Method for preparing ternary anode material precursor from waste lithium battery anode pieces

A technology for used lithium batteries and positive electrode sheets, which is applied in battery electrodes, electrical components, battery recycling, etc., can solve the problems of high cost and slightly toxic organic solvents, enhance structural stability, simplify recycling processes, and improve electricity. Effects of Chemical Properties and Cycling Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

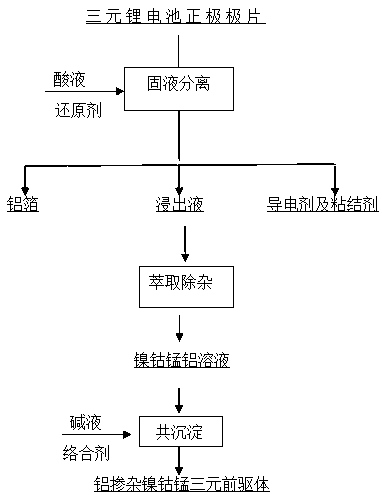

[0022] The method for preparing the precursor of the ternary positive electrode material by utilizing the positive electrode sheet of the waste lithium battery, the steps are as follows:

[0023] Take 20g of the positive electrode tape of the waste ternary lithium-ion battery and immerse it in 1L of sulfuric acid solution with a concentration of 3mol / L. The active material of the positive electrode is completely peeled off from the aluminum foil current collector, and the aluminum foil is taken out for recycling. Add 0.5 L of 1.5 mol / L sodium thiosulfate solution to the acid solution, stir and leaching at 60°C for 80 minutes, filter after leaching to obtain a mixed solution of nickel, cobalt, manganese, lithium, and aluminum sulfate. Use sodium hydroxide solution to adjust the pH value of the solution to 3.0, extract with P204, use the raffinate as the raw material solution after two-stage extraction, and adjust the content of nickel, cobalt, and manganese ions to make it meet ...

Embodiment 2

[0025] The method for preparing the precursor of the ternary positive electrode material by utilizing the positive electrode sheet of the waste lithium battery, the steps are as follows:

[0026] Take 30g of the positive electrode tape of the waste ternary lithium-ion battery and immerse it in 1L hydrochloric acid solution with a concentration of 0.5mol / L. The active material of the positive electrode is completely peeled off from the aluminum foil current collector, and the aluminum foil is taken out for recycling. Add 0.6 L of hydrogen peroxide solution with a concentration of 0.3 mol / L to the acid solution, stir and leach for 50 minutes at 40°C, filter after leaching to obtain a mixed solution of nickel, cobalt, manganese, lithium, and aluminum sulfate. Use sodium hydroxide solution to adjust the pH value of the solution to 3.5, extract with P204, and use the raffinate as the raw material solution after the three-stage extraction to adjust the content of nickel, cobalt, and ...

Embodiment 3

[0028] The method for preparing the precursor of the ternary positive electrode material by utilizing the positive electrode sheet of the waste lithium battery, the steps are as follows:

[0029] Take 40g of the positive electrode tape of the waste ternary lithium-ion battery and immerse it in 3L of nitric acid solution with a concentration of 1mol / L. The active material of the positive electrode is completely peeled off from the aluminum foil current collector, and the aluminum foil is taken out for recycling. Add 1 L of sodium sulfite solution with a concentration of 1 mol / L to the acid solution, stir and leach for 40 minutes at 70°C, filter after leaching to obtain a mixed solution of nickel, cobalt, manganese, lithium, and aluminum sulfate. Use sodium hydroxide solution to adjust the pH value of the solution to 4.0, extract with P507, use the raffinate as the raw material solution after two-stage extraction, and adjust the content of nickel, cobalt, and manganese ions to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com