Integrated ammonia-process desulfurization method of various acidic gases in oil refining device

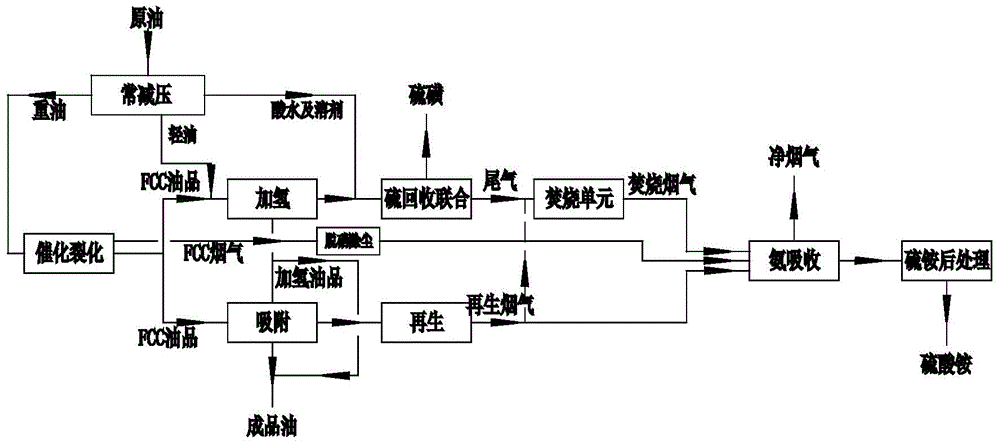

A technology for ammonia desulfurization and oil refining equipment, which is applied to chemical instruments and methods, separation methods, and hydrocarbon oil treatment, and can solve problems such as difficulty in meeting national emission requirements, complicated treatment processes, and waste liquid discharge, and achieve significant environmental benefits. and social benefits, the process is simple, and the effect of not increasing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 15t / h crude oil is often decompressed to obtain 1.9t / h light oil, 10t / h heavy oil, sour water and solvent, and 10t / h heavy oil enters the catalytic cracking unit to obtain 3.1t / h FCC oil with S content of 600ppm, 2.4t / hS FCC oil with 125ppm content, 12600Nm 3 / h, SO 2 The FCC flue gas with a concentration of 0.3% is treated by three-stage cyclone dust removal and SCR denitrification, 3.1t / h FCC oil with a S content of 600ppm and light oil with a 1.9t / h and 1000ppm hydrogenation unit are used to obtain 4.4t / h S content of 30ppm Hydrogenated oil is used as refined oil, sour water produced by atmospheric pressure and hydrogenation, and solvent sulfur recovery unit, after treatment, 5Nm 3 / h Tail gas with sulfide content of 1.2%, incinerated at 840-880°C, flue gas residence time 1.5-2.7s, 7.5Nm after incineration 3 / h, SO 2 Incineration flue gas with concentration of 0.8%, hydrogen sulfide and organic sulfur content of 4.7ppm. 2.4t / h FCC oil with 125ppm S content was re...

Embodiment 2

[0040] 80t / h crude oil is often decompressed to obtain 15t / h light oil, 50t / h heavy oil, sour water and solvent, and 50t / h heavy oil enters the catalytic cracking unit to obtain 15t / h FCC oil with S content of 6200ppm, 12t / h FCC oil with S content of 325ppm FCC oil, 63000Nm 3 / h, SO 2 The FCC flue gas with a concentration of 0.4% is treated by two-stage cyclone dust removal and SNCR denitrification, and the FCC oil product with a S content of 15t / h of 6200ppm and the light oil with a S content of 15t / h of 2700ppm are processed by a hydrogenation unit to obtain a hydrogenated oil with a S content of 27t / h of 42ppm Products, acid water produced by atmospheric pressure and hydrogenation, and solvent sent to the sulfur recovery unit, through the sulfur recovery unit to obtain 382Nm 3 / h Tail gas with sulfide content of 1.2%, incinerated at 800-850°C, flue gas residence time 2.5-3.6s, after incineration to obtain 762Nm 3 / h, SO 2 Incineration flue gas with a concentration of 0.6...

Embodiment 3

[0042] 160t / h crude oil is often decompressed to obtain 48t / h light oil, 100t / h heavy oil, acid water and solvent, and 100t / h heavy oil enters the catalytic cracking unit to obtain 32t / h FCC oil with S content of 3200ppm, 25t / h FCC oil with S content of 425ppm FCC oil, 120000Nm 3 / h, SO 2 The FCC flue gas with a concentration of 0.35% is treated with two-stage cyclone dust removal and SNCR denitrification, and 32t / h of oil with a S content of 3200ppm and 48t / h of light oil are hydrogenated to obtain 67t / h of hydrogenated oil with a S content of 15ppm. The sour water and solvent produced by pressure and hydrogenation are sent to the sulfur recovery unit, and the sulfur recovery unit can obtain 2650Nm 3 / h tail gas with a sulfide content of 1.35%, incinerated at 810-900°C, the residence time of flue gas is 1.1-2.9s, and 4240Nm is obtained after incineration 3 / h, SO 2 Incineration flue gas with a concentration of 0.844% and a hydrogen sulfide and organic sulfur content of 6.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com