivation method of keratinocyte and melanocyte and application

InactiveCN105112353AEliminate the effects ofImprove proliferative abilityArtificial cell constructsVertebrate cellsDiseaseCutin

The invention provides a mixed cultivation method of keratinocyte and melanocyte comprising: breaking the skin sample reserving epidermal layer and at least part of corium layer, cold digesting by pancreatin; collecting deposition organization; heat digesting by I type collagenase, collecting cells; primary inoculating, culturing in KGM-Gold medium; subcultring to the cells merge, culturing in KGM-Gold medium to the cells differentiate and stratify; collecting the formed skin sheet. The mixed cultivation method of keratinocyte and melanocyte uses the medium only for skin keratinocyte and melanocyte with which can avoid pollution of the other cells, and can get skin sheet including functional melanocyte and distributing uniformly. The mixed cultivation method of keratinocyte and melanocyte can get large area of skin sheet from quite small area of autologous sample, solve the problem of shortage of the skin source at skin grafting for the patient with large-area skin diseases, and apply in skin diseases of pigment deficiency such as leucoderma and so on.

Owner:赫柏慧康生物科技无锡有限公司 +1

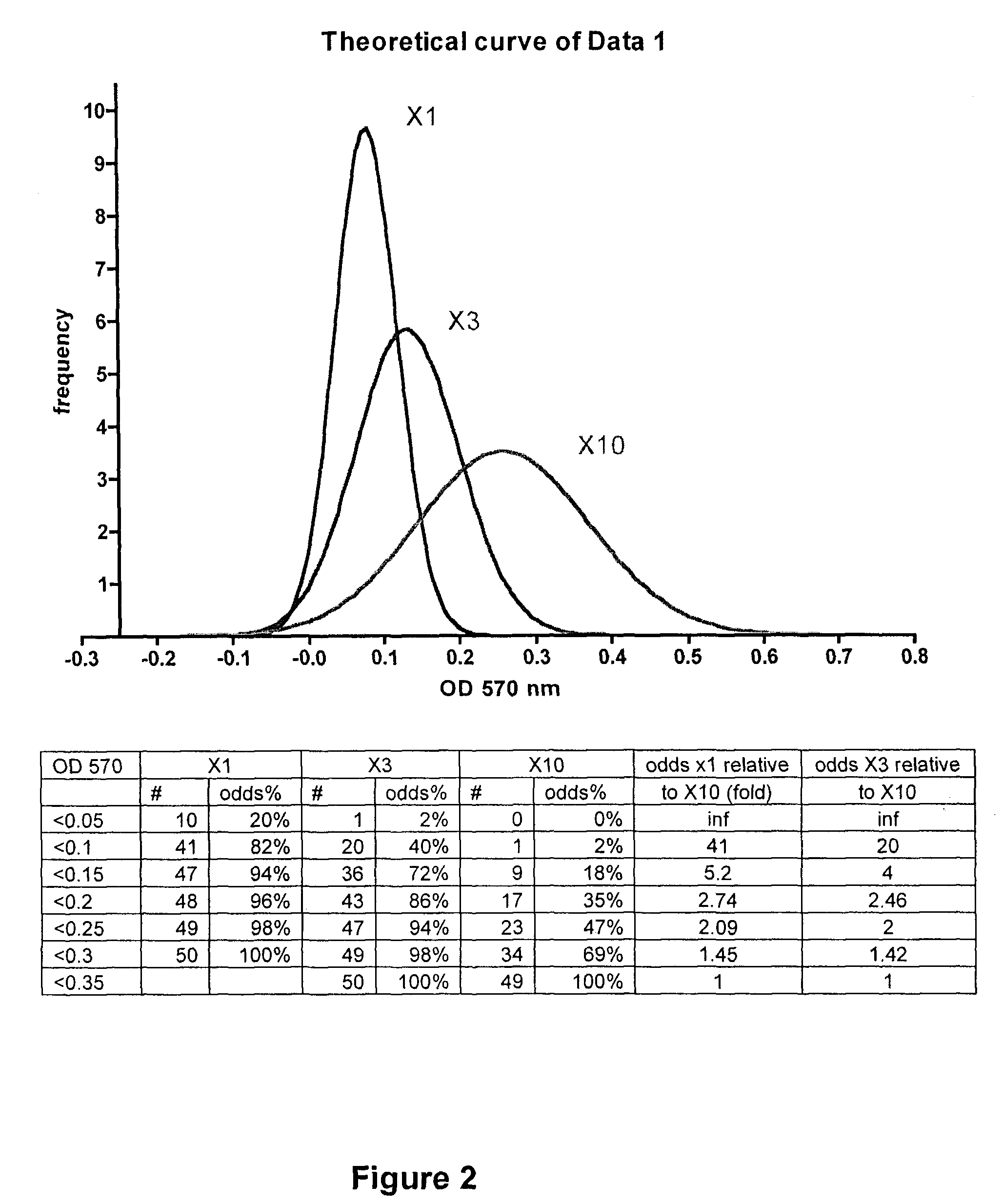

Direct Assay of Skin Protein in Skin Samples Removed by Tape Stripping

InactiveUS20080188387A1Cost effectiveImprove throughputCosmetic preparationsMake-upSAA proteinMedicine

The present invention provides for a method of measuring the amount of skin removed by tape stripping. In one aspect of the invention, the invention provides a method for the direct assay of protein in skin samples removed by tape stripping, with a view to combining the protein measurement obtained with a corresponding skin cholesterol measurement to identify individuals at risk of having atherosclerosis as well as those at risk of developing atherosclerosis and similar diseases associated with and attributable to high cholesterol levels. Moreover, the present invention allows a comparative measurement of the amount of skin removed by tape stripping that does not rely solely on the area of the sample removed. Additionally, in one aspect of the invention, the method of this invention can allow relative levels of skin cholesterol to be compared based on the relative amounts of skin removed.

