Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Uranium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uranium nitride refers to a family of several ceramic materials: uranium mononitride (UN), uranium sesquinitride (U₂N₃) and uranium dinitride (UN₂). The word nitride refers to the −3 oxidation state of the nitrogen bound to the uranium.

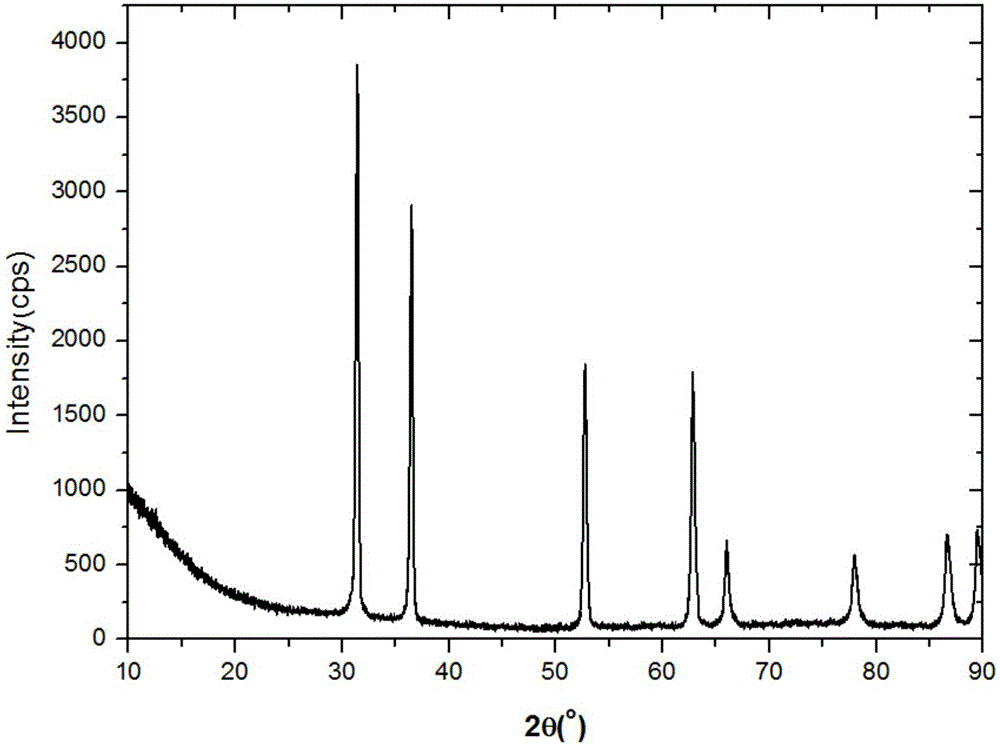

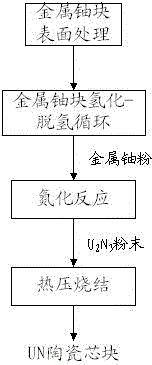

Preparation method of uranium nitride fuel powder and pellet

ActiveCN103466568AHigh purityHigh sintering activityNuclear energy generationNitrogen-metal/silicon/boron binary compoundsSurface cleaningDehydrogenation

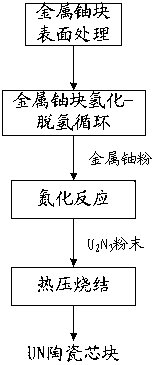

The invention relates to a preparation method of uranium nitride fuel powder and a pellet, which comprises the following steps: (1) carrying out surface cleaning treatment on a pure metal uranium lump; (2) hydrogenating the pure metal uranium lump in hydrogen at 150-300 DEG C for 2-16 hours, dehydrogenating in a vacuum, and repeating the hydrogenation-dehydrogenation several times to obtain metal uranium powder; (3) nitridizing the metal uranium powder in nitrogen at 200-600 DEG C for 6-24 hours to obtain U2N3 powder; (4) denitrifying the U2N3 powder in a mold, keeping the system vacuum, pressurizing the mold to 30-60 MPa, sintering at 1450-1620 DEG C for 1-2 hours, and cooling to obtain the UN ceramic pellet. The method provided by the invention is simple in technique and easy to control; and the obtained intermediate product U2N3 powder has higher purity and higher sintering activity, and can be finally subjected to hot pressed sintering to obtain the UN fuel pellet of which the TD is up to 98.9%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Low temperature route to uranium nitride

A method of preparing an actinide nitride fuel for nuclear reactors is provided. The method comprises the steps of a) providing at least one actinide oxide and optionally zirconium oxide; b) mixing the oxide with a source of hydrogen fluoride for a period of time and at a temperature sufficient to convert the oxide to a fluoride salt; c) heating the fluoride salt to remove water; d) heating the fluoride salt in a nitrogen atmosphere for a period of time and at a temperature sufficient to convert the fluorides to nitrides; and e) heating the nitrides under vacuum and / or inert atmosphere for a period of time sufficient to convert the nitrides to mononitrides.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

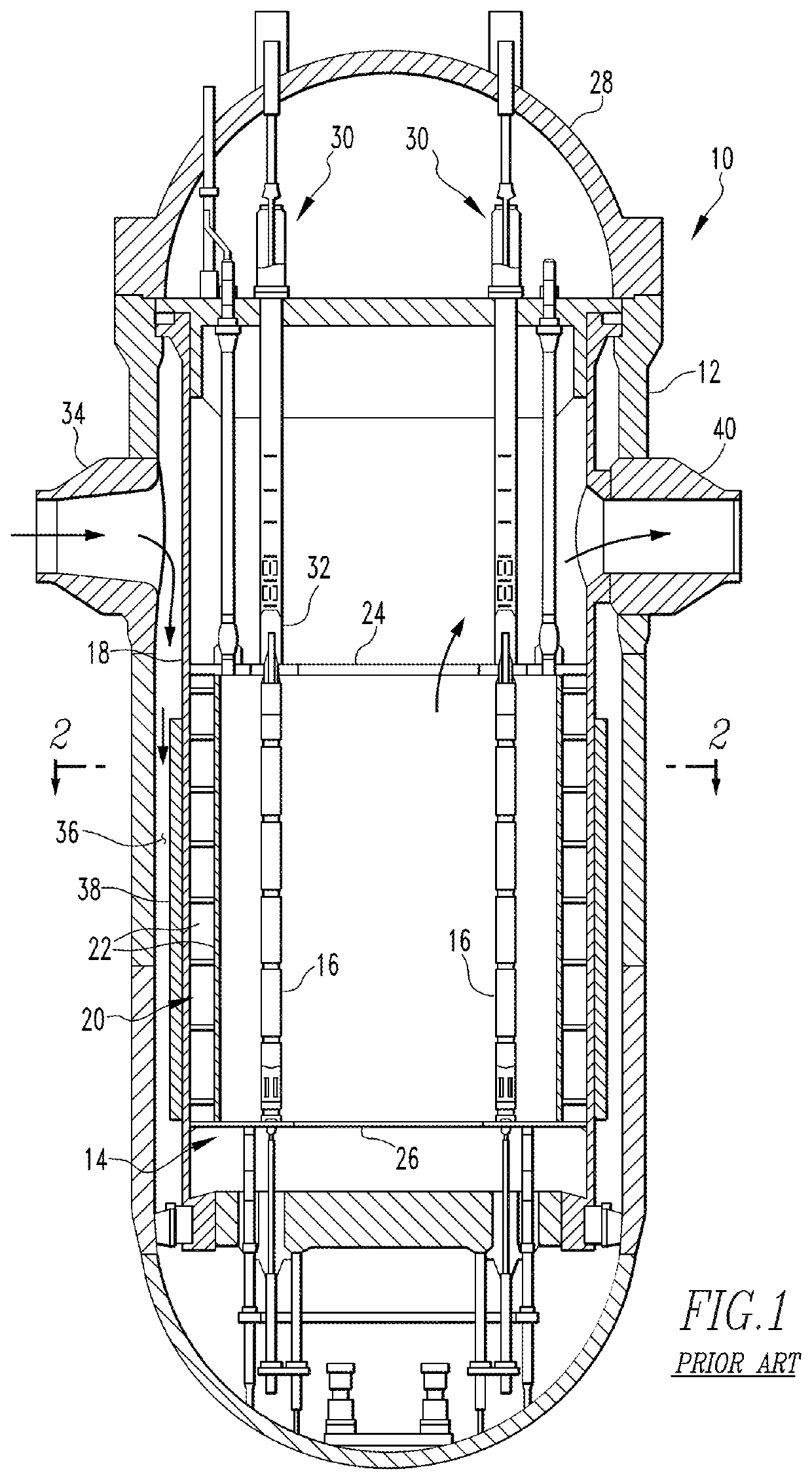

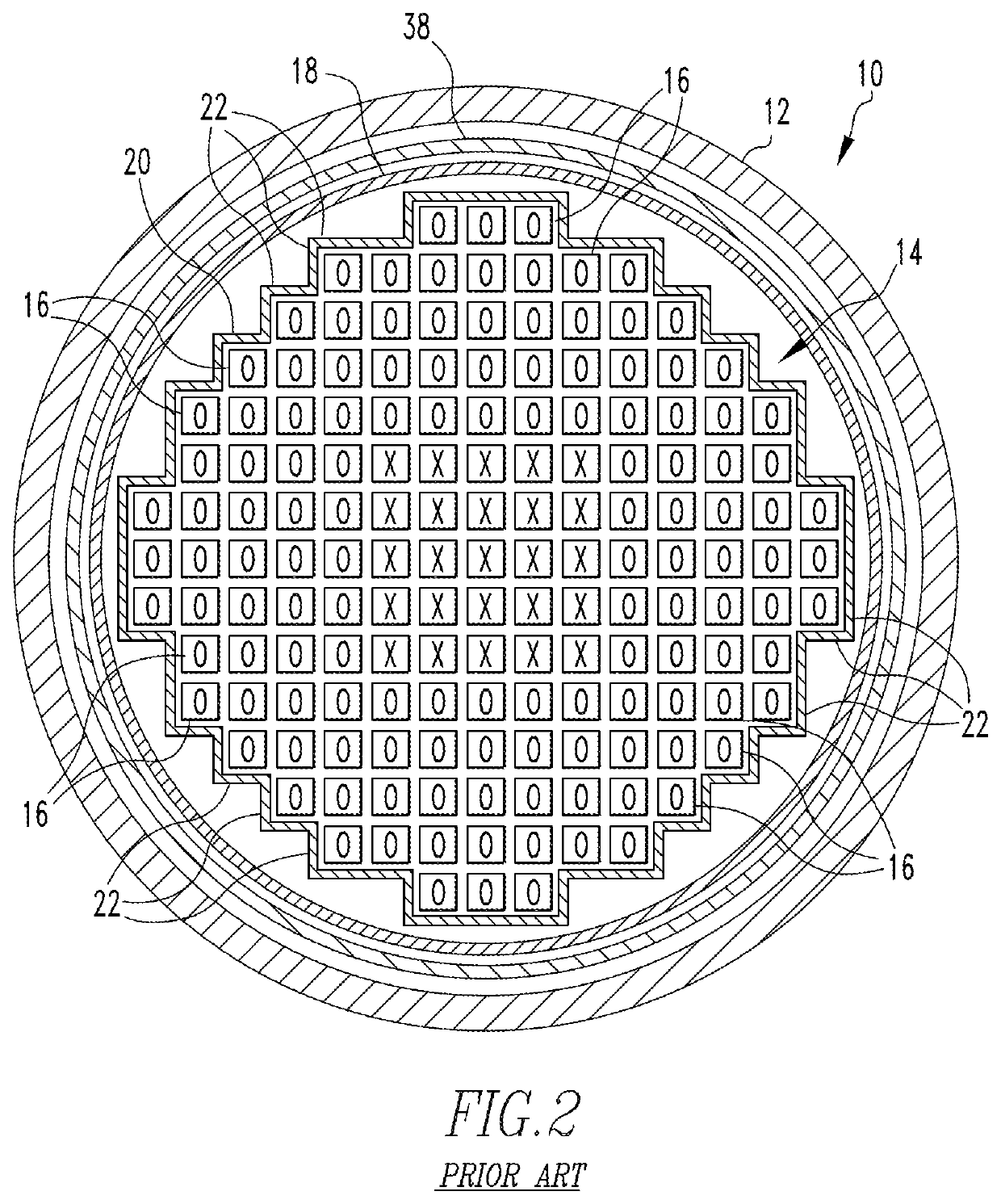

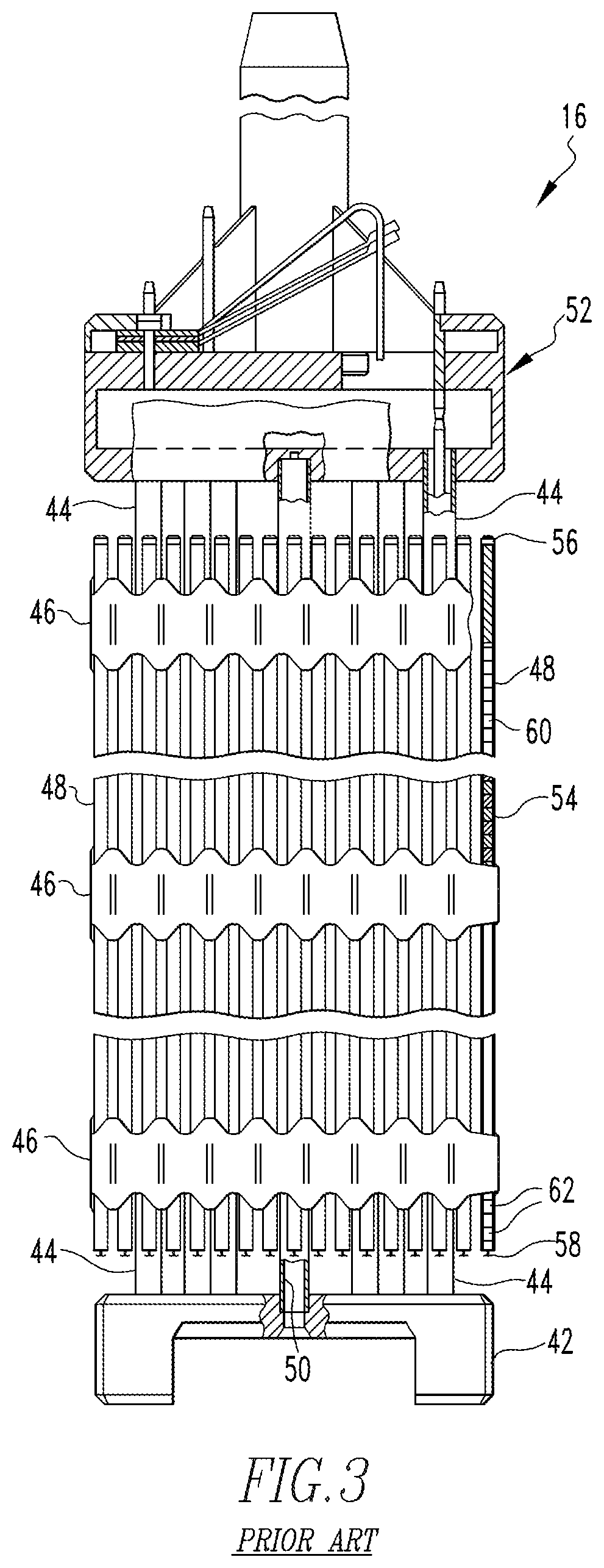

Extension of methods to utilize fully ceramic micro-encapsulated fuel in light water reactors

