Process and device for treating vulcanization waste gas on basis of low temperature plasma technology

A low-temperature plasma and exhaust gas technology, applied in membrane technology, gas treatment, separation methods, etc., can solve problems such as air pollution and ingress, and achieve the effects of low operating costs, high density, and reduced exhaust gas collection and exhaust fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

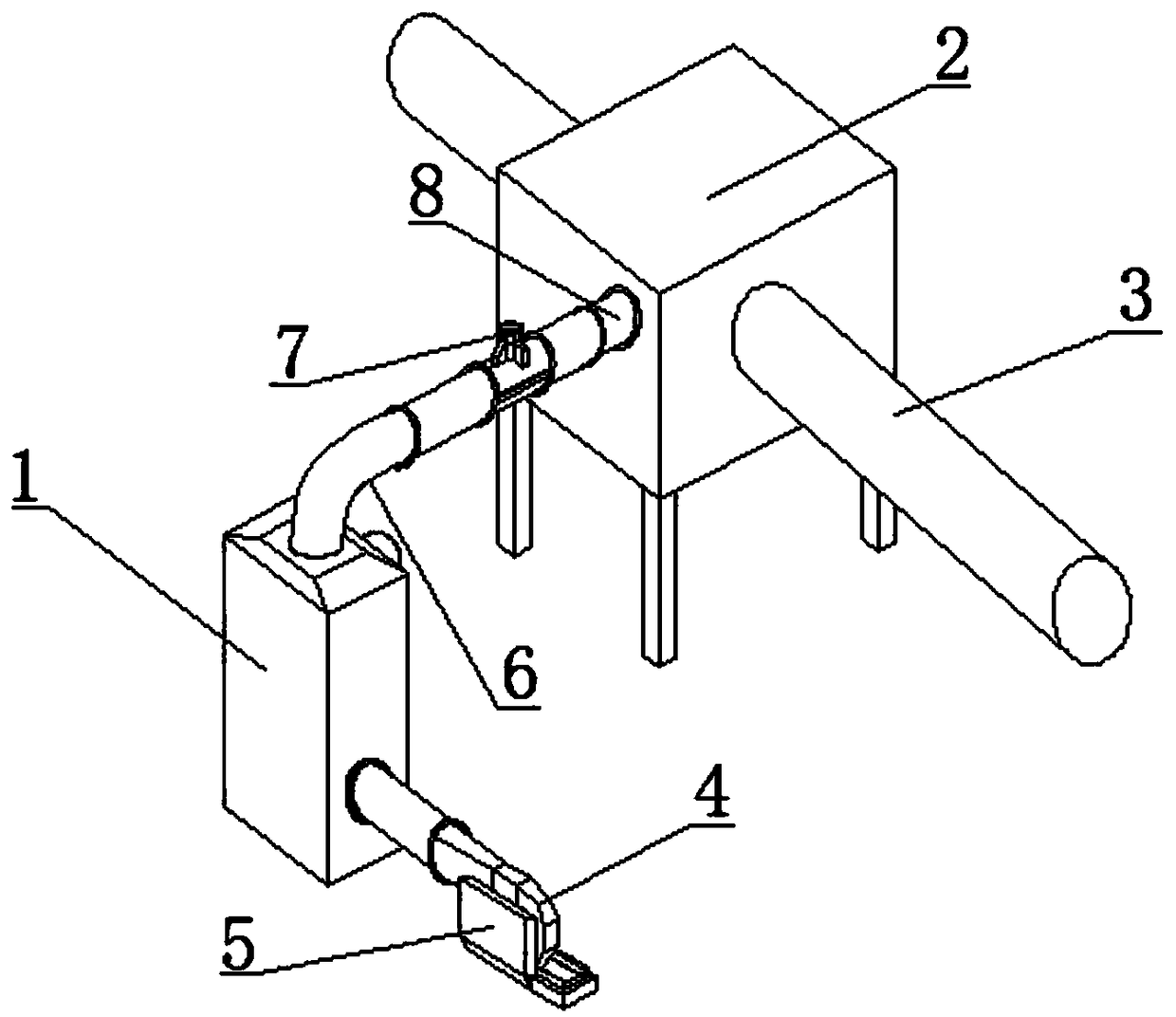

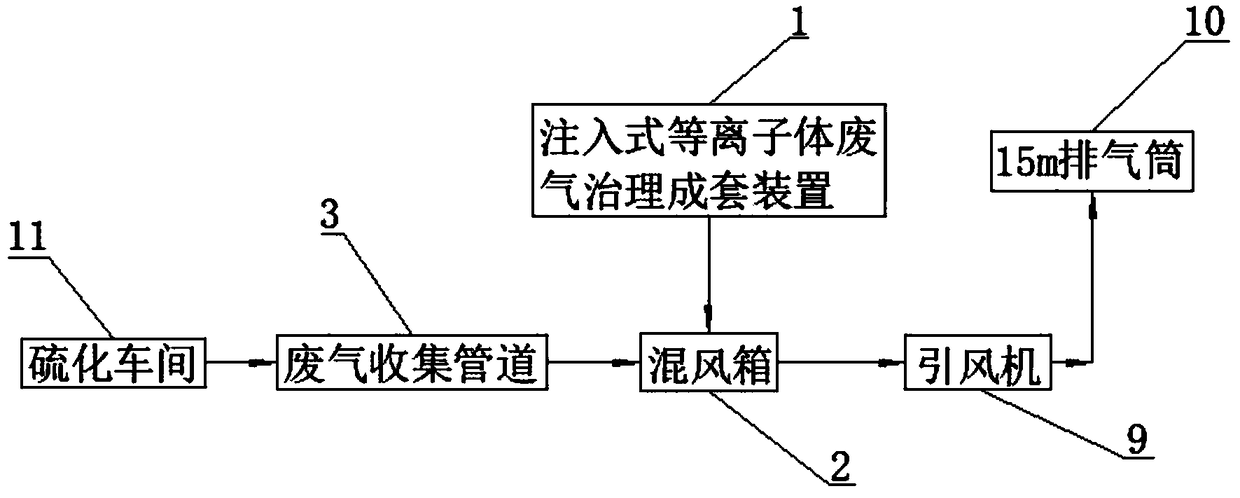

[0030] like Figure 1-2 As shown, a device for treating sulfide exhaust gas based on low-temperature plasma technology includes an injection-type low-temperature plasma exhaust gas treatment complete set 1, and the injection-type low-temperature plasma exhaust gas treatment complete set 1 includes an injection fan 4, and the injection fan 4 A pretreatment system is provided downstream, a discharge system is provided downstream of the pretreatment system, an injection system is provided downstream of the discharge system, and the injection system is connected to the discharge system and the air mixing box 2;

[0031] The injection-type low-temperature plasma waste gas treatment complete set 1 also includes a control system, the control system includes a sensor module and a PLC module, the sensor module is arranged inside the discharge system, the downstream of the sensor module is connected to the PLC module, and the downstream of the PLC module Connect the pretreatment system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com