Owner:MIRACULINS

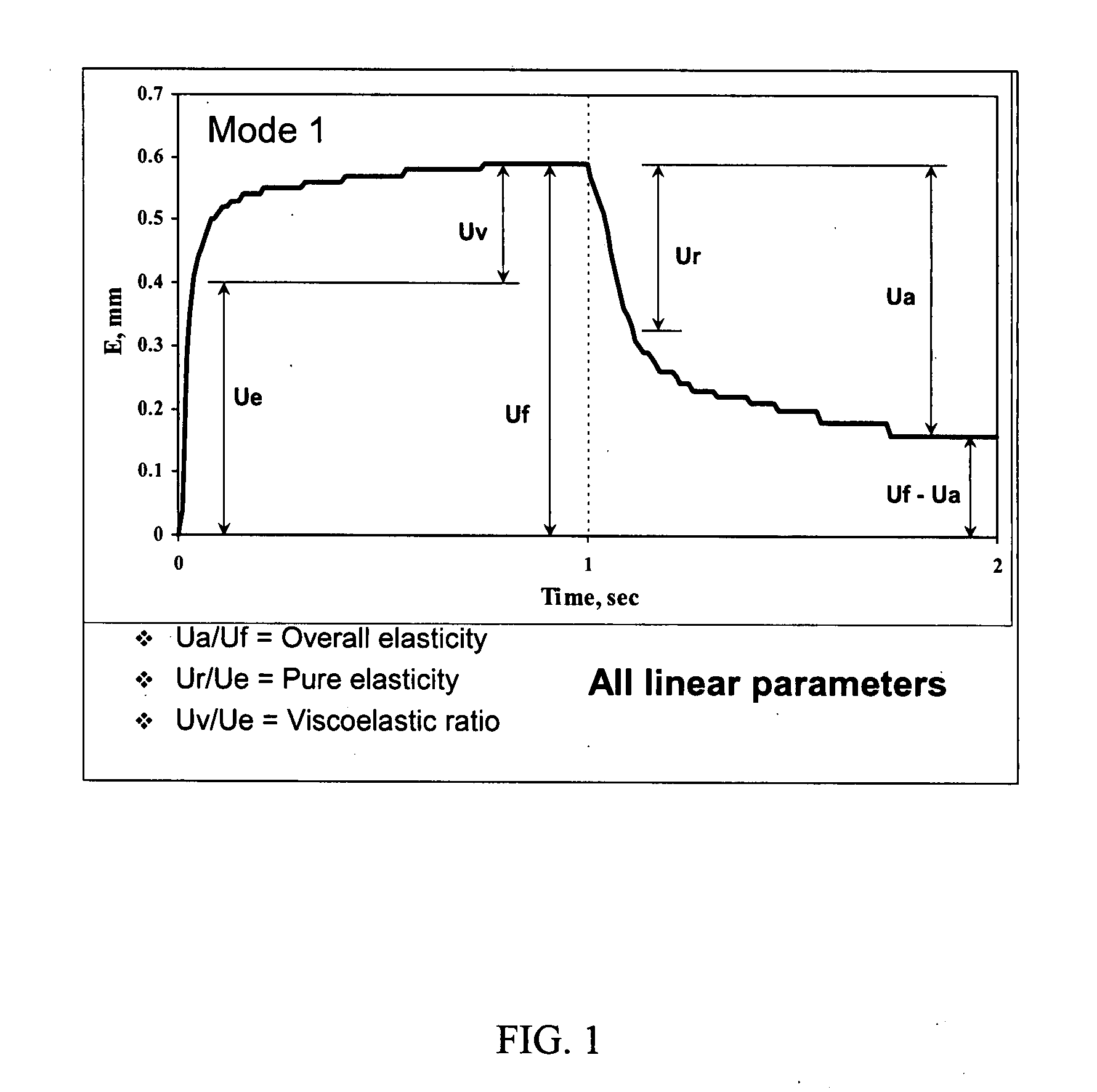

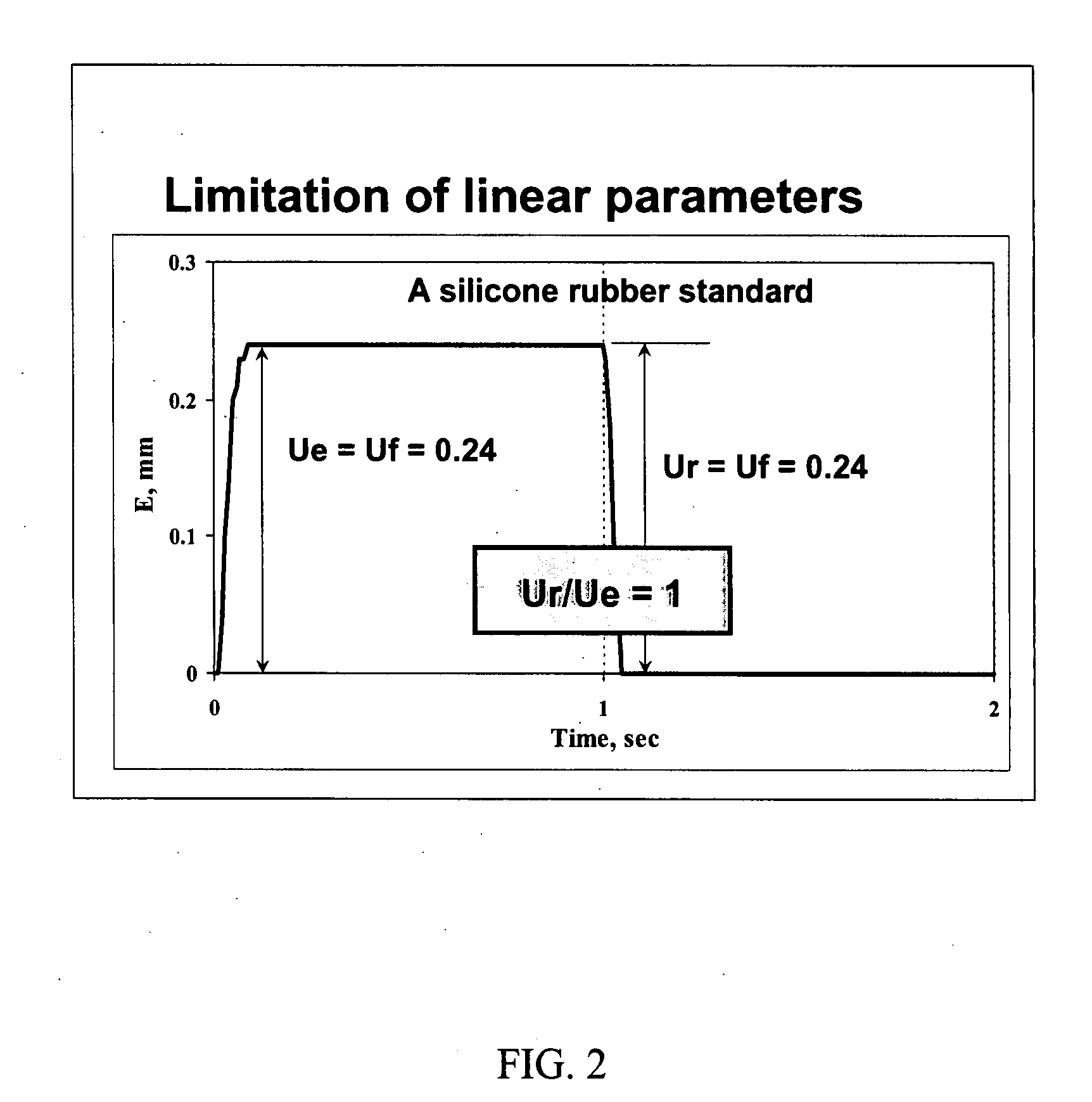

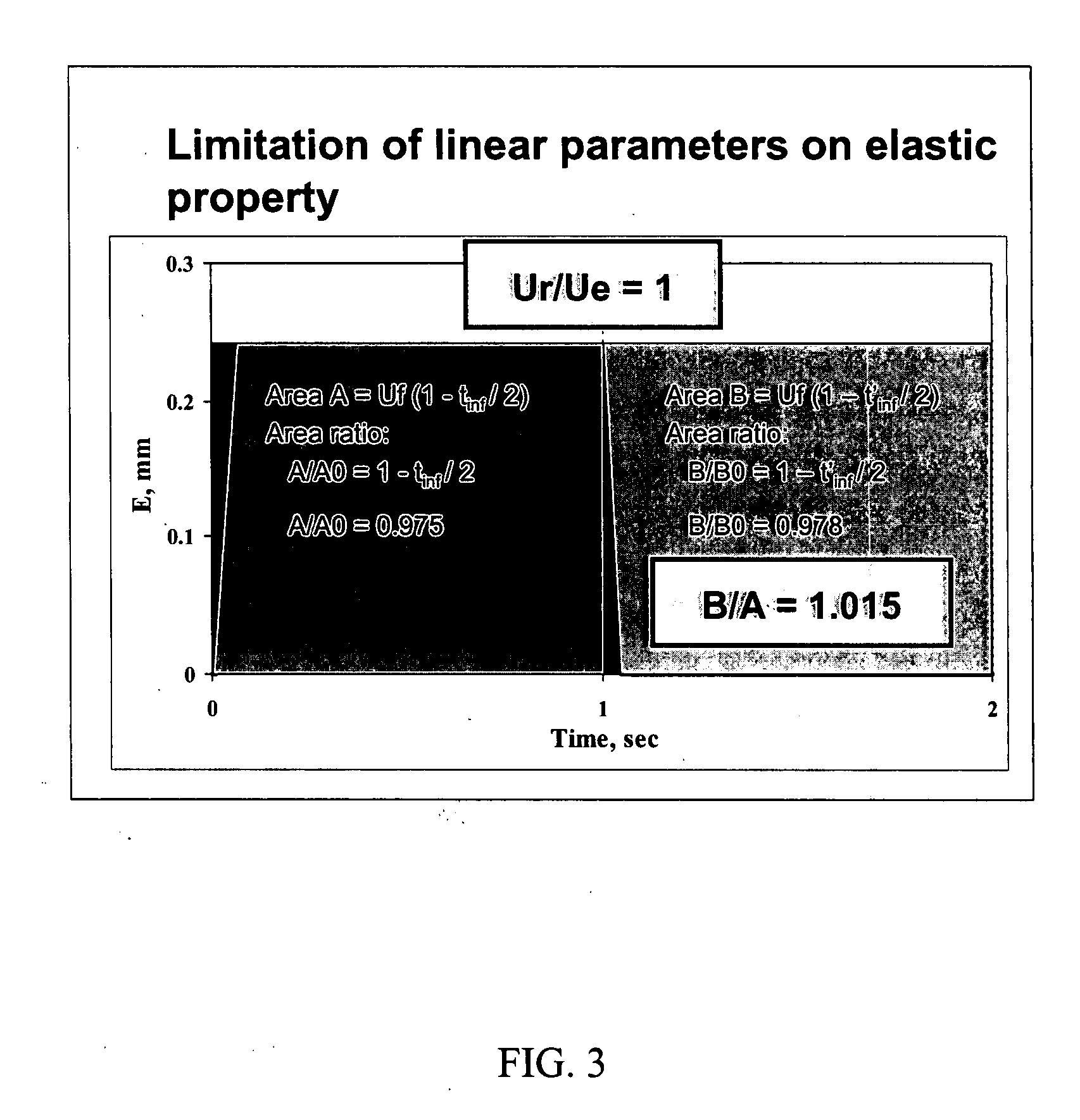

Methods for determining elastic and viscoelastic properties of skin

ActiveUS20080087098A1Promotes skin healthDiagnostics using suctionFlow propertiesRelaxation curveOral treatment

The invention relates to methods of measuring the overall elasticity of skin and determining the portion of the overall elasticity that is due to elastic properties and the portion of overall elasticity that is due to viscoelastic properties of the skin and correlating the results of the measurement to an individual's chronological age. The invention also relates to methods of measuring improvements in a person's skin health by measuring elasticity before, during and after human clinical trials of topical and / or oral treatment compositions. The parameters for determining elasticity are based on areas that are defined on a deformation / relaxation curve and require that an inflection point be determined for each skin sample analyzed.

