Preparation method of single-crystal-morphology lithium ion battery positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high energy consumption, high raw material cost, complex synthesis process, etc., and achieve uniformity, low cost, and simple process. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

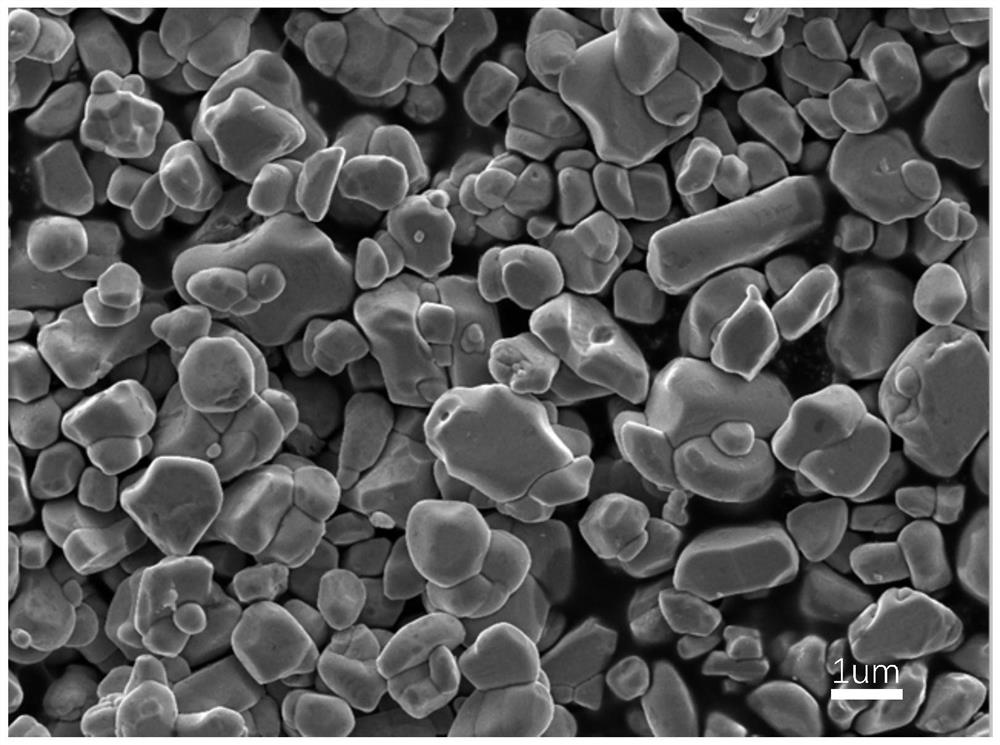

[0040] A preparation method of a single crystal morphology lithium ion battery cathode material of the present invention, comprising the following steps:

[0041] (1) Add sodium hydroxide solution and pure water as bottom water in the reaction kettle to make the bottom water pH=13;

[0042] (2) Turn on the stirring, feed nitrogen, and 2mol / L nickel sulfate, cobalt sulfate, manganese sulfate mixed salt solution (the metal molar ratio is Ni:Co:Mn=83:11:6) and 10mol / L hydroxide The sodium solution is pumped into the reactor in parallel, wherein the flow of the metal mixed salt solution is 120ml / min, the flow of the sodium hydroxide solution is 50ml / min, and the reaction temperature T=40°C is controlled in the reactor. After 12 hours of reaction, the aging chemical washing to obtain the precursor slurry; take a small amount of precursor slurry to dry to detect the specific surface area, and the specific surface area of the detected precursor is 135m 2 / g;

[0043] (3) Mix the ...

Embodiment 2

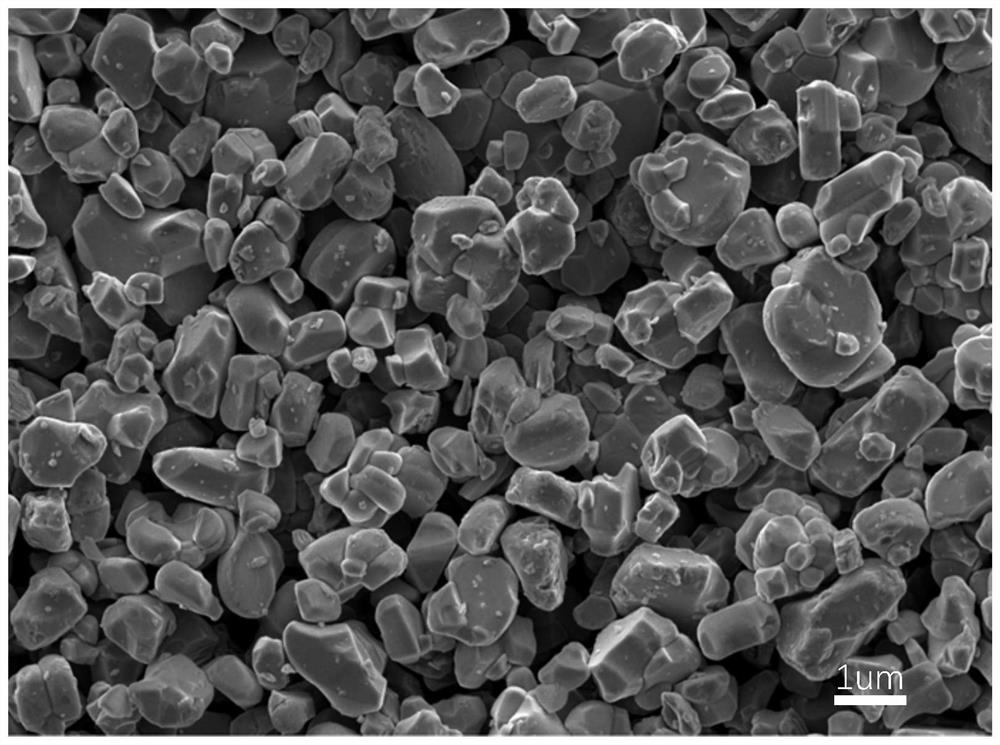

[0050] A preparation method of a single crystal morphology lithium ion battery cathode material of the present invention, comprising the following steps:

[0051] (1) Add sodium hydroxide solution and pure water as bottom water in the reactor, control bottom water pH=12.8;

[0052] (2) Open stirring, pass into nitrogen, mix the sodium hydroxide solution of 2mol / L nickel sulfate, cobalt sulfate, manganese sulfate mixed salt solution (molar ratio Ni:Co:Mn=65:15:20) and 10mol / L Flow is pumped into the reaction still, wherein, the flow of metal mixed salt solution is 100ml / min, the flow of sodium hydroxide solution is 41ml / min, when controlling reaction temperature T=40 ℃, after reacting for 14.5h, carry out aging washing, Obtain the precursor slurry; take a small amount of precursor slurry and dry it to detect the specific surface area, and the specific surface area of the detected precursor is 128m 2 / g;

[0053] (3) Mix the precursor slurry with coarse lithium carbonate (D5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com