Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Low construction and operation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

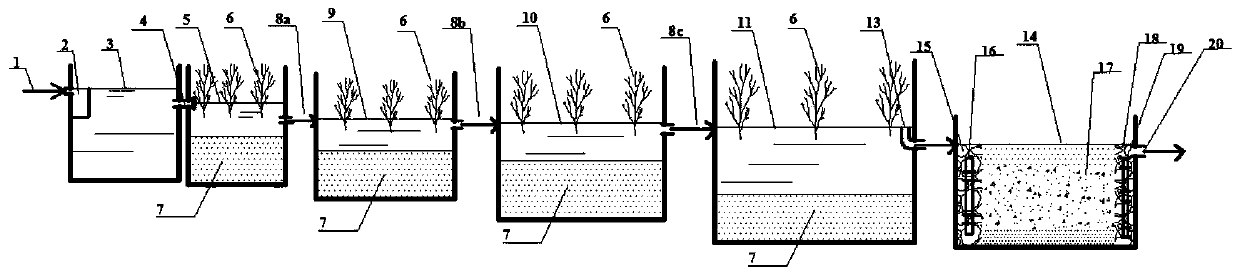

Ecological combined treatment method and device for rural distributed sewage

InactiveCN103880257AEfficient purificationImprove processing efficiencyMultistage water/sewage treatmentConstructed wetlandBiological filter

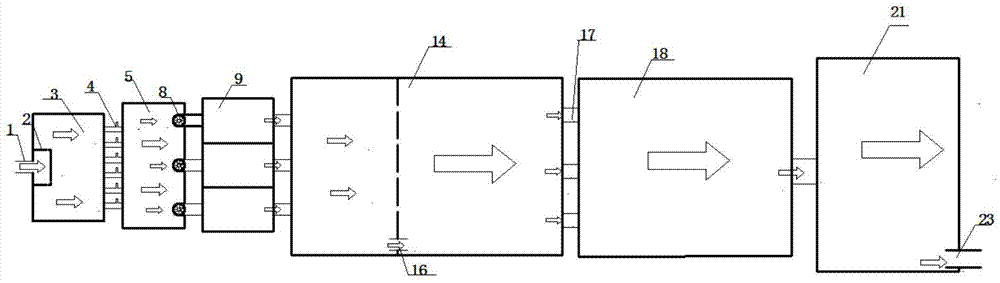

The invention discloses an ecological combined treatment method and device for rural distributed sewage. The method comprises the steps of A) rural sewage collection and pretreatment; B) treatment by a biological filter; C) treatment by an artificial wetland and a stabilization pond; D) ecological landscape configuration. The device is characterized in that a main water inlet pipeline is respectively connected with a lattice pool and a regulation pool, the regulation pool is connected with a horizontal flow biological filter through a water distribution pipe, the horizontal flow biological filter is connected with a vertical flow biological filter through a filter screen-water distribution pipe, the vertical flow biological filter is connected with a first-level artificial wetland via a perforated water collection pipe which is horizontally arranged, the first-level artificial wetland is connected with a second-level artificial wetland through an overflow weir, the second-level artificial wetland is connected with the stabilization pond through a straight flow water drain pipe, and a main water drain pipe is arranged at the tail end of the stabilization pond. According to the method, energy consumption is not required, the operation and the maintenance are simple and convenient, and the method further has the advantages of landscape effect, economic benefits, simple structure and low investment; high-efficient purification of rural distributed domestic and farming sewage is realized, and the removal rate of nitrogen, phosphorus, COD and the like in sewage is above 80% after treatment.

Owner:大长江环境工程技术有限责任公司

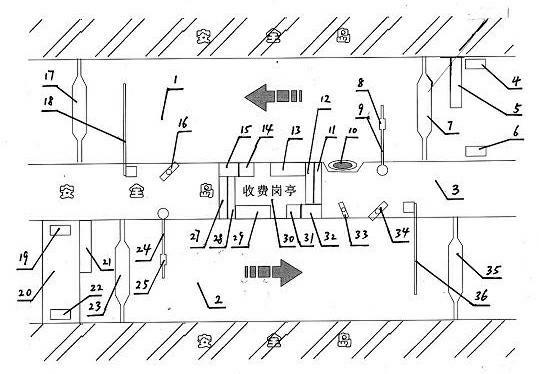

Multi-functional toll collection lane controlling and managing system of toll road

InactiveCN102184580ASafe and fast passSpeed up rapid transit capacityTicket-issuing apparatusToll roadTraffic capacity

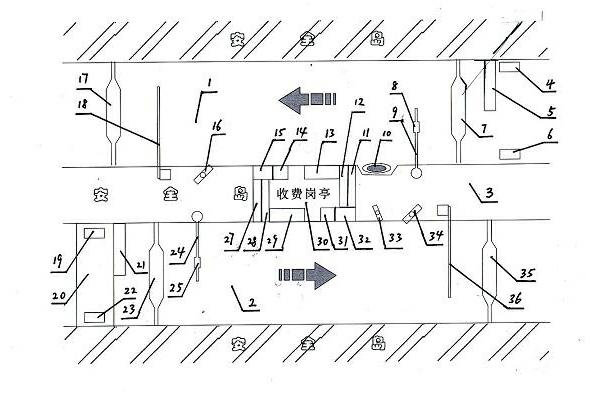

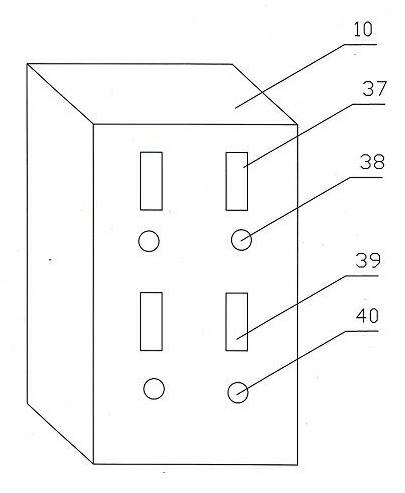

The invention discloses a multi-functional toll collection lane controlling and managing system of toll roads. An industrial personal computer, a car controlled machine, an IC (integrated circuit) card reader, a toll special keyboard and a display screen at an entrance lane direction are arranged in a toll booth; an entrance lane IC card automatic card sender and an entrance lane full-automatic toll data wireless emitter / receiver are arranged at the right side of the toll booth; the industrial personal computer, the car controlled machine, the IC card reader, the toll special keyboard and the display screen at an exit lane direction are arranged in the toll booth; and an exit lane full-automatic toll data wireless emitter / receiver is arranged at the left side of the toll booth. The system of the invention can organically combine three functions of manual toll lane, ETC (electronic toll collection) lane and automatic card sending and reading lane, so that various of vehicles can pass through the entrance and exit lanes of the toll station in a short time; and the system can disperse the vehicles on the square to a maximum extent without building new lanes. The system is safe and quick. In addition, the system can accelerate vehicle traffic capacity and reduce labor intensity of the toll staff.

Owner:王铁中

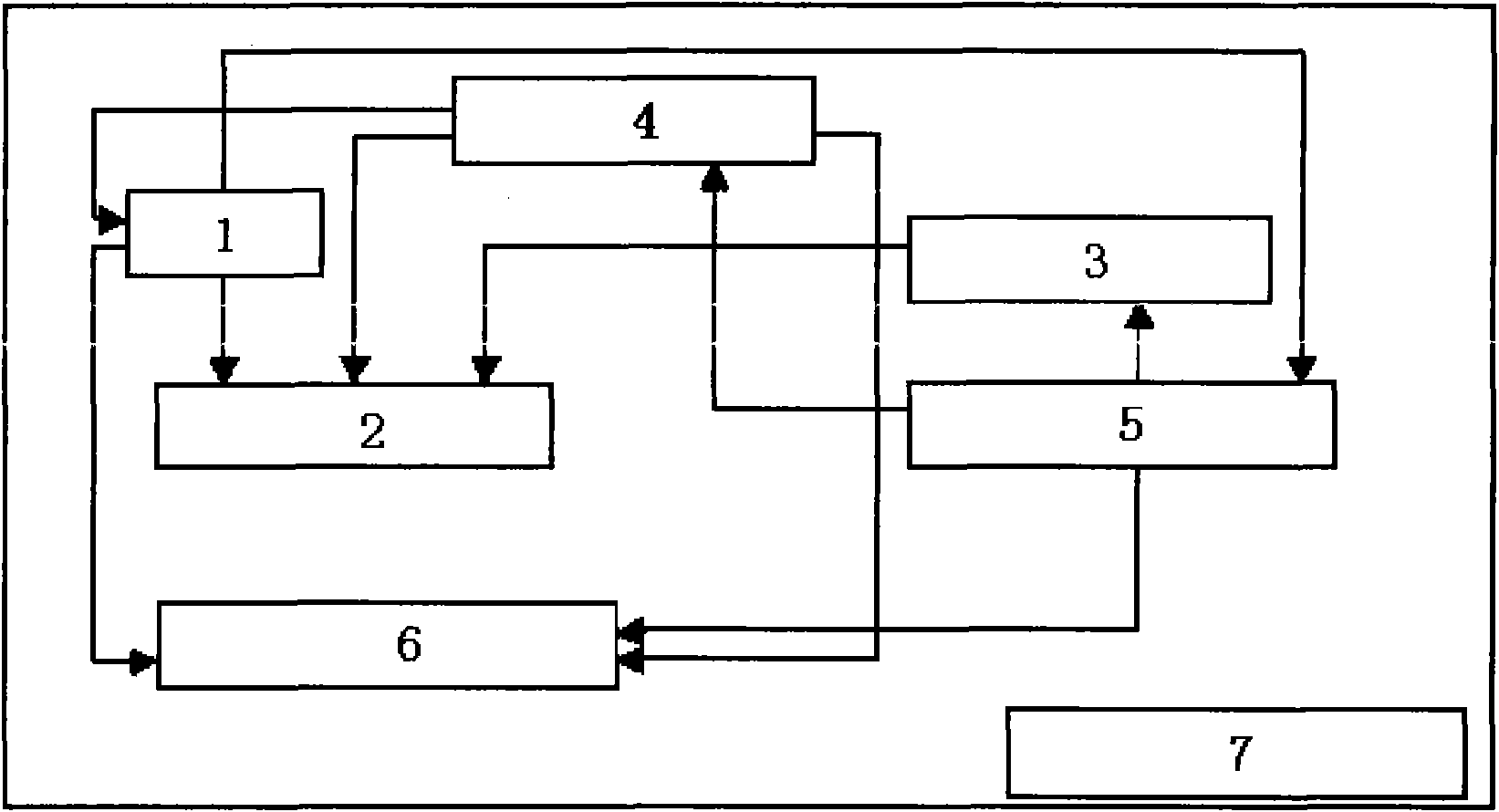

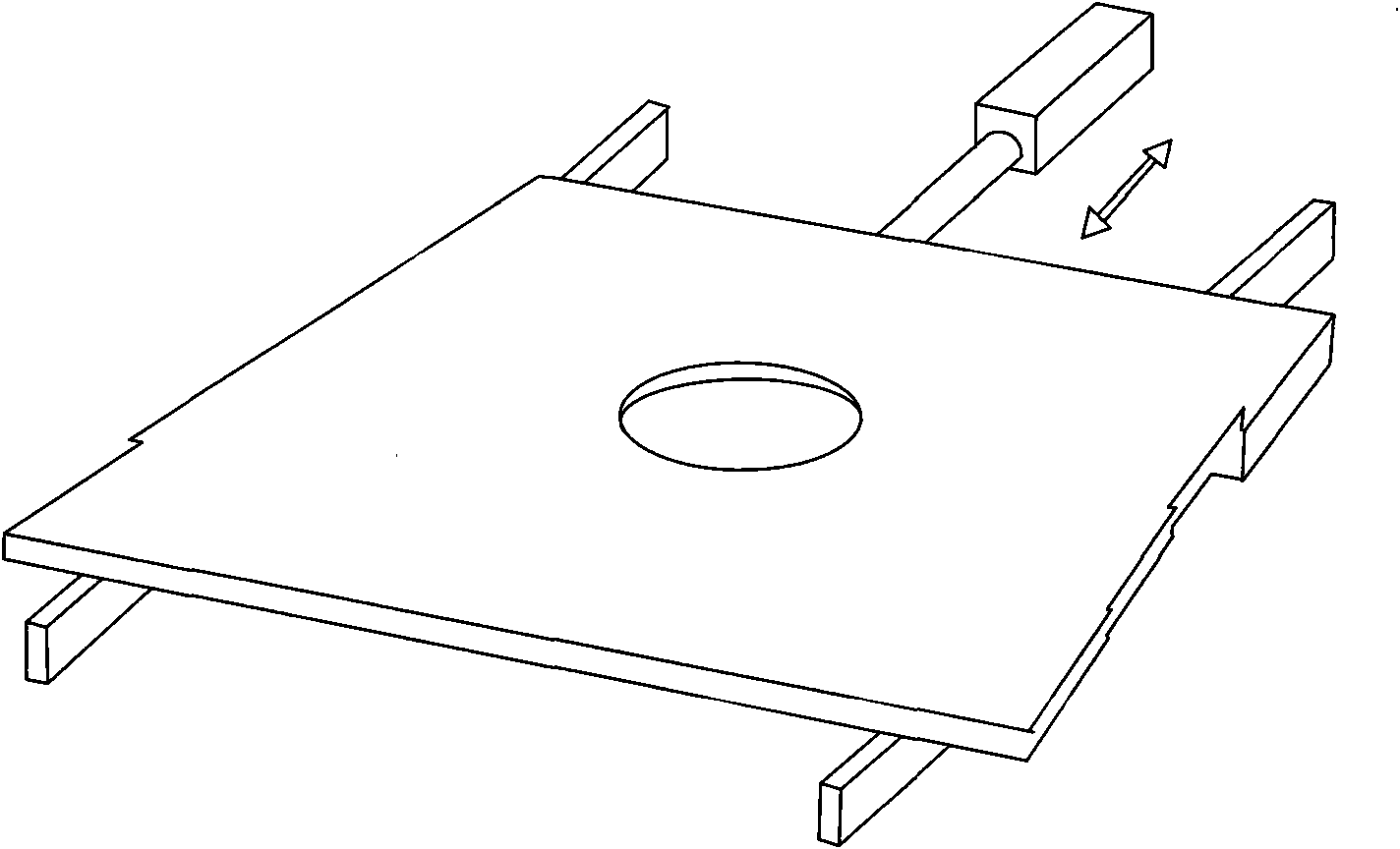

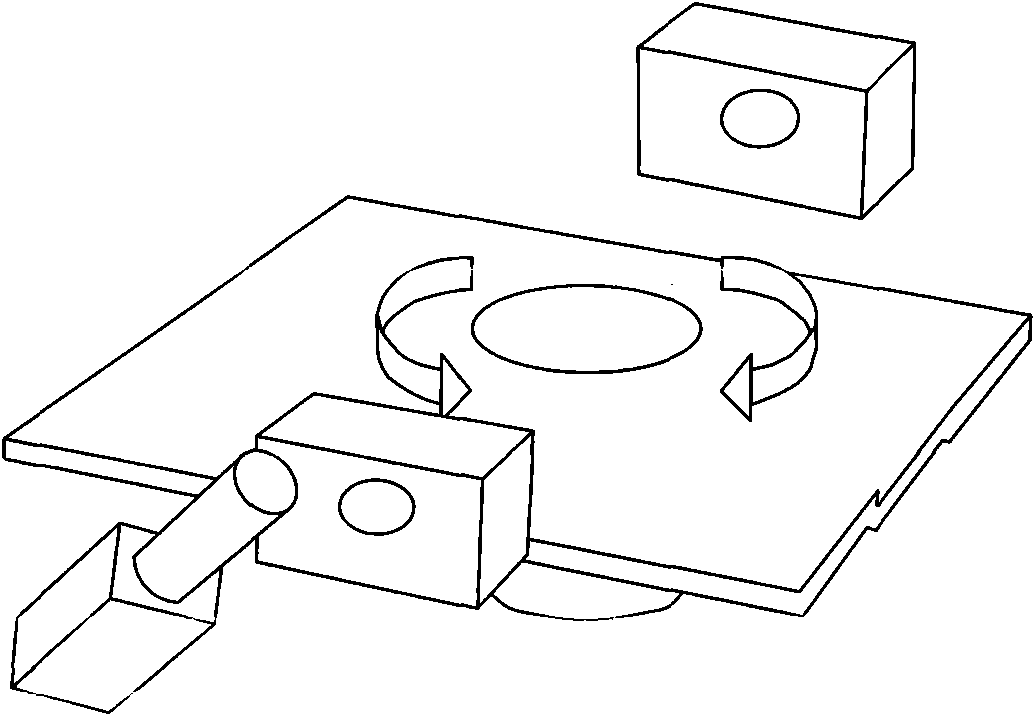

Simulation test method and simulation test system for unmanned aerial vehicle (UAV) system

InactiveCN102109418AReduce flight riskAvoid flying risksStructural/machines measurementBackground informationReal time display

The invention discloses a simulation test method and a simulation test system for an unmanned aerial vehicle (UAV) system. The method comprises the following steps of: arranging the UAV system on a multi-latitude motion platform system, and providing the multidimensional motion of the UAV system by using the multi-latitude motion platform system; providing signal data of simulated motion for the UAV system by using a signal source simulation system; providing a control logic process of motion simulation, platform motion amount closed loop measurement and the corresponding measurement of the UAV system by using a control and measurement system; and providing a drive source required by the motion of the multi-latitude motion platform system by using a motion servo system, and providing a parameter record, real-time display and superposed background information by using a simulation parameter recording and displaying system. By the method and the system, the UAV system can be subjected to dynamic test check and simulation on the ground, and actual flight is replaced, so that actual flight risk is obviously reduced, a test verification period is shortened, and cost is saved.

