Treatment process for recycling water in pulping and papermaking wastewater

A technology of pulping and papermaking and treatment process, which is applied in the direction of waste water treatment in the processing process, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. The effect of simple process and simple management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

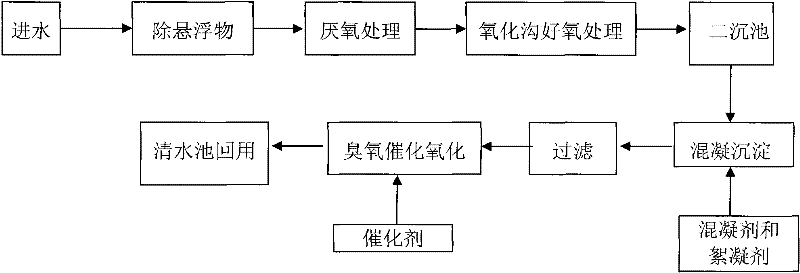

[0057] A trial production test was carried out on the pulping wastewater produced by a pulp and paper mill (see attached figure 1 ), the design water volume of the system is 1800m 3 / d. Influent water (most of the data) indicators are: COD is 3000-4000mg / L, BOD is 800-1300mg / L, SS is 600-800mg / L, and chroma is 300-450 times.

[0058] Pulping and papermaking wastewater water reuse treatment process: the pulping and papermaking wastewater is treated by anaerobic treatment after removal of suspended solids, then aerobic treatment by oxidation ditch, and then enters the secondary settling tank for sedimentation to separate mud and water, and then coagulates and settles , filter, and then carry out ozone catalytic oxidation treatment; wherein,

[0059] The removal of suspended solids is through coagulation reaction and primary sedimentation treatment: the dosage of polyaluminum chloride in the coagulation reaction is 250mg / L, the dosage of polyacrylamide is 2mg / L, and the reactio...

Embodiment 2

[0069] A trial production test was carried out on the production wastewater of a pulp and paper mill. The design water volume of the system is 3000m 3 / d. Influent water (most of the data) indicators are: COD is 2500-3500mg / L, BOD is 700-1000mg / L, SS is 500-800mg / L, and chroma is 280-400 times.

[0070] Pulping and papermaking wastewater water reuse treatment process: the pulping and papermaking wastewater is treated by anaerobic treatment after removal of suspended solids, then aerobic treatment by oxidation ditch, and then enters the secondary settling tank for sedimentation to separate mud and water, and then coagulates and settles , filter, and then carry out ozone catalytic oxidation treatment; wherein,

[0071] The removal of suspended solids is through coagulation reaction and primary sedimentation treatment: the dosage of polyaluminum chloride in the coagulation reaction is 200mg / L, the dosage of polyacrylamide is 2mg / L, and the reaction time is 25min, the sedimentat...

Embodiment 3

[0081] A trial production test was carried out on the production wastewater of a pulp and paper mill. The design water volume of the system is 3500m 3 / d. Influent water (most of the data) indicators are: COD is 2000-3000mg / L, BOD is 600-1000mg / L, SS is 400-700mg / L, and chroma is 250-400 times.

[0082] Pulping and papermaking wastewater water reuse treatment process: the pulping and papermaking wastewater is treated by anaerobic treatment after removal of suspended solids, then aerobic treatment by oxidation ditch, and then enters the secondary settling tank for sedimentation to separate mud and water, and then coagulates and settles , filter, and then carry out ozone catalytic oxidation treatment; wherein,

[0083] The removal of suspended solids is through coagulation reaction and air flotation treatment: the dosage of polyferric sulfate in the coagulation reaction is 180mg / L, and the dosage of polyacrylamide is 2mg / L , the reaction time is 20min, the residence time of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com