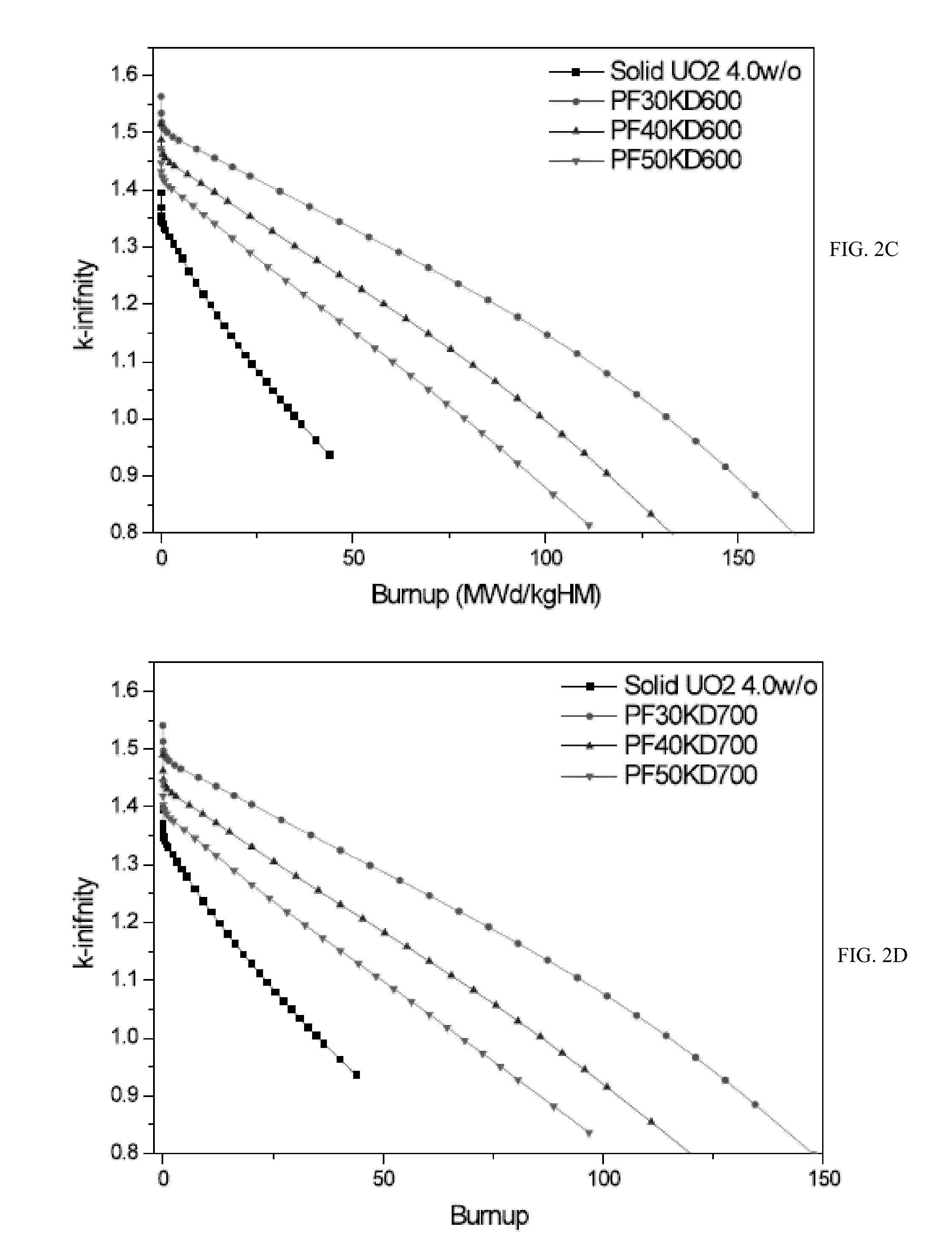

InactiveUS20130322590A1Heavy qualityLarge caliberOptical rangefindersNuclear energy generationMicrometerUranium nitride

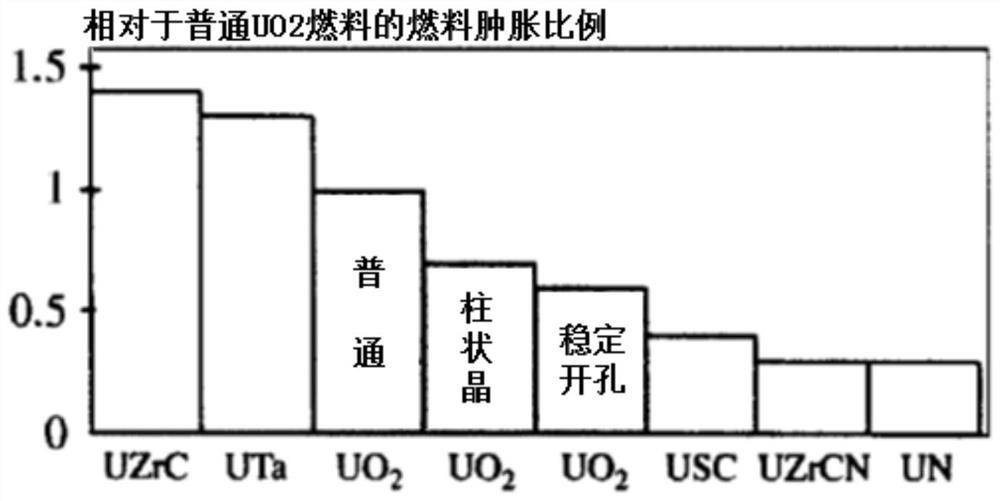

A 12×12 fully ceramic micro-encapsulated fuel assembly for a light water nuclear reactor includes a set of FCM fuel rods bundled in a square matrix arrangement. The fully ceramic micro-encapsulated fuel is comprised of tristructural-isotropic particles. Each tristructural-isotropic particle has a kernel that is comprised uranium nitride. The kernel diameter is 400 or more micrometers. The fully ceramic micro-encapsulated fuel is further mixed with a burnable poison material.

Owner:KOREA ATOMIC ENERGY RES INST

Use of isotopically enriched nitride in actinide fuel in nuclear reactors

InactiveUS20050286676A1Lower the volumeFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The present invention provides a nuclear fuel comprising an actinide nitride such as uranium nitride, suitable for use in nuclear reactors, including those based substantially on thermal fission, such as light and heavy water or gas-cooled nuclear reactors. The fuel contains nitrogen which has been isotopically enriched to at least about 50% 15N, most preferably above 95%. The fuel can be in the form of particles, pellets, in annular form or other forms having high surface to volume ratios.

Owner:WESTINGHOUSE ELECTRIC CORP

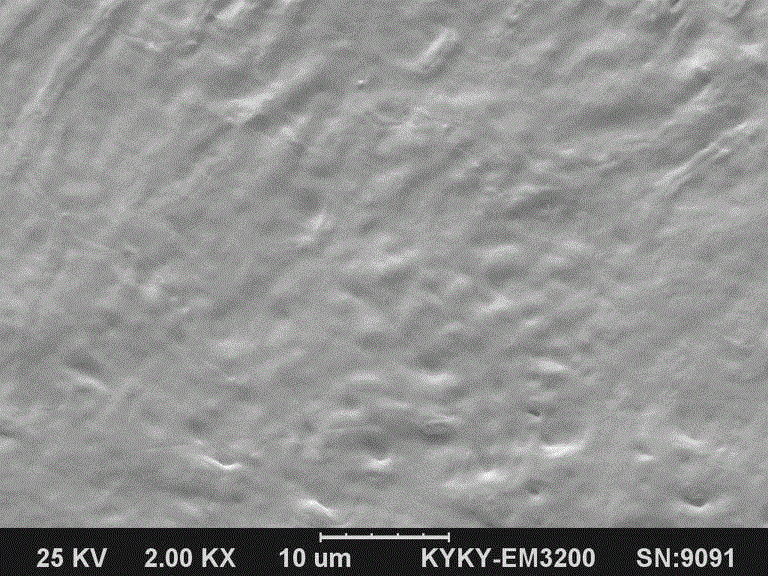

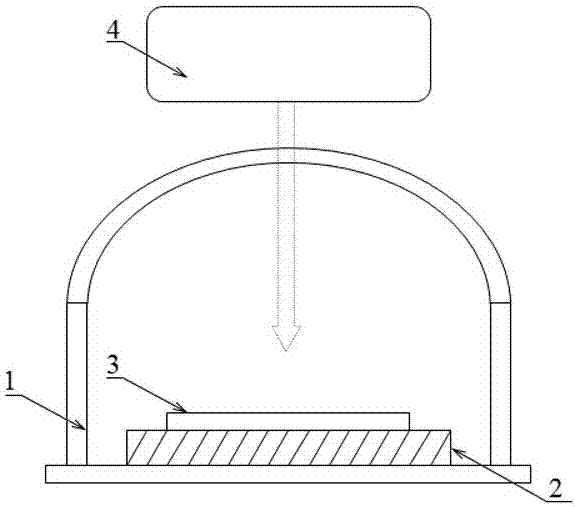

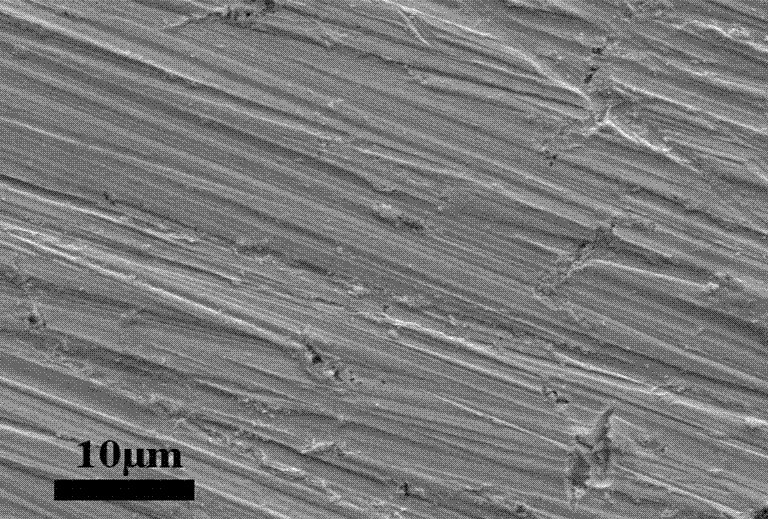

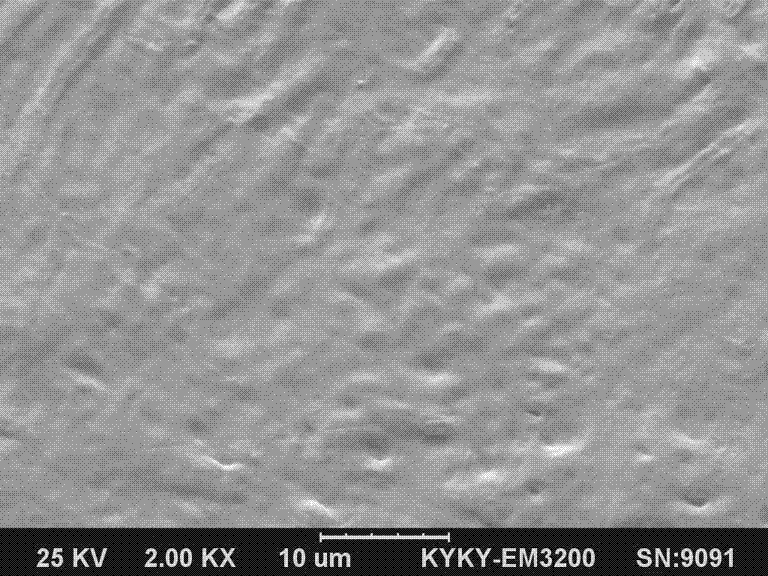

Method and device for preparing uranium surface anti-corrosion protecting layer through atmospheric laser passivation

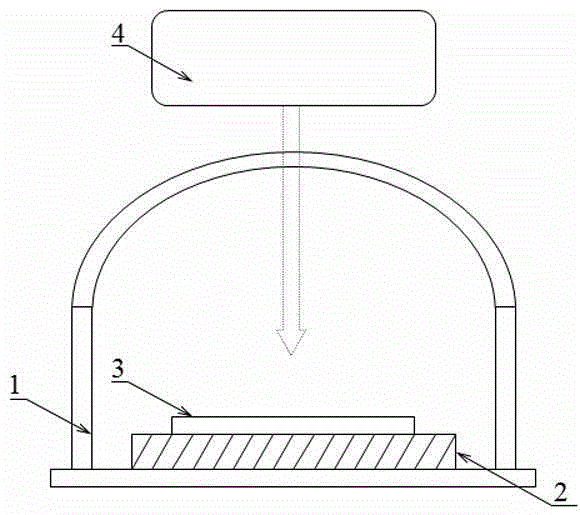

ActiveCN105063547AEliminate vacuuming stepSimple processSolid state diffusion coatingNitrogenNanosecond pulse

The invention discloses a method and a device for preparing a uranium surface anti-corrosion protecting layer through atmospheric laser passivation and aims to solve the problems that workpiece sizes are limited, demands of industrial production and application are hardly met and prepared uranium nitride films are still corroded to a certain degree in terms of current uranium nitride film preparation by laser nitridation. In the atmospheric environment, the workpiece surface is scanned through nanosecond pulse laser, the laser energy density is 20-70J / cm2, the overlapping ratio is 80%-95%, and therefore a uranium nitrogen oxygen passive film in a ceramic state is prepared on the workpiece surface. A vacuum environment and a special gas source are not required; machining demands of plane workpieces, abnormal-shaped workpieces and large workpieces can be met; the machining speed is high; the demands of the industrial application can be met. Meanwhile, the prepared uranium nitrogen oxygen passive film is excellent in corrosion resistance, pre-treatment of the workpiece surface is not needed; the quantity of generated wastes is small; environment-friendly effect is achieved. By means of the method and the device for preparing the uranium surface anti-corrosion protecting layer through atmospheric laser passivation, during workpiece machining, burrs of the workpiece surface can be removed, and the method and the device have good application prospects.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