Owner:贵州贵航无人机有限责任公司

Charging station layout programming method based on V-graph and HS algorithm

InactiveCN106503845ALow construction and operation costsSolving planning problems with uneven distributionForecastingApparatus for hiring articlesHarmony memoryComputer science

The invention discloses a charging station layout programming method based on a V-graph and an HS algorithm. The method comprises the steps of firstly, estimating the range of charging stations which are constructed in a programming area through anticipation of charging queuing waiting time; secondly, comprehensively considering multiple factors such as a charging requirement and a region characteristic, establishing a charging station layout programming object according to a charging station construction / operation cost, a charging on-the-way time consumption cost and an arrival-at-station queuing waiting time cost; and finally, randomly generating station address coordinates of the charging stations in the programming area, coding the station address coordinate for obtaining one-directional vectors, defining the service range of each charging station by means of a Voronoi-graph (the V-graph in short) and generating an initial harmony vector, calculating a solution by means of a harmony search (HS) algorithm and storing the solution in a harmony memory (HM), updating the harmony memory through studying the harmony memory and tone fine turning until a number of updating times of the harmony memory is reached, finding out a charging station layout programming objective value and determining an optimal charging station layout programming solution. The charging station layout programming method has advantages of effective integration of multiple factors and high calculating speed. Furthermore the charging station layout programming method can be used for finding out an optimal value.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

A power supply method and a charging device for a super capacitor energy storage type trolley car

InactiveCN108988447AImprove survival rateReduce dependenceBatteries circuit arrangementsRailway vehiclesCapacitanceElectricity

The invention discloses a power supply method and a charging device for a super capacitor energy storage type trolley car, the power supply is that when a tram with on-board supercapacitors arrives atthe station, The pantograph is powered from the DC / DC chopper to the on-board supercapacitor. DC energy is output to DC / DC chopper after AC / DC converter rectifies 380V three-phase AC input from powergrid, and DC energy is output to DC / DC chopper by ground supercapacitor. The vehicle-mounted supercapacitor is charged after pantograph is fully charged. The DC / DC chopper stops charging the vehicle-mounted supercapacitor when the vehicle-mounted supercapacitor is fully charged or when the tram leaves the station. The output switch of the DC / DC chopper is turned off and the pantograph is loweredback. The AC / DC converter switches to the ground supercapacitor to charge the ground supercapacitor so as to obtain the continuous replenishment of the pre-stored DC energy. The invention has the advantages of improving the survival rate of the trolley, reducing the capacity dependence on the power supply network and the impact on the power supply network, and reducing the construction and operation cost.

Owner:NARI TECH CO LTD +1

Treatment process for recycling water in pulping and papermaking wastewater

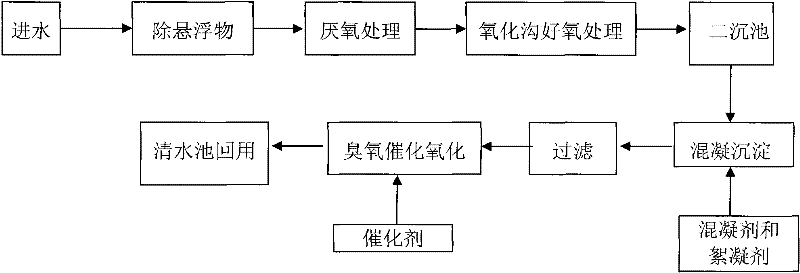

ActiveCN102531275AEasy to handleEmission reductionMultistage water/sewage treatmentWaste water treatment from plant processingReclaimed waterCatalytic oxidation

The invention discloses a treatment process for recycling water in pulping and papermaking wastewater. The treatment process comprises the following steps of: removing suspended matters of the pulping and papermaking wastewater and carrying out anaerobic treatment; and then, carrying out aerobic treatment through an oxidation ditch and inputting the wastewater into a secondary sedimentation basin to precipitate and carry out mud-water separation; and then, carrying out coagulating sedimentation and filtering; and finally, carrying out ozone catalytic oxidation treatment to obtain the water. The treatment process provided by the invention has the advantages of simple process flow, lower construction and operation cost and simplicity in management, and can effectively treat the pulping and papermaking wastewater and realize reuse of reclaimed water, so that the treatment process has an extremely good application prospect.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

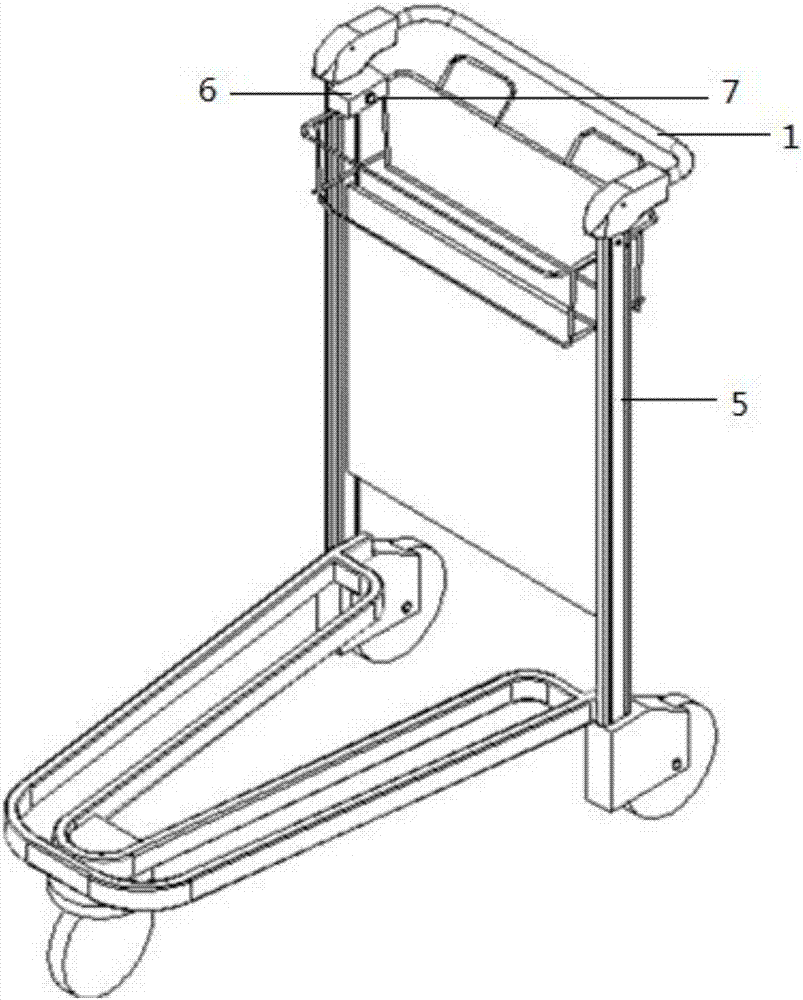

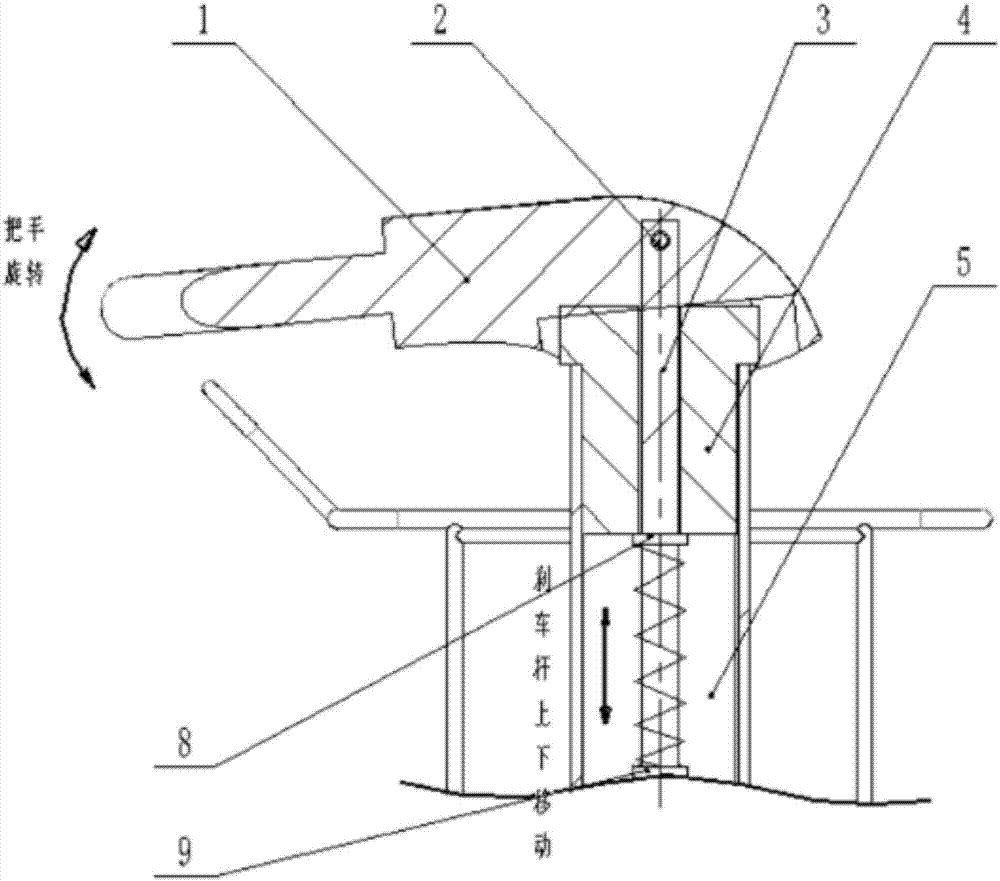

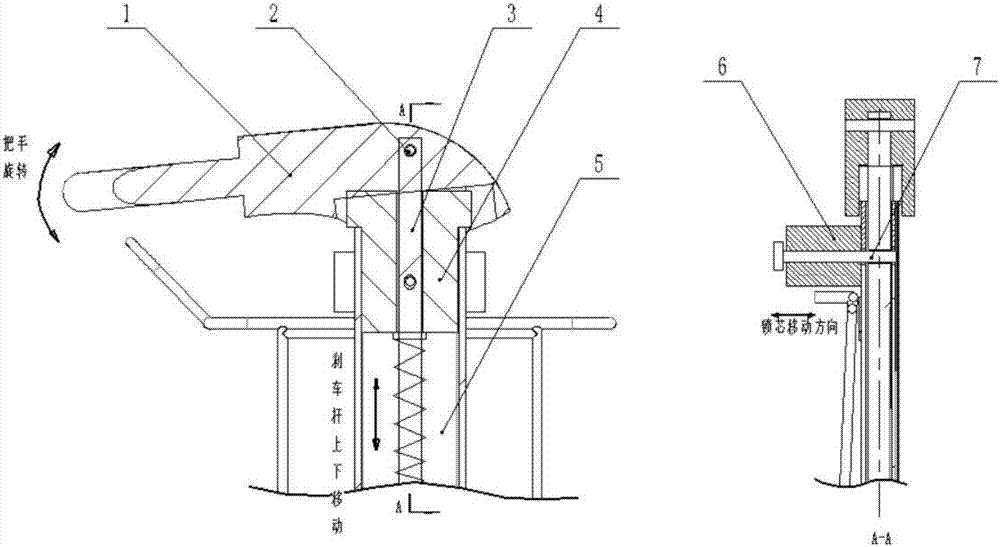

Shared cart with intelligent lock

PendingCN107215366AMaster the distribution location in real timeRealize shared leasingAnti-theft cycle devicesApparatus for meter-controlled dispensingBrakeControl engineering

The invention discloses a shared cart with an intelligent lock. The intelligent lock is mounted at the position of a side beam of the cart, a lock cylinder of the intelligent lock corresponds to a lock hole in a brake rod inside the side beam, the intelligent lock is controlled by external instructions to extend out of or retract into the lock cylinder, and use or recycle of the cart is realized. The cart can be shared under authorization and conveniently managed by operators, and economic benefits can be achieved by shared use.

Owner:QINGDAO KRUND ROBOT CO LTD

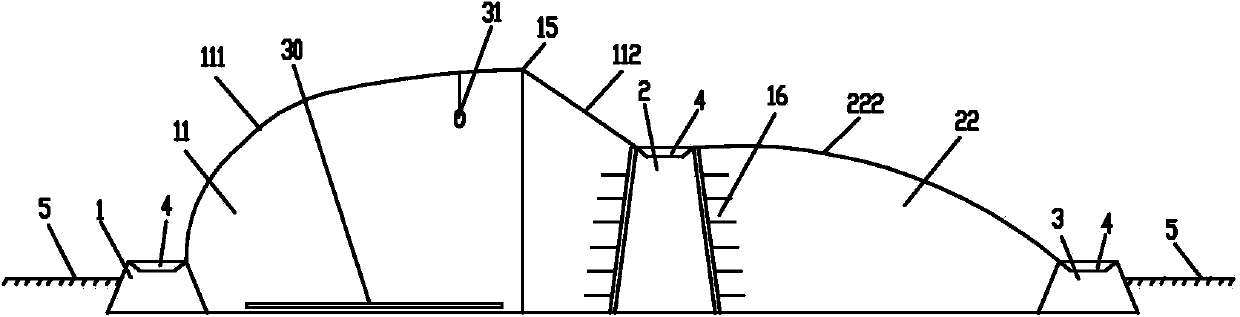

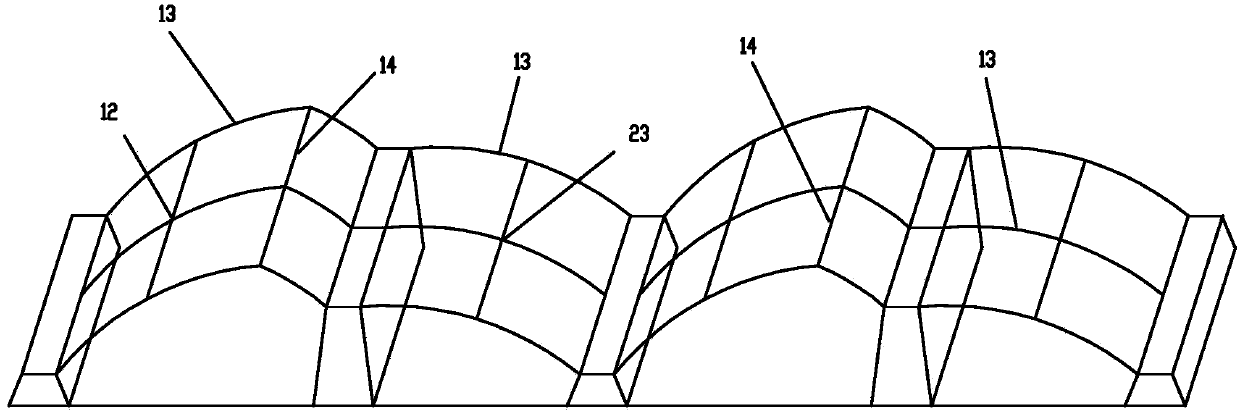

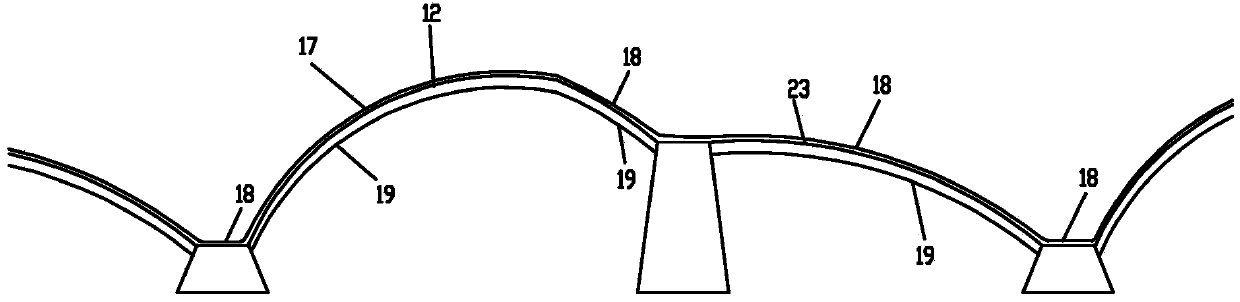

Ecological and energy-saving solar greenhouse of composite mud wall-canopy structure

ActiveCN103749210AImprove sunlight utilizationDoes not increase the angle of incidence of sunlightClimate change adaptationSaving energy measuresTemperature controlEngineering

The invention discloses an ecological and energy-saving solar greenhouse of a composite mud wall-canopy structure. The ecological and energy-saving solar greenhouse of the composite mud wall-canopy structure comprises multiple greenhouse units which are connected. Each greenhouse unit comprises a front wall, a middle wall and a rear wall, wherein a sun shed is arranged between the front wall and the middle wall, a dark shed is arranged between the middle wall and the rear wall, a sun shed steel arch is arranged in the sun shed, the span of the sun shed steel arch is 9 m-11 m, the height of a ridge of the sun shed steel arch is 5 m-6 m, the distance between the ridge and the edge of the northern side of the front wall is 7.5 m-8.5 m, the distance between the ridge and the edge of the southern side of the middle wall is 1.5 m-2.5 m, the shed face between the ridge and the front wall forms a front shed face, the shed face between the ridge and the middle wall forms a rear shed face, the included angle between the rear shed face and the ground is smaller than 45 degrees and is larger than a local sunlight incidence angle on winter solstice, the front shed face of the sun shed is covered with five multifunctional co-extrusion films, and the rear shed face of the sun shed and the shed face of the dark shed are covered with double-layer hollow PE films. According to the ecological and energy-saving solar greenhouse of the composite mud wall-canopy structure, the sunlight utilization rate and the land utilization rate are improved greatly, the temperature control performance is perfect, and year-round production can be achieved.

