Combined process for treating high-ammonia-nitrogen wastewater and treatment system

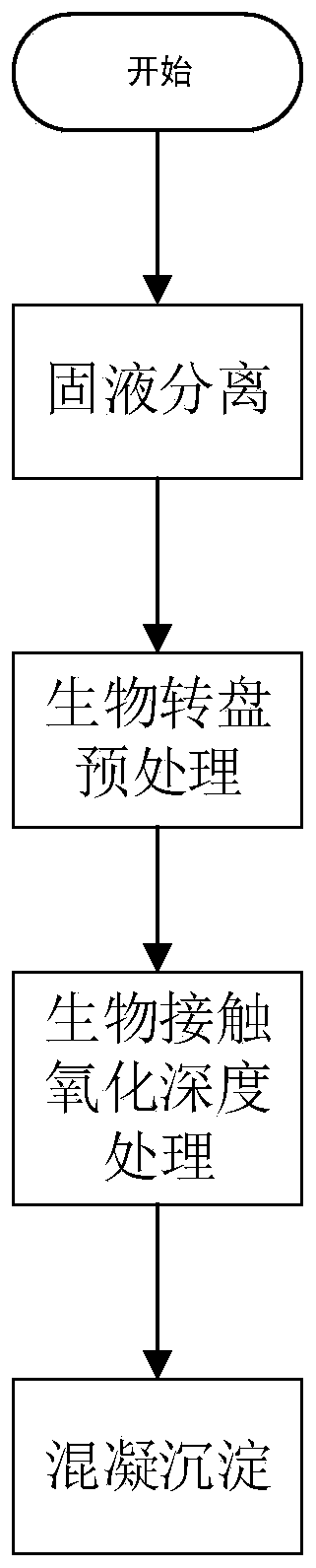

A wastewater treatment and combined process technology, which is applied in the field of combined processes and treatment systems for high-ammonia nitrogen wastewater treatment, can solve the problems of increasing biological disc plates, complicated process flow, limiting pollutant treatment effect, etc., so as to improve the process treatment effect, Enhanced denitrification and phosphorus removal efficiency and good sludge sedimentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] According to the above steps, after the raw water of a pig farm in Banan, Chongqing, the solid-liquid separation of feces and waste liquid is achieved through a centrifuge, the supernatant is taken as influent water, which is sequentially passed through the biological turntable pretreatment unit 300 and biological contact The advanced oxidation treatment unit 400 has a processing capacity of 100L / d.

[0062] During the operation of the treatment system, the ambient temperature is kept at 25-28°C, the hydraulic retention time of the biological turntable pretreatment unit 300 is set to 24h, and four turntables 301 are used for grading treatment. The water end 305 to the water outlet 306 are arranged in sequence, the rotation speed of the first turntable at the water inlet is 100rpm / min, the second turntable is 60rpm / min, the third turntable is 30rpm / min, and the turntable at the water outlet is 100rpm / min. 10rpm / min, so that the dissolved oxygen concentration of the high ...

Embodiment 2

[0068] After the pig farm wastewater is treated by anaerobic fermentation, the biogas slurry produced has the characteristics of high ammonia nitrogen and low carbon nitrogen ratio. The two major treatment difficulties of traditional nitrogen removal technology are: high ammonia nitrogen has biological toxicity, which inhibits the growth of microorganisms; the concentration of organic matter in biogas slurry is low, and the biodegradability is poor, resulting in C / N imbalance, which cannot provide sufficient carbon sources for microorganisms, making wastewater detoxification. Nitrogen is less effective.

[0069] The combined process of the present invention is used to treat the biogas slurry of a fine-breed pig farm in Banan, Chongqing City. After the biogas slurry is sequentially treated by the biological turntable pretreatment unit and the biological contact oxidation advanced treatment unit, the effluent of the coagulation and sedimentation unit can meet the discharge standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com