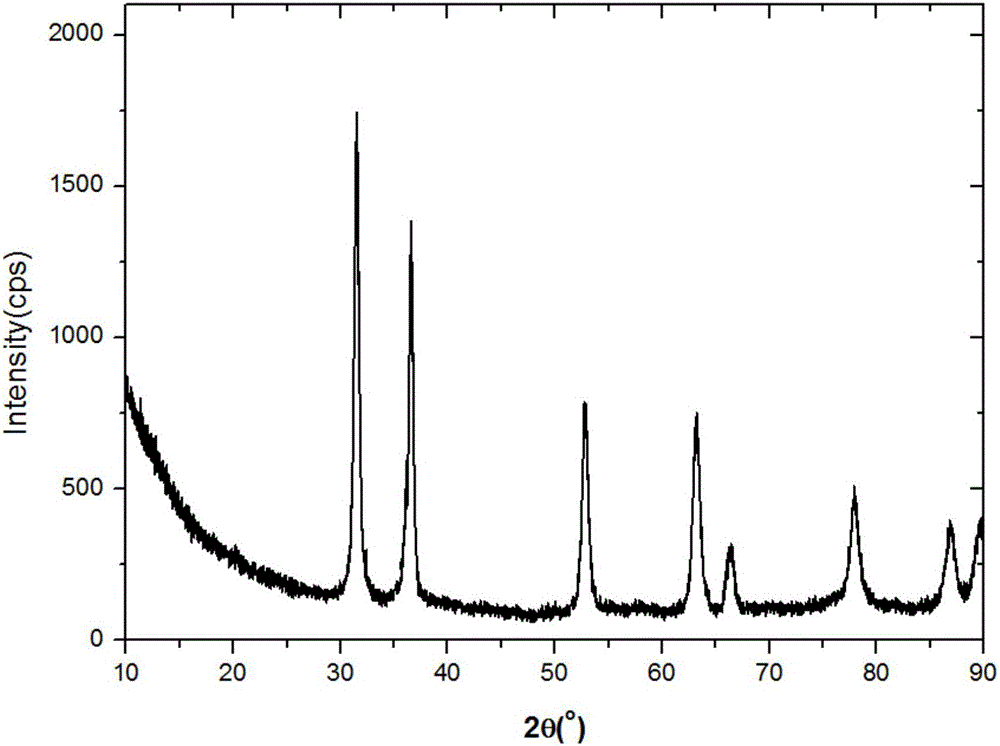

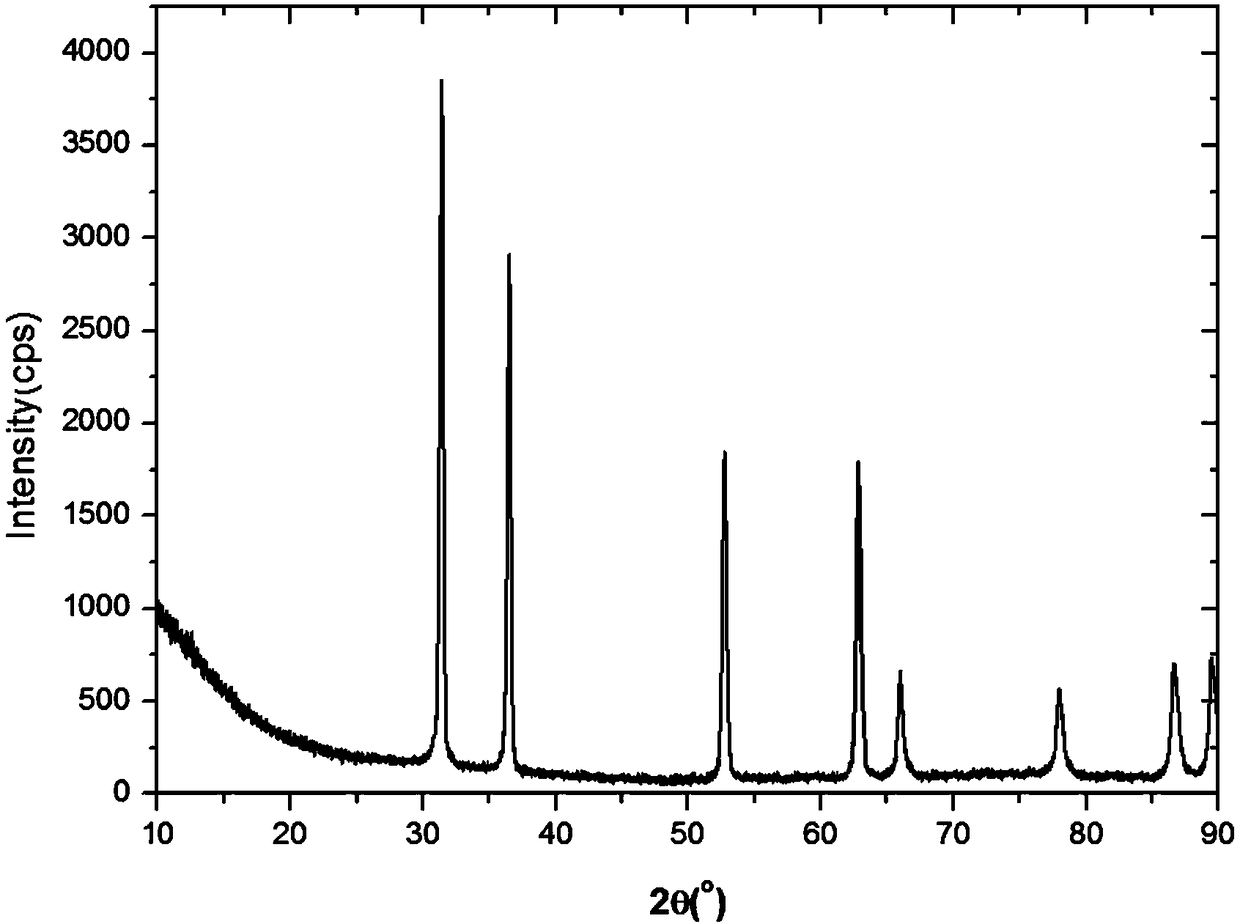

Low-temperature synthesis method for uranium nitride powder

ActiveCN106829886ASmall granularityLow impurity contentNuclear energy generationNitrogen-metal/silicon/boron binary compoundsHydrogenSynthesis methods

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

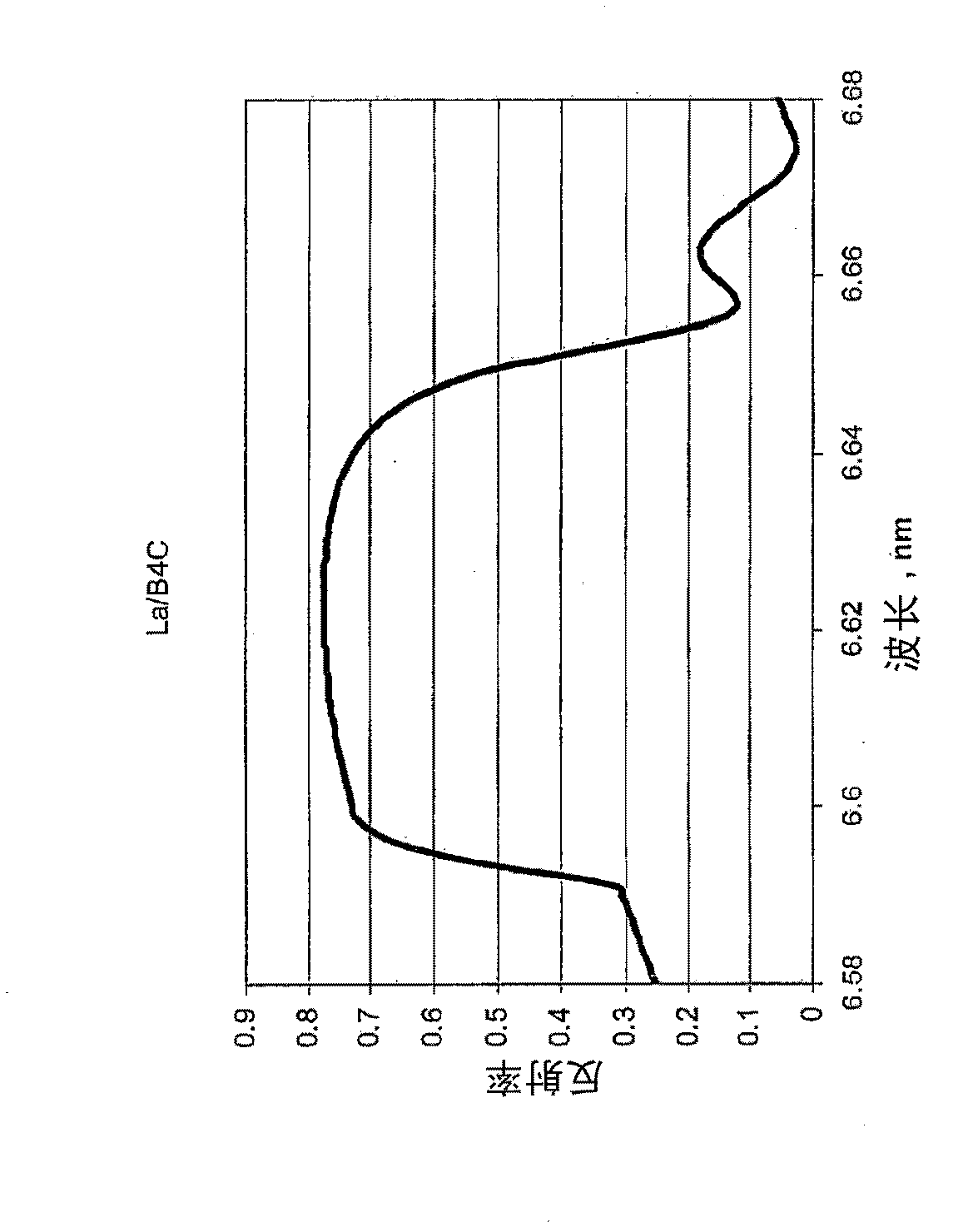

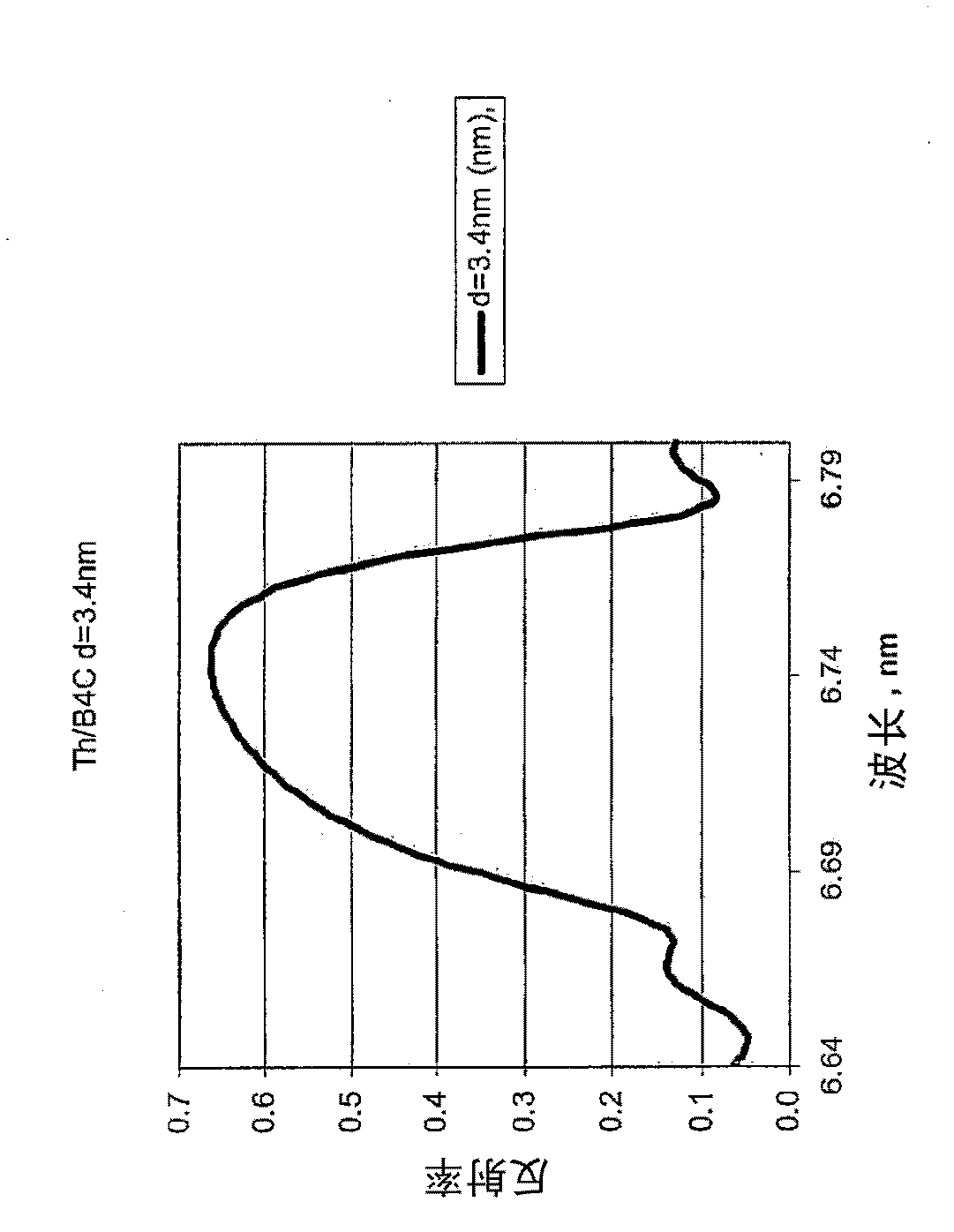

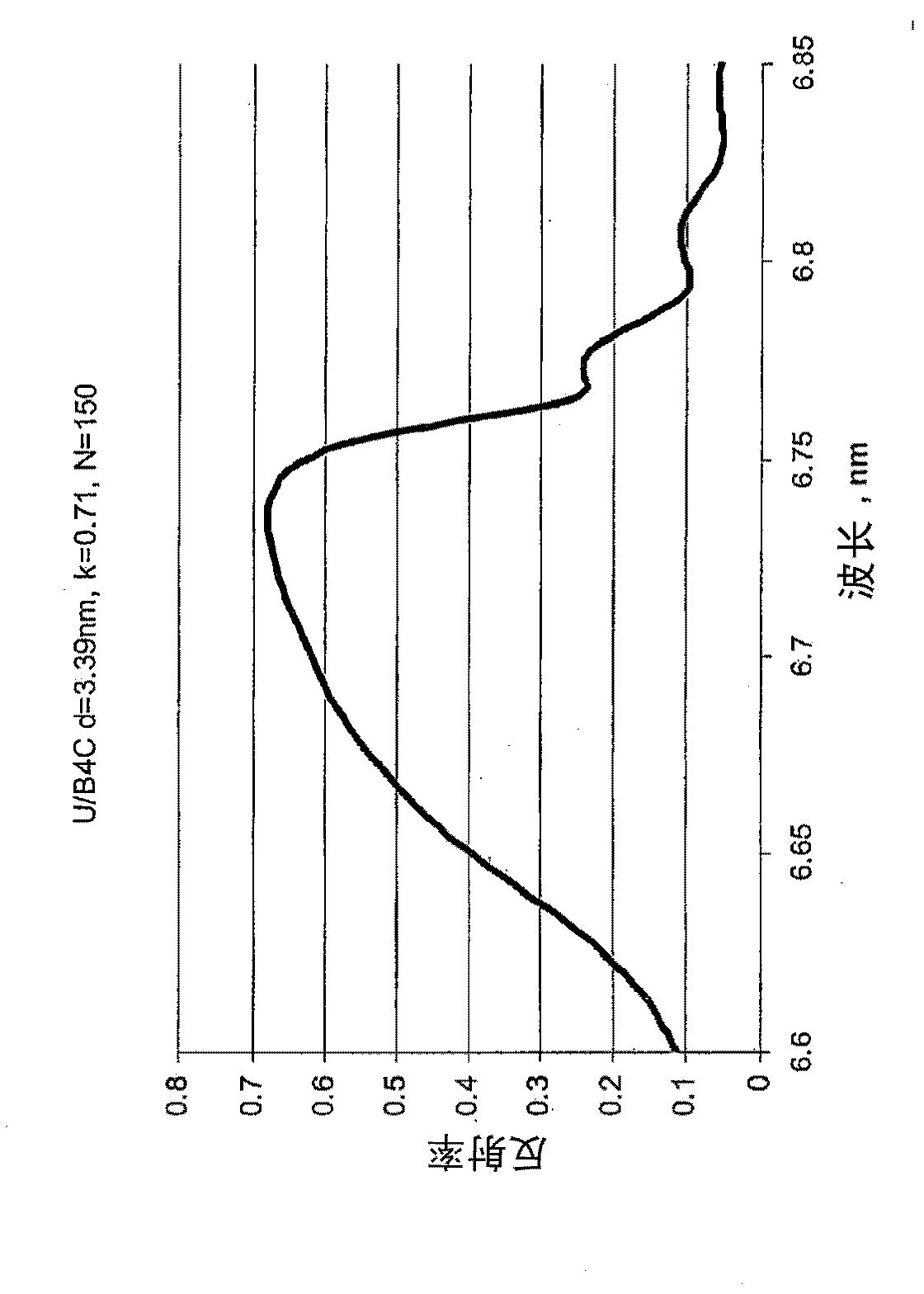

Multi-layer reflecting mirror and lithographic device

ActiveCN102736441ANanoinformaticsHandling using diffraction/refraction/reflectionCarbon nitrideLanthanum

The invention discloses a multi-layer reflecting mirror and a lithographic device. The multi-layer reflecting mirror is configured to reflect radiation whose wavelength is within the range of approximately 6.4nm-7.2nm. The multi-layer reflecting mirror has an alternating layer having a first layer and a second layer. The first and second layers are selected from the following groups: uranium or uranium compound or uranium nitride and a B4C layer; thorium or thorium compound or thorium nitride and the B4C layer; lanthanum or lanthanum compound or lanthanum nitride and a B9C layer; lanthanum or lanthanum compound or lanthanum nitride and the B4C layer; uranium or uranium compound or uranium nitride and the B9C layer; thorium or thorium compound or thorium nitride and the B9C layer; lanthanum or lanthanum compound or lanthanum nitride and a boron layer; uranium or uranium compound or uranium nitride and the boron layer; carbon or carbon compound or carbon nitride and the boron layer; thorium or thorium compound or thorium nitride and the boron layer.