Owner:靳玉环

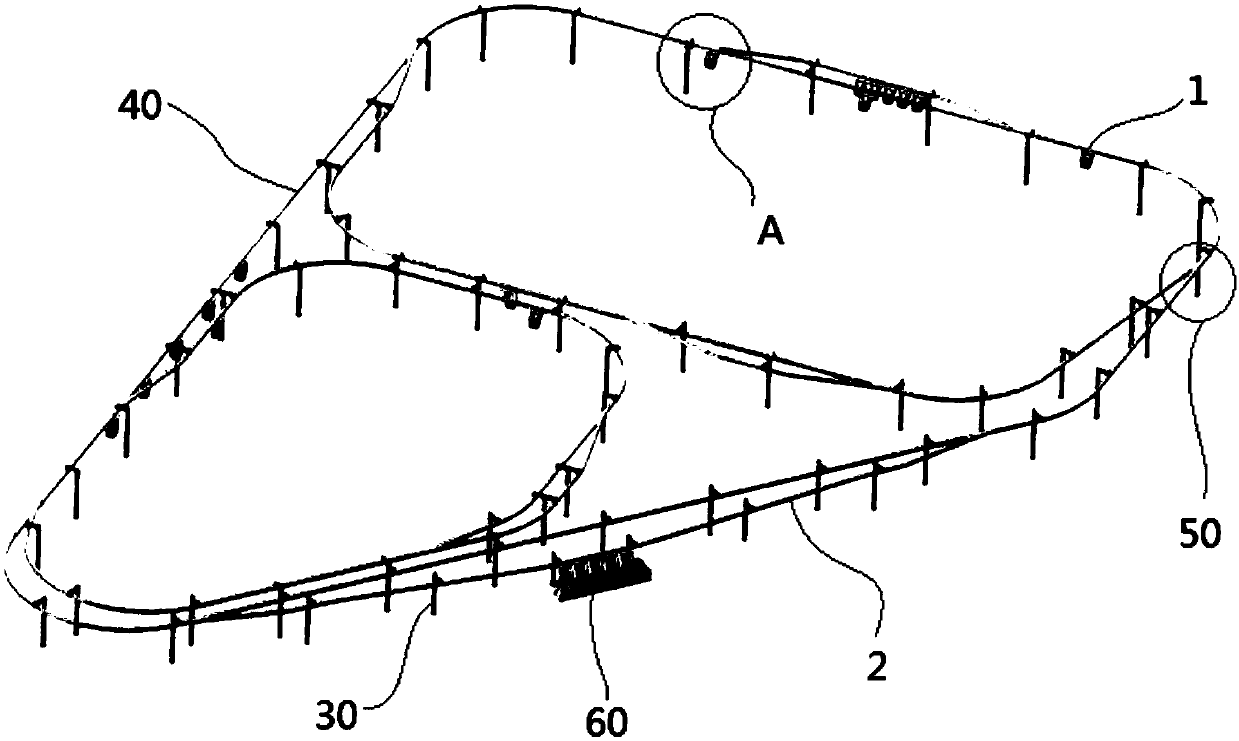

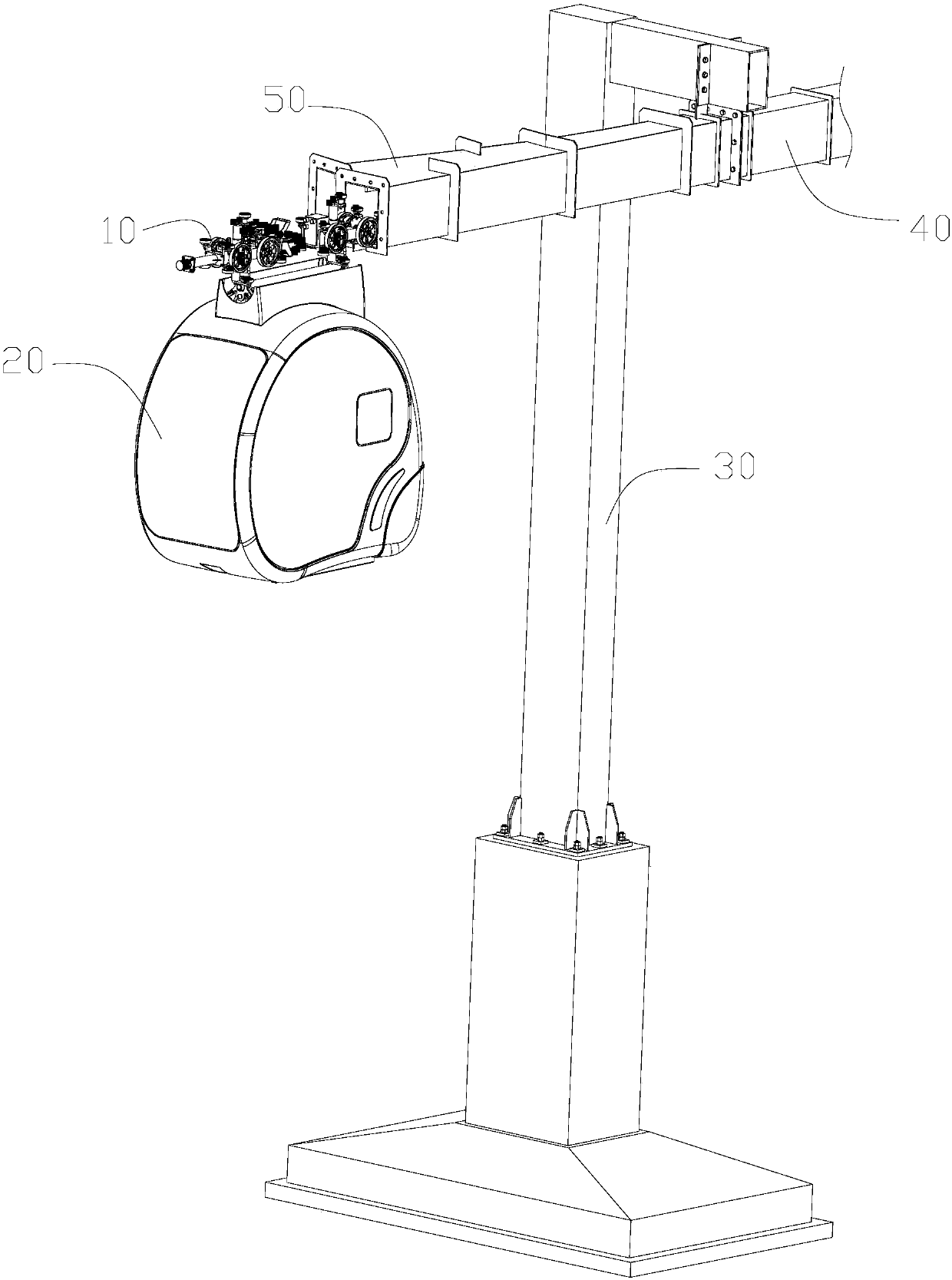

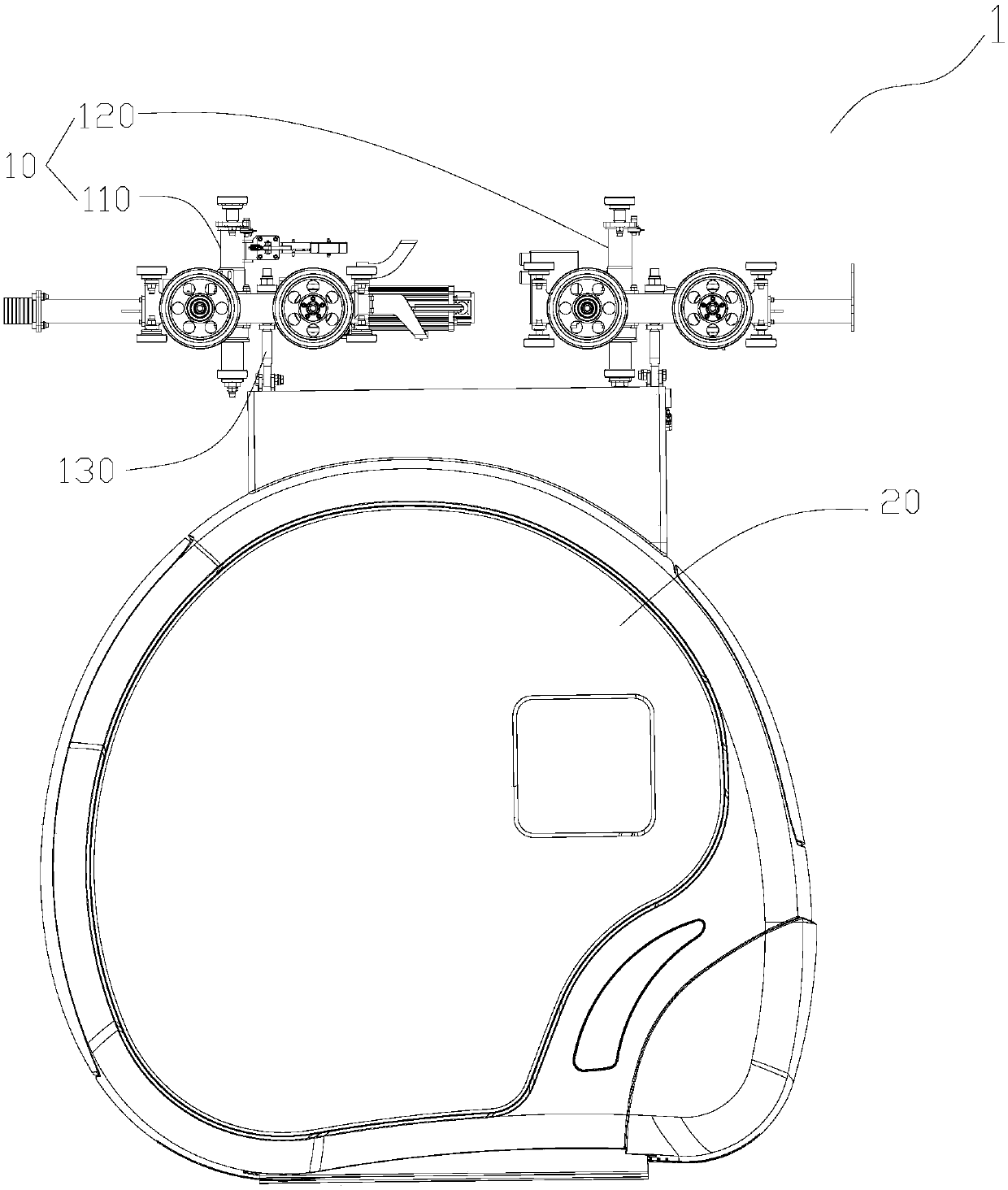

Micro-rail traffic system

ActiveCN109532868ASimple structureEasy to installRailway componentsElevated railway with suspended vehicleTerrainOperational costs

The present invention relates to a micro-rail traffic system including a rail system, a train system and a dispatching control system. The rail system includes a suspended track structure for suspending the train system. The train system includes a carriage and a running mechanism. The carriage is suspended in the track structure by the running mechanism that drives the carriage to run along the track structure. The dispatching control system includes a dispatching control center that controls the train system to operate on the track structure. The micro-rail traffic system provided by the invention is simple in overall structure, convenient to install, disassemble and expand, reduces construction and operation costs, improves adaptability to various complex terrains, minimizes occupancy of original roads, and improves the composite use degree of roads, is convenient for passengers to travel.

Owner:CRRC TANGSHAN CO LTD

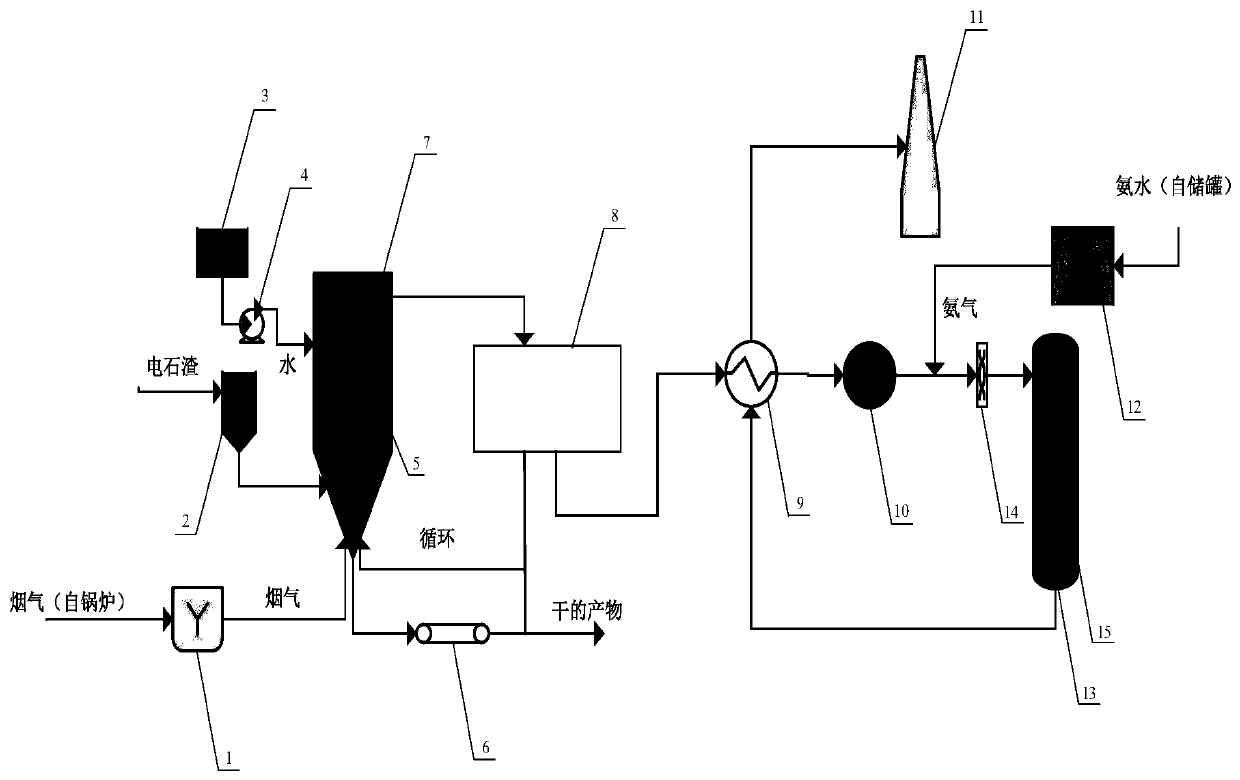

Carbide slag semi-dry desulfurization and low-temperature SCR denitration flue gas treatment device and process

PendingCN110787630ALow construction and operation costsGood value for moneyGas treatmentDispersed particle filtrationPtru catalystSlag

The invention belongs to the technical field of thermal power plant flue gas treatment environmental protection, and specifically relates to a carbide slag semi-dry desulfurization and low-temperatureSCR denitration flue gas treatment device. The carbide slag semi-dry desulfurization and low-temperature SCR denitration flue gas treatment device comprises a primary pre-dust remover, a carbide slagpowder bin, a water tank, a high-pressure water pump, a backflow type atomizing nozzle, an ash discharge conveyor, a desulfurizing tower, a bag-type dust remover, a GGH, a steam heater, a chimney, anammonia water evaporation system, an SCR reactor, an ammonia spraying grid, a catalyst, and a rectifying grid; flue gas is sequentially delivered through the desulfurizing tower, the bag-type dust collector, the GGH, the steam heater and the SCR reactor to remove SO2 and NOx in the flue gas; a low-temperature SCR denitration process is added on the basis of original SNCR denitration; indexes of SO2 and NOx concentration at a flue gas outlet after transformation reach national ultra-clean emission standards, the semi-dry flue gas desulfurization process is a novel process, SO3, HCL, HF and heavy metals such as Hg can be removed besides SO2, and due to low construction and operation cost and high cost performance, the carbide slag semi-dry desulfurization and low-temperature SCR denitrationflue gas treatment device is gradually popularized and applied in small and medium-sized thermal power generating units.

Owner:陕西大秦环境科技有限公司

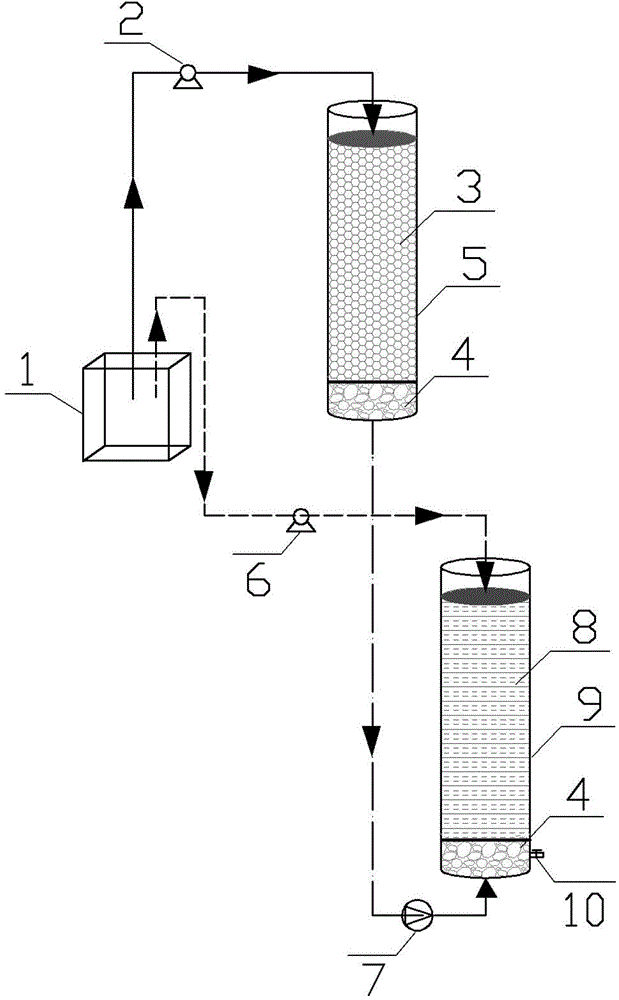

System capable of utilizing acid to neutralize slags and dehydrated aluminum sludge to treat nitrogenous wastewater and method thereof

ActiveCN103395951BEfficient removalReduce energy consumptionMultistage water/sewage treatmentSlagSludge

The invention belongs to the field of nitrogenous wastewater treatment, and discloses a system capable of utilizing acid to neutralize slag and dehydrated aluminum sludge to treat nitrogenous wastewater and a method thereof. The system comprises an acid neutralizing slag device and a dehydrated aluminum sludge device, the acid neutralizing acid device is arranged above the dehydrated aluminum sludge device, the bottom of the acid neutralizing acid device is higher than the top of the dehydrated aluminum sludge device, the bottom of the acid neutralizing acid device communicates with the bottom of the dehydrated aluminum sludge device through a channel, and a valve is arranged on a position, where is close to the dehydrated aluminum sludge device, on the channel. The system also comprises a water storage tank, a first water pump is arranged on a channel, which connects the water storage tank and the upper end of the acid neutralizing slag device, and a second water pump is arranged on a channel, which connected the water storage tank and the upper end of the dehydrated aluminum sludge device. The system utilizes acid to neutralize slag and takes the dehydrated aluminum sludge as the reaction medium, through constructing of a two-grade filter tank to implement alternate operation of nitrogenous waste water, and thus high efficient elimination of ammonia nitrogen and total nitrogen is achieved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