Owner:ACCESS BUSINESS GRP INT LLC

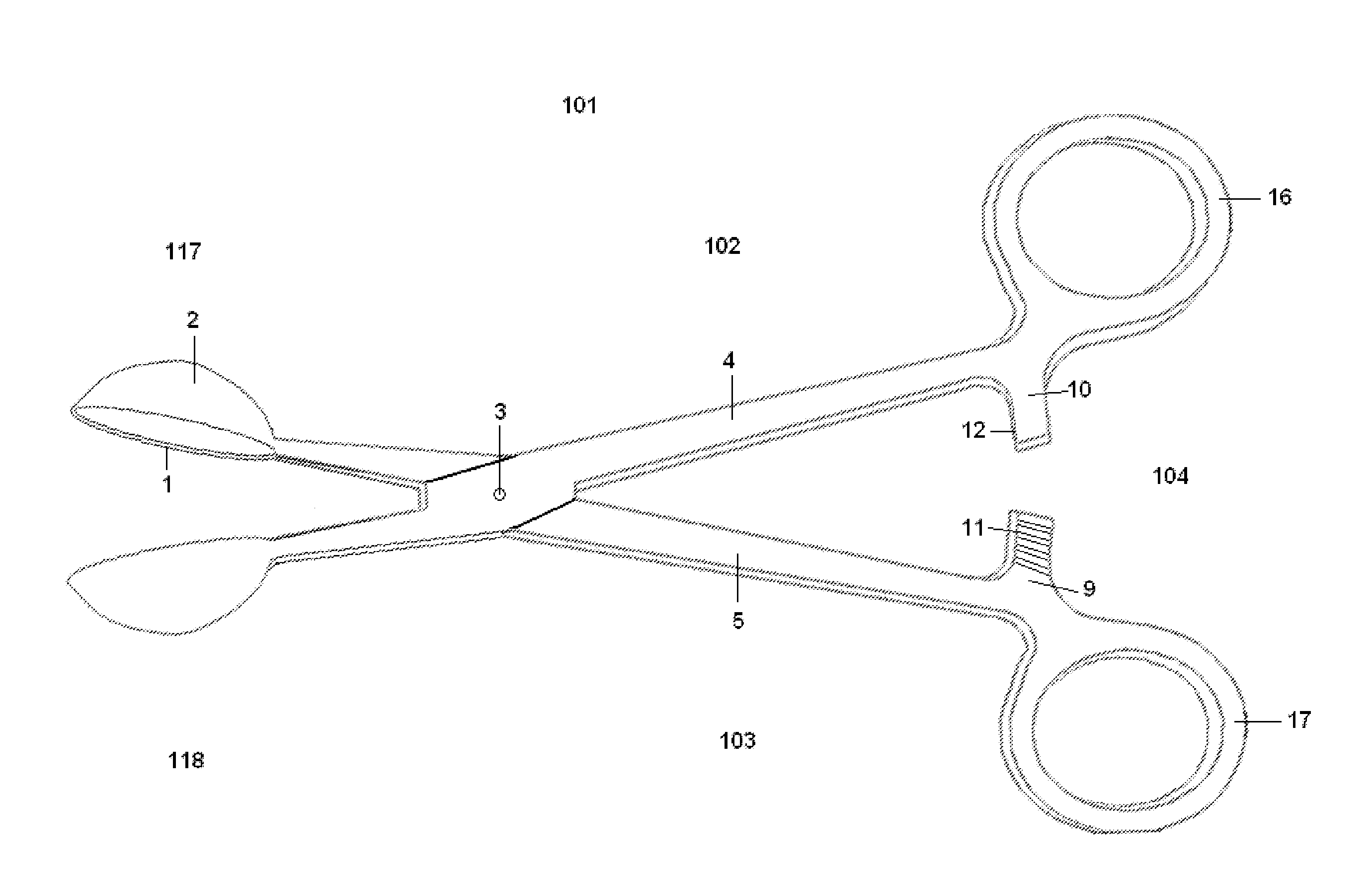

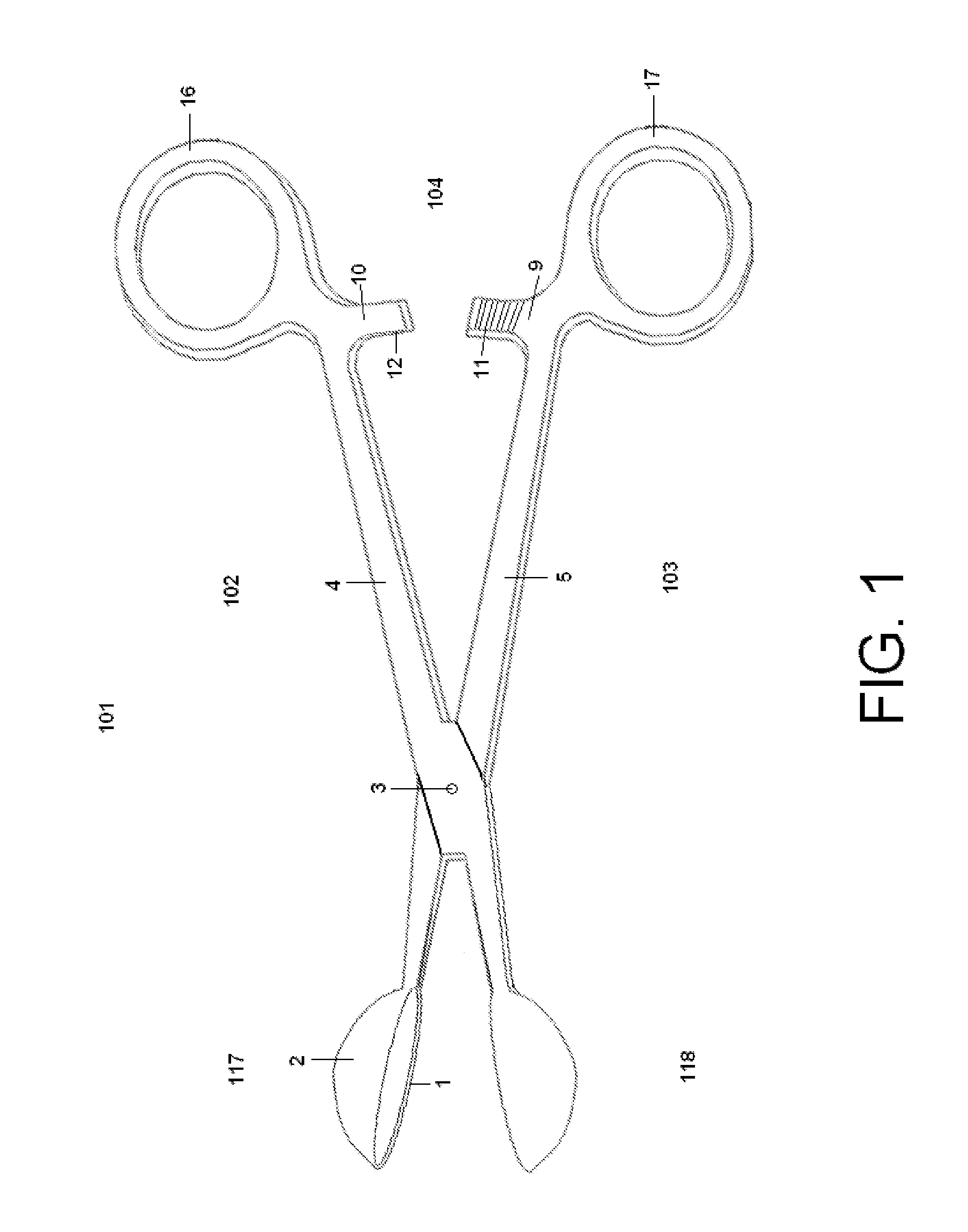

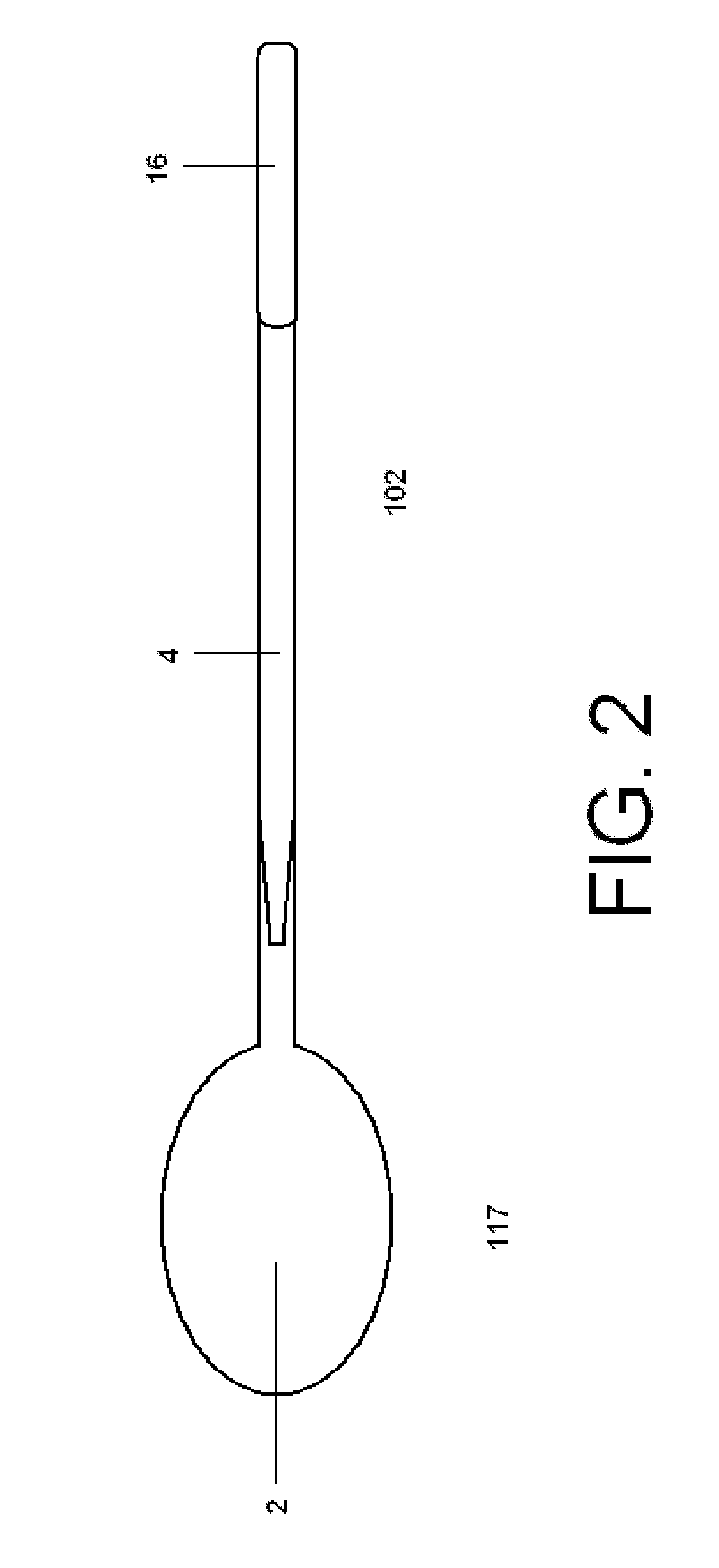

Skin Biopsy Clamp

InactiveUS20090105608A1Improve efficiencyEasy to handleSurgical needlesVaccination/ovulation diagnosticsBiopsy lesionSkin abnormality

A spoon-shaped skin biopsy instrument is used in the removal of superficial skin samples and skin abnormalities for subsequent laboratory analysis. The spoon-shaped skin biopsy instrument is comprised of a pair of spoon-shaped cutting edges, which surround the desired skin sample, a crossed-members apparatus with finger loops, and a pivot point that connects the crossed members. This present invention maximizes surgical efficiency and handling and minimizes operation time.

Owner:CHIU KWOK WAI +3

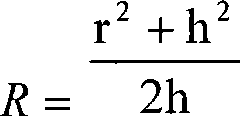

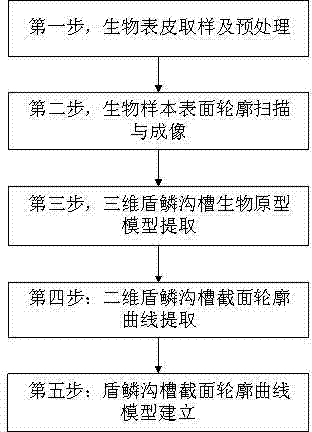

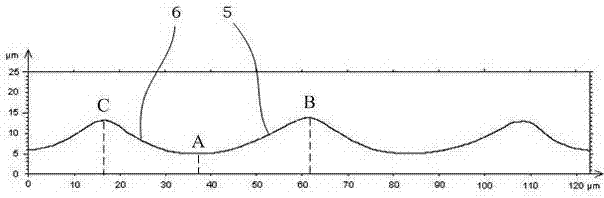

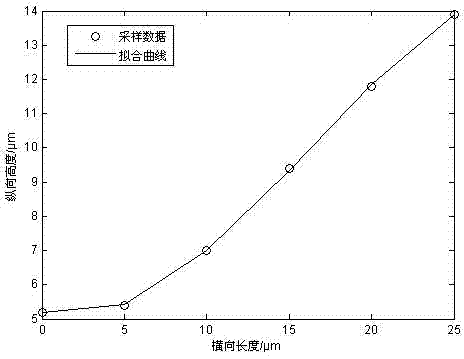

Modeling method of cartilaginous fish placoid scale groove section profile curve

The invention discloses a modeling method of a cartilaginous fish placoid scale groove section profile curve. The method comprises the following steps of: sampling and preprocessing biological skin; scanning and imaging the surface profile of a biological sample; extracting a three-dimensional placoid scale groove biological prototype model; extracting a two-dimensional placoid scale groove section profile curve; and establishing a placoid scale groove section profile curve model and the like to finally obtain a mathematical model of the placoid scale groove section profile curve on the cartilaginous fish skin sample. The method has the advantages that: by performing high-definition surface profile scanning and imaging on the cartilaginous fish skin sample, the fitting degree between the established mathematical model and the prototype model is high. The cartilaginous fish placoid scale groove section profile curve mathematical model established by the method can be taken as a data source for manufacturing a high-reality bionic drag-reduction surface by using digital control processing equipment.

Owner:SHANDONG UNIV OF TECH

Method for preparing cod collagen

InactiveCN101250218AShorten the production cycleQuality improvementProtein composition from fishPeptidesWater bathsSlag

A preparation method of cod skin collagen, which is characterized in that the method comprises thawing frozen cod skin sample, removing impurity, washing via tap water and breaking mechanically, adding pretreated cod skin into hydrochloride to be immerged, mixing uniformly, adjusting pH value, bathing in water and centrifugally treating, extracting the left slag via hot water, centrifugally treating, combining extracts, concentrating and drying to obtain collagen product. The invention has short production period, whose product is white or light yellow, has high quality and is soluble in water.

Owner:OCEAN UNIV OF CHINA

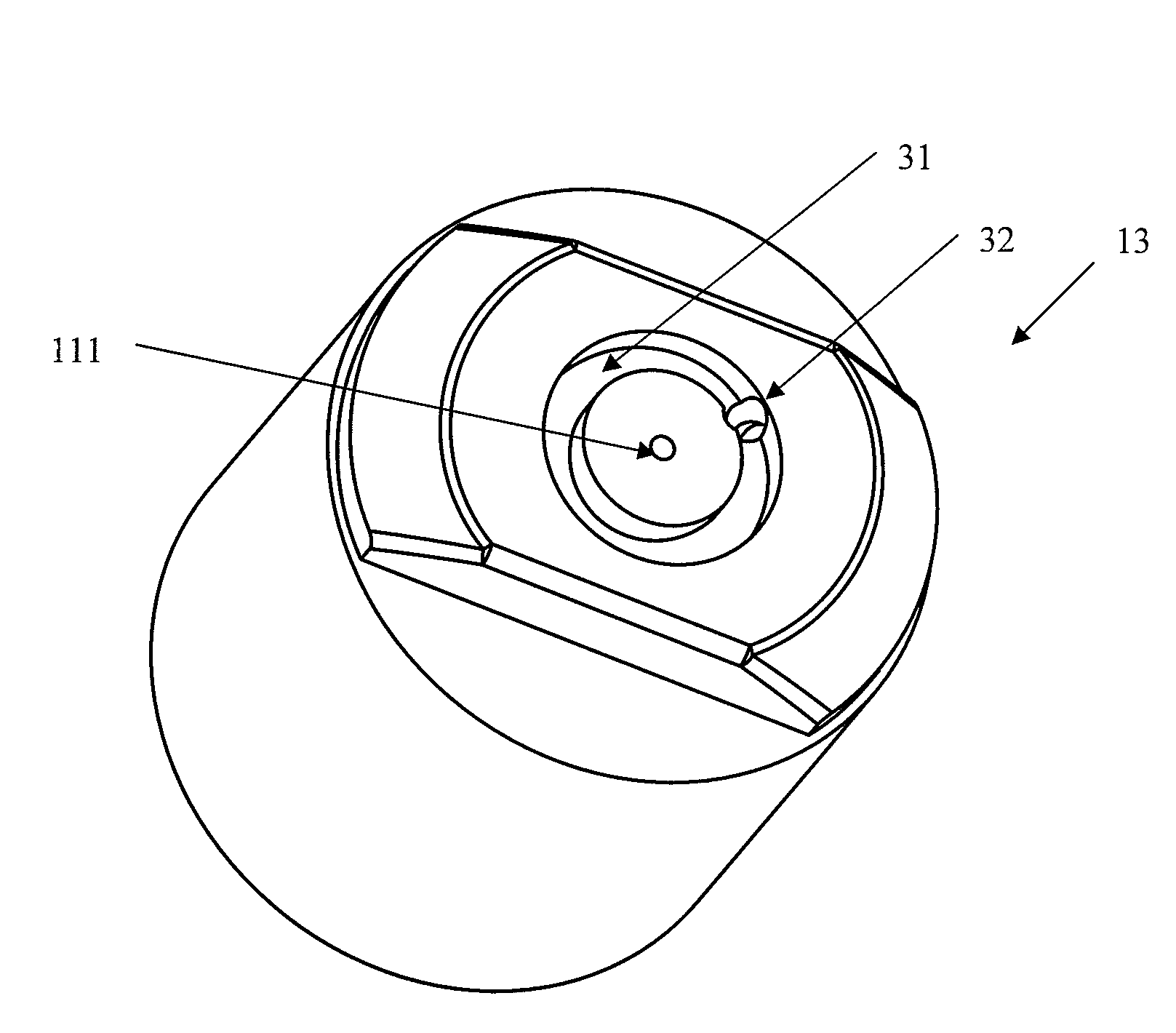

Method and apparatus for coupling a channeled sample probe to tissue

ActiveUS20080319382A1Good optical performanceMinimizing sampling errorMaterial analysis by optical meansMedical devicesAnalyteThin layer

Sampling is controlled in order to enhance analyte concentration estimation derived from noninvasive sampling. More particularly, sampling is controlled using controlled fluid delivery to a region between a tip of a sample probe and a tissue measurement site. The controlled fluid delivery enhances coverage of a skin sample site with the thin layer of fluid. Delivery of contact fluid is controlled in terms of spatial delivery, volume, thickness, distribution, temperature, and / or pressure.