Owner:ASML NETHERLANDS BV

Use of isotopically enriched actinide fuel in nuclear reactors

InactiveUS20060251206A1Lower the volumeFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The present invention provides a nuclear fuel rod, assembly comprising an actinide nitride such as uranium nitride, suitable for use in nuclear reactors, including those based substantially on thermal fission, such as light and heavy water or gas-cooled nuclear reactors. The fuel contains nitrogen which has been isotopically enriched to at least about 50% 15N, most preferably above 95%. The fuel can be in the form of particles, pellets, in annular form or other forms having high surface to volume ratios.

Owner:WESTINGHOUSE ELECTRIC CORP

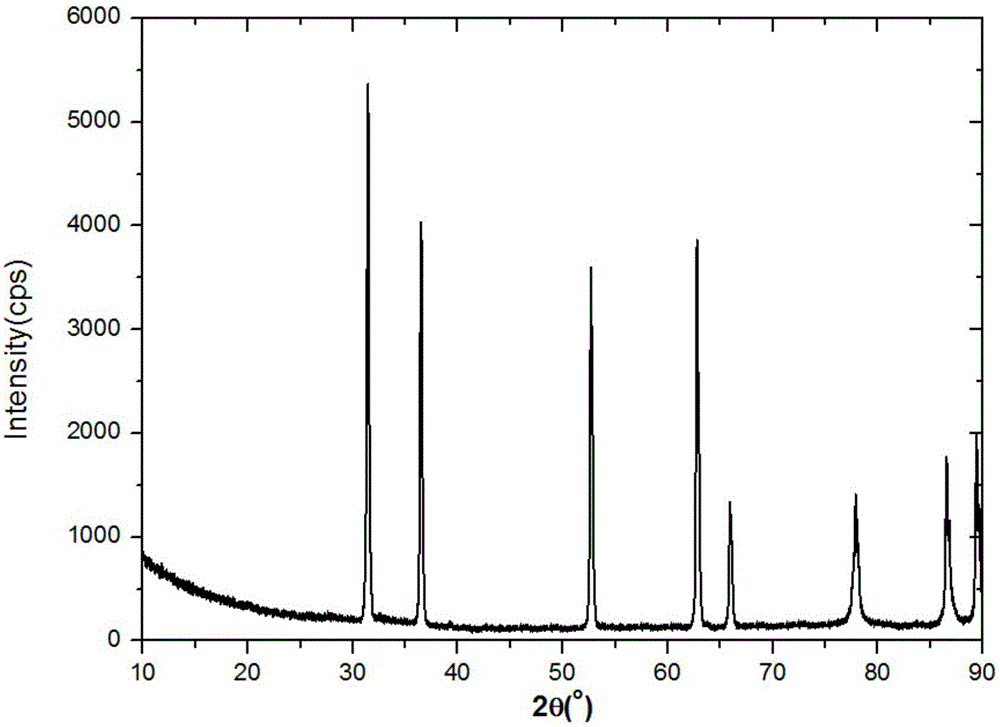

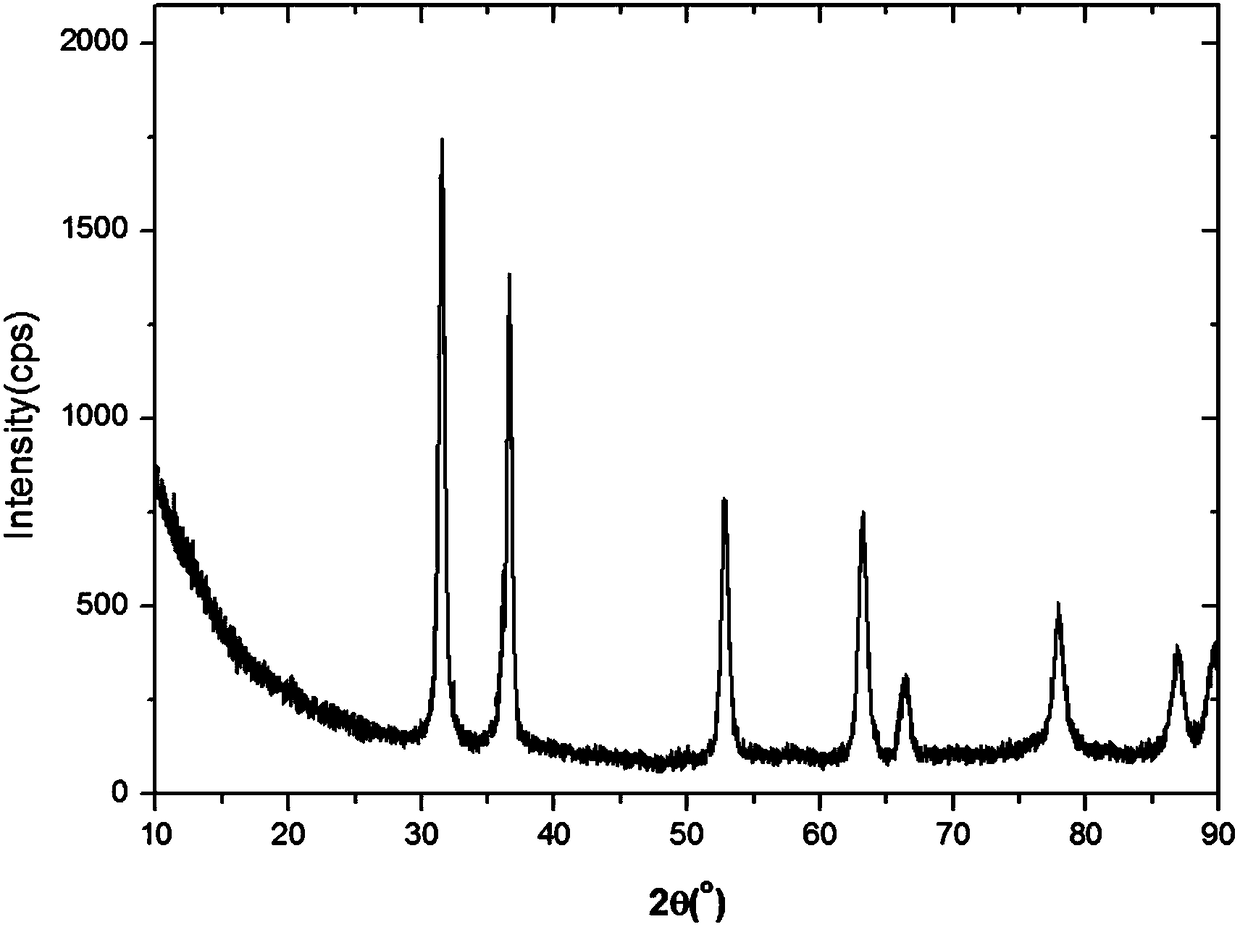

Method for preparing uranium nitride pellet

ActiveCN108305693AExcellent surface appearanceImprove power densityNuclear energy generationReactor fuel susbtancesChemical compositionNuclear reactor

The invention relates to the technical field of preparation of nuclear fuel pellets, and particularly discloses to a method for preparing a uranium nitride pellet. The method comprises the following steps: 1, preparing a hydrogenation-dehydrogenation sample; 2, performing hydrogenation-dehydrogenation to prepare uranium powder; 3, preparing uranium sesquinitride powder; 4, molding a uranium sesquinitride green body; step 5, sintering the green body to form the uranium nitride pellet. The uranium nitride pellet obtained by the method has good surface appearance, and the density and the chemicalcomposition of the pellet meet the requirements of technical indexes, so the pellet can be used in a novel nuclear reactor to improve the core power density and reduce the release of fission products.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

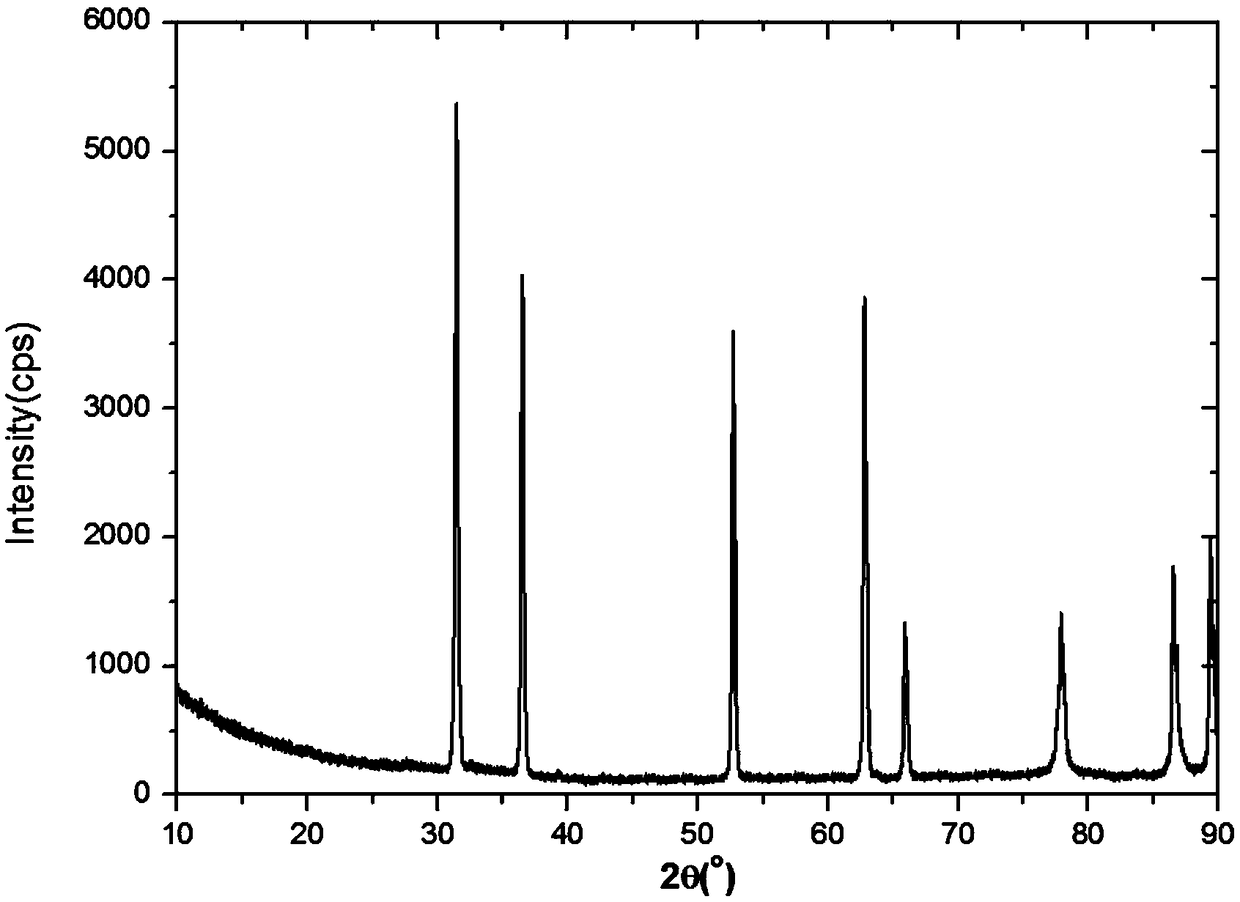

Preparation method of UO2 composite UN-UO2 fuel pellet

The invention belongs to the technical field of preparation of uranium nitride composite fuel pellets, and particularly relates to a preparation method of a UO2 composite UN-UO2 fuel pellet. The preparation method comprises the steps of preparing metal uranium powder through cyclic hydrogenation dehydrogenation, and carrying out nitridation to obtain a uranium nitrogen compound; pre-pressing the uranium nitrogen compound in a graphite mold, carrying out high-temperature denitrification on the mold and the uranium nitrogen compound in a tungsten-molybdenum sintering furnace to obtain a blocky UN material, and crushing and ball-milling the blocky UN material to prepare UN powder which can stably exist at room temperature; taking the UN powder and 5-80 wt% of UO2 powder, and carrying out dry three-dimensional mixing or wet ball milling mixing with ethyl alcohol as a medium to obtain UN-UO2 mixed powder; after the cylindrical UN-UO2 green body is sleeved with the annular UO2 green body, assembling cover-shaped UO2 green bodies on the upper portion and the lower portion of the combined green body,obtaining a UO2-wrapped UN-UO2 green body, placing the UO2-wrapped UN-UO2 green body in a graphite mold to be subjected to hot pressing sintering, and obtaining the UN-UO2 composite fuel pellet of a UO2 wrapping area. The method has a wide application prospect in the light water reactor.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Preparation method of uranium nitride composite uranium silicide fuel pellet

InactiveCN113012834AHigh uranium densityImprove thermal conductivityNuclear energy generationReactors manufactureDehydrogenationIngot

The invention belongs to the technical field of preparation of uranium nitride composite fuel pellets, and particularly relates to a preparation method of a uranium nitride composite uranium silicide fuel pellet. The preparation method comprises the steps of preparing a U3Si2 ingot through vacuum induction melting of metal uranium and monatomic silicon, and crushing and ball-milling to obtain U3Si2 powder; carrying out cyclic hydrogenation dehydrogenation on metal uranium to prepare metal uranium powder, and conducting nitridation to obtain a uranium nitrogen compound; pre-pressing the uranium nitrogen compound in a graphite mold, carrying out high-temperature denitrification on the uranium nitrogen compound together with the mold in a tungsten-molybdenum sintering furnace to obtain a blocky UN material, and carrying out crushing and ball milling to prepare UN powder which can stably exist at room temperature; carrying out dry three-dimensional mixing or wet ball milling mixing with ethyl alcohol as a medium on the UN powder and 10-80 wt% of U3Si2 powder, obtaining UN-U3Si2 mixed powder, and preparing the UN-U3Si2 composite fuel pellet through pressureless sintering or hot pressing sintering. The pellet has higher uranium density, higher heat conductivity coefficient and certain steam oxidation resistance, and the overall capacity of a system for bearing serious accident conditions is enhanced.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