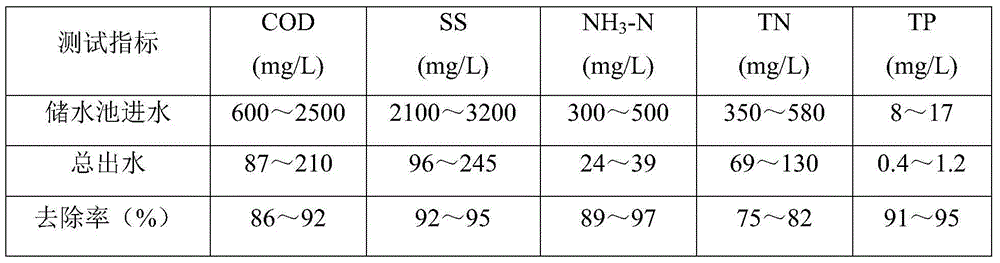

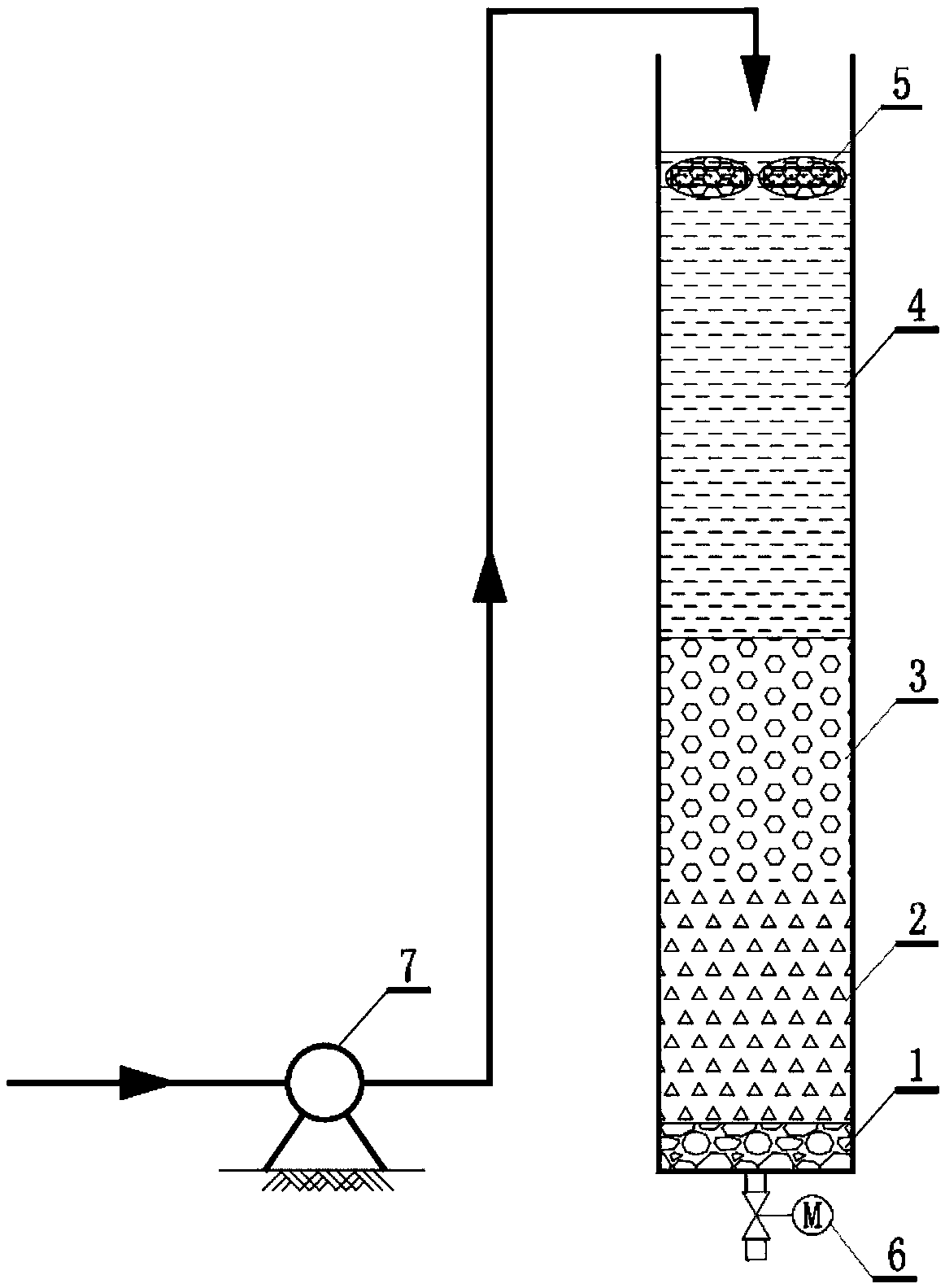

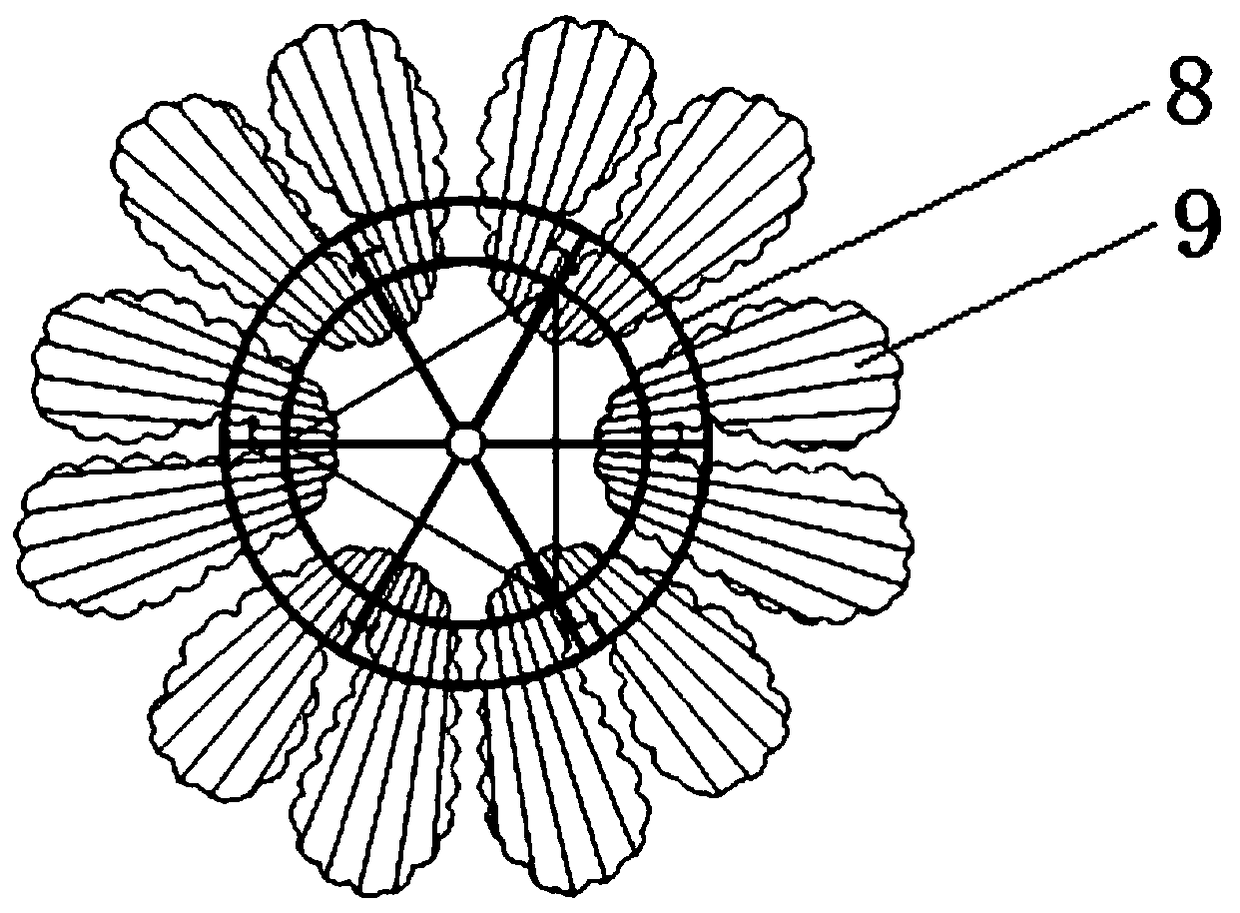

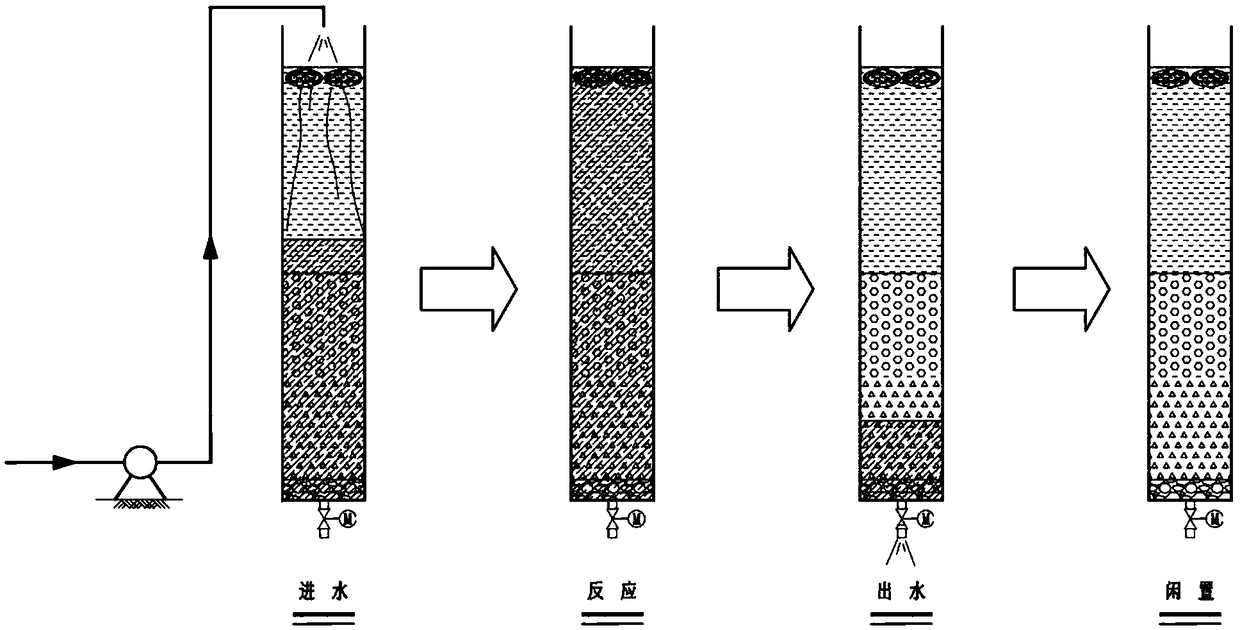

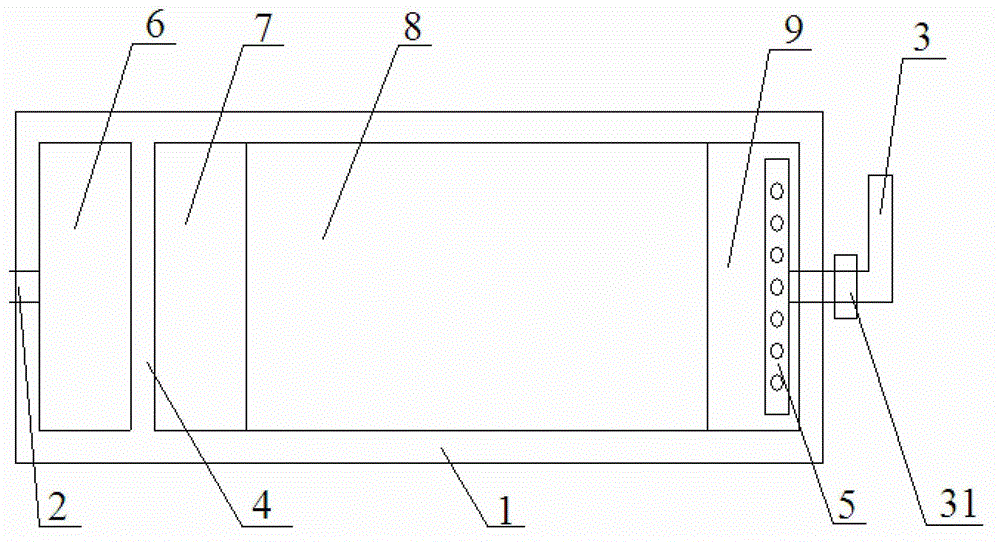

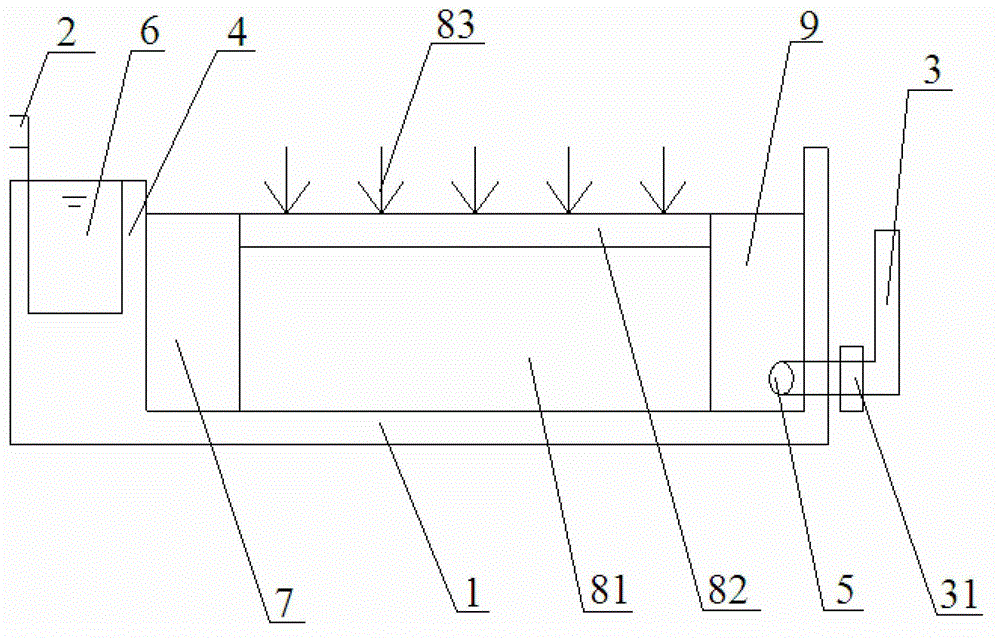

Efficient sewage purifying biological filter device and using method

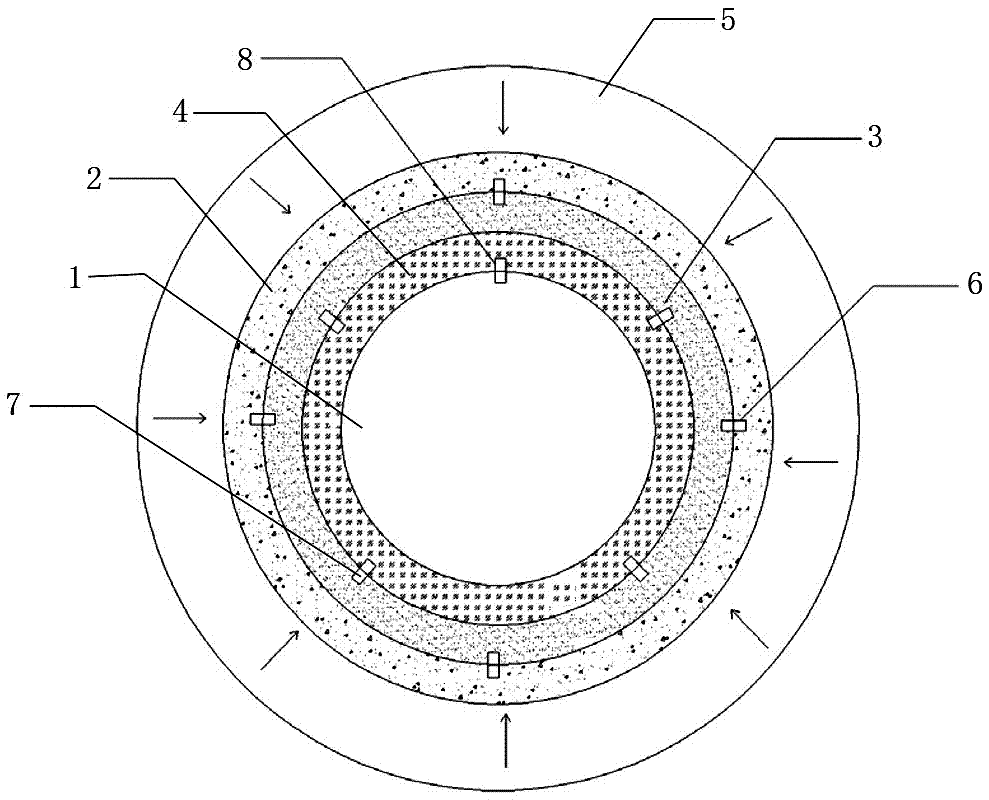

PendingCN109399808AReduce cloggingAvoid cloggingWater treatment parameter controlWater treatment compoundsFiberBiological filter

The invention relates to an efficient sewage purifying biological filter device and a using method. The device comprises a column-type sewage treatment pond, an inorganic porous filler layer, an organic fiber medium layer, a water inlet pipe arranged on the top of the column-type sewage treatment pond, a water outlet pipe arranged at the bottom of the column-type sewage treatment pond, a water inlet pump arranged on the water inlet pipe and a water outlet valve arranged on the water outlet pipe, wherein the inorganic porous filler layer and the organic fiber medium layer are successively arranged in the column-type sewage treatment pond from bottom to top, and the inorganic porous filler layer in the column-type sewage treatment pond comprises upper and lower layers, namely, a volcanic layer and ceramsite or a zeolite layer from bottom to top; a gravel layer is arranged on the lower portion of the inorganic porous filler layer. The device has a good synchronous effect of removing organic matters, nitrogen and phosphorus in sewage, the sewage treatment capacity of the device can be effectively improved, blockage of a filter is delayed, construction and operation cost is low, and thedevice can be flexibly used for dispersed sewage treatment on various occasions and is especially applicable to treatment of the sewage with low carbon nitrogen ratio.

