Device and method for treating refractory iron ore

An iron ore, difficult to select technology, applied in the direction of improving process efficiency, etc., can solve the problems of not mentioning the equipment that can be industrialized, not having the practicality of industrial scaled production, and the recovery rate is less than 55%, Achieve the effect of saving high-quality fuel, improving economies of scale and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

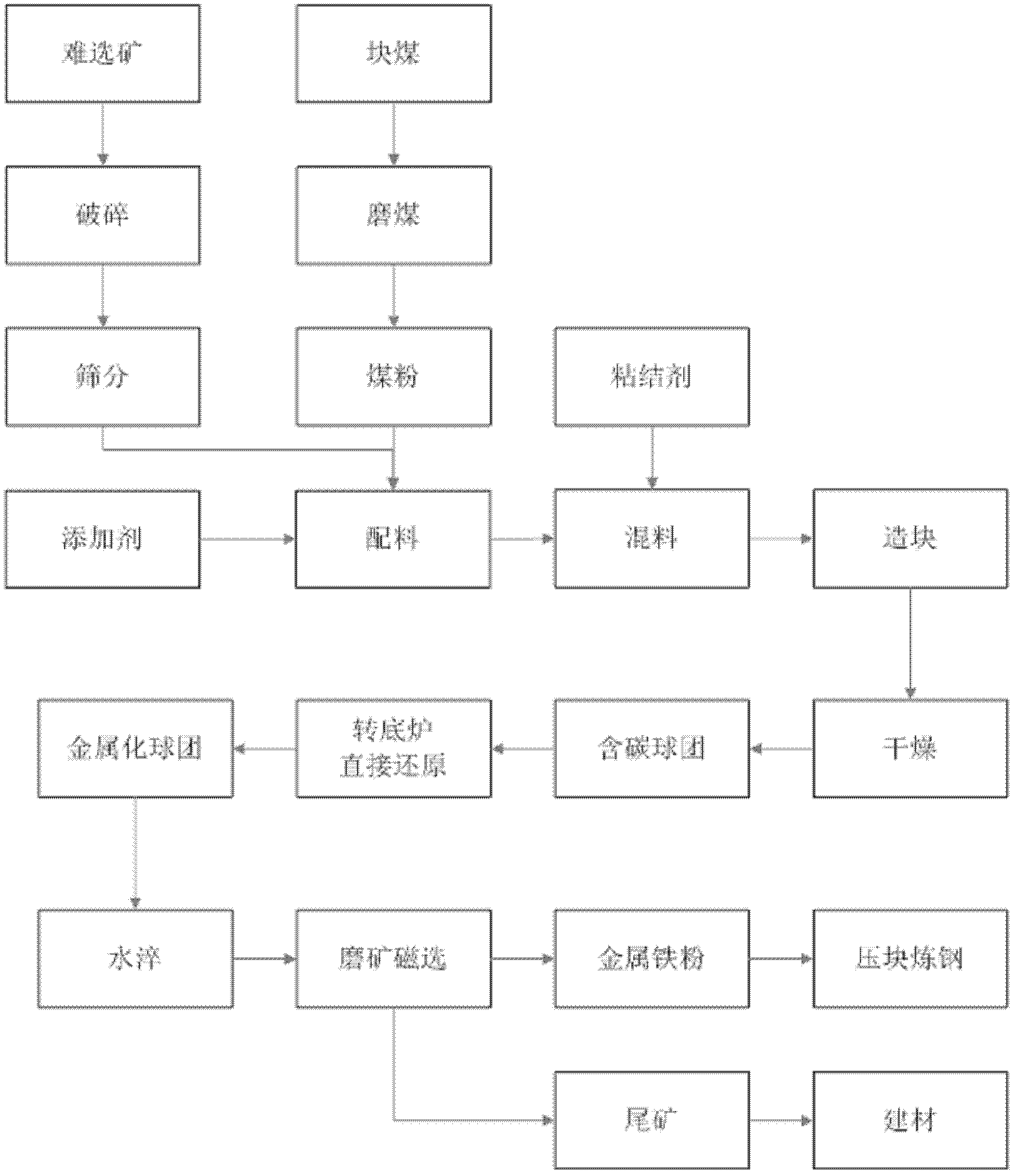

[0075] Example 1

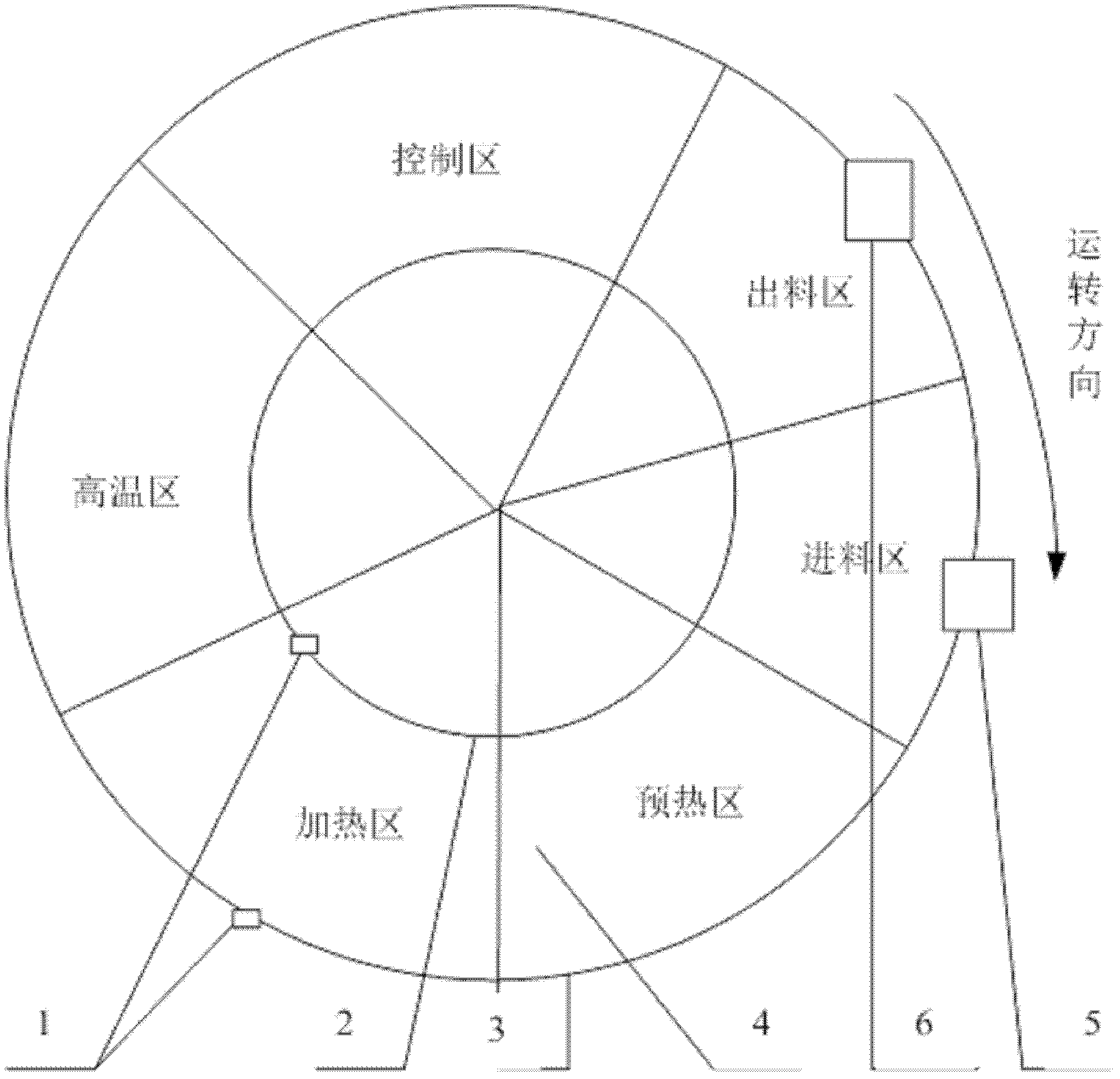

[0076] Use fine-grained hard-to-select hematite ore with a total iron content of 44.98%. 63 parts of hard-to-select hematite ore according to the fine particles; 14 parts of anthracite; 4 parts of binder, after mixing uniformly, use a pair of roller high-pressure ball press to form agglomerates, and pass the dried carbonaceous pellets through the distributing device Distributed into the rotary hearth furnace, the carbon-containing pellets pass through the feeding zone, preheating zone, heating zone, high temperature zone, control zone and discharge zone of the regenerative rotary hearth furnace in sequence; the process parameters are as follows:

[0077] Preheating zone: temperature 800℃~1000℃, time 3min;

[0078] Heating zone: temperature 1000℃~1250℃, time 3min;

[0079] High temperature zone: temperature 1250℃~1350℃, time 15min;

[0080] Control area: temperature 1350℃~1200℃, time 8min.

[0081] Finally, the metallization rate of the metallized pellets discharged f...