Owner:GLT ACQUISITION

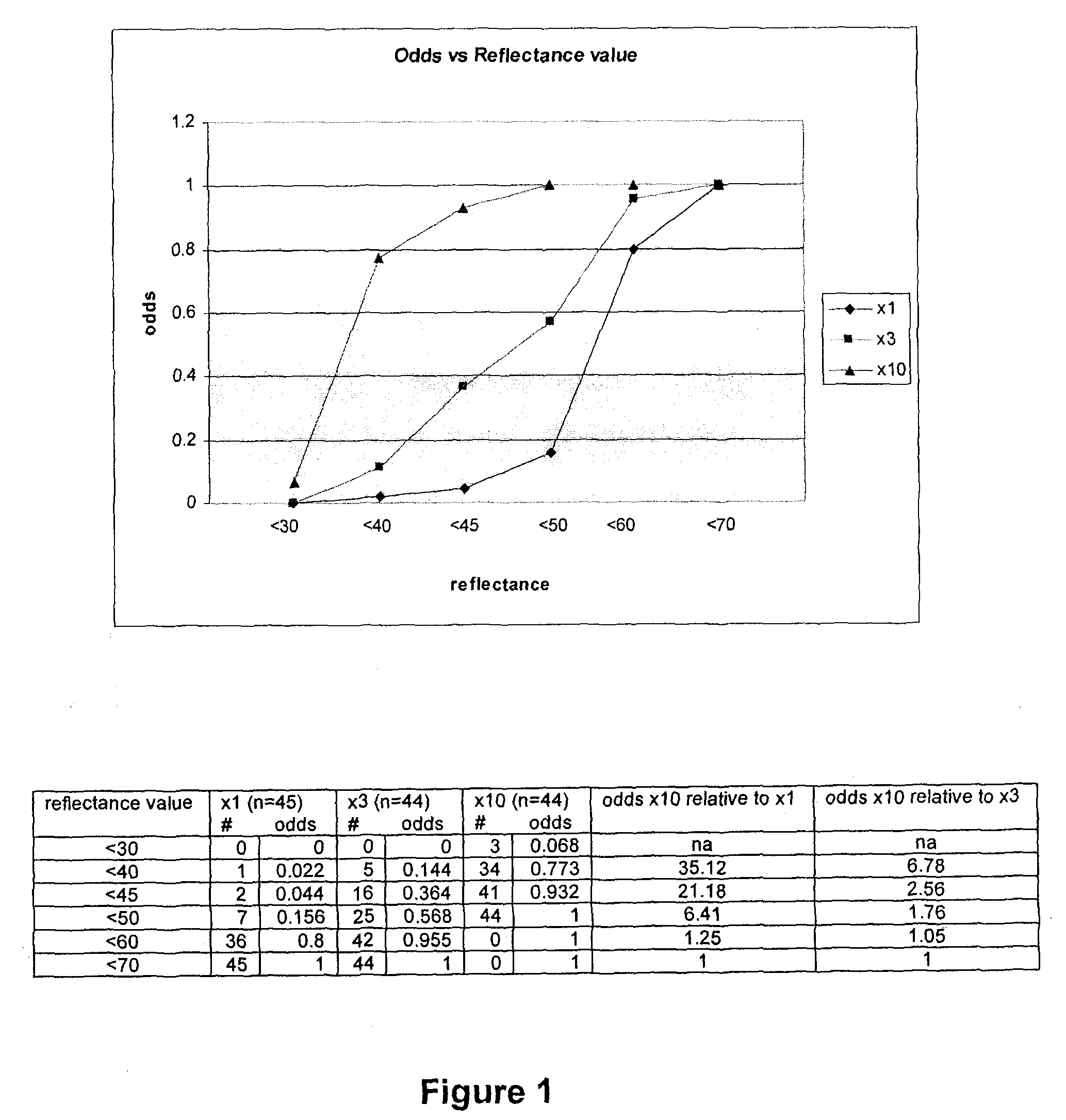

Direct assay of skin cholesterol in skin samples removed by tape stripping

Skin cholesterol is measured by applying an adhesive tape onto a selected area of the skin to adhere the tape to the selected skin area and stripping the tape off the selected skin area to obtain a sample representative of the outer stratum corneum layer of the skin, the sample adhering to the tape so as to have exposed skin constituents. The sample is assayed using a detector reagent that specifically binds to cholesterol and in addition has an indicator component that allows quantitation of the amount of cholesterol present in the exposed skin constituents.

Owner:麦拉克林有限公司

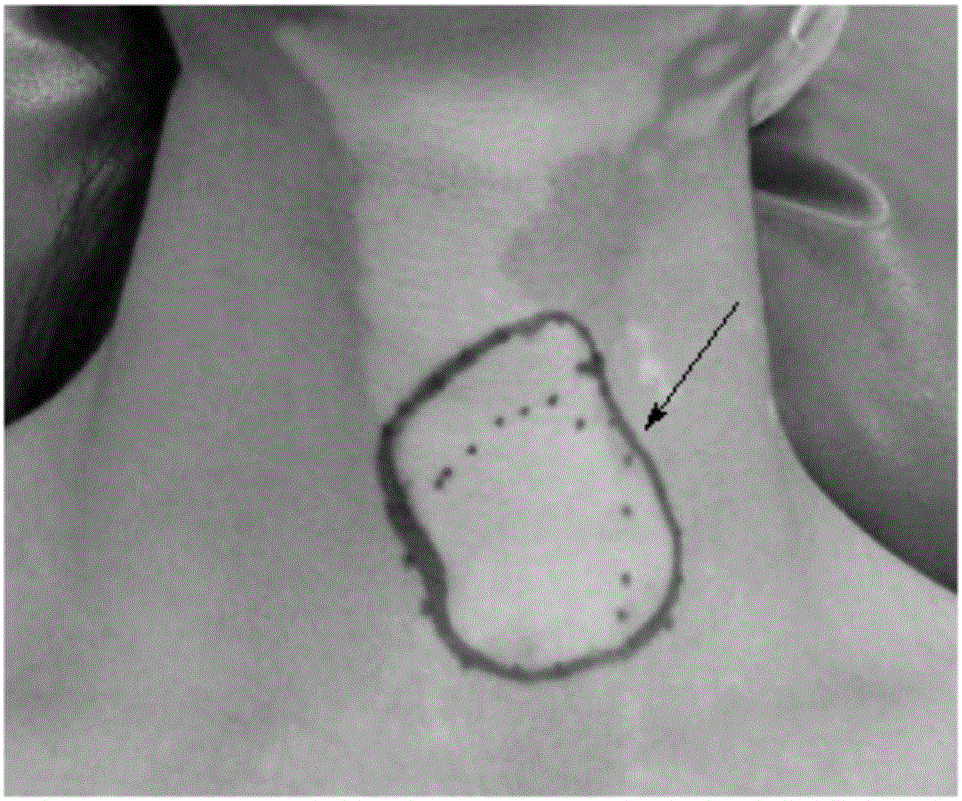

Method for Detection of Melanoma

The present invention provides non-invasive methods for detecting, monitoring, staging, and diagnosing malignant melanoma in a skin sample of a subject. The methods include analyzing expression in skin sample of one or more melanoma skin markers. The melanoma skin markers include IL-1 RI, endothelin-2, ephrin-A5, IGF Binding Protein 7, HLA-A0202 heavy chain, Activin A (βA subunit), TNF RII, SPC4, and CNTF Rα. The skin sample can include nucleic acids, and can be a human skin sample from a lesion suspected of being melanoma.

Owner:DERMTECH INT

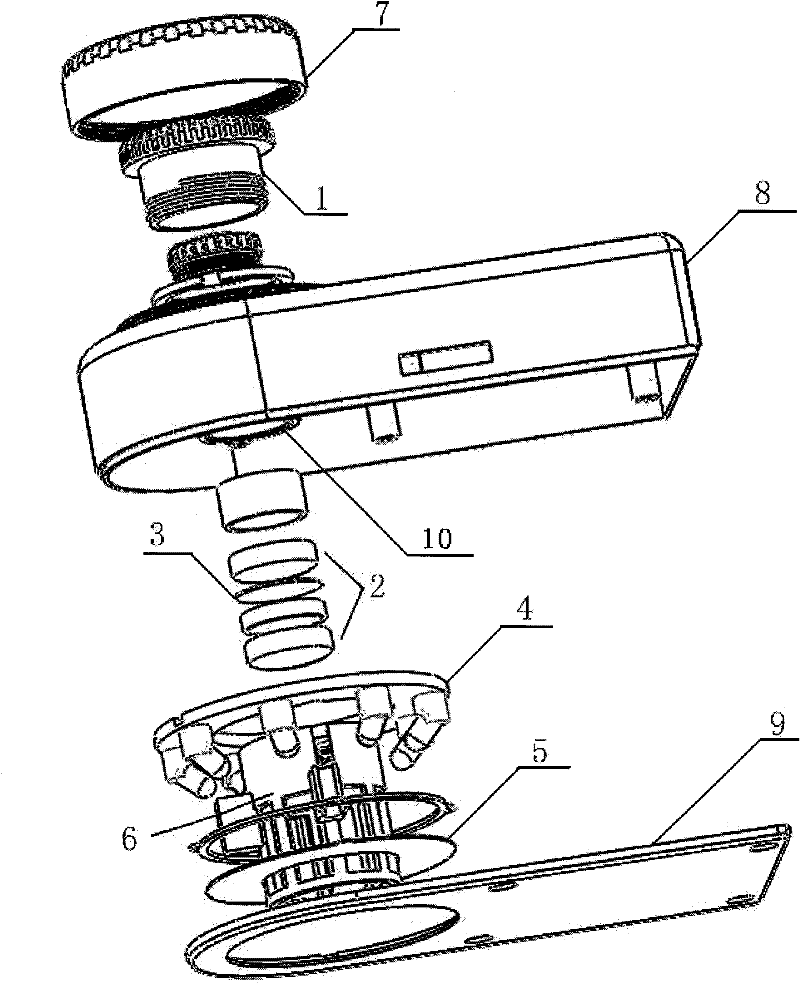

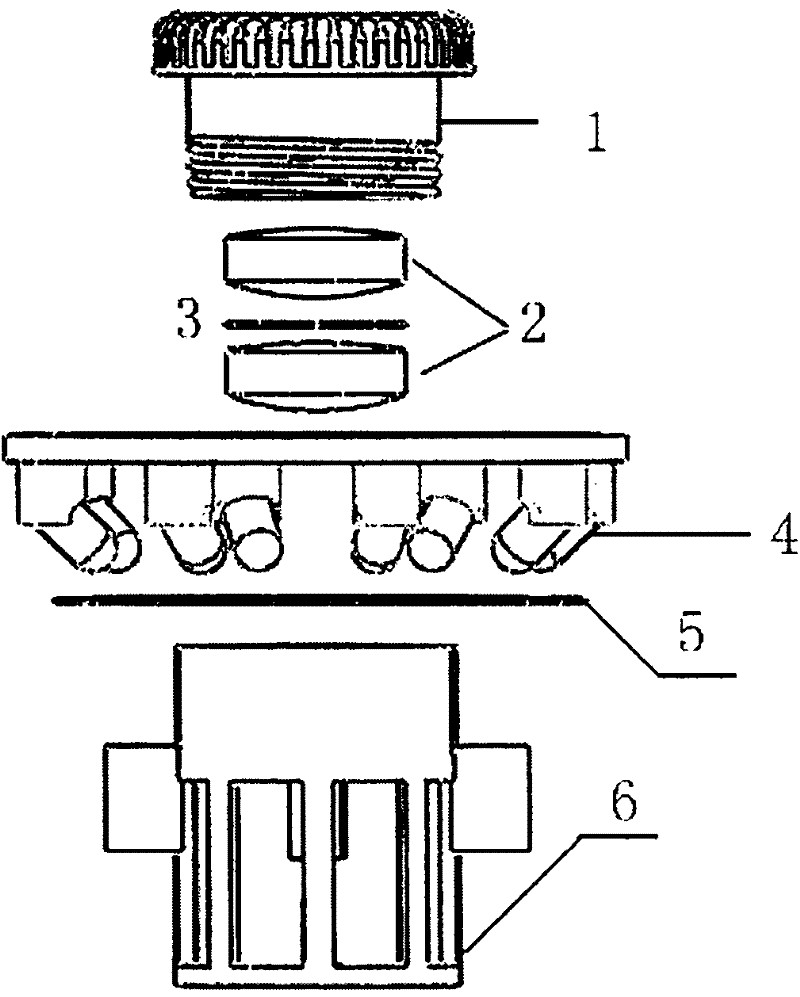

Polarized skin lens

InactiveCN102240205AEliminate the effects ofRealize early imaging diagnosisDiagnostic recording/measuringSensorsFine structureMedicine