Owner:YUNNAN UNIV

Active distribution network planning method for improving distributed generation consumption capacity

PendingCN110289611AImprove absorption capacityLow construction and operation costsSingle network parallel feeding arrangementsAc network with energy trading/transmission rightsEngineeringElectric vehicle

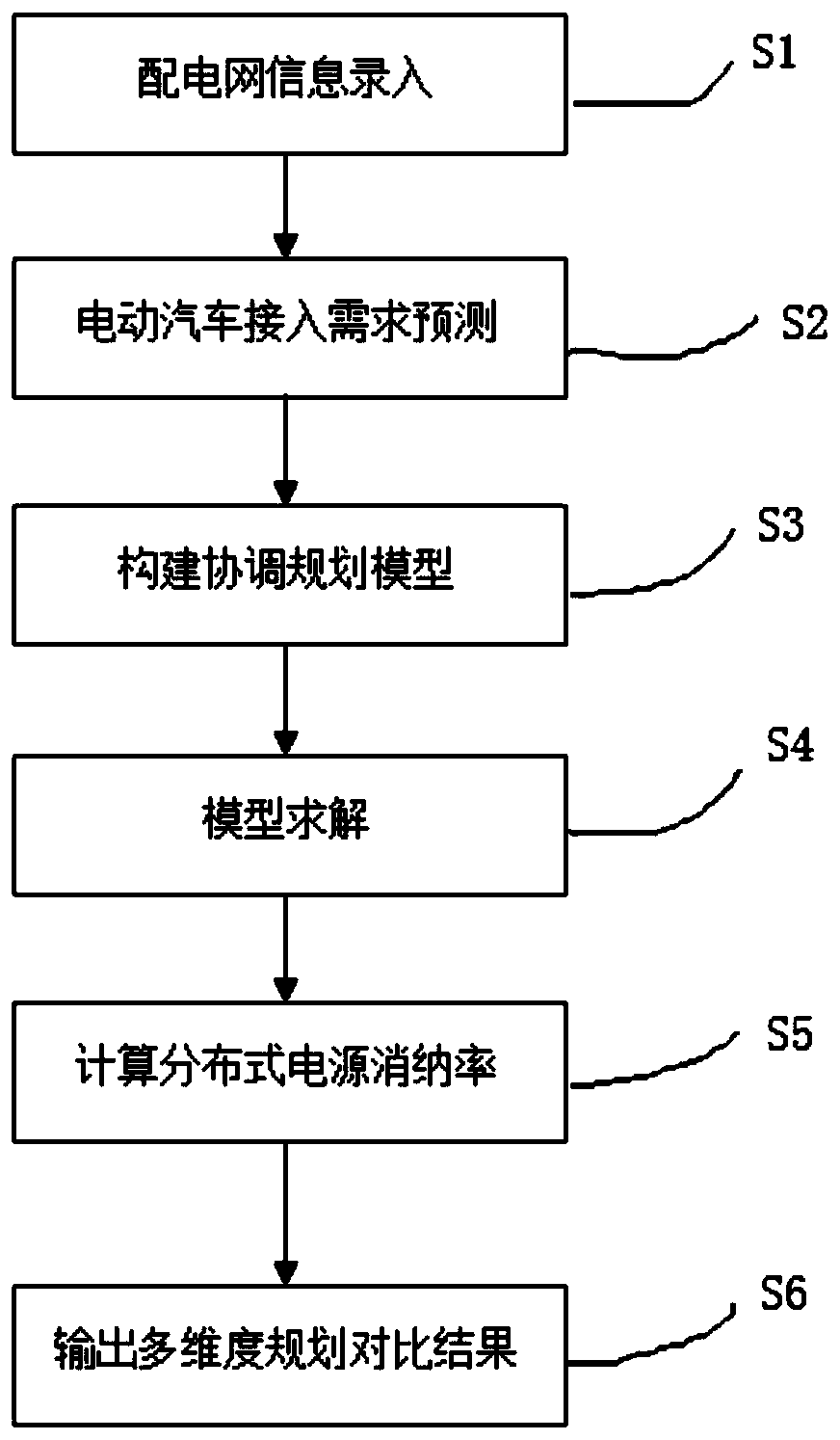

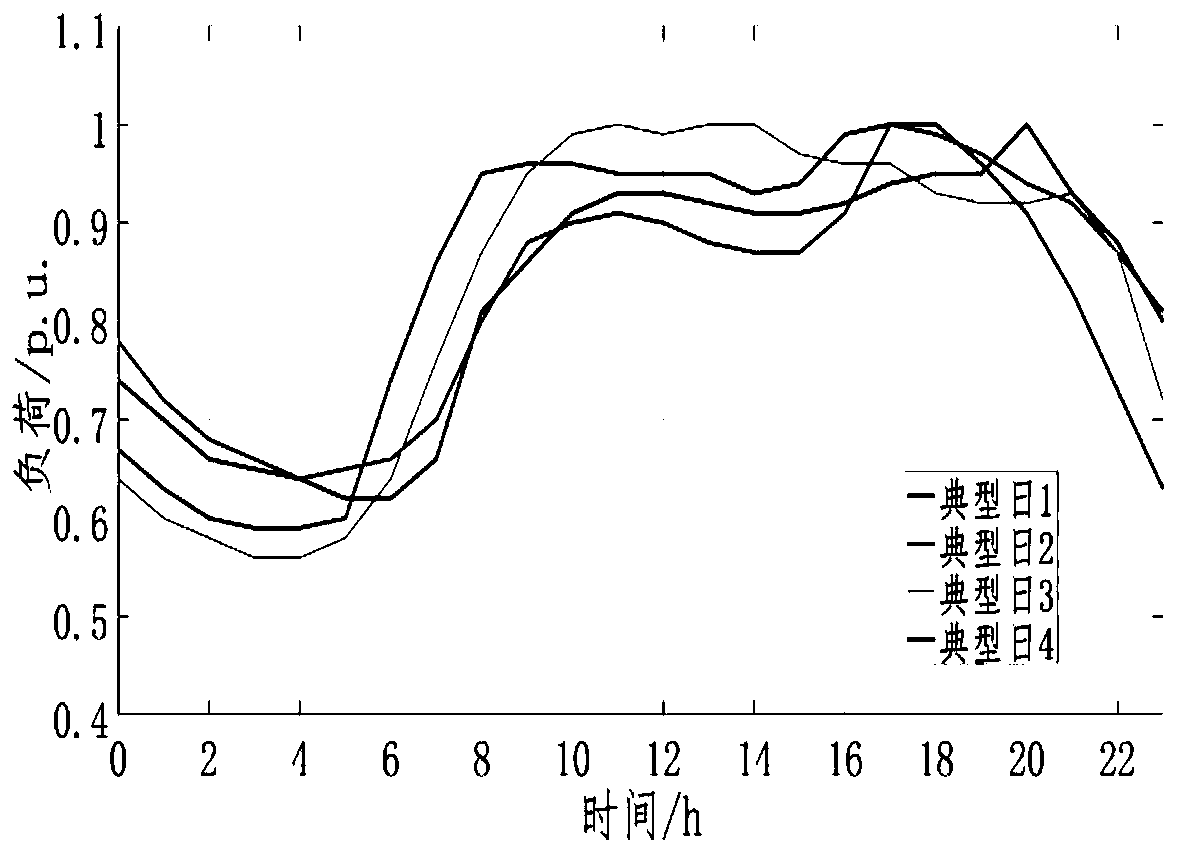

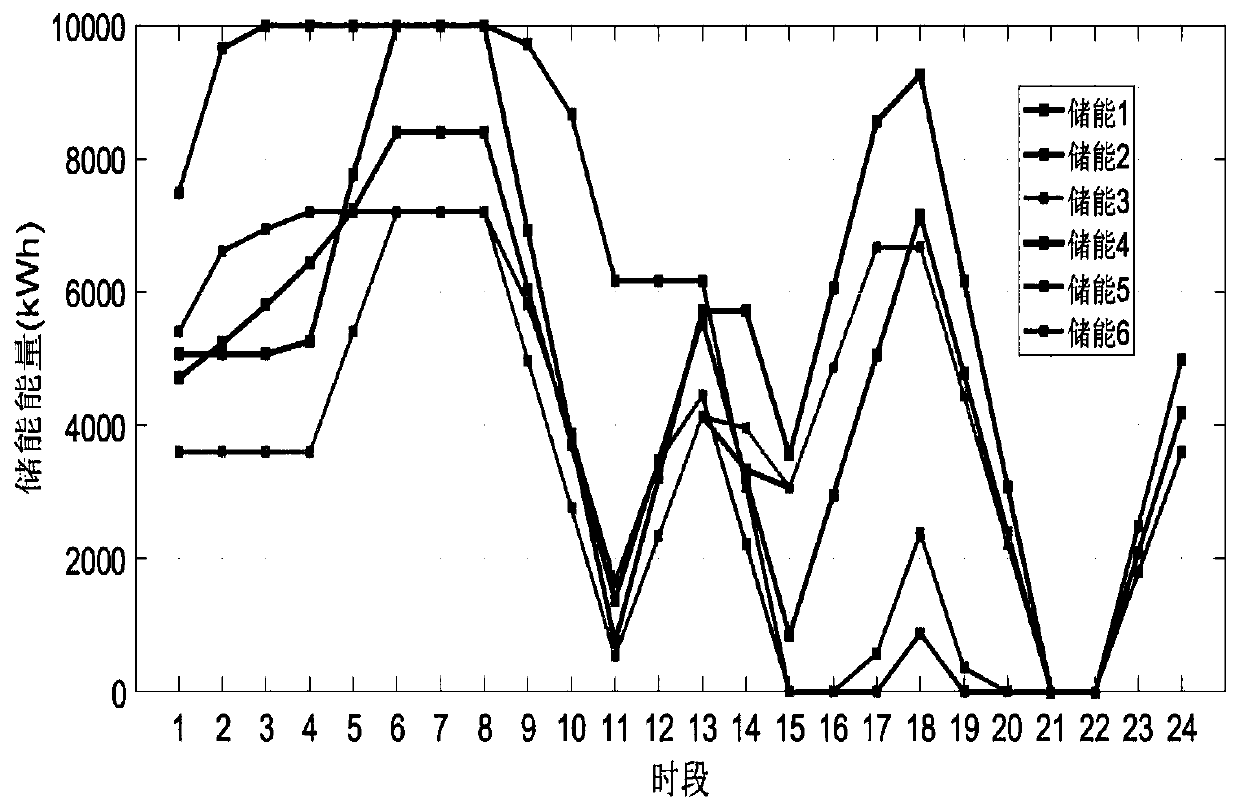

The invention discloses an active distribution network planning method for improving a distributed generation consumption capacity, characterized by comprising the following steps of S1, inputting distribution network information; S2, predicting an electric vehicle access demand; S3, in consideration of the construction cost and the running cost, defining an objective function to minimizing the total cost, and by using the distributed generation and energy storage as variables, carrying out source-grid-storage coordination planning and constructing a coordination planning model; S4, solving the model; S5, calculating a distributed generation consumption rate [omega]; and S6, outputting a multi-dimensional planning comparison result. The method has the beneficial effects of minimizing the overall construction operation cost, considering the grid consumption capacity, realizing the source-grid-charge-storage coordination planning, using a multi-time-scale and multi-constrained planning model, and considering the difference of distributed generation permeability and storage access scale in different stages, and can be applied to the planning and design of county distribution network with different distributed generation permeability.

Owner:国网浙江海宁市供电有限公司 +1

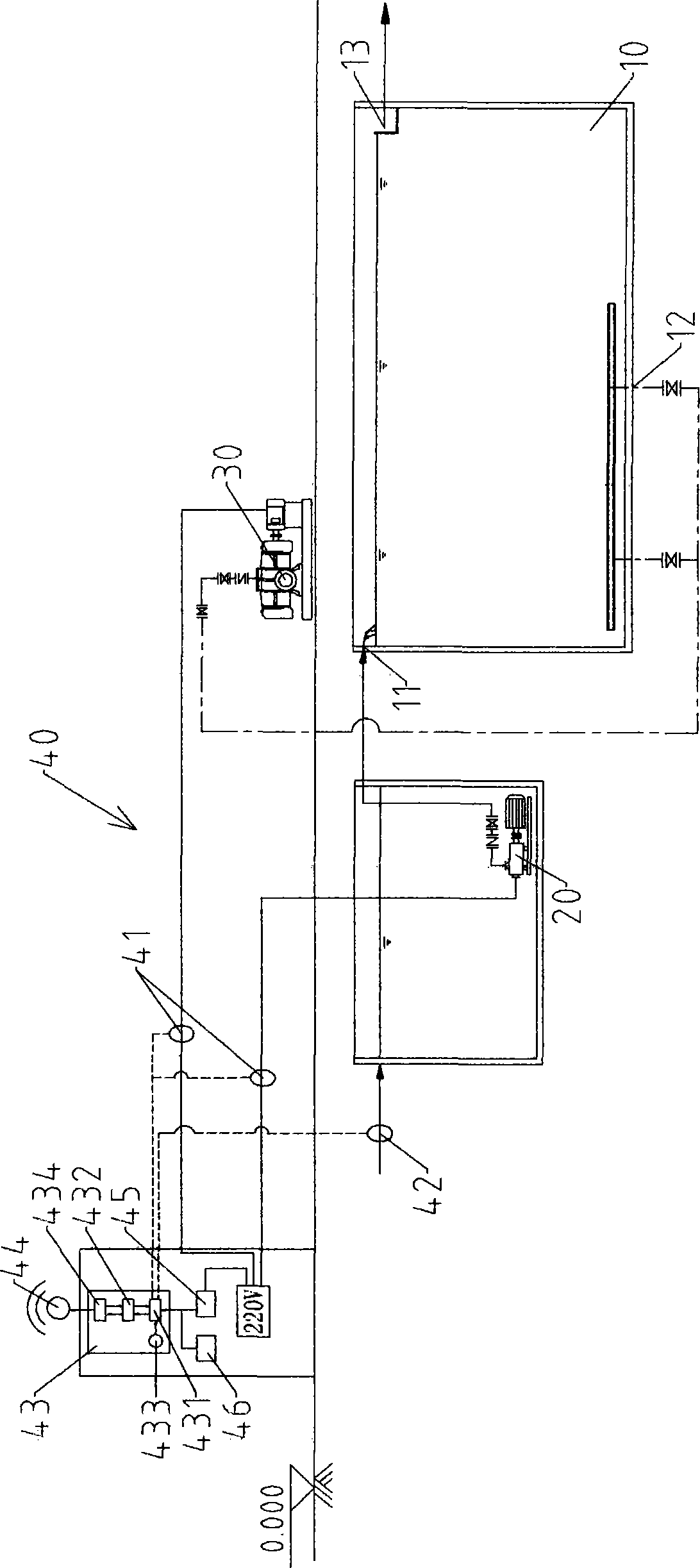

Operation monitoring and managing system for rural domestic sewage disposal facility

InactiveCN103760861ALow costLow construction and operation costsProgramme total factory controlComputer terminalSewage treatment

The invention discloses an operation monitoring and managing system for a rural domestic sewage disposal facility. The system comprises a monitoring unit, a central platform, a mobile terminal and at least one sewage disposal facility. The monitoring unit comprises current transformers, a flow sensor, an AC / DC converter, a standby battery, a main control circuit board and a GPRS unit which is connected to a data interface and connected with the central platform in a signaling mode. The operation monitoring and managing system has the advantages of judging operation conditions of the domestic sewage disposal facility, obtaining power consumption for operation of the domestic sewage disposal facility and being capable of performing multi-point operation monitoring at the same time, flexible, simple, low in cost and suitable for performing centralized operation managing on rural small-size scattered-type domestic sewage disposal in villages and towns.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV

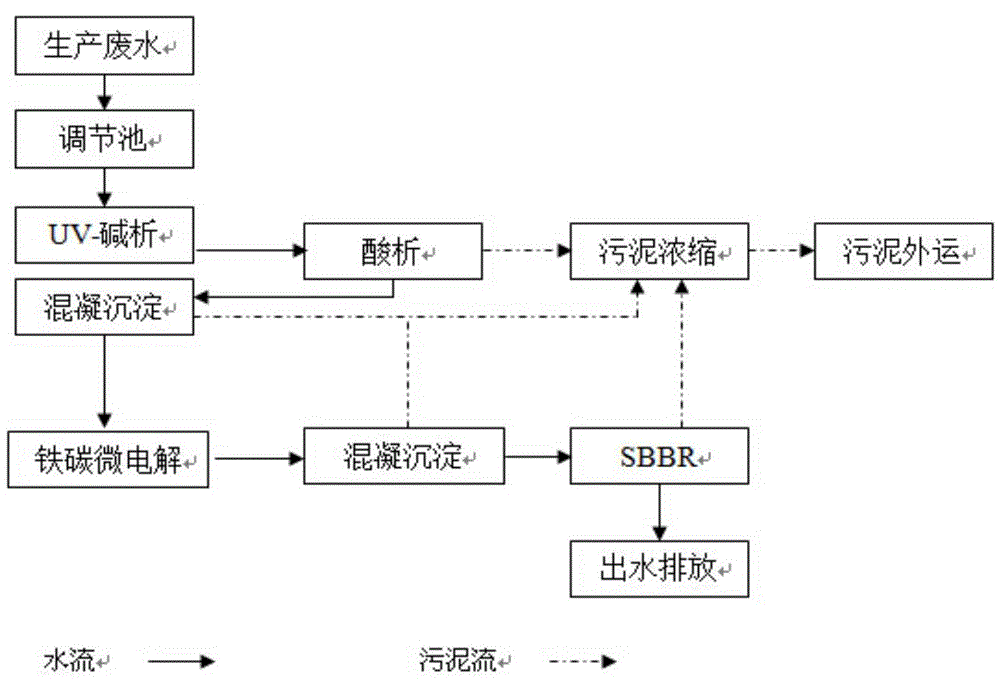

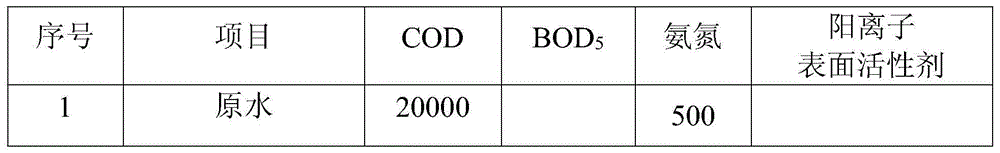

Methylene dithiocyanate wastewater treatment method

ActiveCN104860455AIncrease concentrationIncrease the amount of fixationMultistage water/sewage treatmentNature of treatment waterElectrolysisMethylene dithiocyanate

The invention relates to a wastewater treatment method, in particular to a treatment method for wastewater of methylene dithiocyanate production. The method adopts a photolysis, demulsification, iron-carbon micro-electrolysis and SBBR (sequencing batch biofilm reactor) combined process and has the characteristics of relatively simple process, high treatment efficiency, easiness in implementation and maintenance, low operation cost and the like; the methylene dithiocyanate wastewater treated with the treatment method can be drained up to the standard.

