Dialysis cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

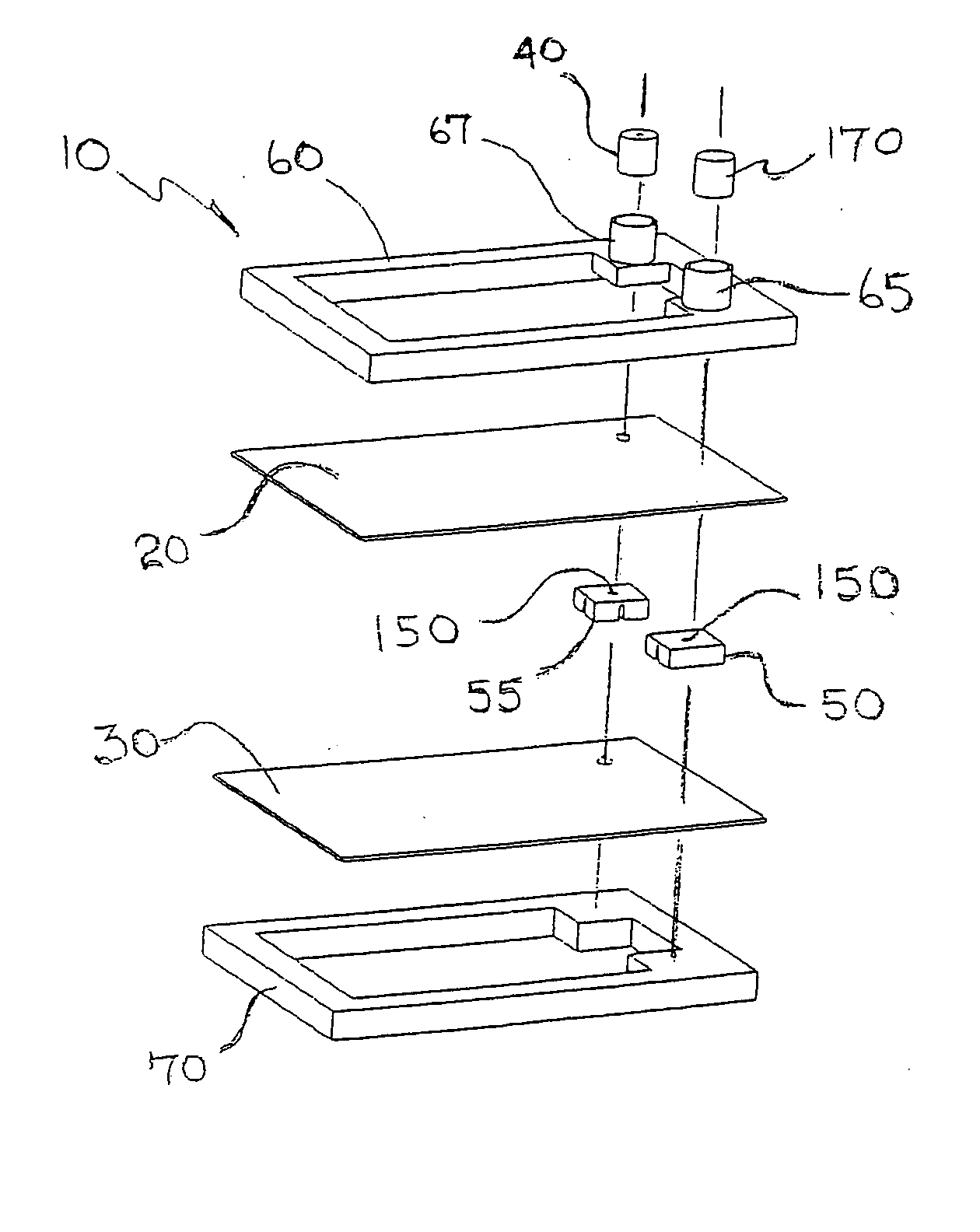

[0029] Exploded views of a preferred embodiment of dialysis cartridge 10 are depicted in FIG. 1A from an upper perspective, and FIG. 1B from a lower perspective. Needle access disk 50 and pipette access disk 55 reside between upper membrane 20 and lower membrane 30. Upper frame 60 and lower frame 70 sandwich upper membrane 20 and lower membrane 30 together about their perimeters, and at the upper surfaces of needle access disk 50 and pipette access disk 55, making a liquid tight compartment for sample. Perimeter sealing ridge 62, emanating from upper frame 60, presses against lower frame 70 in order to create a liquid tight seal about the perimeter of upper membrane 20 and lower membrane 30. Upper frame 60 contains needle access port holder 65, pipette access port holder 67, each with fluid transport opening sealing ridges 63, best shown in FIG. 1C which is Detail A of FIG. 1B. Fluid transport opening sealing ridges 63 apply the appropriate force against needle access disk 50 and pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com