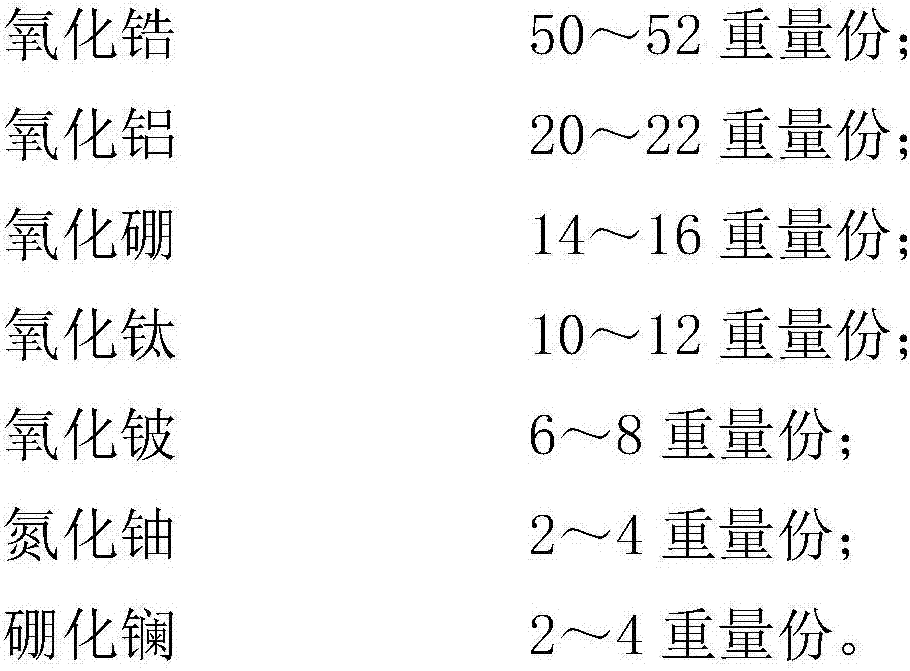

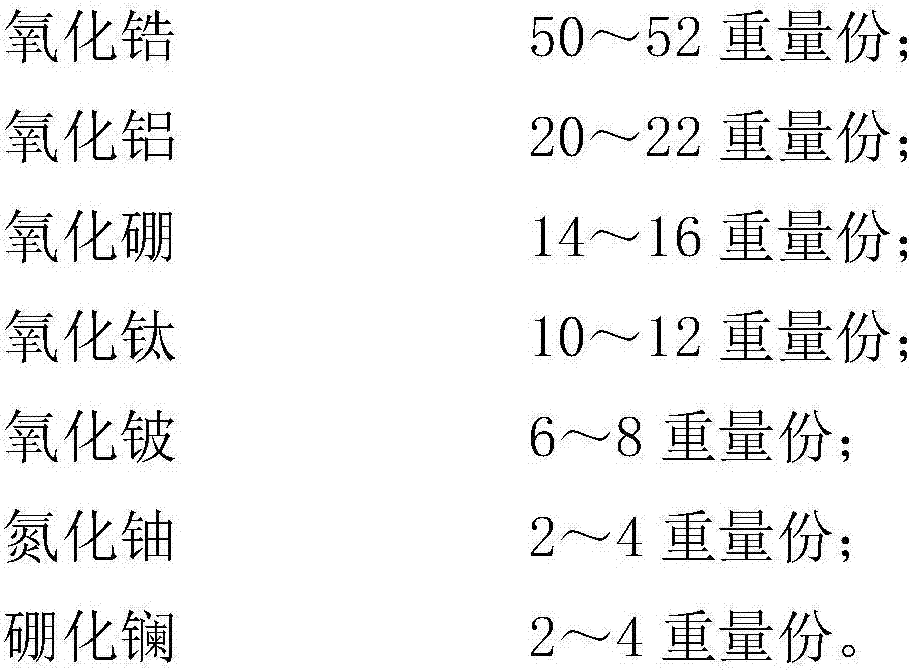

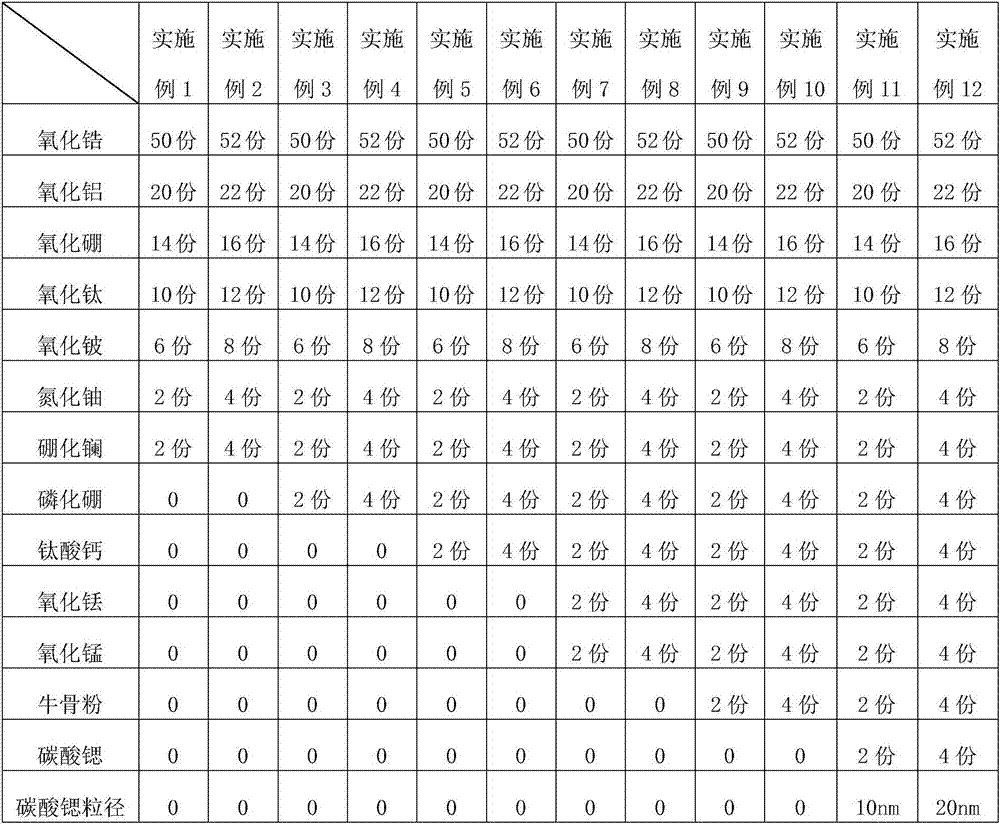

High-strength wear-resistant ceramic powder

The invention discloses high-strength wear-resistant ceramic powder which is prepared from the following components in parts by weight: 50-52 parts of zirconium oxide, 20-22 parts of aluminum oxide, 14-16 parts of boron oxide, 10-12 parts of titanium oxide, 6-8 parts of beryllium oxide, 2-4 parts of uranium nitride and 2-4 parts of lanthanum boride. According to the scheme, the ceramic powder is improved and optimized, multiple metal oxides, carbides and phosphides with a synergistic effect are introduced, and the strength and the wear resistance of the ceramic are effectively enhanced; by adding animal bone ash powder into the powder, the mechanical strength and the structural toughness of the ceramic are improved; by adding the nanoscale strontium carbonate into the powder, when the ceramic powder is calcined, multiple tiny cavities are formed in the ceramic by the tiny carbon dioxide gases obtained by decomposing the strontium carbonate; the cavities are combined to form a honeycomb-like structure or a microporous structure, and the strength, the wear resistance and the toughness of the ceramic are further improved.