Owner:GUANGDONG ENG TECH INST

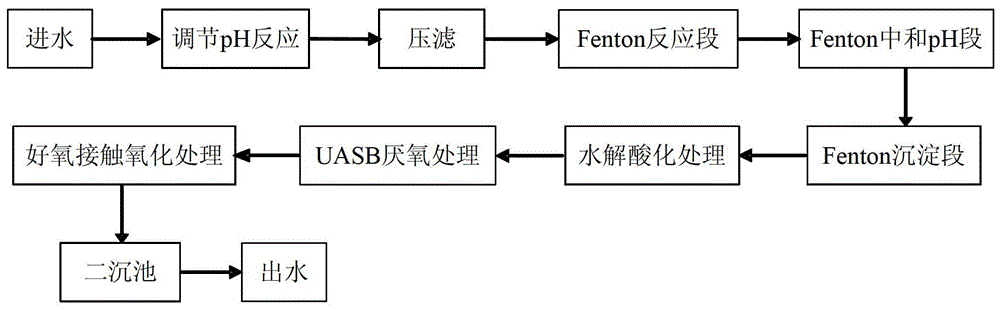

Treatment process for polycrystalline silicon cutting mortar recovered wastewater

ActiveCN103803758AThe processing process is simpleLow construction and operation costsMultistage water/sewage treatmentAnaerobic treatmentPolycrystalline silicon

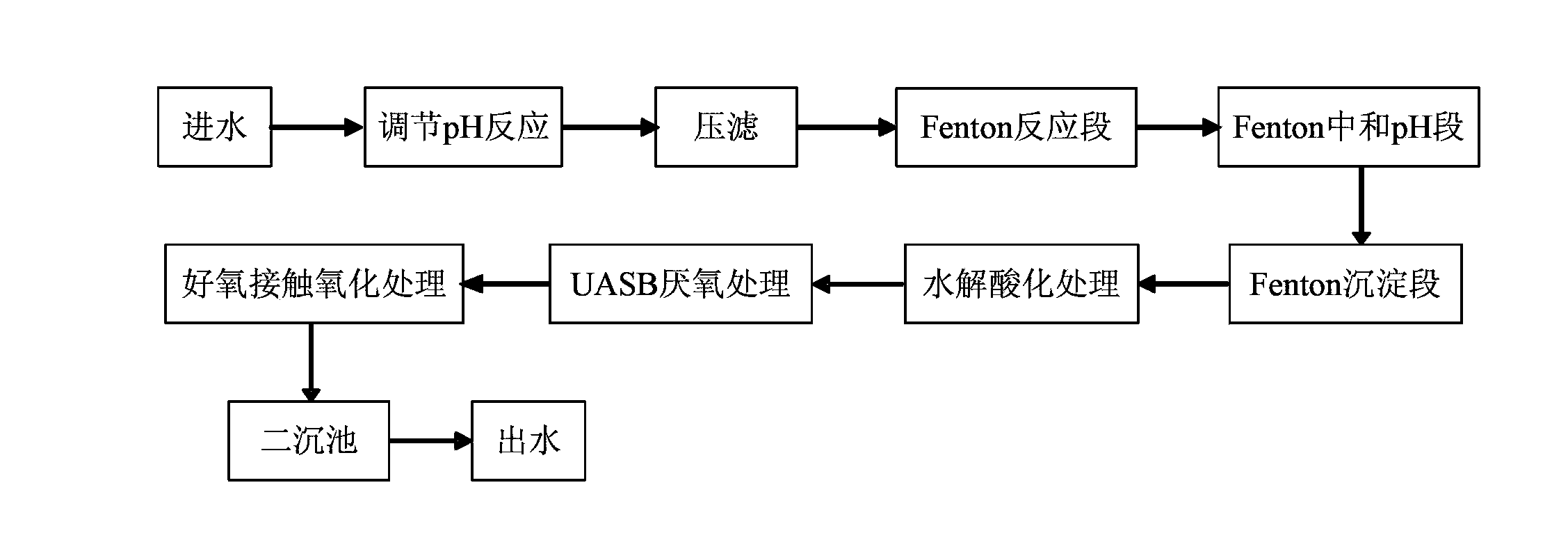

The invention discloses a treatment process for polycrystalline silicon cutting mortar recovered wastewater. The treatment process comprises the following steps: regulating pH of polycrystalline silicon cutting mortar recovered wastewater to 9.5-9.9, reacting and filter-pressing; carrying out Fenton oxidation treatment; implementing hydrolytic acidification treatment, upflow anaerobic sludge blanket (UASB) anaerobic treatment and aerobiotic contact oxidation treatment, and carrying out solid-liquid separation through settling by a secondary sedimentation tank. The treatment process is simple and convenient in flow, relatively low in construction and operation cost, simple in management, and capable of effectively treating the polycrystalline silicon cutting mortar recovered wastewater.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

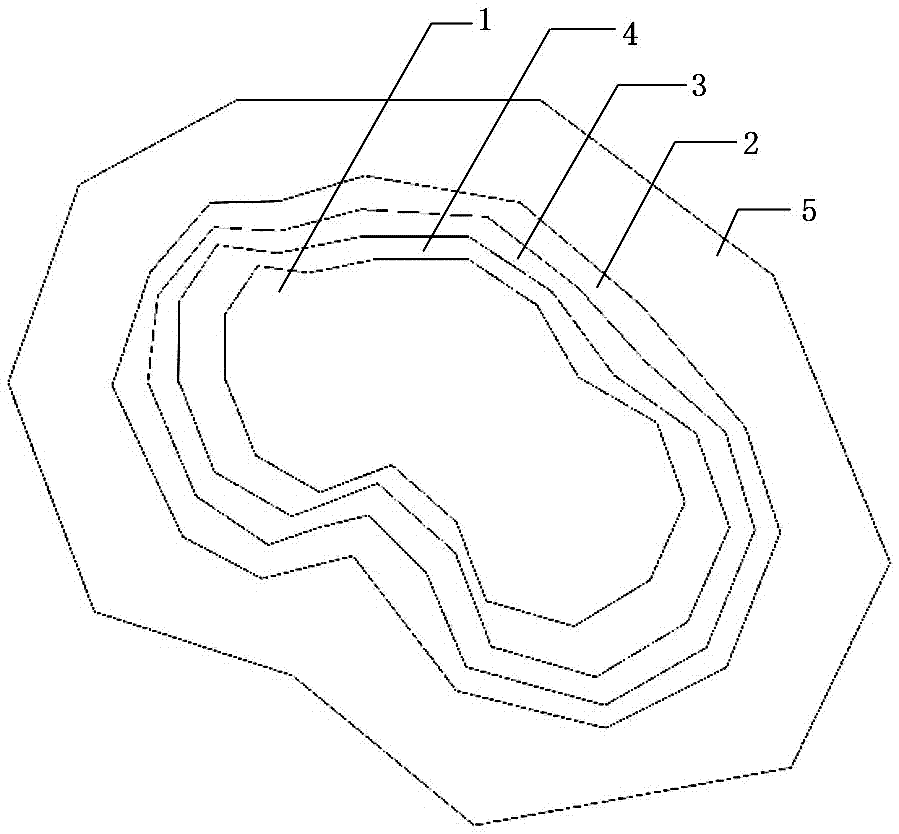

Wetland system integrating rainwater collection, regulation and storage, and purification and construction method of wetland system

PendingCN107503426AGood landscape effectLow construction and operation costsSewerage structuresPaving gutters/kerbsRainwater harvestingStormwater

The invention provides a wetland system integrating rainwater collection, regulation and storage, and purification. The wetland system comprises a landscape pond, a third-level wetland, a second-level wetland and a first-level wetland nested at the outer side of the landscape pond in the sequence from inside to outside, and a water-pervious concrete pavement nested at the outer side of the first-level wetland, wherein the first-level wetland communicates with the second-level wetland through first communicating pipelines, the second-level wetland communicates with the third-level wetland through second communicating pipelines, the first communicating pipelines and the second communicating pipelines are arranged in a staggered manner, a horizontal overflow pipe is arranged at the upper end of the inner wall of the landscape pond, and the overflow pipe communicates with a municipal rainwater pipe network. With the wetland system integrating rainwater collection, regulation and storage, and purification, the problems that during rainfall of existing communities, water accumulates on the road surface, while for landscape water, a water source is in shortage, and the water quality is difficult to maintain, are solved, and meanwhile, an important role is played for alleviating urban water logging.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Combined process for treating high-ammonia-nitrogen wastewater and treatment system

ActiveCN111484204APrevent sinkingIncrease contactTreatment using aerobic processesTreatment by combined electrochemical biological processesElectrolysisSlurry

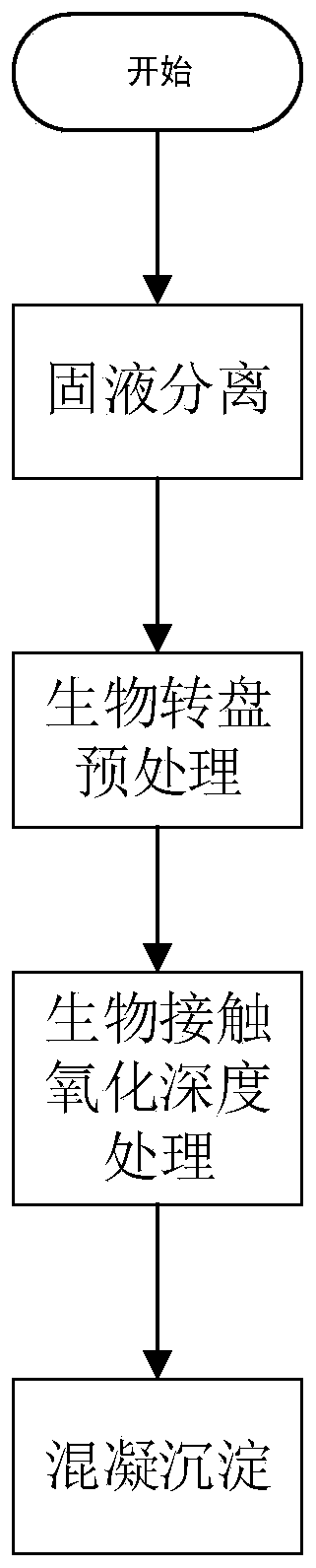

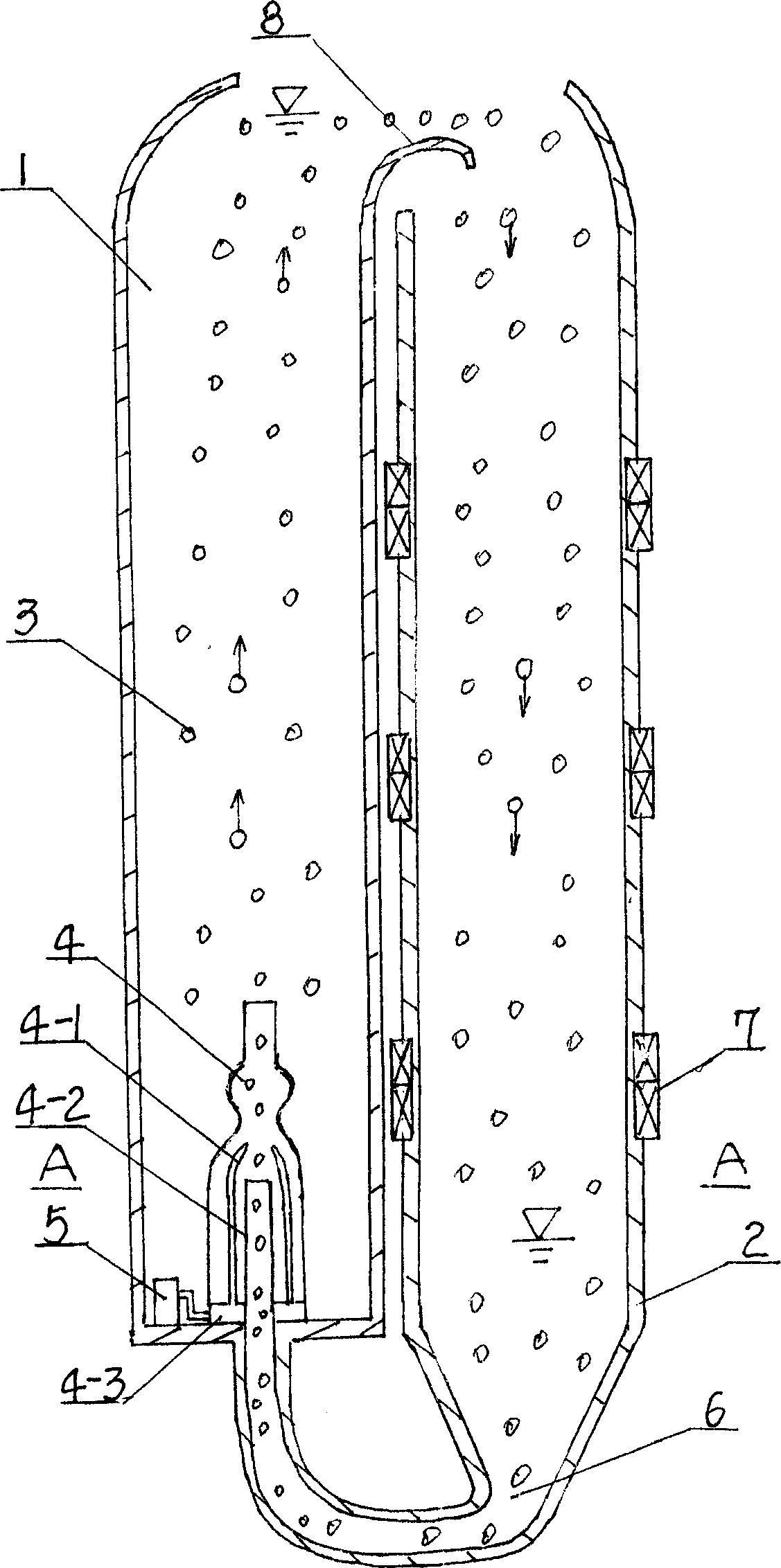

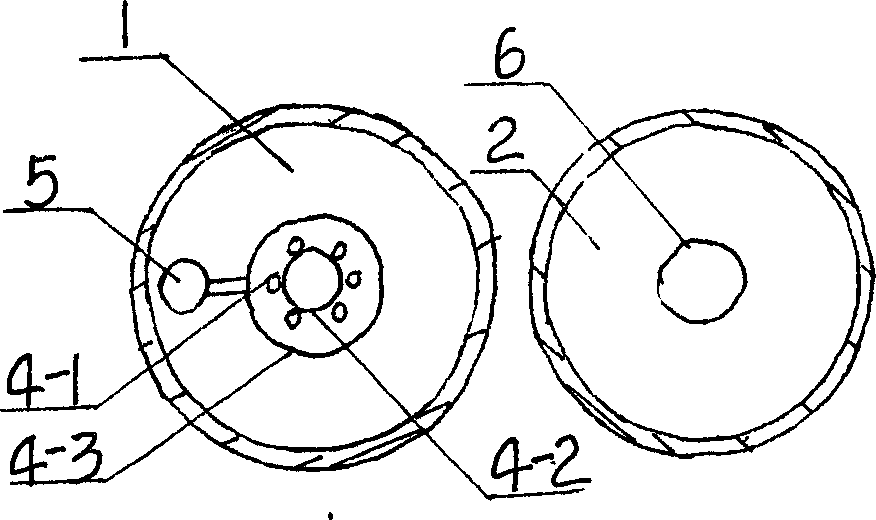

The invention discloses a combined process for treating high-ammonia-nitrogen wastewater. The method comprises the following steps: carrying out solid-liquid separation; carrying out biological rotating disc pretreatment; carrying out biological contact oxidation deep treatment; and carrying out coagulating sedimentation;a biological rotating disc pretreatment unit of a treatment system adopted inthe process is supported on a same rotating shaft by adopting a plurality of rotating discs; each rotating disc is driven to rotate by planet row reduction gearboxes with different transmission ratios; the rotating speed of the rotating disc is gradually reduced from the water inlet end to the water outlet end; the biological rotating disc pretreatment unit also adopts a blast aeration device toadjust the dissolved oxygen concentration of the high-ammonia-nitrogen waste liquid; a pretreatment system has higher pollutant load; a plurality of contact oxidation fillers are arranged in the biological contact oxidation advanced treatment unit; by means of the electrolysis and biological membrane degradation characteristics of iron-carbon micro-electrolysis-activated carbon fiber combination,the nitrogen and phosphorus removal efficiency of the system is enhanced, particularly when low-carbon high-ammonia-nitrogen wastewater (biogas slurry) is treated, serious imbalance of the C / N ratio in the biogas slurry is overcome, and the treatment efficiency of the high-ammonia-nitrogen wastewater is improved.