The invention discloses a polarized skin lens, which can be applied for observing the deep-layer fine structure of a skin pigment damaging part directly, and does not need an infiltrated liquid. The polarized skin lens provided by the invention comprises a lens base, a lens group and a ring-shaped light source, wherein the lens group is arranged in the lens base; the ring-shaped light source is arranged at the periphery of the lens base; the lens group comprises at least two lenses; the polarized skin lens also comprises a first polarized sheet arranged in the lens base, and a ring-shaped second polarized sheet arranged at the periphery of the lens base; the first polarized sheet is arranged between the lenses of the lens group; the second polarized sheet is arranged between the ring-shaped light source and a skin sample to be tested; and the second polarized sheet and the first polarized sheet are vertical on the polarization direction. The polarized skin lens does not need the infiltrated liquid, and has the characteristics of being small, convenient and simple and being easy in operation.

Owner:PEKING UNIV

Novel human epidermal culture method

The invention discloses a novel human epidermal culture method. The method includes the following steps of (1), skin sample treatment and cell separation; (2), culture of epidermal cells; (3), passage of the epidermal cells and stripping of tissue engineered skin; (4), quality inspection of the tissue engineered skin. A preparation method of a KMSFM culture medium includes: taking DSFM of Gibco as a basis; using low calcium ion concentration; adding bovine pituitary extract (BPE), bovine insulin, bovine transferrin, bFGF, cortisol, heparin and endothelin at the same time. By the novel human epidermal culture method, bovine serum is removed, mixing of non-human-derived ingredients can be reduced greatly, and cost and unsafe factors are reduced; a culture system coated by I-type collagen is used, cell growth slowness caused by removing of nourishing layer cells is avoided, and the novel human epidermal culture method can be used for treating skin pigment diseases such as leukoderma and giant pigmented nevus.