Owner:苏州楚博生物技术有限公司

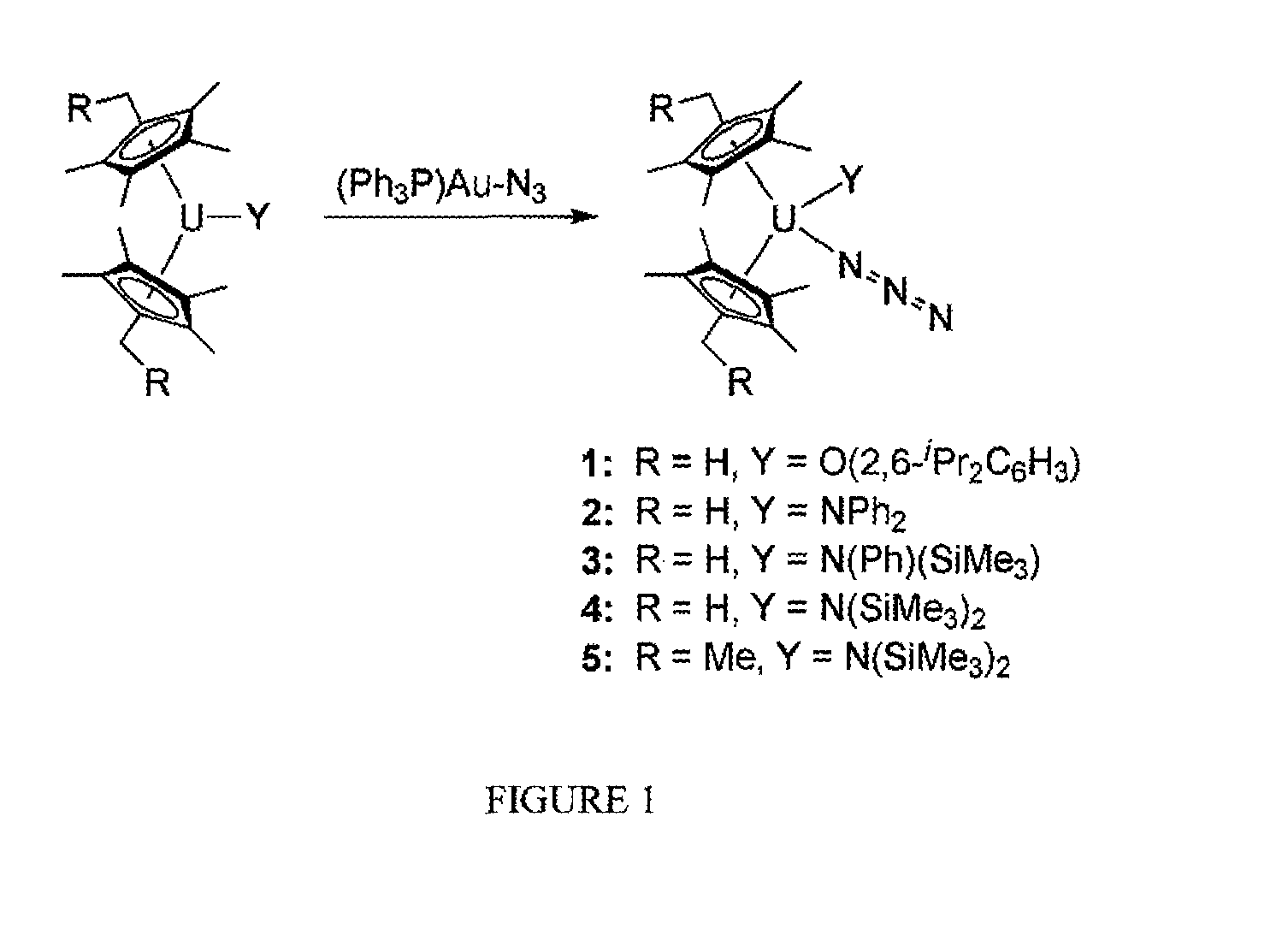

Method of preparation of uranium nitride

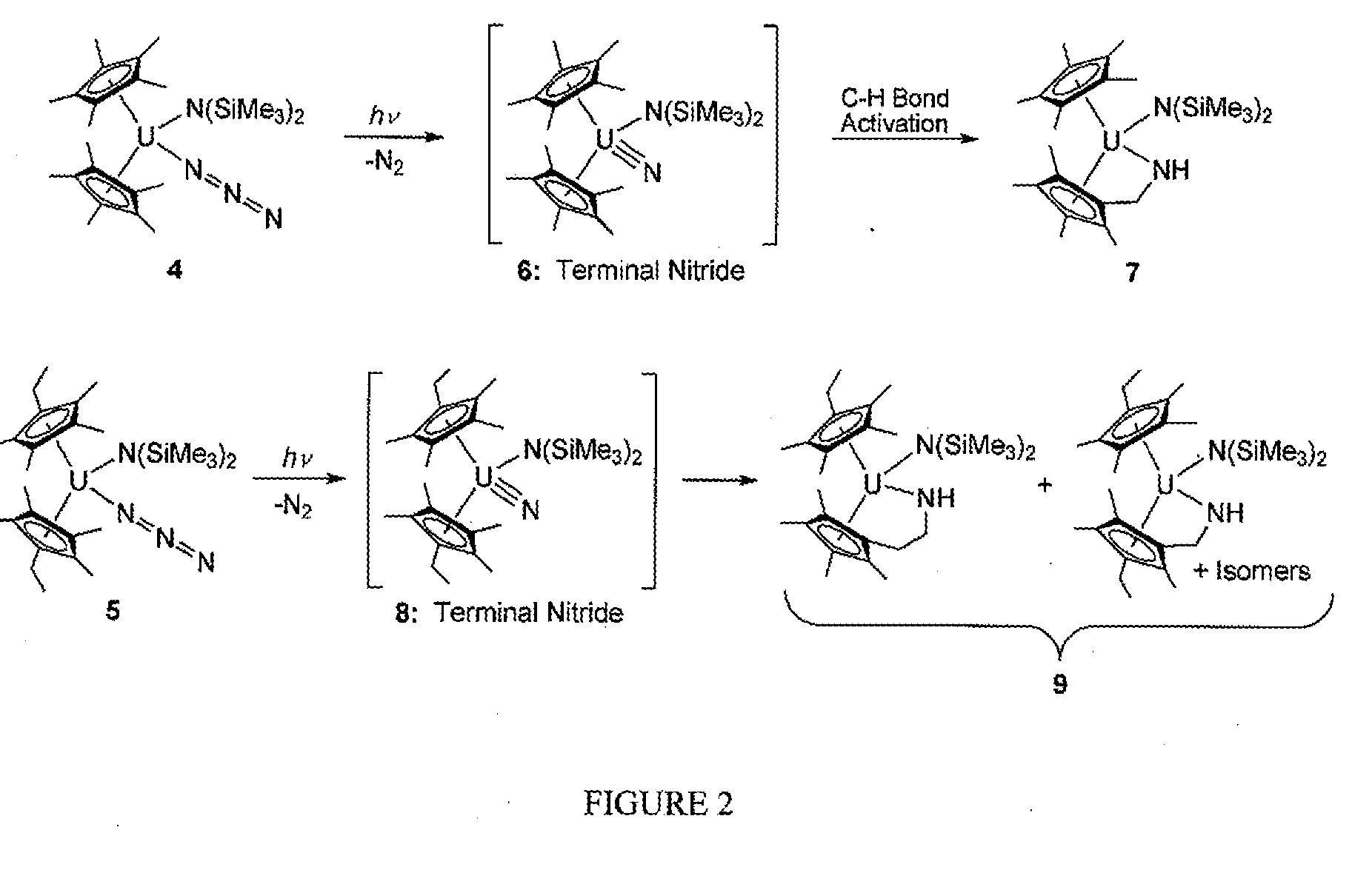

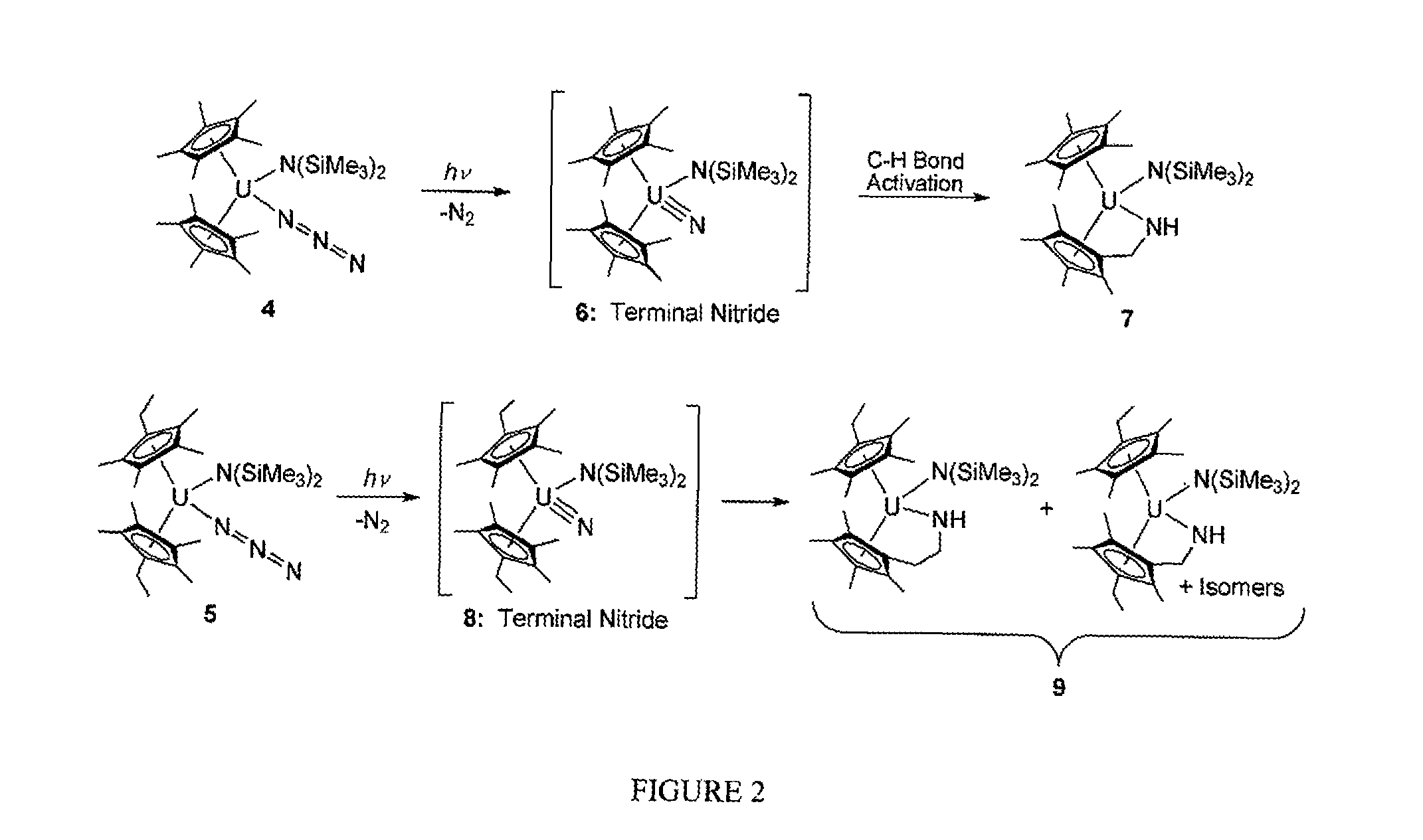

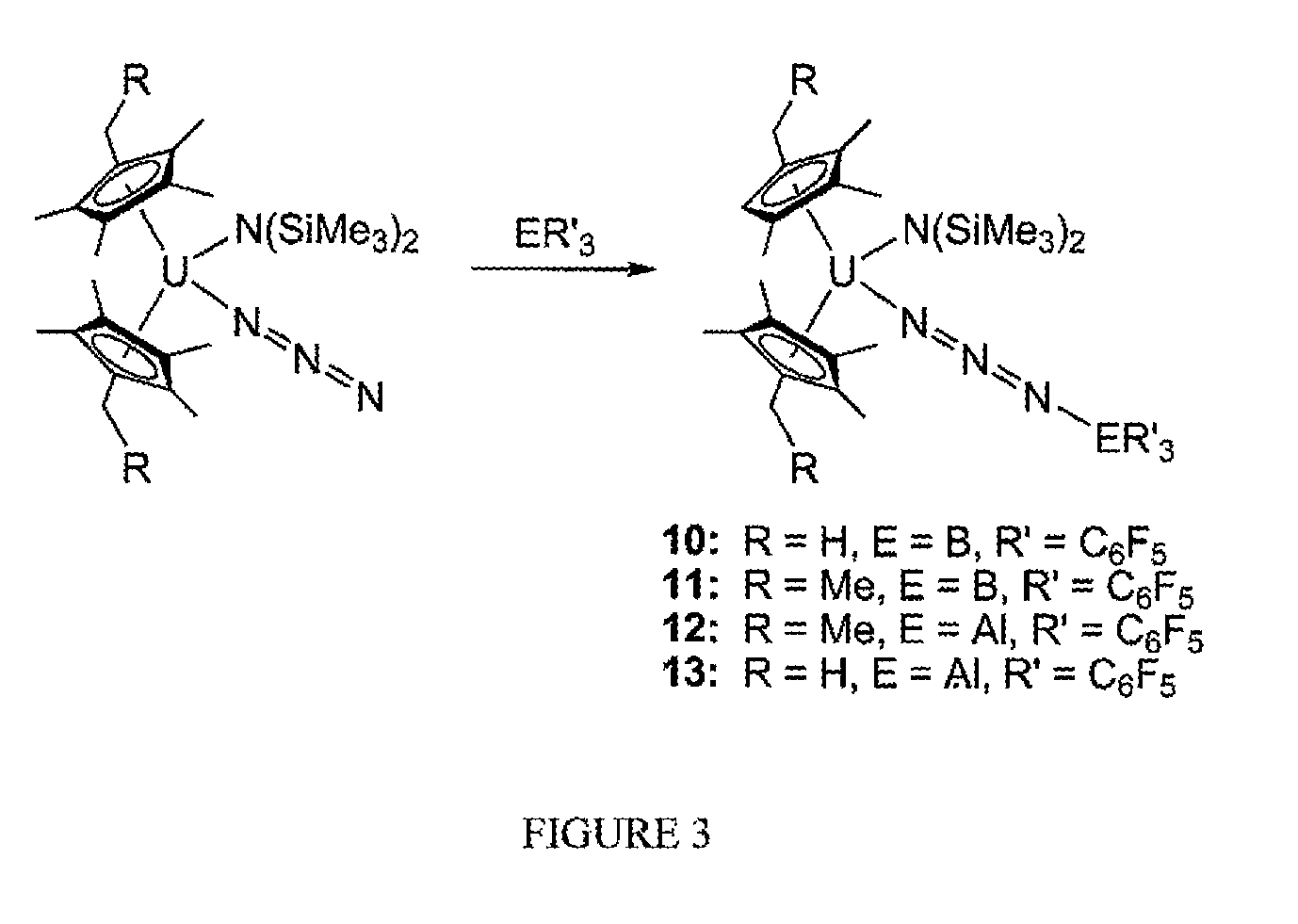

ActiveUS20120073956A1In-vivo radioactive preparationsCyanogen compoundsTitanium nitrideUranium nitride

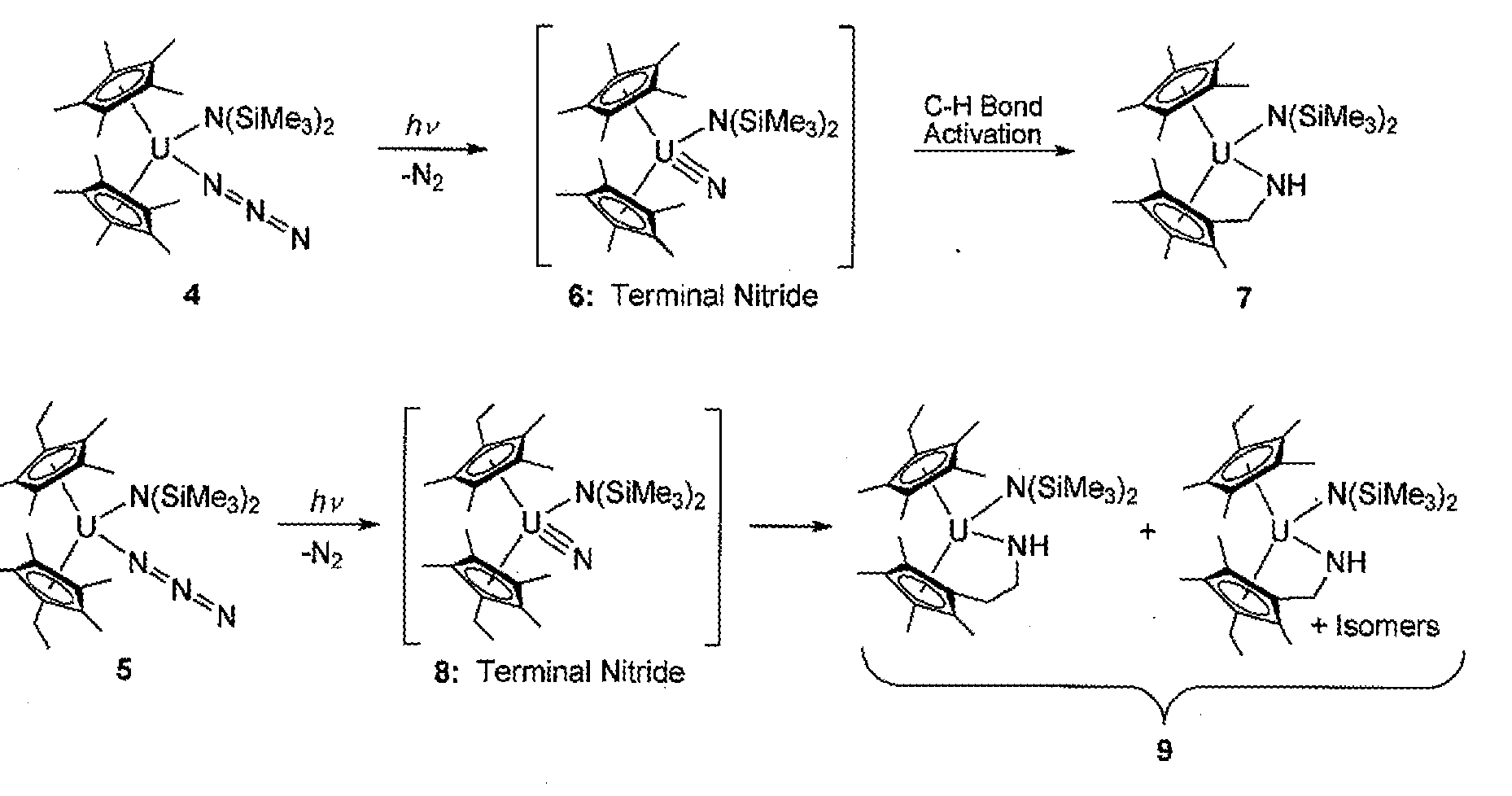

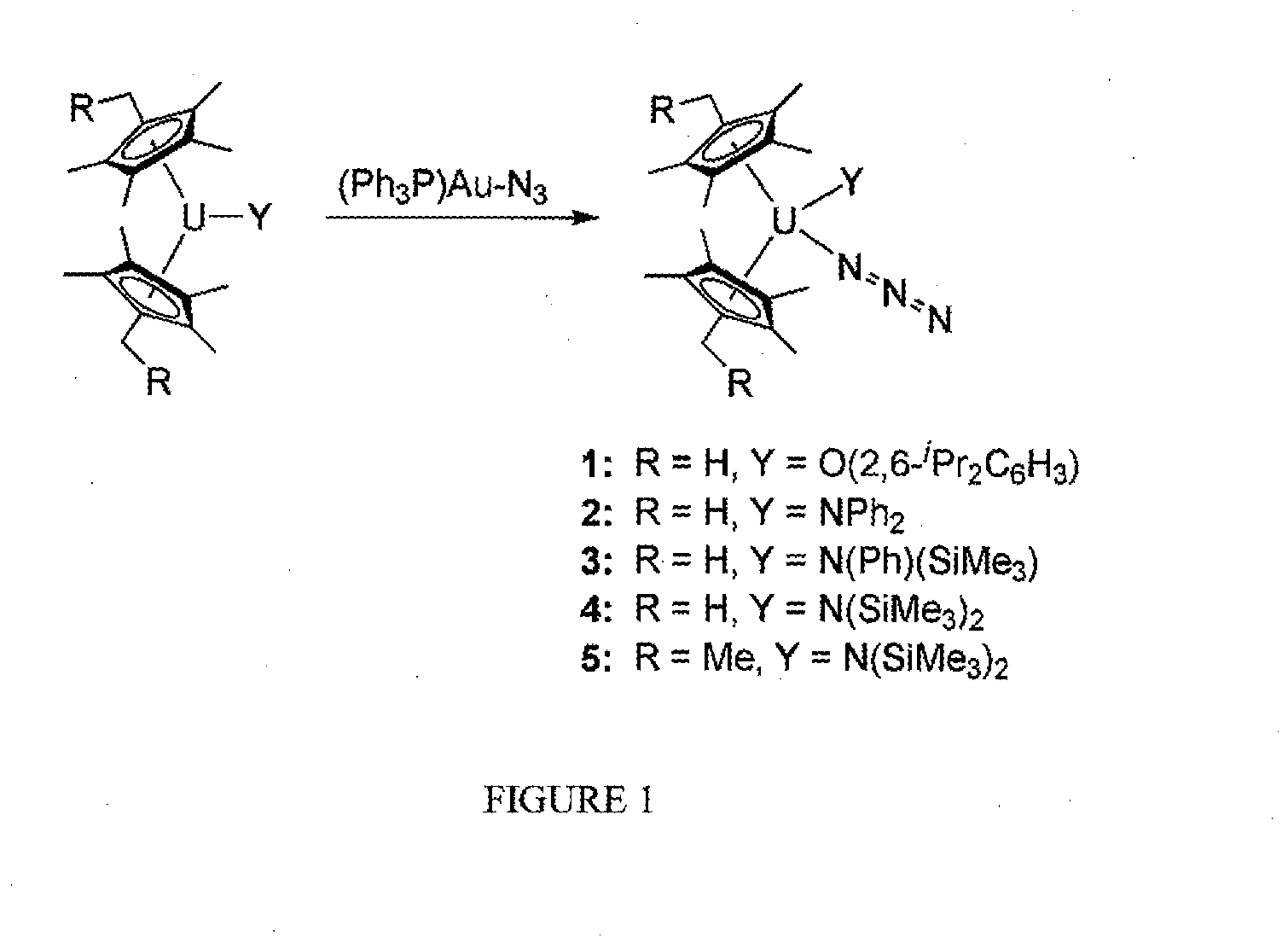

Method for producing terminal uranium nitride complexes comprising providing a suitable starting material comprising uranium; oxidizing the starting material with a suitable oxidant to produce one or more uranium(IV)-azide complexes; and, sufficiently irradiating the uranium(IV)-azide complexes to produce the terminal uranium nitride complexes.

Owner:TRIAD NAT SECURITY LLC

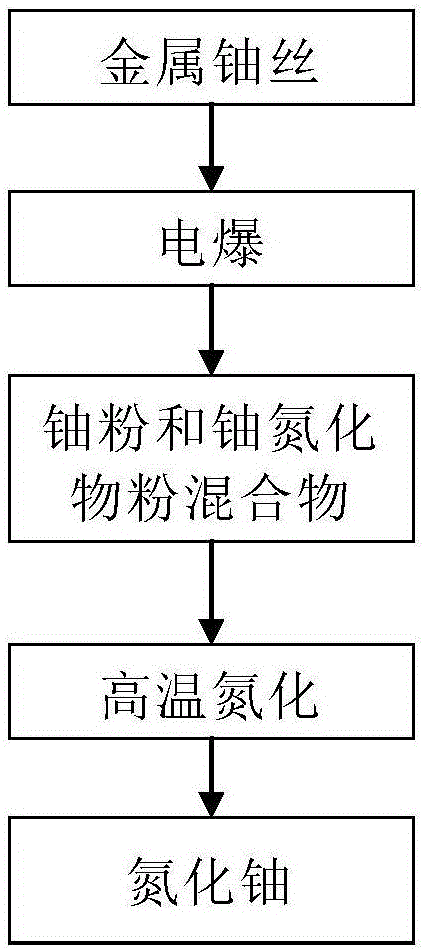

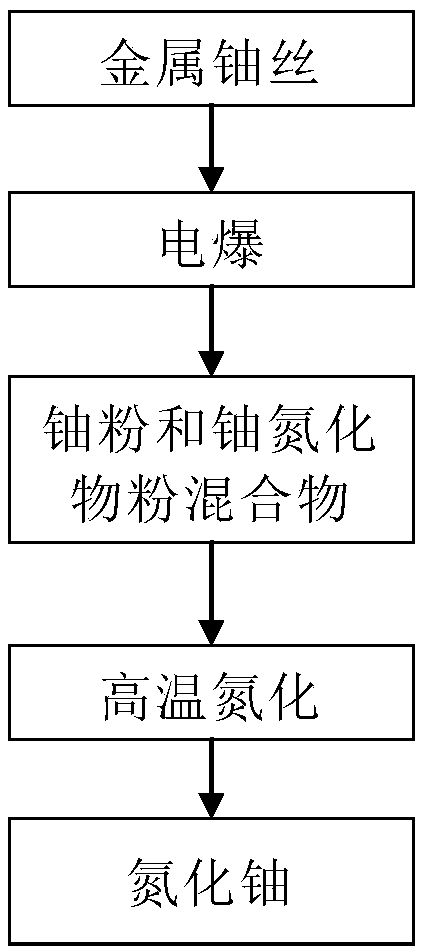

Manufacturing technique of high-activity uranium nitride powder

InactiveCN106744734ASmall granularityHigh activityNitrogen-metal/silicon/boron binary compoundsChemical reactionNitrogen

The invention provides a manufacturing technique of high-activity uranium nitride powder. The manufacturing technique comprises the following steps: electrically blasting metal uranium wire under a high-purity nitrogen environment, enabling the metal uranium to chemically react with the nitrogen in the blasting process, thereby generating the mixture of ultrafine uranium powder and uranium nitride powder; and enabling the mixture to react with the nitrogen at high temperature to obtain the uranium nitride. The manufacturing technique provided by the invention has the advantages of being low in energy consumption, and the prepared uranium product is good in activity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Sintering with sps/fast uranium fuel with or without burnable absorbers

The present invention relates to nuclear fuel compositions including uranium dioxide with integral fuel burnable absorber, and triuranium disilicide and a composite of uranium mononitride and triuranium disilicide with or without integral fuel burnable absorber, and methods of sintering these compositions. The sintering is conducted using SPS / FAST apparatus and techniques. The sintering time and temperature is reduced using SPS / FAST as compared to conventional sintering methods for nuclear fuel compositions. The nuclear fuel compositions of the present invention are particularly useful in light water reactors.

