Preparation method of uranium nitride fuel powder and pellet

A technology of uranium nitride and diuranium trinitride, which is applied in the field of nuclear fuel preparation, can solve problems such as the reduction of cold-pressed forming density, and achieve the effects of easy control, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

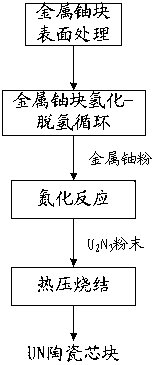

[0033] Such as figure 1 Shown, the preparation method of uranium nitride fuel powder and pellet provided by the present invention comprises the following steps:

[0034] (1) Surface purification treatment of pure metal uranium block.

[0035] Polish the pure metal uranium block with sandpaper, remove the surface oxide film with dilute nitric acid, wash with absolute ethanol, and quickly proceed to the next step after drying.

[0036] In the present invention, pure metal uranium is selected as the reaction raw material instead of uranium dioxide, which avoids the oxygen in the raw material remaining in the uranium nitride powder, and because there is no uranium dioxide, there is no need to add carbon to reduce the uranium dioxide Uranium, thus avoiding the introduction of carbon and oxygen impurity elements in uranium nitride powder from the source.

[0037] (2) Cyclic hydrogenation-dehydrogenation method to prepare metal uranium powder.

[0038] The metal uranium powder pre...

Embodiment 1

[0053] Polish the pure uranium metal block with sandpaper, remove the oxide film on the surface with dilute nitric acid, wash with absolute ethanol, and quickly transfer it into a resistance furnace after drying, and vacuumize the furnace.

[0054] Raise the temperature of the furnace to 150°C and fill it with 0.1MPa 99.999% high-purity H 2 Carry out the hydrogenation reaction, the hydrogenation holding time is 16h, after the first hydrogenation is completed, the furnace is evacuated to maintain a vacuum of 5Pa, and the temperature is raised to 600°C for 2h for dehydrogenation, after the dehydrogenation is completed, H 2 , for the second hydrogenation. Hydrogenation-dehydrogenation was cycled 4 times to obtain metal uranium powder. In the process of hydrogenation-dehydrogenation cycle, except that the hydrogenation holding time was reduced from 16h for the first time to 12h, 10h, and 8h, the other parameters remained unchanged.

[0055] After the last dehydrogenation, the met...

Embodiment 2

[0058] The process of preparing metal uranium powder in the present embodiment is identical with embodiment 1, and difference is:

[0059] During cyclic hydrogenation-dehydrogenation, the furnace temperature is raised to 230°C for hydrogenation, and the dehydrogenation is carried out at 490°C and the vacuum degree in the furnace is 50Pa;

[0060] After cyclic hydrogenation-dehydrogenation, metal uranium powder is cooled to 400°C with the furnace, and 0.2MPa99.999% high-purity N is introduced 2 , keep warm for 15h, carry out nitriding reaction;

[0061] Before hot pressing and sintering, denitrify at 1200°C for 1 h, and then maintain a vacuum of 2×10 -2 Pa, hot press sintering at 1600°C and mold pressure of 60MPa, heat preservation and pressure holding for 1h, the obtained UN pellet density is 98.9%TD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com