Owner:赫柏慧康生物科技无锡有限公司

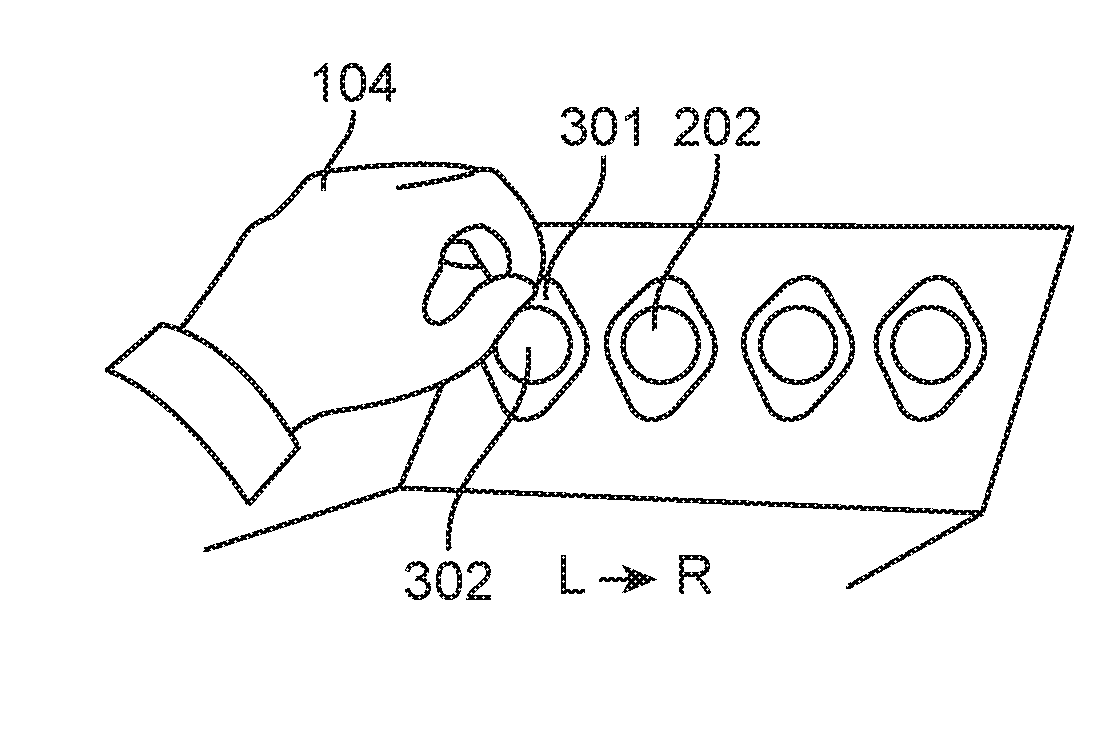

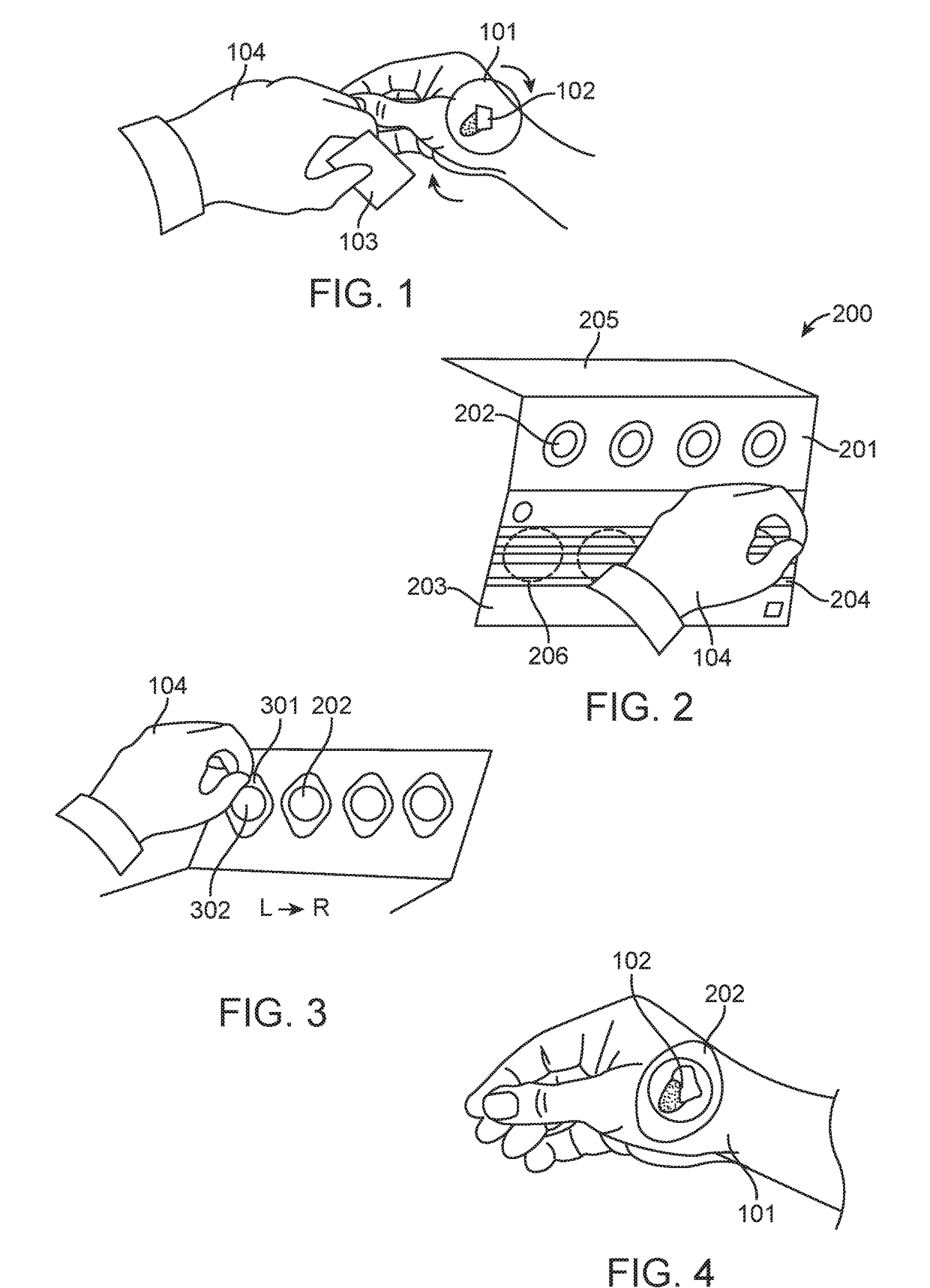

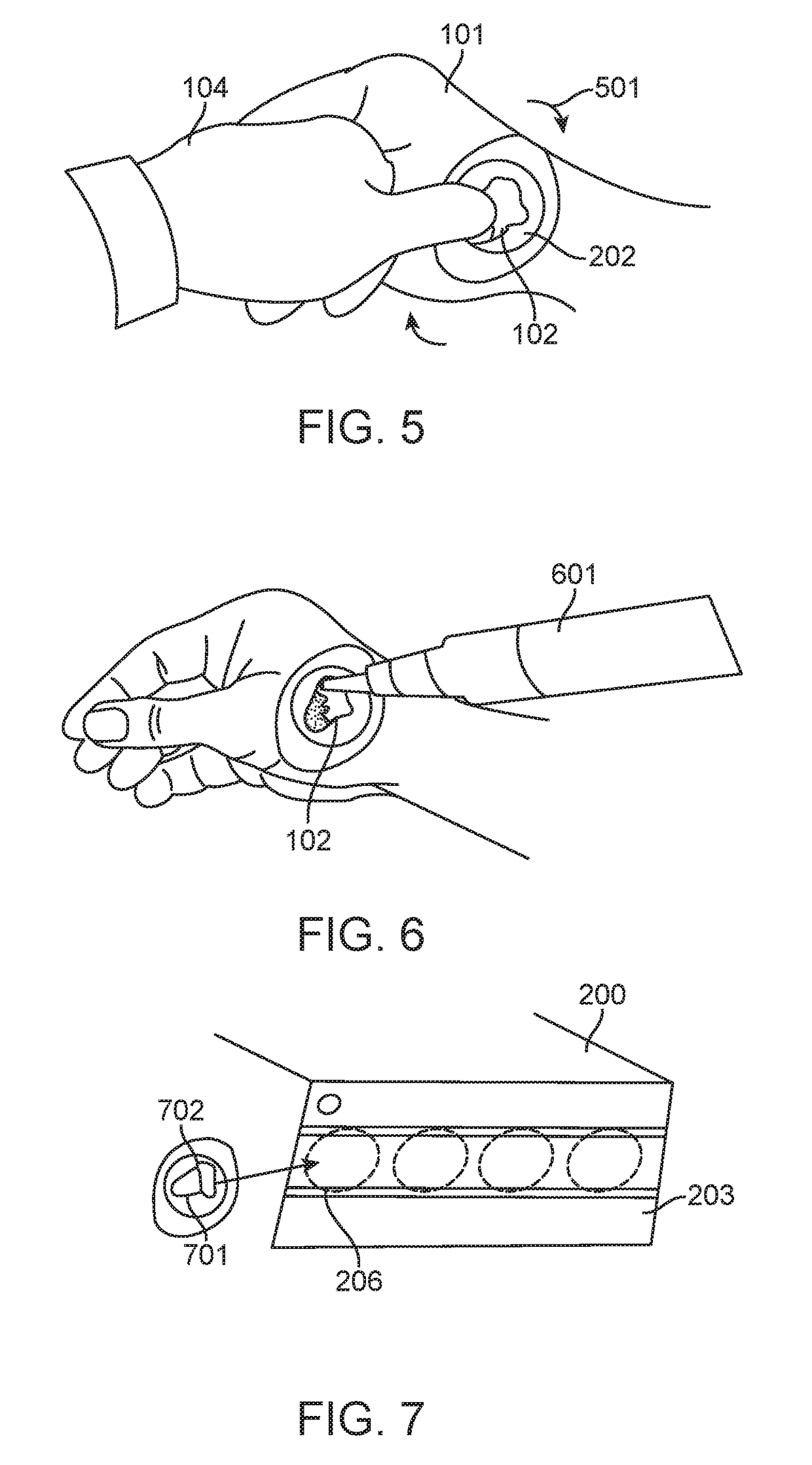

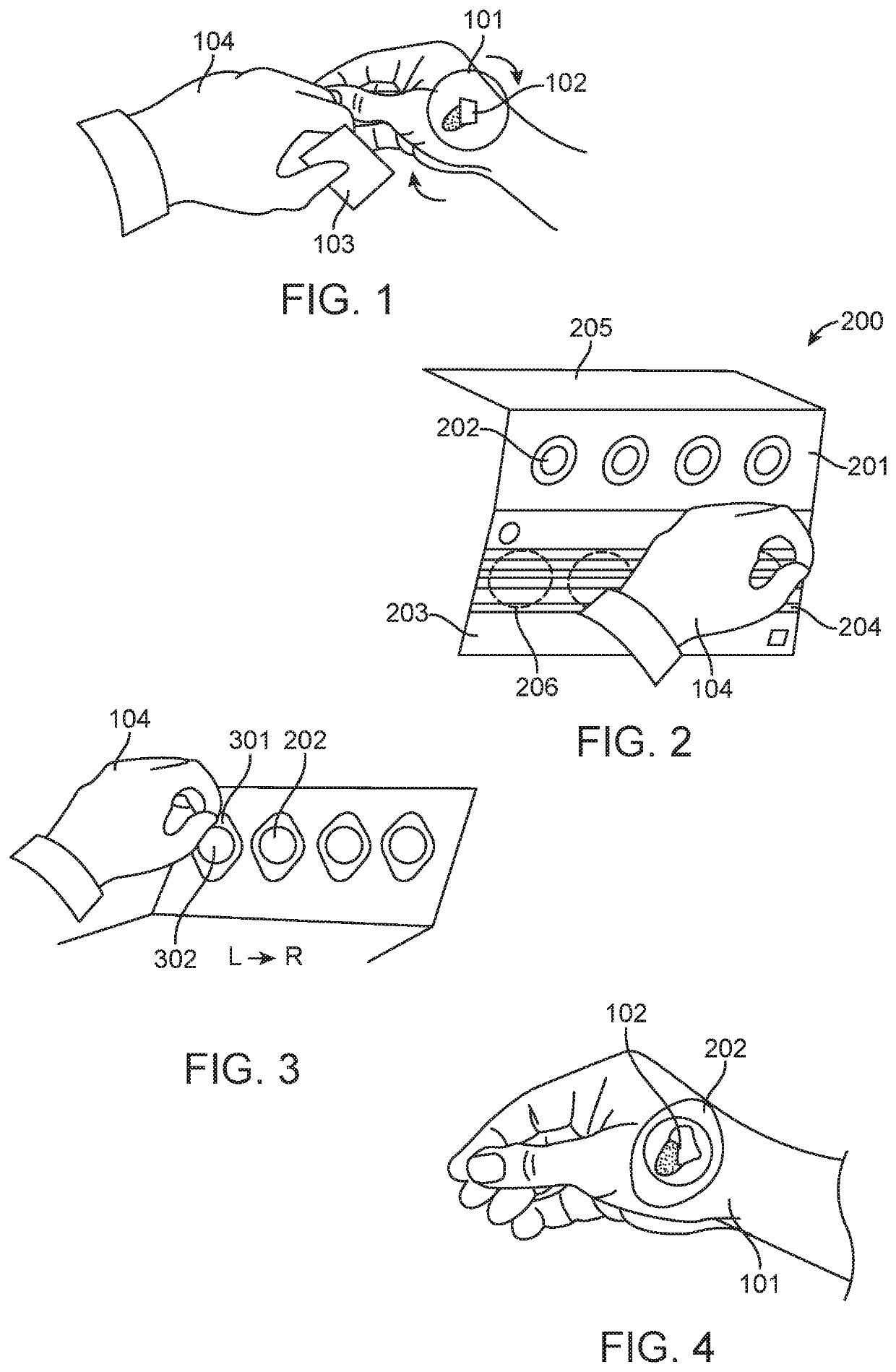

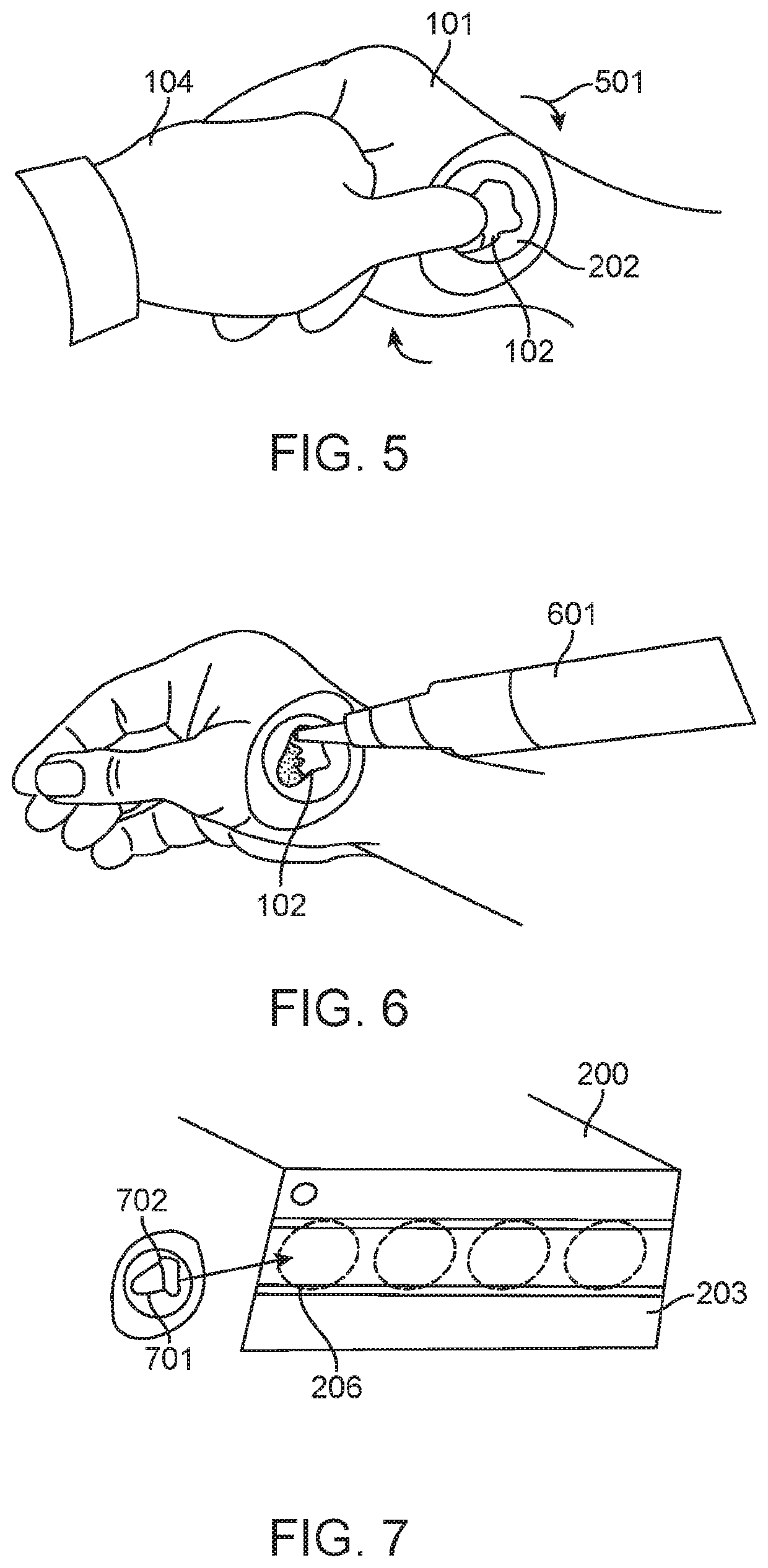

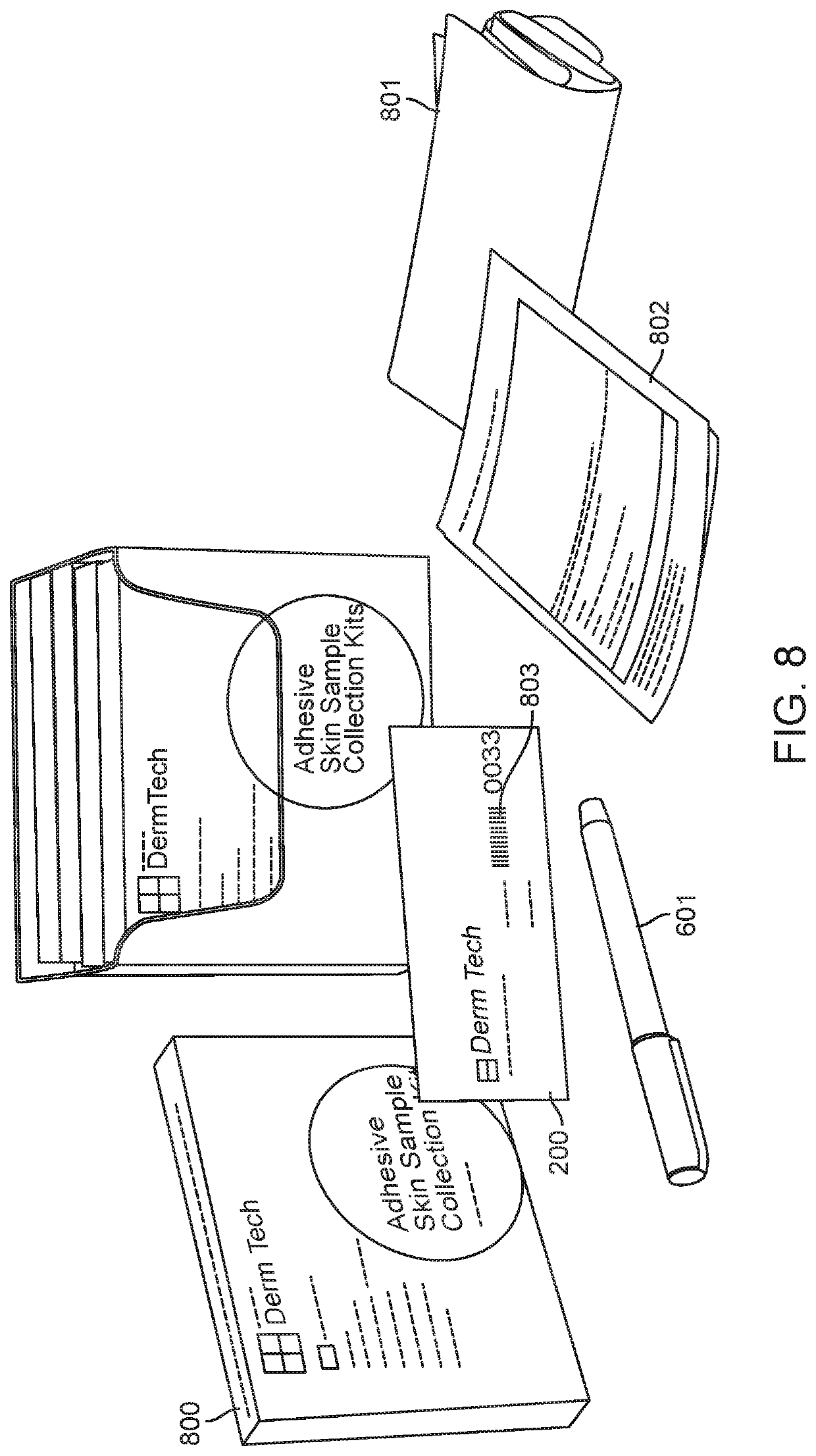

Non-invasive skin collection system

ActiveUS20180110500A1Reduced survival rateLow costSurgical furnitureSurgical needlesCollection systemSubject matter

The subject matter described herein provides non-invasive tape stripping methods for the collection of a skin sample. The tape stripping method includes applying and removing at least one adhesive tape, provided that a skin sample is adhered to the adhesive tape after removal. The at least one adhesive tape is supplied in an adhesive skin sample collection kit. The adhesive skin sample collection kit further comprises a sample collector and instructions for use sheet.