Owner:WESTINGHOUSE ELECTRIC CORP

Preparation method of uranium nitride fuel powder and pellets

ActiveCN103466568BHigh purityHigh sintering activityNuclear energy generationNitrogen-metal/silicon/boron binary compoundsHydrogenSurface cleaning

The invention relates to a preparation method of uranium nitride fuel powder and a pellet, which comprises the following steps: (1) carrying out surface cleaning treatment on a pure metal uranium lump; (2) hydrogenating the pure metal uranium lump in hydrogen at 150-300 DEG C for 2-16 hours, dehydrogenating in a vacuum, and repeating the hydrogenation-dehydrogenation several times to obtain metal uranium powder; (3) nitridizing the metal uranium powder in nitrogen at 200-600 DEG C for 6-24 hours to obtain U2N3 powder; (4) denitrifying the U2N3 powder in a mold, keeping the system vacuum, pressurizing the mold to 30-60 MPa, sintering at 1450-1620 DEG C for 1-2 hours, and cooling to obtain the UN ceramic pellet. The method provided by the invention is simple in technique and easy to control; and the obtained intermediate product U2N3 powder has higher purity and higher sintering activity, and can be finally subjected to hot pressed sintering to obtain the UN fuel pellet of which the TD is up to 98.9%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Preparation method of uranium nitride composite uranium dioxide fuel pellet

InactiveCN113012833AWater-resistantNuclear energy generationReactors manufactureUranium oxideDehydrogenation

The invention belongs to the technical field of preparation of uranium nitride composite fuel pellets, and particularly relates to a preparation method of a uranium nitride composite uranium dioxide fuel pellet. The preparation method comprises the steps of preparing metal uranium powder through cyclic hydrogenation dehydrogenation, and obtaining a uranium nitrogen compound through nitridation; pre-pressing a uranium nitrogen compound in a graphite mold, carrying out high-temperature denitrification on the mold and the uranium nitrogen compound in a tungsten-molybdenum sintering furnace to obtain a blocky UN material, and crushing and ball-milling the blocky UN material to prepare UN powder which can stably exist at room temperature; taking UN powder and 5-80 wt% of UO2 powder, and carrying out dry three-dimensional mixing or wet ball milling mixing with ethyl alcohol as a medium to obtain UN-UO2 mixed powder; and putting the UN-UO2 mixed powder into a graphite mold, and carrying out hot pressed sintering so as to prepare the solid UN-UO2 composite fuel pellet. The UN powder which can stably exist in the air is prepared, mixing of the UN powder and the UO2 powder in the atmospheric environment is achieved, the technological operation difficulty is lowered, and the technological period is shortened.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Uranium carbide pellets, preparation method thereof, and fuel rod

ActiveCN107500767BAvoid melting point problemsSuitable for industrial productionNuclear energy generationReactor fuel susbtancesUranium carbideSlurry

The invention discloses a uranium carbide pellet, a preparation method thereof and a fuel rod. The preparation method of uranium carbide pellets comprises the following steps: S1, weighing uranium nitride powder and a carbon source according to a molar ratio of 1:0.8-1.5 and adding them to a solvent, and mixing them uniformly to form a slurry; S2, mixing the Drying the slurry to obtain a mixed powder; S3, pressing the mixed powder into a green body with a density of 50% or more; S4, high-temperature pressureless sintering to obtain a uranium carbide pellet with a density ≥ 95%. In the present invention, uranium nitride and carbon source are used as raw materials to realize two processes of carbothermal reduction reaction and densification sintering under high-temperature pressureless sintering, without using hot-press sintering process with low production efficiency, and without introducing sintering aids. It avoids the problem of lowering the melting point of pellets, can realize batch sintering, has low energy consumption, and is suitable for industrial production of fuel pellets.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

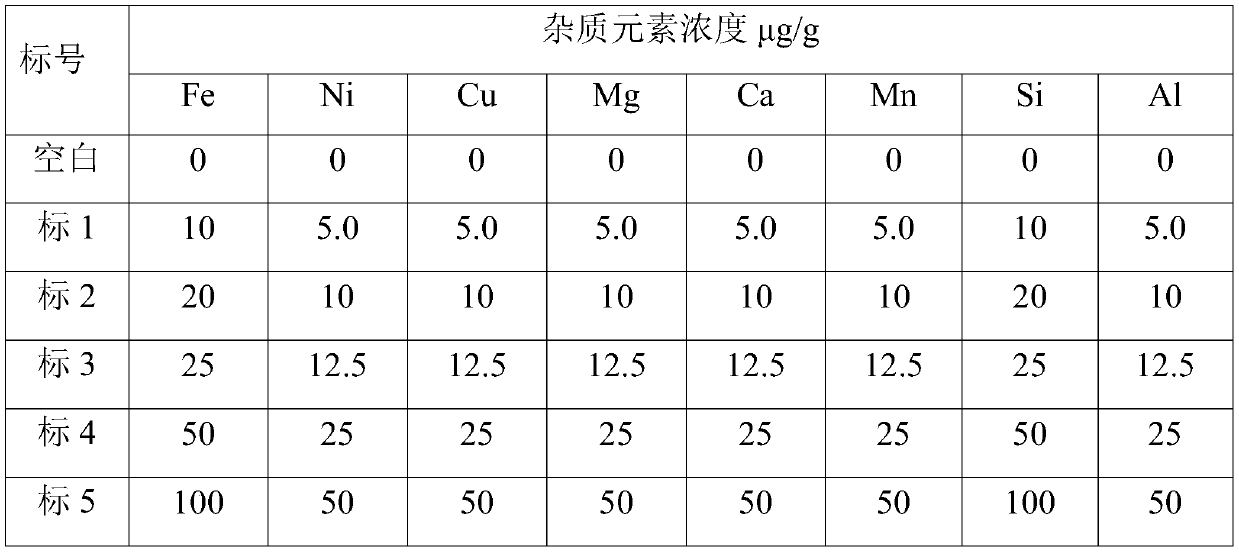

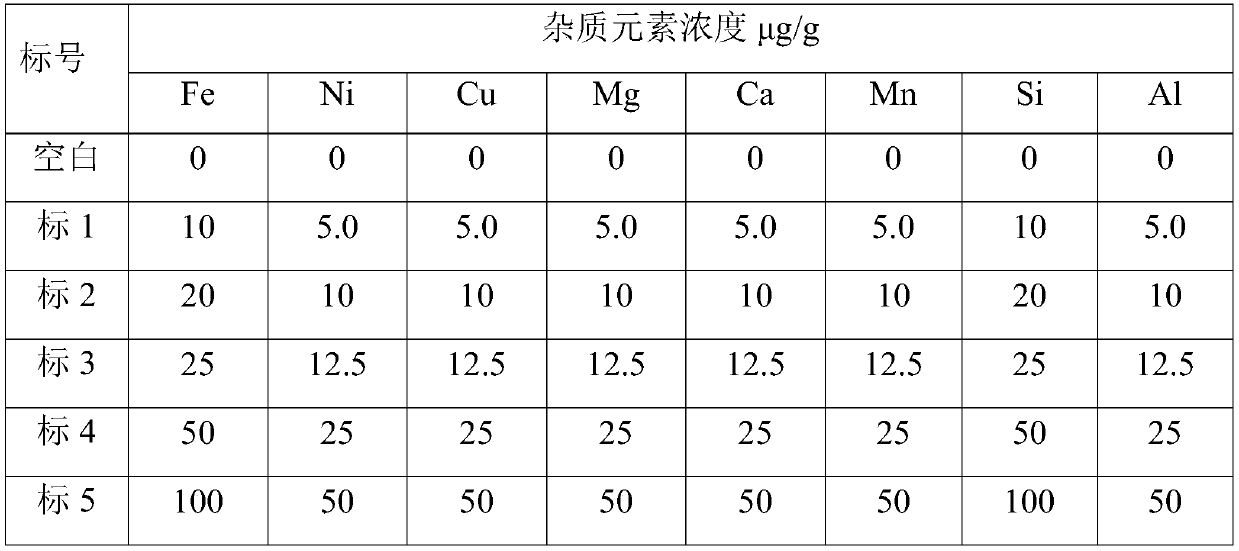

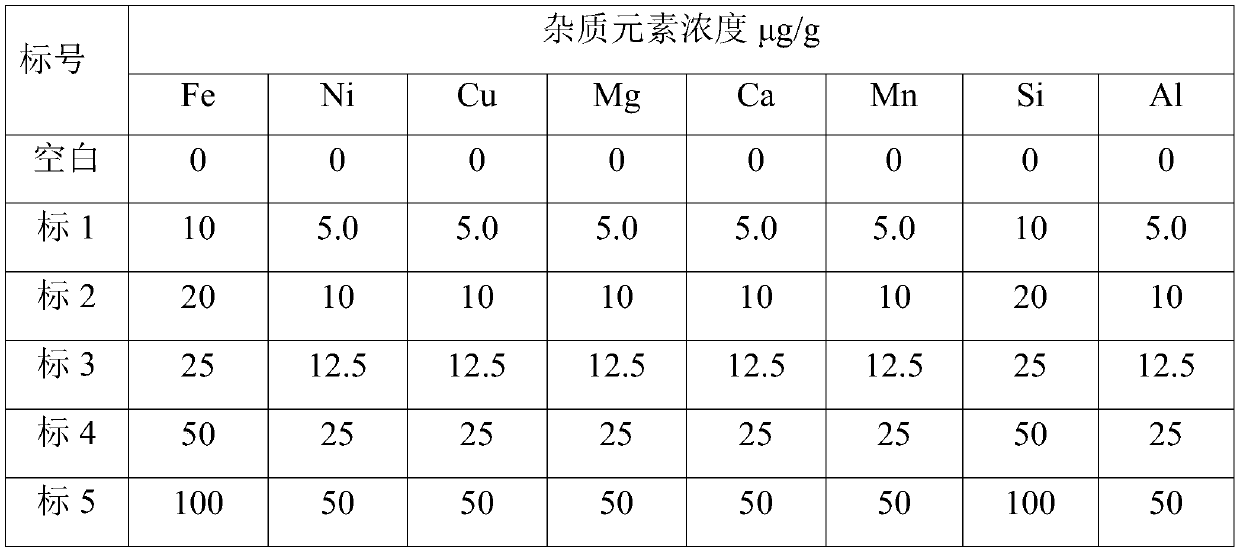

Method for determining content of impurity elements in uranium nitride solid sample

PendingCN111307783AAccurate determination of contentThe detection data is accuratePreparing sample for investigationAnalysis by thermal excitationChromatographic separationUranium nitride

The invention relates to a method for determining the content of impurity elements in a uranium nitride solid sample. The method comprises the following steps: step 1, dissolving a sample; weighing 1.0 g of a sample, putting the sample into a 150 mL quartz beaker, adding 5-10 mL of a concentrated nitric acid solution, heating and dissolving the sample, after the sample is completely dissolved, evaporating the sample to 2-3 mL at a low temperature, taking down the sample, and cooling the sample to room temperature; 2, separating a uranium matrix; separating a uranium matrix in the sample by adopting an extraction method-reversed phase chromatographic separation column method; step 3, determination of a sample; iCP-AES (Inductively Coupled Plasma-Atomic Emission Spectrometry) is adopted, andthe sample from which the uranium matrix is separated is determined by a standard curve method. The invention successfully establishes a method for determining the content of impurity elements in uranium nitride powder or pellet by plasma emission spectrometry. The content of impurity elements can be accurately determined by utilizing the experimental conditions listed in the content of the invention, accurate detection data is reported, a method is provided for related detection of uranium nitride in the future, and special production is effectively matched.

Owner:CHINA NORTH NUCLEAR FUEL

Low Temperature Synthesis of Uranium Nitride Powder

ActiveCN106829886BSmall granularityLow impurity contentNitrogen compoundsNuclear energy generationSynthesis methodsReaction temperature

The invention belongs to the field of nuclear fuel preparation and provides a low-temperature synthesis method for uranium nitride powder for solving the problems that an existing uranium nitride powder synthesis technology is over-high in reaction temperature, high in product impurity content or complicated in technological process. The synthesis method comprises the following steps: (1) enabling metallic uranium to fully react with hydrogen to generate uranium hydride powder, increasing the temperature and lastingly vacuumizing to dehydrogenize and convert the uranium hydride powder into metallic uranium powder, and repeating for multiple times; and (2) carrying out quantitative reaction on the metallic uranium powder and nitrogen at a high temperature to prepare the uranium nitride powder. The low-temperature synthesis method for the uranium nitride powder has the advantages of short technological process and low synthesis temperature; the production energy consumption can be significantly reduced; the synthesized uranium nitride powder is small in particle size, low in impurity content and beneficial to improvement of the sintering activity of the uranium nitride powder.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