Owner:CHONGQING UNIV OF TECH

Hydro-float solid-liquid magnetic fluid generating technology device

InactiveCN1832307AReduce unit kilowatt investmentImprove efficiencyDynamo-electric machinesHydroelectricityWater reservoir

This invention relates to a water power floatation solid-liquid magnetic fluid generating device including vertical cylinders A and B, a multiple solid-liquid magnetic fluid generating winding, slides, magnetic particles and their circulation generator, which utilized water power floatage to generate to reduce cost.

Owner:HEBEI AGRICULTURAL UNIV.

Process for removing geosmin in raw water of drinking water

InactiveCN108996739AImprove securityGood for healthWater contaminantsWater aerationWater useFiltration

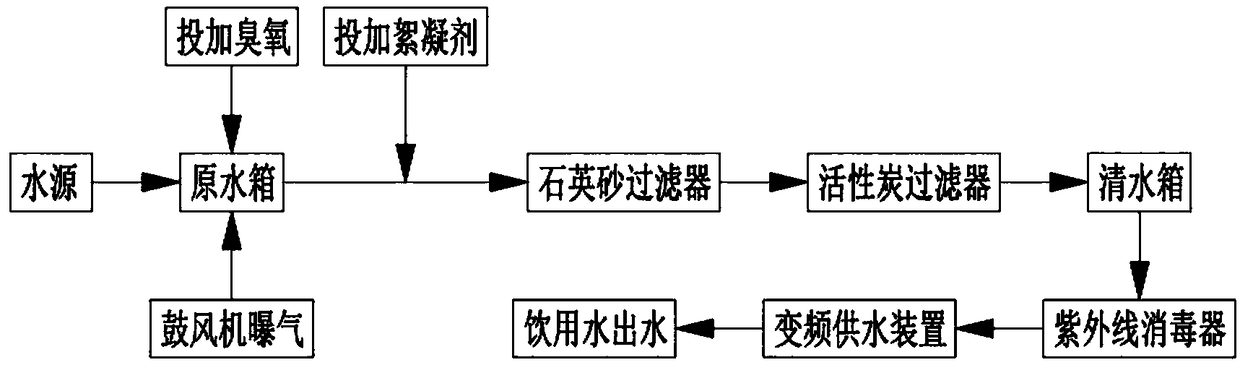

The invention relates to a process for removing geosmin in raw water of drinking water. The process comprises the following steps: introducing raw water into a raw water tank; carrying out aeration inthe raw water tank by using a blower, and adding ozone into the raw water tank for strong oxidation at the same time; mixing the water out of the raw water tank with a coagulant for a coagulation reaction; carrying out filtration after full coagulation; introducing filtered drinking water into a clean water tank; transporting the treated drinking water to each water use site by using a frequencyconversion water supply device; and arranging disinfection device between the water out of the clean water tank and the frequency conversion water supply device for disinfection treatment. Compared with the prior art, the treatment process provided by the invention has the advantages of high pollutant removal efficiency, high utilization rate of ozone and activated carbon, less dosage, less investment of water treatment equipment, no secondary pollution and the like.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Efficient recovery method of elementary substance zinc in zinc smelting tail gas of electric furnace

ActiveCN110029233APrevent oxidationAvoid cloggingProcess efficiency improvementRecovery methodElectric arc furnace

The invention discloses an efficient recovery method of elementary substance zinc in zinc smelting tail gas of electric furnace. The method comprises the following steps of 1 ) preparing a quenching salt solution; 2) zinc smelting tail gas of the electric furnace subjected to condensation and zinc collecting is conveyed to a washing tower through a conveying pipeline, quenching on the tail gas bytaking the salt solution prepared in the step (1) in the washing tower as a washing solution, and collecting elementary substance zinc in the tail gas; and 3) collecting a zinc elementary substance and a washing liquid which are collected after quenching, collecting the zinc elementary substance and the washing liquid into a tower bottom, filtering and separating to recover elementary substance zinc, and the separated salt solution is subjected to salt supplementing and / or supplementing water and then returning to the step (2) for recycling. According to the method disclosed by the invention, the quenching solution is mainly used for efficiently cooling the zinc smelting tail gas, so that the elementary substance zinc in the tail gas is rapidly condensed and collected, so that the zinc elementary substance is effectively prevented from being oxidized, and meanwhile, the phenomenon that the condensed zinc liquid is blocked and damaged due to the fact that the condensed zinc liquid isadhered to the tower wall, the pipeline and other equipment can be avoided. The method disclosed by the invention has the advantages that the construction operation cost is low, the operation is simple, and the high-efficiency recovery of elementary substance zinc in the zinc smelting tail gas of the electric furnace can be realized.

Owner:KUNMING UNIV OF SCI & TECH

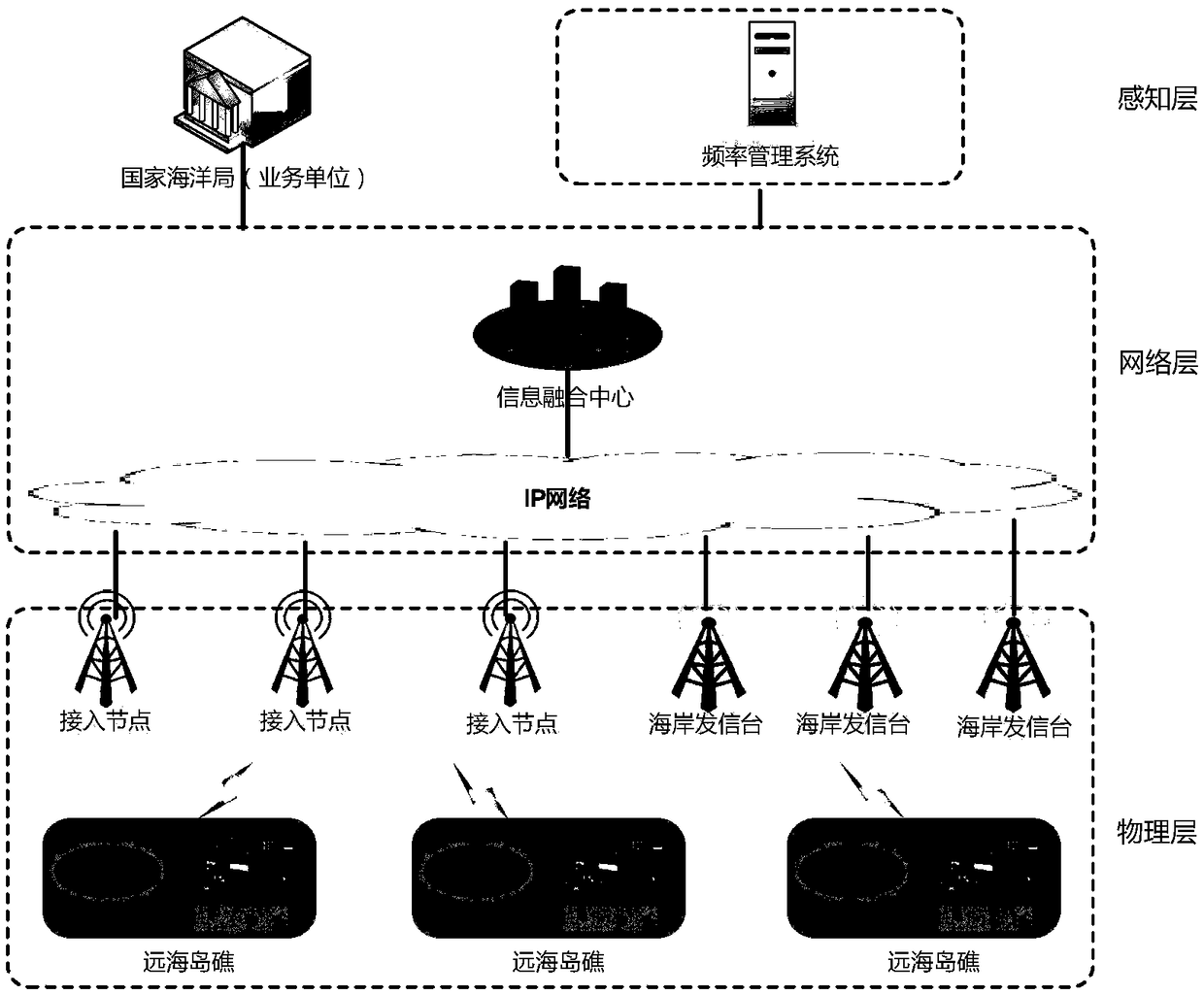

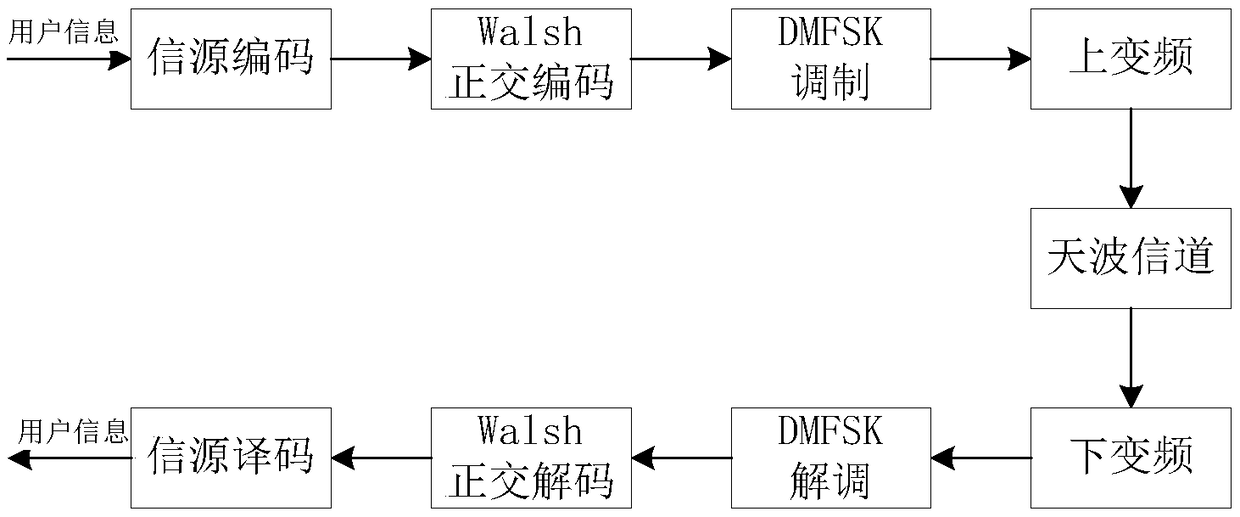

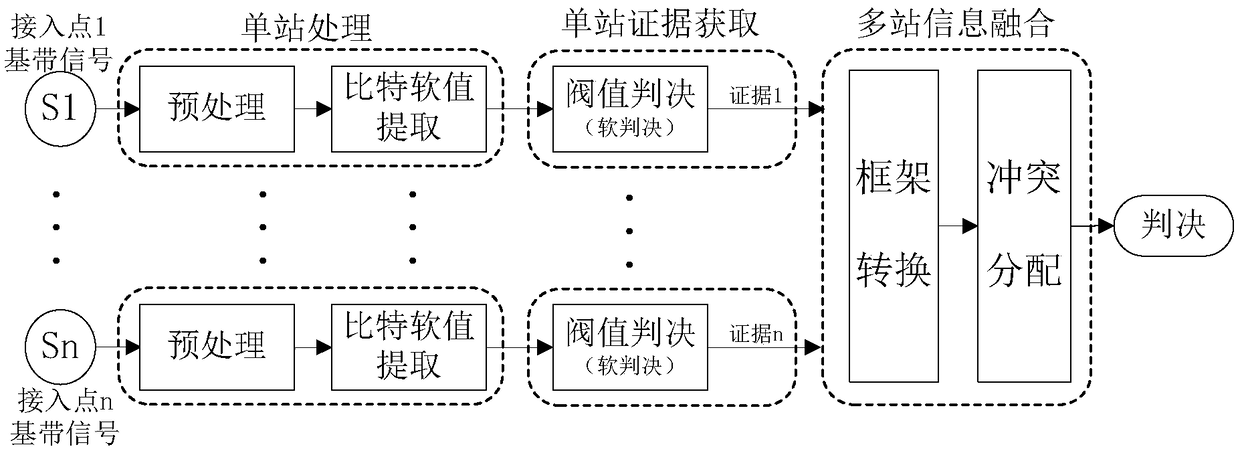

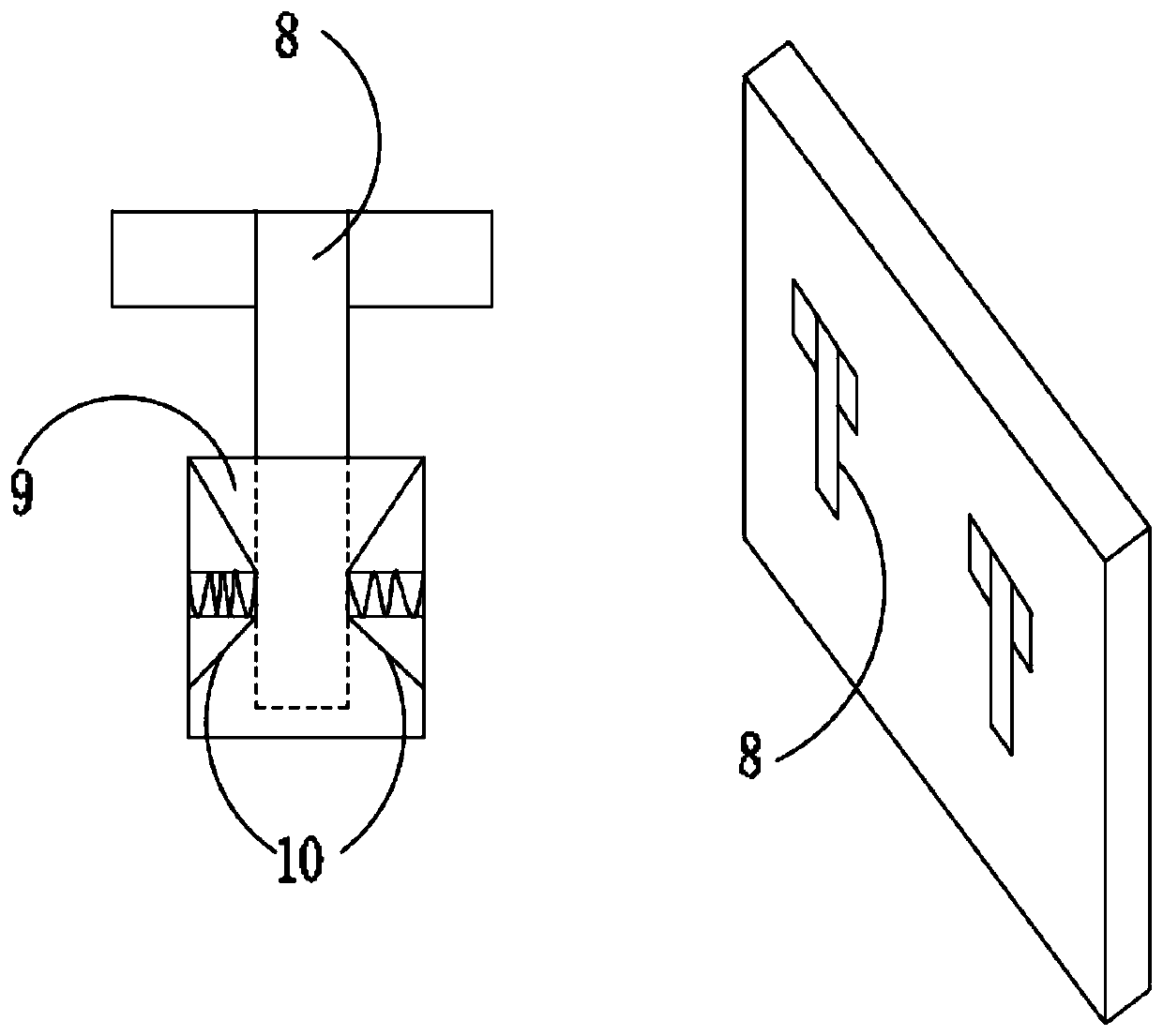

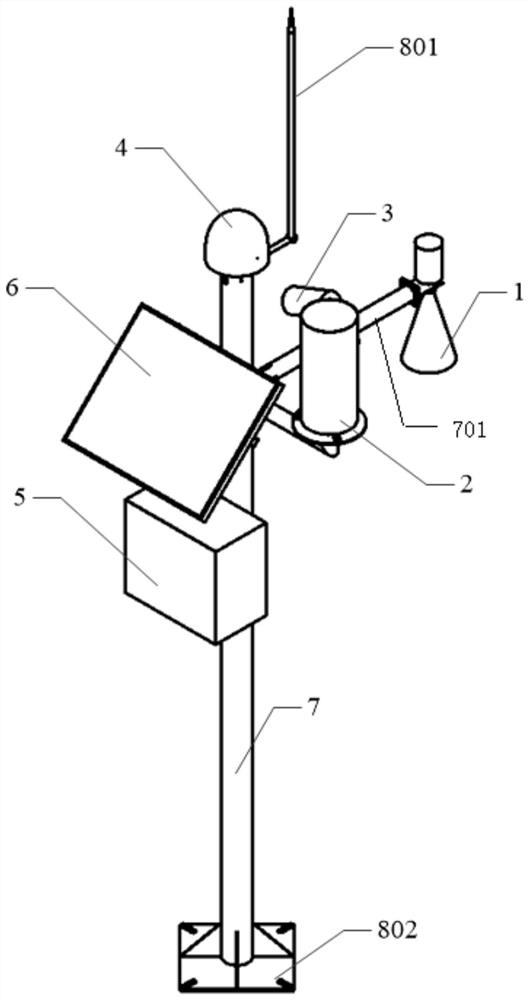

Offshore islands and reefs environmental monitoring system and decision-making fusion method

ActiveCN109088923ALow construction and operation costsLow costParticular environment based servicesFrequency-modulated carrier systemsWide areaOperational costs

The invention discloses a distant sea island reef environment monitoring system and a decision-level fusion method. The system adopts a physical layer, a network layer and a sensing layer three-layerstructure. The physical layer is configured with an access node, a coastal transmitting station and an offshore island and reef radio station. The offshore island and reef radio station receives the data uploaded by the environmental monitoring sensor and uploads the data to the network layer through the access node. The network layer includes IP bearer network and information fusion system. The sensing layer comprises a frequency management system and business units, wherein the frequency management system is used for dynamically planning the working frequency of the offshore island reef radio station and scheduling the corresponding coastal transmitter, and the business units are used for acquiring the monitoring situation data of each island reef environment. The invention adopts the wide-area cooperative receiving characteristic, relies on the communication base station widely distributed on the land of the iron tower company, the construction and operation cost is extremely low, and the multi-channel decision-making level fusion algorithm can effectively guarantee the reliable reporting of the environmental monitoring data of the offshore islands and reefs.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Multifunctional combined rod for urban road and design method of multifunctional combined rod

PendingCN111519559AReduce in quantityAvoid wastingTraffic signalsRoad signsLight equipmentStructural engineering

The invention provides a multifunctional combined rod for an urban road. The multifunctional combined rod comprises a rod main body, a rod head, a first connecting rod, a second connecting rod and a cross arm; the rod head is used for carrying lighting equipment; the rod head is connected with the rod main body; the rod main body is connected with the cross arm; mounting guide rails are arranged on four sides of the rod main body; and the mounting guide rails are used for mounting functional facilities; the cross arm is provided with a plurality of first installation positions, a plurality ofsecond installation positions and a plurality of third installation positions. According to the multifunctional combined rod of the invention, the problem that main rod pieces arranged on municipal roads are generally single-purpose single-rods is solved; various rod lines and road landscapes on urban roads are messy and unsystematic, function independently and are mutually shielded; repeated construction may disturb residents and waste resources; and the various messy and clustered rod pieces and cases matched with the rod pieces severely destroy the urban appearance and influence traffic, and construction and operation cost is increased. With the multifunctional combined rod adopted, the above problem can be solved.