Owner:DERMTECH INC

Determining age ranges of skin samples

InactiveUS20150259739A1Reducing and increasing expression of geneReduce and increase expressionOrganic active ingredientsBiocideProtein profilingProtein molecules

The present invention provides methods for characterizing a skin sample of a subject as belonging to an age range by analyzing nucleic acid or protein molecules obtained from the subject. The methods include analyzing expression or mutations in epidermal samples, of one or more skin markers. The methods can include the use of a microarray to analyze gene or protein profiles from a sample and compare them with a known skin age index. Therapeutic and cosmetic formulations are also provided herein.

Owner:DERMTECH INT

Channeled tissue sample probe method and apparatus

InactiveUS20090318786A1Good optical performanceMinimizing sampling errorMaterial analysis by optical meansDiagnostic recording/measuringAnalyteTissue sample

Sampling is controlled in order to enhance analyte concentration estimation derived from noninvasive sampling. More particularly, sampling is controlled using controlled fluid delivery to a region between a tip of a sample probe and a tissue measurement site. The controlled fluid delivery enhances coverage of a skin sample site with the thin layer of fluid. Delivery of contact fluid is controlled in terms of spatial delivery, volume, thickness, distribution, temperature, and / or pressure.

Owner:GLT ACQUISITION

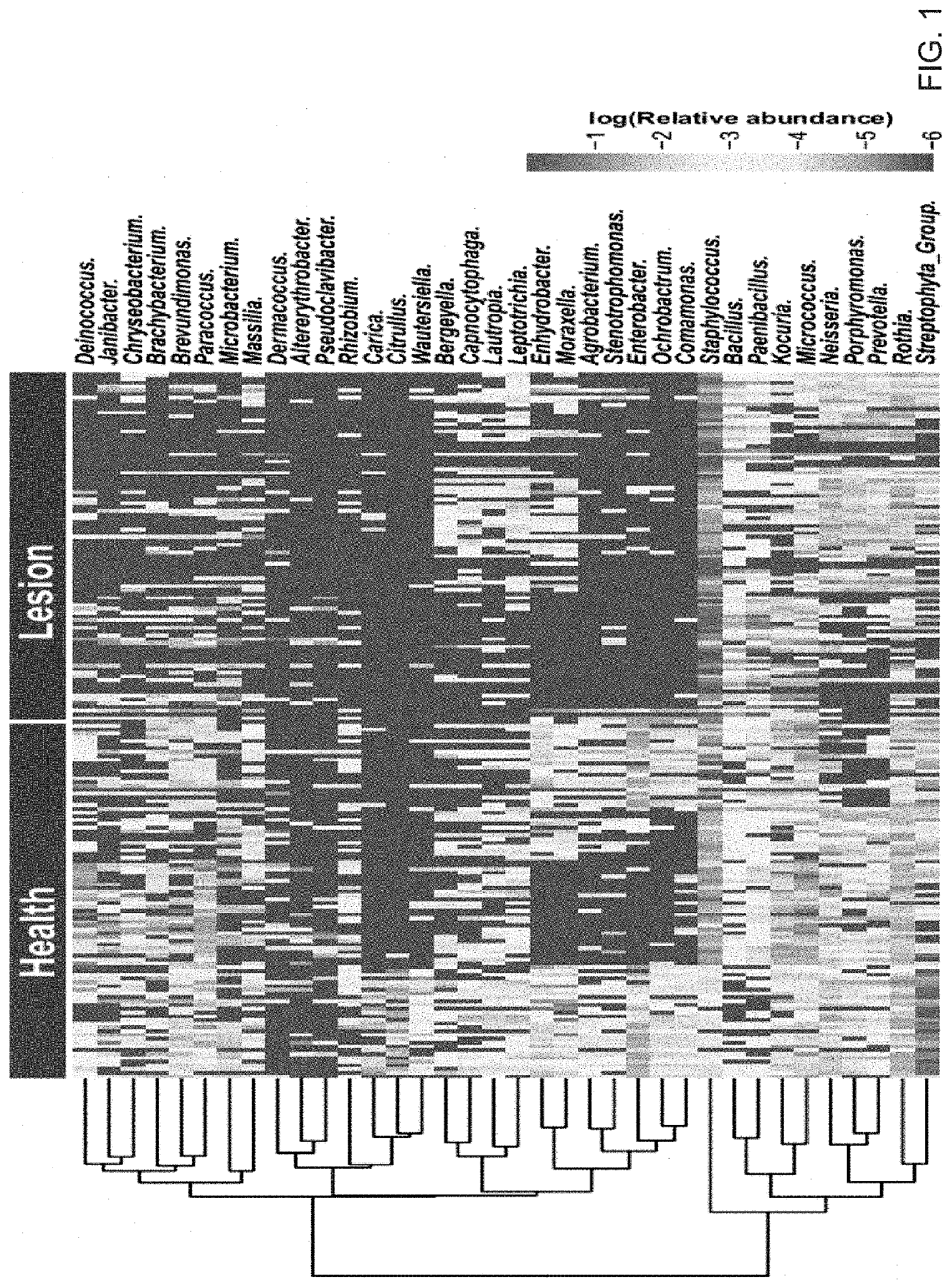

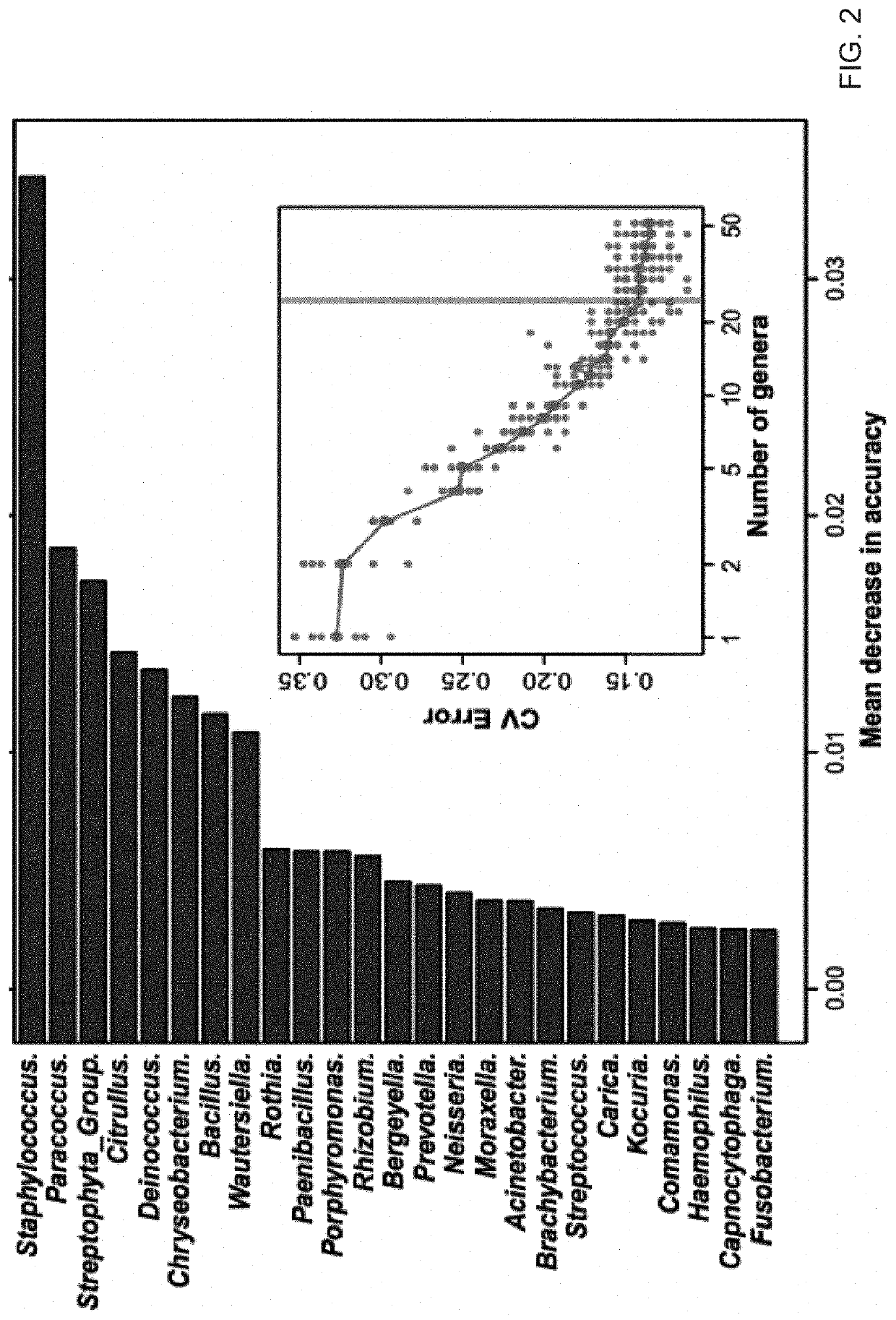

Method of Screening Skin Products

InactiveUS20200040373A1Effective treatmentMicrobiological testing/measurementDisease diagnosisMicroorganismHealth index

A method evaluating a skin cleansing composition for an ability to treat a skin condition, can include a) identifying a target skin condition or lack of target skin condition on a skin sample; b) taking a baseline measurement of a Microbial index of Skin Health via a Microbial index of Skin Health Method; c) performing a wash protocol with the cleansing composition via the Wash Protocol Method; and d) taking a second measurement of the Microbial Skin Health Measurement after the Wash Protocol; wherein an increase from the baseline Microbial Skin Health Index of 5 or more signifies the cleansing product is efficacious for treatment of the identified skin condition.

