Comprehensive extraction of valent metal from bismuth-containing polymetallic material

A valuable metal, comprehensive extraction technology, applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of low product added value, unsatisfactory separation, difficult to handle, etc., to achieve high product added value, High metal recovery rate and good economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described with specific embodiments in conjunction with the drawings.

[0025] The bismuth-containing material used in this embodiment has the following composition:

[0026] Pb38% Cu12% Bi18% Fe1.2% Ag3.5% Te15% Other 12.8%;

[0027] The material is smelter waste residue, which is lumpy and has metallic luster after crushing. The higher value of the material is silver and tellurium, and the others can be recovered from by-products.

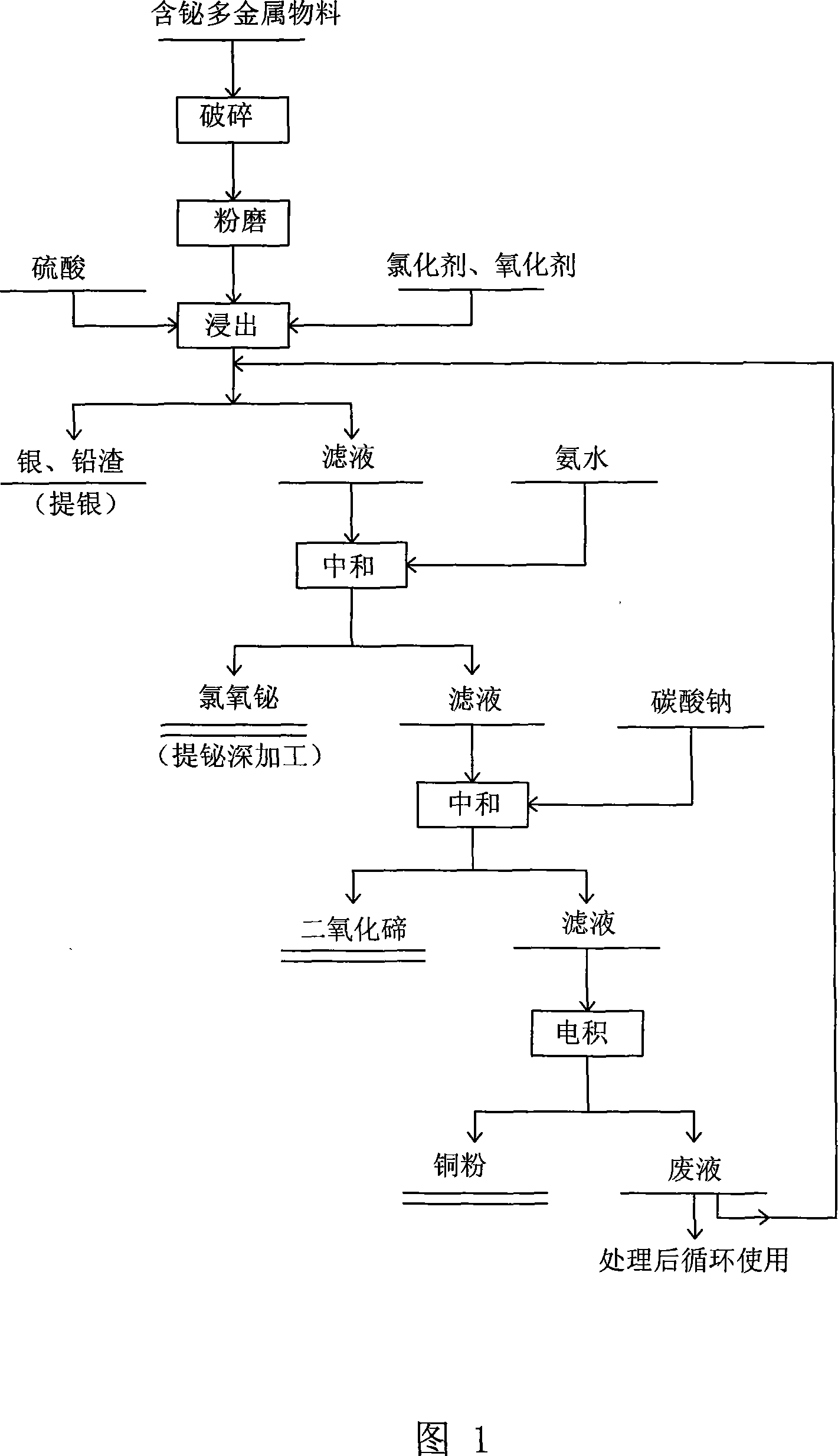

[0028] The process steps for comprehensively extracting valuable metals from the above-mentioned bismuth-containing materials are shown in Figure 1;

[0029] a. Crushing: large pieces of material are crushed by the crusher until the particle diameter is less than 2cm;

[0030] b. Grinding: The crushed materials are pulverized by Raymond pulverizer, controlling 80% of the material particle size to below -120 mesh; the grinding process is a mechanical activation process, which can effectively improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com