Method for recycling anode material of lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in the field of cathode material recycling of lithium ion batteries, can solve the problems of easily destroying the specific active structure of cathode materials, single metal and its compounds, and physical or chemical pollution, etc., and achieves environmental friendliness. , High production efficiency and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

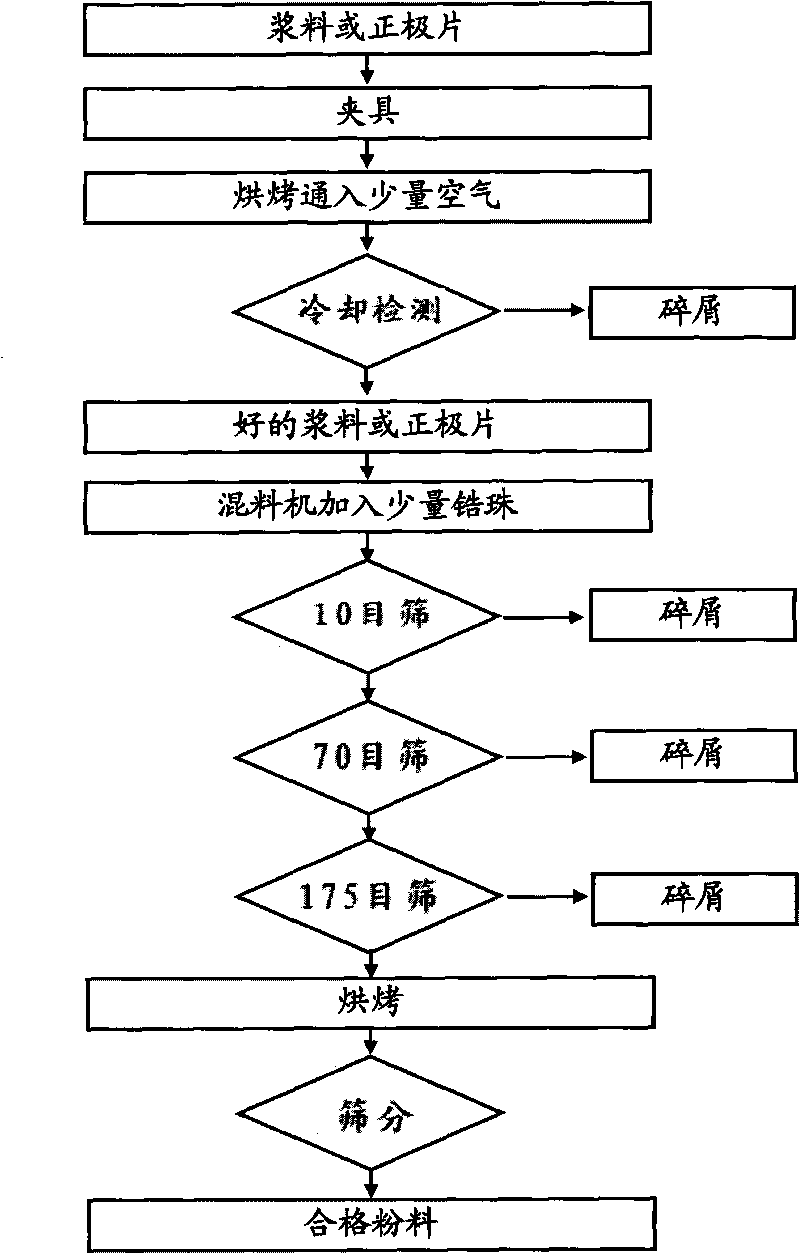

[0034] Embodiment 1: Slurry recovery method.

[0035] First, the dry slurry (which can be one or more of lithium cobaltate, lithium nickel cobalt manganese, lithium nickel cobalt aluminum, lithium iron phosphate, conductive carbon) is crushed into particles with a particle size of less than 10mm, and then paved Put it on a plate and put it in a high-temperature furnace (such as a muffle furnace) for high-temperature baking. The temperature of the muffle furnace can be raised to 400-600°C first, or the temperature can be raised to 400-600°C after the powder is put in. During the baking process, a small amount of air can be introduced into the oven to create an oxygen-enriched atmosphere. . After baking, take out the processed powder and cool it down, then pulverize it in a pulverizer for 10-60 minutes, and then sieve the powder with a 10-mesh to 200-mesh sieve machine, and the powder that can pass through a 200-mesh sieve is recyclable Qualified powder can be directly package...

Embodiment 2

[0036] Embodiment 2: Lithium cobalt oxide pole piece recovery method.

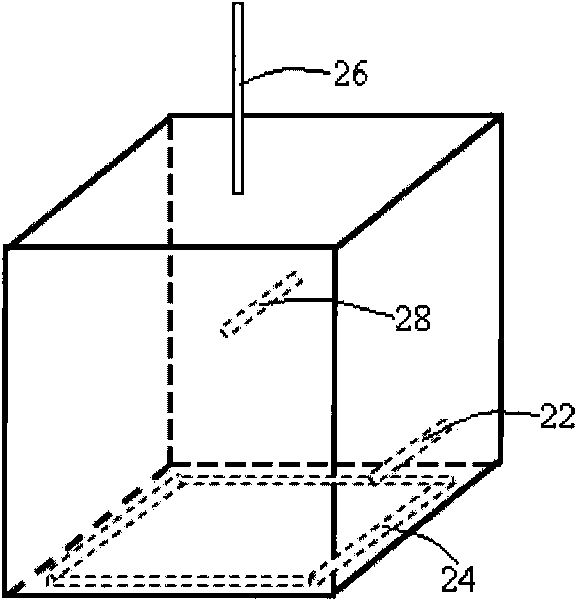

[0037] First of all, the lithium cobalt oxide pole pieces to be recovered are used or not with clamps (such as image 3 Shown) placed in a container (such as a plate) after finishing, and then put the plate into a high-temperature furnace (such as a muffle furnace) for high-temperature baking. The temperature of the muffle furnace can be raised to 400-600°C first, or the temperature can be raised to 400-600°C after putting in the materials. During the baking process, a small amount of air can be fed into the high-temperature furnace or not to create an oxygen-enriched atmosphere. After the baking is finished, take out the pole pieces to cool down, then use a mixer to add or not add zirconium glass beads for powder removal, and then sieve the processed pole piece powder with a 10-mesh to 200-mesh powder sieving machine and discharge it. The powder that can pass through the 200-mesh sieve is recyclable qual...

Embodiment 3

[0039] Embodiment 3: Lithium nickel cobalt manganese pole piece recovery method.

[0040] The process parameters and process are the same as those in Example 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com