Owner:四川城乡发展工程设计有限公司

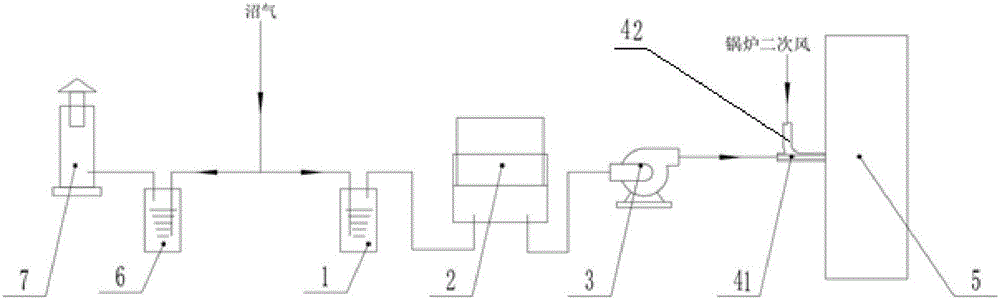

Methane utilization system and methane utilization method for waste incineration plant

InactiveCN106196079AImprove securityGuarantee continuous and stable operationIncinerator apparatusBuffer tankIncineration

The invention provides a methane utilization system and a methane utilization method for waste incineration plant. The utilization system for waste incineration plant comprises a first methane treating system and a second methane treating system; the first methane treating system comprises a first water-sealed tank, a pressure stabilizing buffer tank, a booster fan and waste incinerator secondary air casing pipes; the secondary air casing pipes comprise the first casing pipe and the second casing pipe, and the first casing pipe communicates with the second casing pipe; the methane mixes with secondary air coming from the second casing pipe after passing through the first casing pipe along the first water-sealed tank and the booster fan, and then enters the furnace of a waste incinerator; the second methane treating system comprises a second water-sealed tank and a methane dedicated incinerator; and the methane goes through the second water-sealed tank and then enters the methane dedicated incinerator to be subjected to temporary incineration treatment. According to the utilization system and the utilization method for waste incineration plant methane, the problems of potential safety hazards and energy waste existing in the methods that the methane is diffused into air to be burned or is sucked into a boiler to be burned through an air flue in an existing waste incineration plant are effectively solved.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

Treatment process of recycled waste water from polysilicon cutting waste mortar

ActiveCN103803758BThe processing process is simpleEasy to handleMultistage water/sewage treatmentOxygenFenton oxidation

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

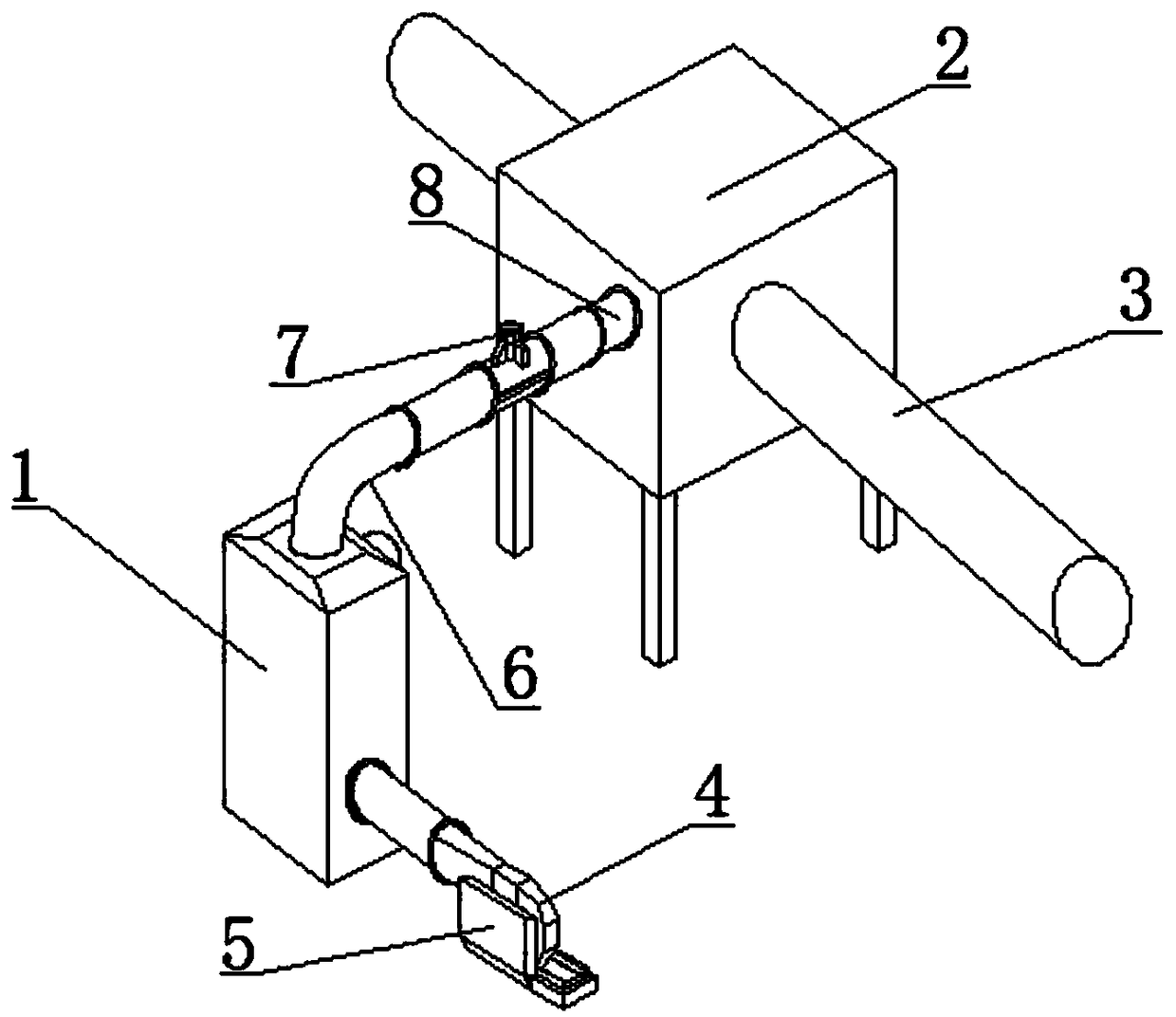

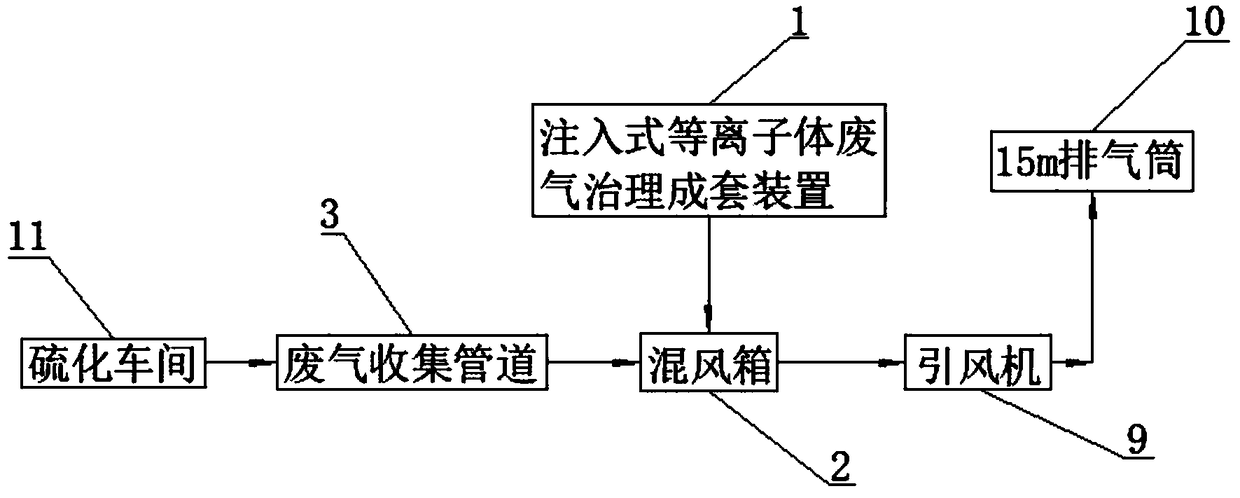

Process and device for treating vulcanization waste gas on basis of low temperature plasma technology

PendingCN109499286AReduce design requirementsImprove discharge efficiencyGas treatmentDispersed particle filtrationVulcanizationEnvironmental engineering

The invention relates to a process and device for treating vulcanization waste gas on the basis of a low temperature plasma technology. The device comprises injection type low-temperature plasma wastegas treatment complete equipment which comprises an injection fan, a pretreatment system is arranged at the downstream of the injection fan, a discharge system is arranged at the downstream of the pretreatment system, an injection system is arranged at the downstream of the discharge system and is connected with the discharge system and an air mixing box, a plasma generation region is independentfrom a reaction region, and potential safety hazards do not exist; the discharge module is pollution-free and is long in service life; barrier discharge is implemented by dual media, and the densityof generated plasma is high; treatment equipment is parallel to a waste gas pipe, waste gas collection and an exhaust fan are omitted, and the running power of an induced draft fan is reduced; the running cost is low; and through engineering test and examination, emission of non-methane hydrocarbons in the treated vulcanization waste gas is far lower than the state required standard which is 10 mg / m<3>, and the treatment efficiency exceeds 60%; and the odor concentration treatment efficiency exceeds 80%.

Owner:CAS NEW WORLD HEFEI ENVIRONMENTAL PROTECTION TECH CO LTD

Multi-parameter integrated small reservoir monitoring device

PendingCN114184237ARealize unified automatic collectionRealize access collectionMeasurement devicesStream gaugeIntegrated monitoring

The invention discloses a multi-parameter integrated small reservoir monitoring device. The device comprises a vertical rod, a water level gauge, a rain gauge, a camera, a GNSS receiving terminal and a data acquisition unit. The water level gauge is fixed on the vertical rod, is connected with the data acquisition unit through an RS485 interface, and is used for water level acquisition; the rain gauge is fixed on the vertical rod, is connected with the data acquisition unit and is used for acquiring rainfall; the camera is fixed on the vertical rod, is connected with the data acquisition unit through a serial port and is used for acquiring video images; and the GNSS receiving terminal is fixed at the top of the vertical rod, is connected with the data acquisition unit through an RS485 interface, and is used for acquiring horizontal and vertical displacement of the dam. Integrated monitoring of important monitoring items such as the water level, rainfall, video images and surface deformation of the small reservoir is achieved, and the problems that existing small monitoring items are incomplete, and the automation degree is low are solved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

System for treating constructed wetland fillers of organic composite slag

ActiveCN102910740ASimple operation and managementLow construction and operation costsBiological water/sewage treatmentWater qualityEnvironmental engineering

The invention relates to a system for treating constructed wetland fillers of organic composite slag and aims at strengthening denitrification treatment of nitrate-nitrogen pollution water. The system comprises a structure, a water inlet pipe and a water outlet pipe are arranged at the front end and the rear end of the structure respectively, the inside of the structure is divided into a water storage area, a water distribution area, a treatment area and a water collection area from front to back, matrixes in the water distribution area and in the water collection area are pebble fillers, the treatment area comprises a humus soil layer and a filler layer from top to bottom, plants are planted on the humus soil layer, and matrixes in the filler layer are the organic composite slag. Compared with systems in prior art, the system for treating the constructed wetland fillers of the organic composite slag has the advantages that additional carbon sources are not required to be added, the operating management is simple, the building and operating costs are low, the system is high in ability for removing nitrate and nitrogen and good in outlet water quality, a certain removal rate of the nitrate and the nitrogen can be guaranteed under the condition of low carbon sources in winter, the removal rate of the nitrate and the nitrogen can reach over 50% under the condition of a certain carbon source in summer, and the removal rate can be greatly increased with increase of carbon sources in the inflow.

Owner:SHANGHAI MUNICIPAL SEWERAGE CO LTD +1

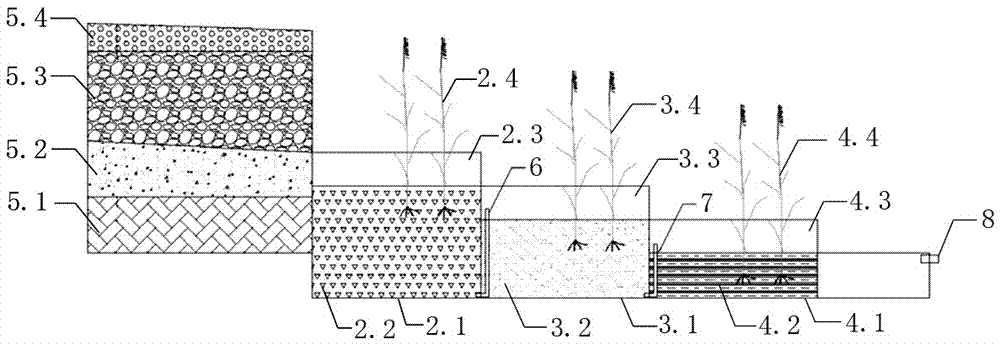

A method and device for advanced treatment of rural sewage combined with artificial wetland and infiltration system

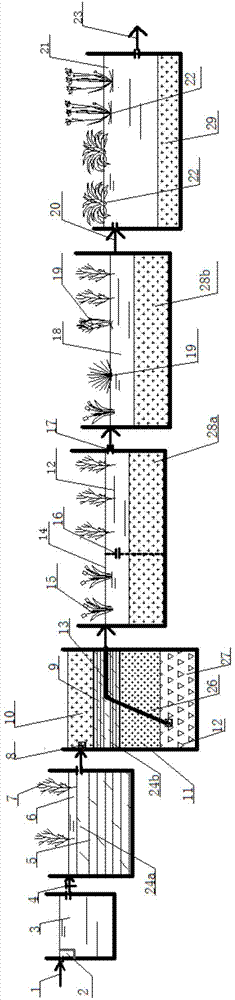

ActiveCN105293841BGood serviceImprove the ecological environmentMultistage water/sewage treatmentConstructed wetlandEcological environment

The invention discloses a method for advanced treatment of rural sewage by combining an artificial wetland and a percolation system. At the same time, the device for rural sewage treatment is disclosed. The sewage is collected into the main water inlet pipe through the collection pipe network. The first, second, third and fourth surface flow artificial wetlands are connected in turn through the overflow weir, and then connected to the horizontal subsurface flow infiltration system through the "∟" type overflow drainage pipe. After the filter system perforates the "Ш" type water collection pipe, it discharges the treated water up to the standard through the "─" type direct current drainage pipe. This method is easy to operate and maintain, has landscape effects and economic benefits, simple structure, low investment, and realizes decentralized rural Efficient treatment of domestic and aquaculture sewage to achieve effective protection of the rural ecological environment.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

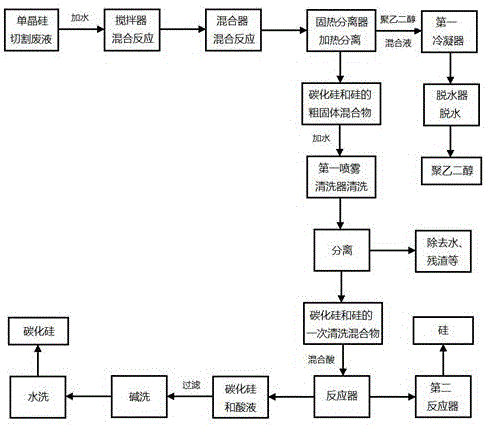

Novel manufacturing technique of recycling monocrystal silicon cutting waste mortar

The invention discloses a novel manufacturing technique of recycling the monocrystal silicon cutting waste mortar. In the process of recycling the silicon wafer cutting liquid in the waste mortar, silicon carbide micromist and solid monocrystal silicon in the waste mortar are recycled at the same time, and the recovery rate is high. The recycled silicon wafer cutting liquid has the same surface activity, suspension force and carrying force as the new cutting liquid. The process of the manufacturing technique is simple and convenient in operation, short in constructing and operating costs and easy in management, capable of recycling effectively the monocrystal silicon cutting waste mortar.

Owner:合肥耀贝软件开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com