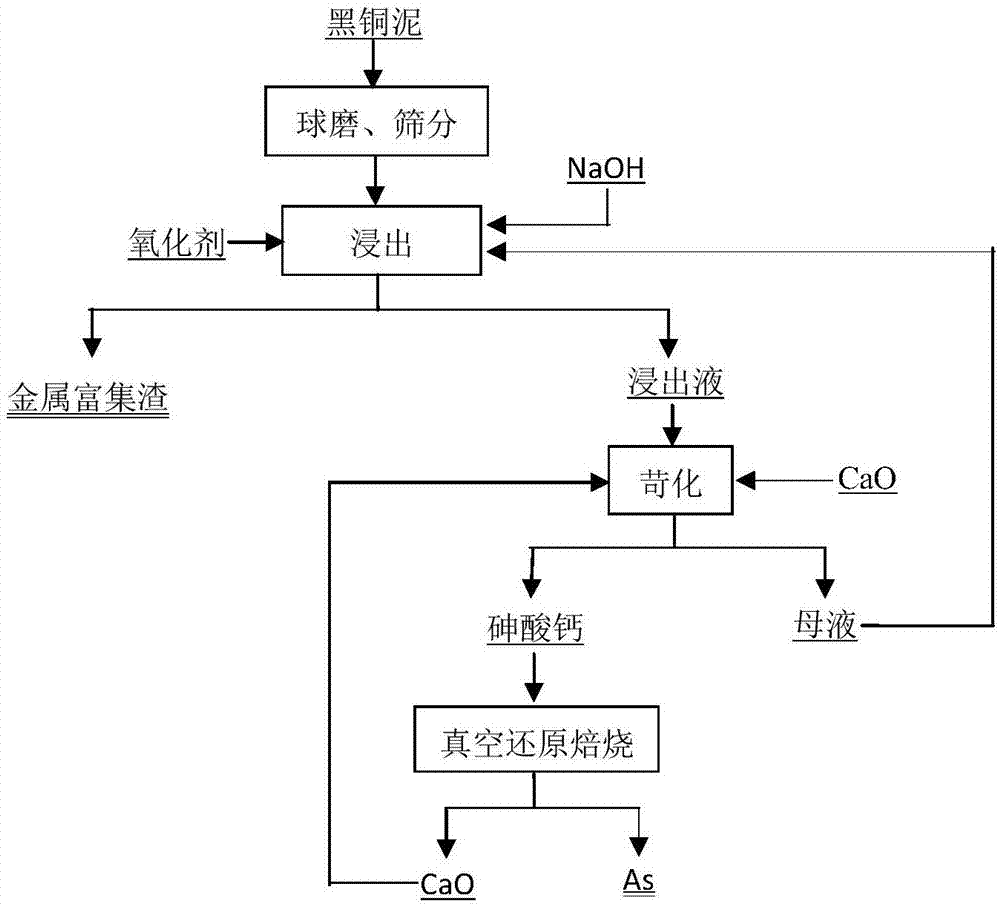

Method for recovering arsenic from black copper sludge

A black copper slime and arsenic recovery technology, which is applied in the treatment of black copper slime and the cleaning treatment of arsenic-containing black copper slime, can solve the problems of potential safety hazards, arsenic dispersion, high cost, etc., and achieve the goal of reducing production costs and avoiding arsenic The effect of accumulation, efficient separation and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get 100kg black copper mud (specific composition is Cu: 30.07%, As: 28.17%, Sb: 2.56%, Bi: 1.49%; Black copper mud phase is mainly Cu 2 As and Cu 3 As) carry out alkaline pressurized oxidation leaching, the leaching process controls sodium hydroxide 1.5mol / L, oxygen pressure 1.0MPa, temperature 120°C, liquid-solid ratio 5:1, reaction time 1.5h, stirring speed 500rpm, after the reaction, Liquid-solid separation is carried out while hot, the leaching slag is copper-enriched slag, the leaching rate of arsenic is 98.78%, and copper is not leached. Add an appropriate amount of lime (Ca / As molar ratio = 1.5) to the leaching solution, and conduct causticization under the conditions of temperature 80°C, time 1h, and stirring speed 300rpm. After the causticization is completed, liquid-solid separation is carried out while it is hot, and the solid phase is arsenic acid Calcium and lye are returned to the pressurized oxidation leaching process, and the precipitation rate of arsen...

Embodiment 2

[0029] Get 100kg black copper mud (specific composition is Cu: 30.07%, As: 28.17%, Sb: 2.56%, Bi: 1.49%; Black copper mud phase is mainly Cu 2 As and Cu 3 As) carry out alkaline oxidation leaching under normal pressure, add appropriate amount of hydrogen peroxide during the leaching process, control sodium hydroxide 2mol / L, temperature 80°C, liquid-solid ratio 7:1, reaction time 2h, stirring speed 400rpm, after the reaction is over, carry out while it is hot Liquid-solid separation, the leaching slag is copper-enriched slag, the leaching rate of arsenic is 94.15%, and copper is not leached. Add an appropriate amount of lime (Ca / As molar ratio = 1.5) to the leaching solution, and conduct causticization under the conditions of temperature 80°C, time 1h, and stirring speed 300rpm. After the causticization is completed, liquid-solid separation is carried out while it is hot, and the solid phase is arsenic acid Calcium and lye are returned to the pressurized oxidation leaching pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com