Novel manufacturing technique of recycling monocrystal silicon cutting waste mortar

A technology for cutting waste sand and production process, applied in recycling technology, silicon, products, etc., can solve the problems of increased processing cost, quality change of cutting fluid, etc., and achieves low construction and operation cost, high recovery rate, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

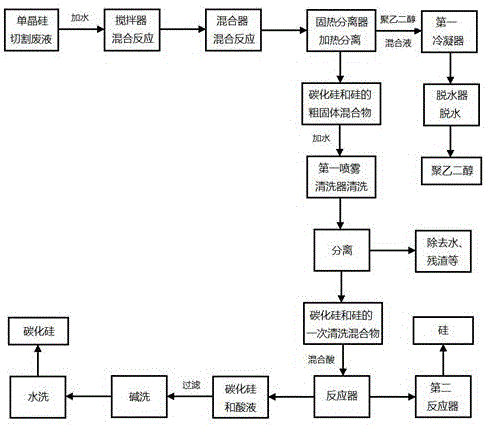

[0014] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention is further described:

[0015] Such as figure 1 As shown, the new monocrystalline silicon cutting waste mortar recycling production process, the specific steps are as follows:

[0016] (1) After adding a certain amount of water to the monocrystalline silicon cutting waste liquid, mix it in the agitator first, then enter the mixer for mixing reaction, and then use the solid heat separator to heat and separate it to obtain polyethylene glycol mixed liquid, silicon carbide and Crude solid mixture of silicon.

[0017] (2) Add water to the coarse solid mixture of silicon carbide and silicon, and then use the first spray cleaner to clean, remove impurities such as water and residue, and obtain a primary cleaning mixture of silicon carbide and silicon, and then add sulfuric acid to react to obtain silicon carbide and acid Liquid, and then after filtration, alkali washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com