Owner:THE PROCTER & GAMBLE COMPANY

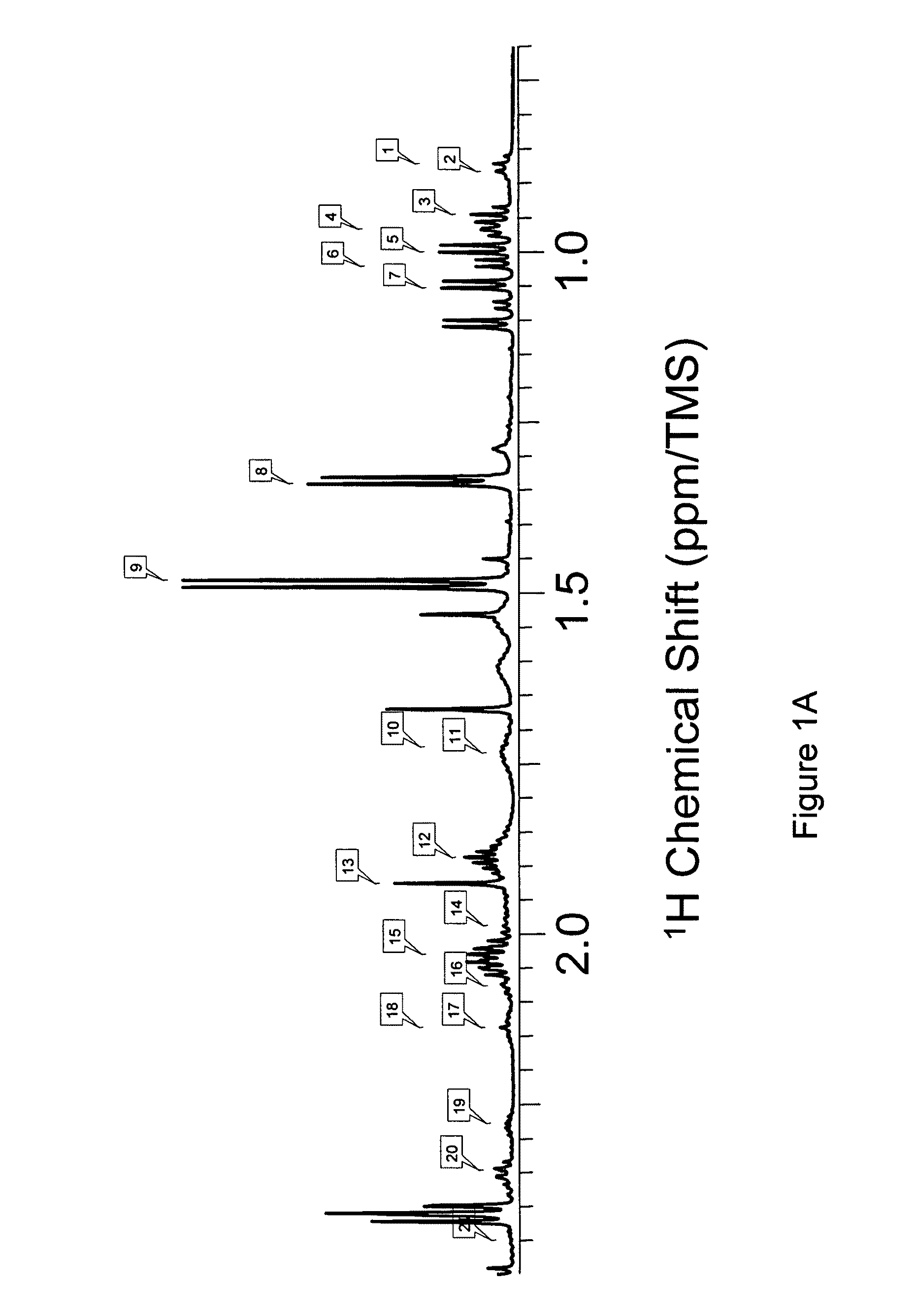

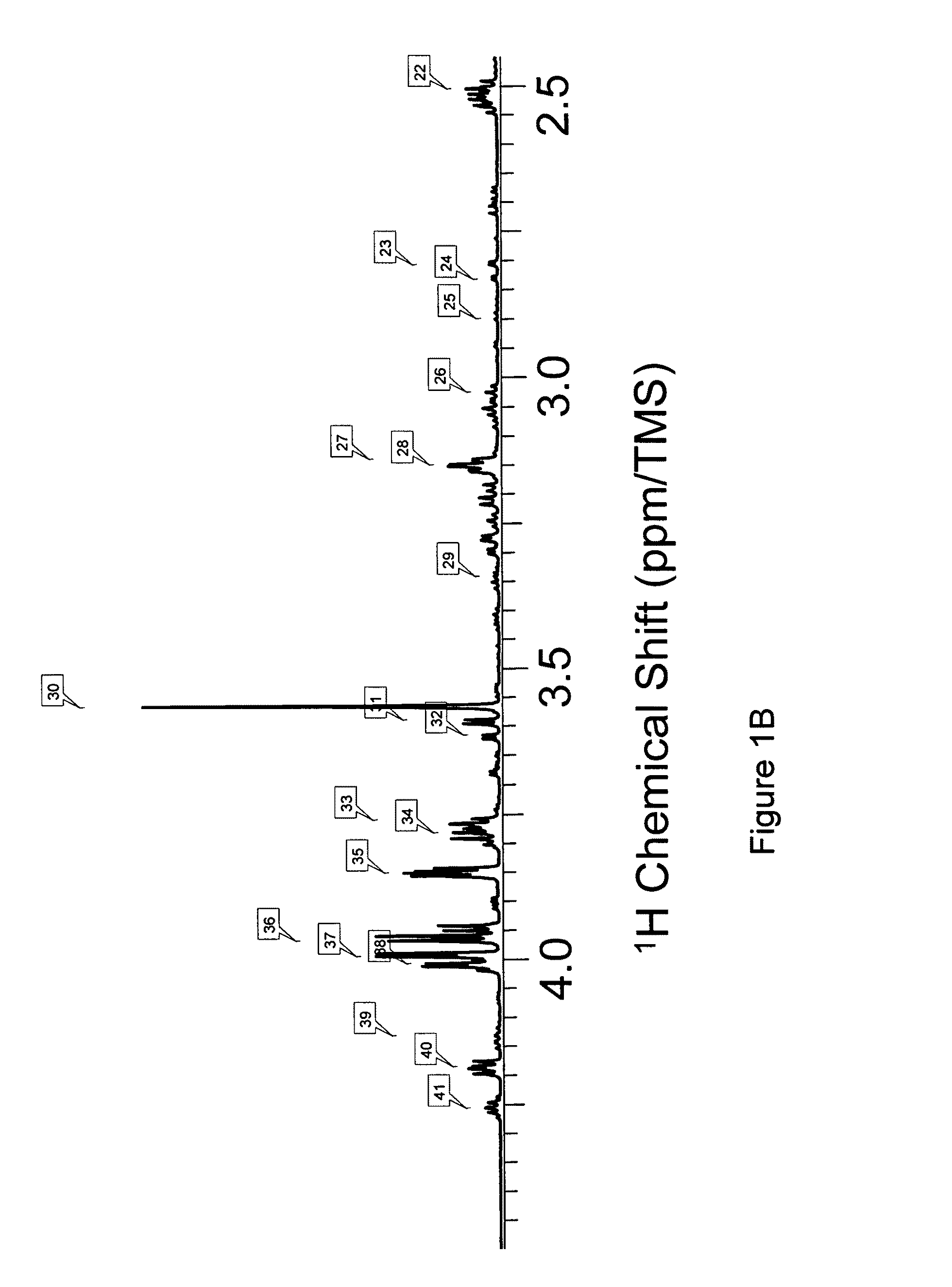

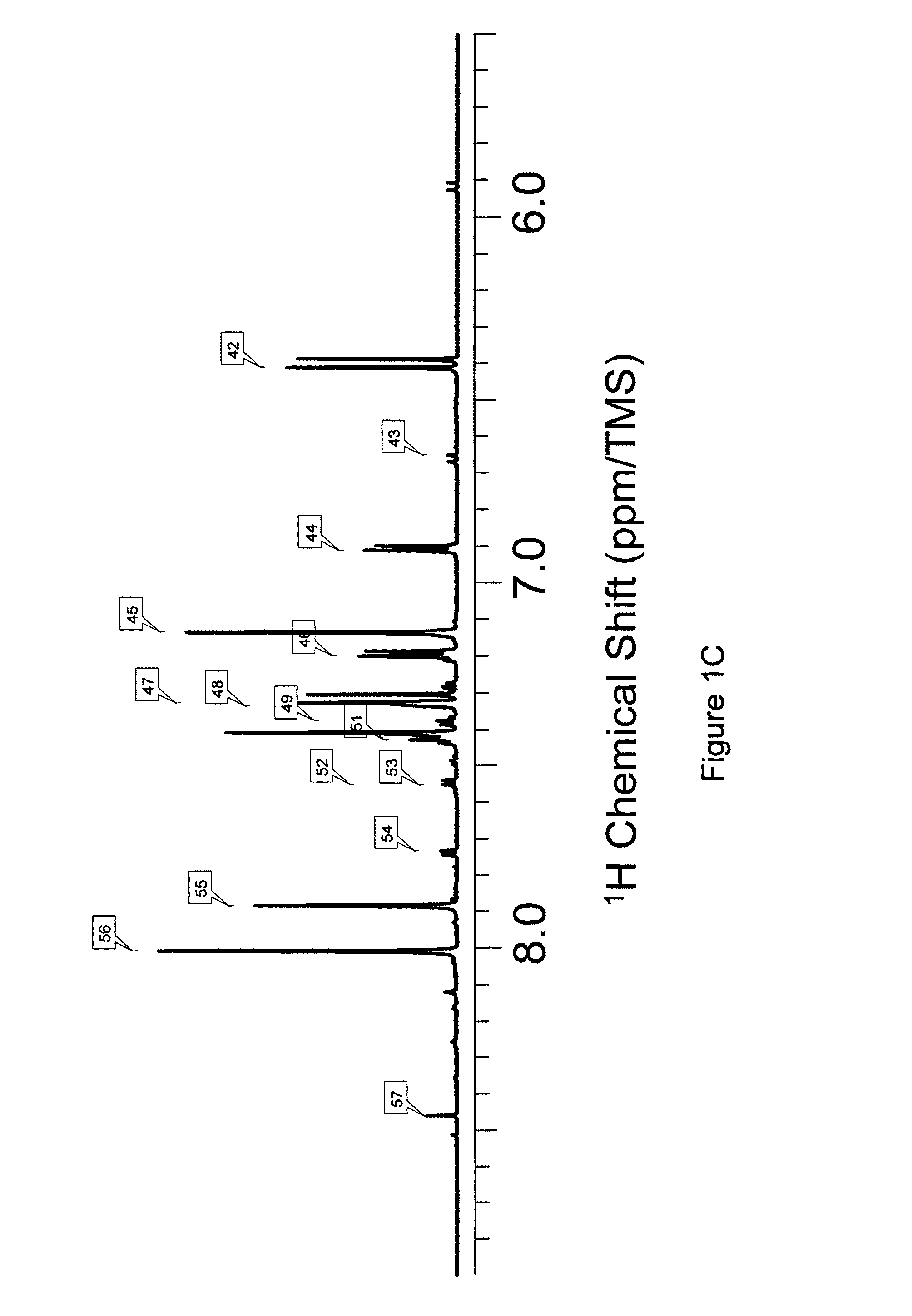

Noninvasive method for measuring metabolites for skin health

A noninvasive method for diagnosing skin health in a subject comprising collecting a skin sample from the subject; detecting a level of one or more small molecule biomarkers in the epithelial cell sample / skin cell sample; diagnosing the subject as having a skin condition based on the level of a detected small molecule biomarker, wherein the detected small molecule is at least one compound chosen from: a compound generated by metabolism of amino acids, a compound generated by dipeptides metabolism, a compound generated by nucleic acids, a compound generated by metabolism of lipids, a compound generated by metabolism of carbohydrates, and mixtures thereof and further small molecule biomarkers as listed in Table 1. Further, a noninvasive method for evaluating the efficacy of products for skin health.

Owner:THE PROCTER & GAMBLE COMPANY

Non-invasive skin collection system

PendingUS20200289099A1Reduced survival rateLow costSurgical furnitureSurgical needlesAdhesive beltCollection system

The subject matter described herein provides non-invasive tape stripping methods for the collection of a skin sample. The tape stripping method includes applying and removing at least one adhesive tape, provided that a skin sample is adhered to the adhesive tape after removal. The at least one adhesive tape is supplied in an adhesive skin sample collection kit. The adhesive skin sample collection kit further comprises a sample collector and instructions for use sheet.

Owner:DERMTECH INC

Metabonomic methods to assess health of skin

The present invention relates to methods of assessing the health of skin. Biomarkers are used to evaluate skin samples. Using metabonomics approaches, samples taken from different skin sites or at different times during a treatment are used to diagnose skin conditions or to appraise various skin treatments for efficacy.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com