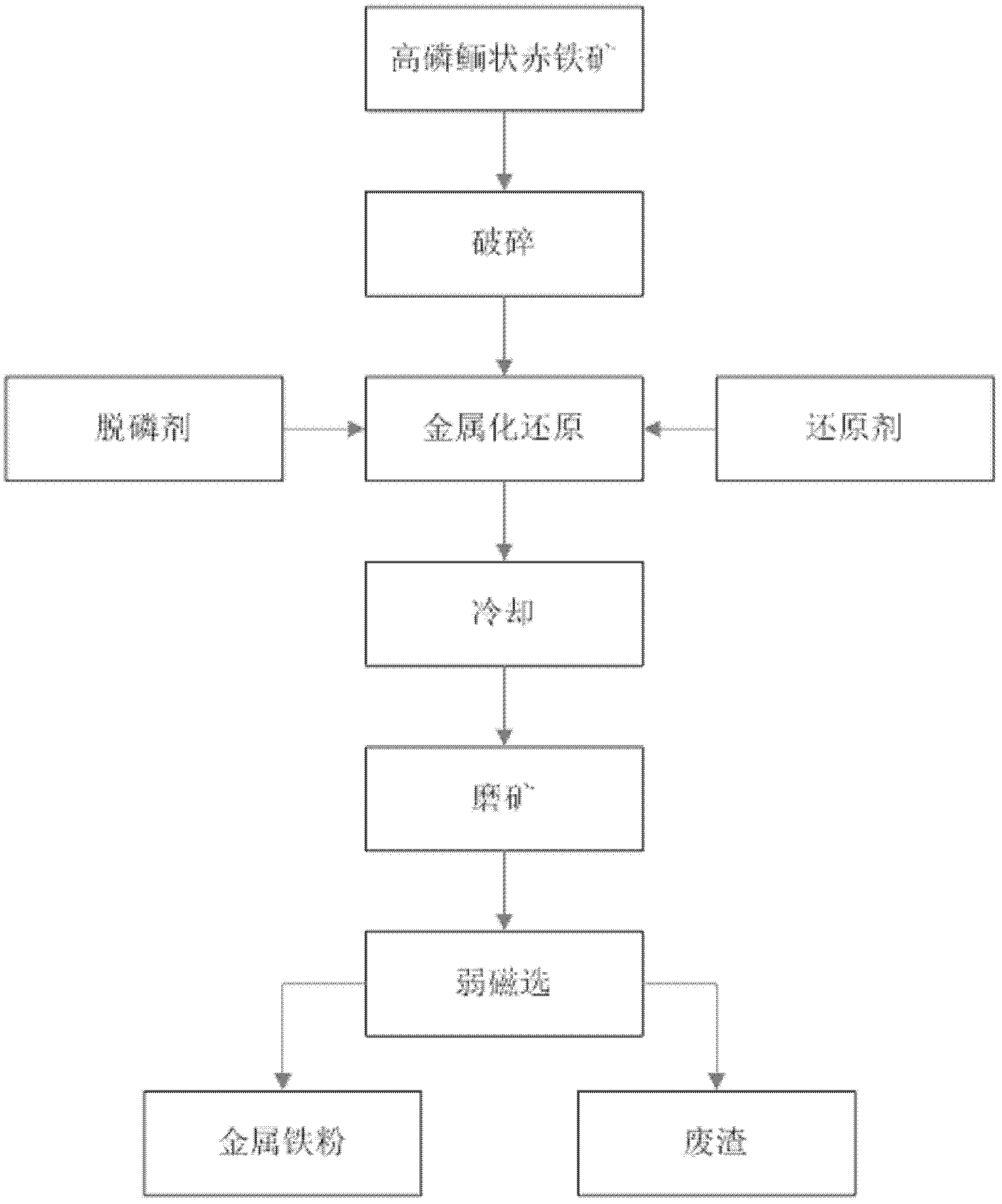

Example Embodiment

[0082] Example 2

[0083] High-phosphorus oolitic hematite is selected. The refractory ore contains 38.33% iron and 0.89% phosphorus. According to 84 parts of high-phosphorus oolitic hematite; 32 parts of lignite; 18 parts of limestone; after the specific gravity of 14 parts of binder is evenly mixed, agglomerates with a pair of roller high-pressure ball press, and the dried carbonaceous pellets are passed through The distributing device is placed into the rotary hearth furnace, and the carbon-containing pellets pass through the feeding zone, preheating zone, heating zone, high temperature zone, control zone and discharge zone of the regenerative rotary hearth furnace in sequence. The process parameters are as follows:

[0084] Preheating zone: temperature: 800℃~1000℃, time: 4min;

[0085] Heating zone: temperature: 1000℃~1250℃, time: 15min;

[0086] High temperature zone: temperature: 1250℃~1350℃, time: 3min;

[0087] Control area: temperature: 1350℃~1200℃, time: 3min.

[0088] Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com