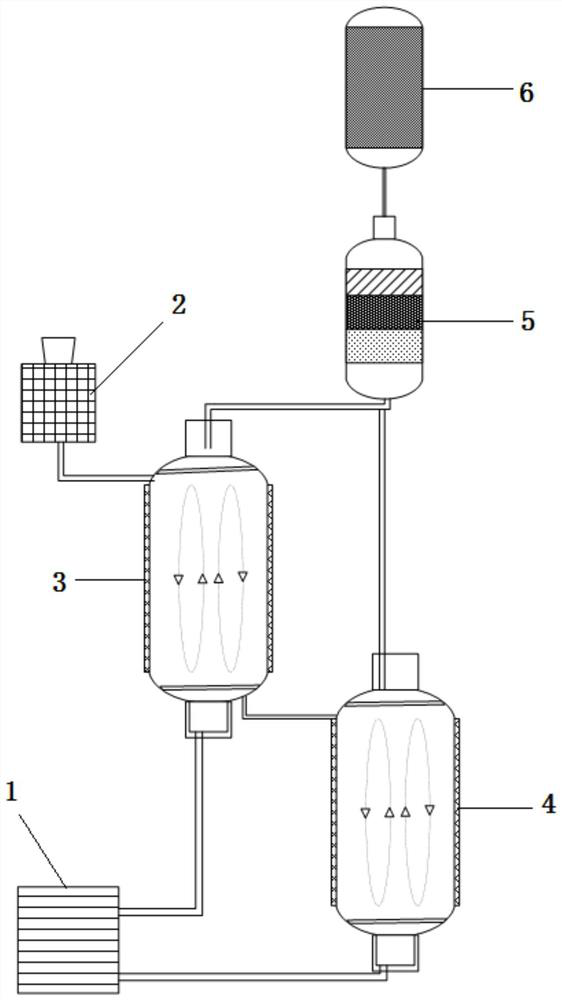

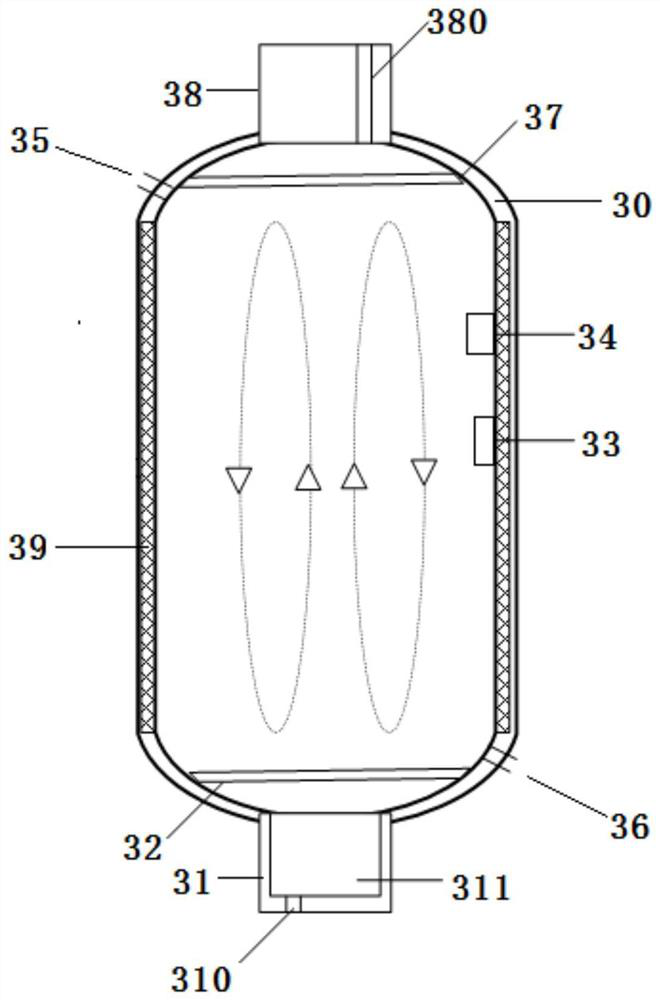

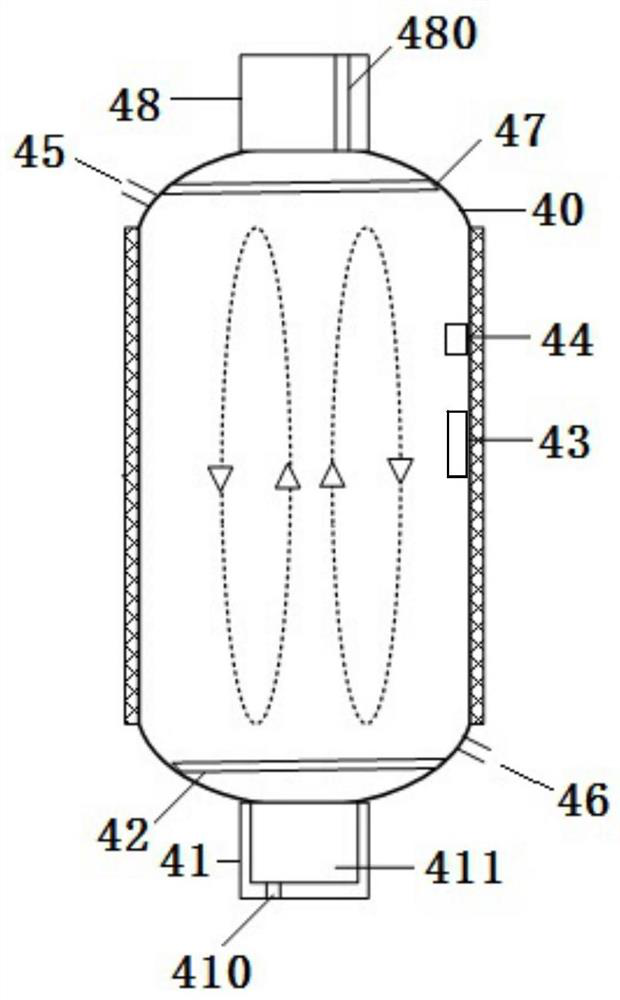

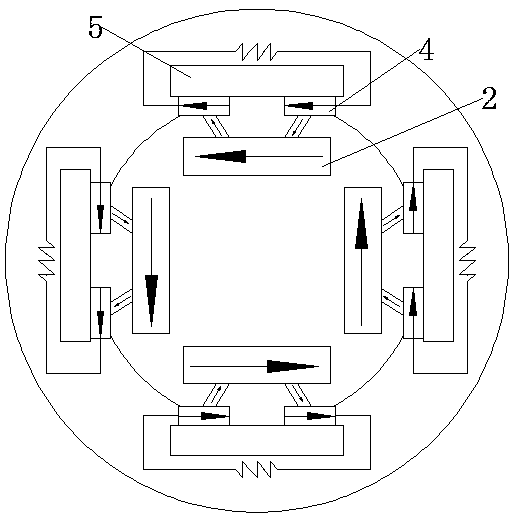

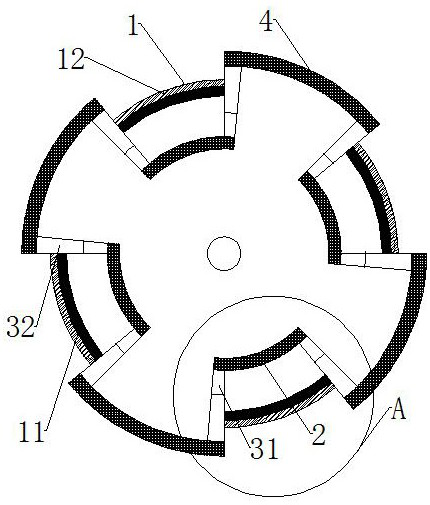

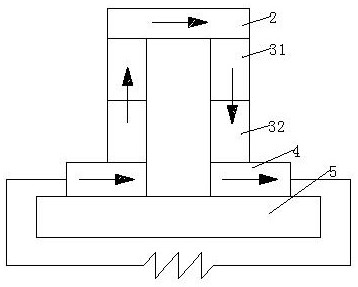

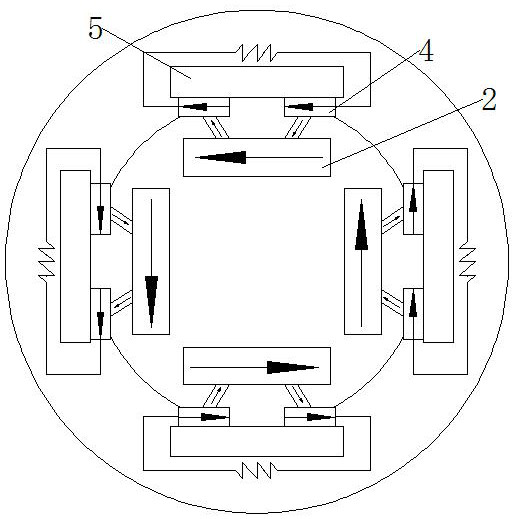

A fluidized bed device for preparing uranium nitride and method of using the same

ActiveCN112044365BHigh preparative reaction yieldThorough treatmentGas treatmentNuclear energy generationFluidized bedProcess engineering

The invention provides a fluidized bed device for preparing uranium nitride, including a gas system, a material mixing system, a low temperature fluidized bed, a high temperature fluidized bed, a tail gas treatment device and an absorption tower; the gas system is connected to a low temperature fluidized bed. The fluidized bed and the high temperature fluidized bed are respectively connected, the mixing system is connected with the low temperature fluidized bed, the low temperature fluidized bed is connected with the high temperature fluidized bed, and the low temperature fluidized bed and the high temperature fluidized bed are respectively connected with the tail gas treatment The device is connected, and the tail gas treatment device is connected with the absorption tower. The present invention also provides a method for using the fluidized bed device for preparing uranium nitride. By controlling the reaction steps to be carried out in the low temperature fluidized bed and the high temperature fluidized bed respectively, the invention ensures the smooth progress of the reaction under different temperature requirements; the tail gas is purified in the tail gas treatment device to ensure that the discharged gas is harmful to the environment No pollution. The invention can ensure high reaction yield of uranium nitride preparation and complete exhaust gas disposal.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Use of isotopically enriched nitride in actinide fuel in nuclear reactors

The present invention provides a nuclear fuel comprising an actinide nitride such as uranium nitride, suitable for use in nuclear reactors, including those based substantially on thermal fission, such as light and heavy water or gas-cooled nuclear reactors. The fuel contains nitrogen which has been isotopically enriched to at least about 50% 15 N, most preferably above 95%. The fuel can be in theform of particles, pellets, in annular form or other forms having high surface to volume ratios.

Owner:WESTINGHOUSE ELECTRIC CORP

Method of preparation of uranium nitride

Method for producing terminal uranium nitride complexes comprising providing a suitable starting material comprising uranium; oxidizing the starting material with a suitable oxidant to produce one or more uranium(IV)-azide complexes; and, sufficiently irradiating the uranium(IV)-azide complexes to produce the terminal uranium nitride complexes.

Owner:TRIAD NAT SECURITY LLC

A kind of high activity uranium nitride powder manufacturing process

InactiveCN106744734BSmall granularityHigh activityNitrogen-metal/silicon/boron binary compoundsChemical reactionNitrogen

The invention provides a manufacturing technique of high-activity uranium nitride powder. The manufacturing technique comprises the following steps: electrically blasting metal uranium wire under a high-purity nitrogen environment, enabling the metal uranium to chemically react with the nitrogen in the blasting process, thereby generating the mixture of ultrafine uranium powder and uranium nitride powder; and enabling the mixture to react with the nitrogen at high temperature to obtain the uranium nitride. The manufacturing technique provided by the invention has the advantages of being low in energy consumption, and the prepared uranium product is good in activity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method and device for preparing anti-corrosion protective layer on uranium surface by atmospheric laser passivation

ActiveCN105063547BEliminate vacuuming stepSimple processSolid state diffusion coatingNitrogenNanosecond pulse

The invention discloses a method and a device for preparing a uranium surface anti-corrosion protecting layer through atmospheric laser passivation and aims to solve the problems that workpiece sizes are limited, demands of industrial production and application are hardly met and prepared uranium nitride films are still corroded to a certain degree in terms of current uranium nitride film preparation by laser nitridation. In the atmospheric environment, the workpiece surface is scanned through nanosecond pulse laser, the laser energy density is 20-70J / cm2, the overlapping ratio is 80%-95%, and therefore a uranium nitrogen oxygen passive film in a ceramic state is prepared on the workpiece surface. A vacuum environment and a special gas source are not required; machining demands of plane workpieces, abnormal-shaped workpieces and large workpieces can be met; the machining speed is high; the demands of the industrial application can be met. Meanwhile, the prepared uranium nitrogen oxygen passive film is excellent in corrosion resistance, pre-treatment of the workpiece surface is not needed; the quantity of generated wastes is small; environment-friendly effect is achieved. By means of the method and the device for preparing the uranium surface anti-corrosion protecting layer through atmospheric laser passivation, during workpiece machining, burrs of the workpiece surface can be removed, and the method and the device have good application prospects.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

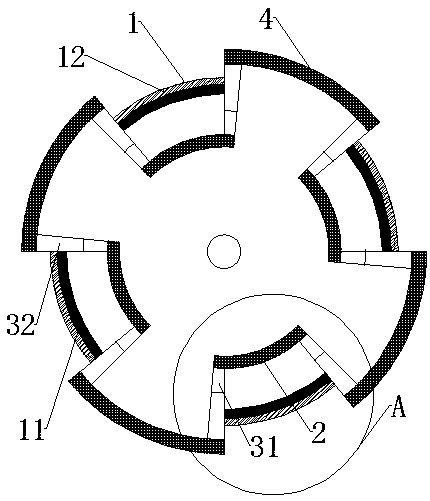

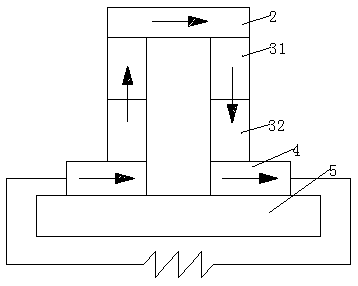

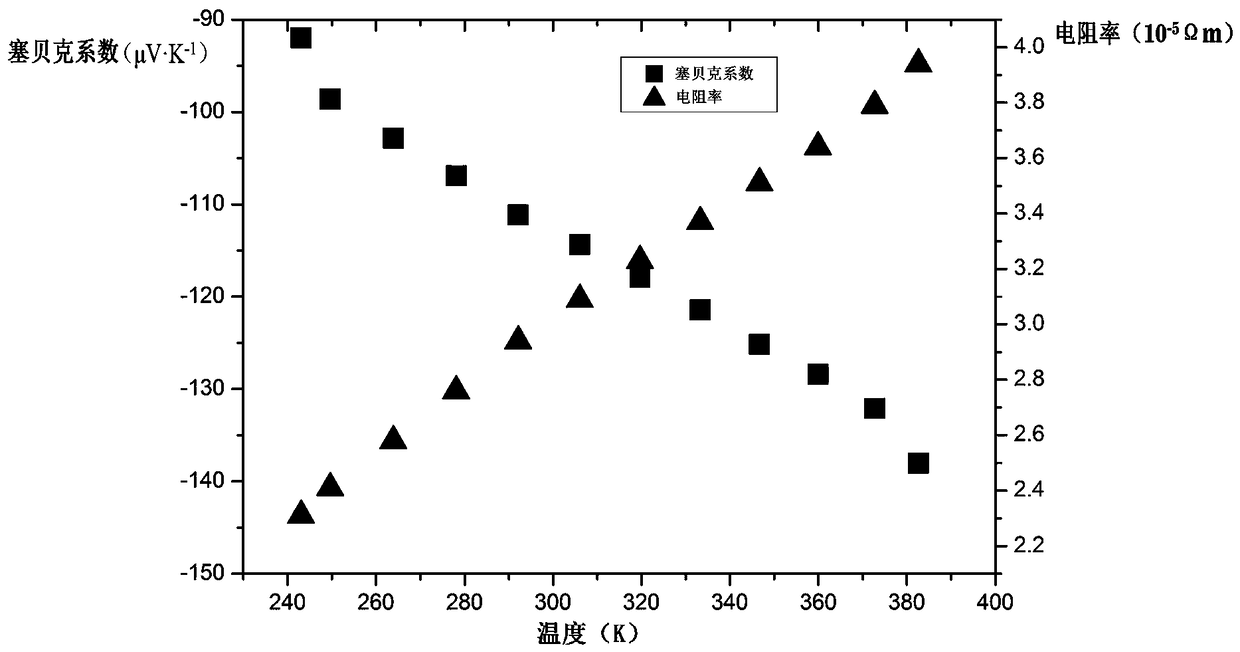

Integrated uranium nitride thermoelectric conversion device

ActiveCN108123026AEfficient integrationReduce volumeThermoelectric device with peltier/seeback effectThermoelectric device junction materialsThermoelectric materialsSemiconductor structure

The invention discloses an integrated uranium nitride thermoelectric conversion device which comprises a shell and a thermoelectric conversion device, wherein the thermoelectric conversion device is mounted on the shell and has a self-heating function; the thermoelectric conversion device comprises a conversion module; the conversion module comprises a first conducting strip, an N-type semi-conductor, a P-type semi-conductor and two second conducting strips respectively connected with the N-type semi-conductor and the P-type semi-conductor; and the N-type semi-conductor and the P-type semi-conductor are the same in structure and respectively comprise high fission concentration areas and low fission concentration areas. According to the integrated uranium nitride thermoelectric conversion device, uranium nitride can serve as a heat source and a thermoelectric conversion material simultaneously, so that the size and the weight of the conversion module are reduced, and the energy efficiency of the whole thermoelectric conversion device is improved; the adopted uranium nitride is a fissile high-energy material, so that heat energy can be released stably for a long time, and therefore,the uranium nitride is an ideal heat source of the thermoelectric conversion device; after an adopted energy conversion part of a thermoelectric material is integrated with a radioactive heat source,the irradiation damage to the thermoelectric material is effectively avoided, and the service life of a thermoelectric device is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

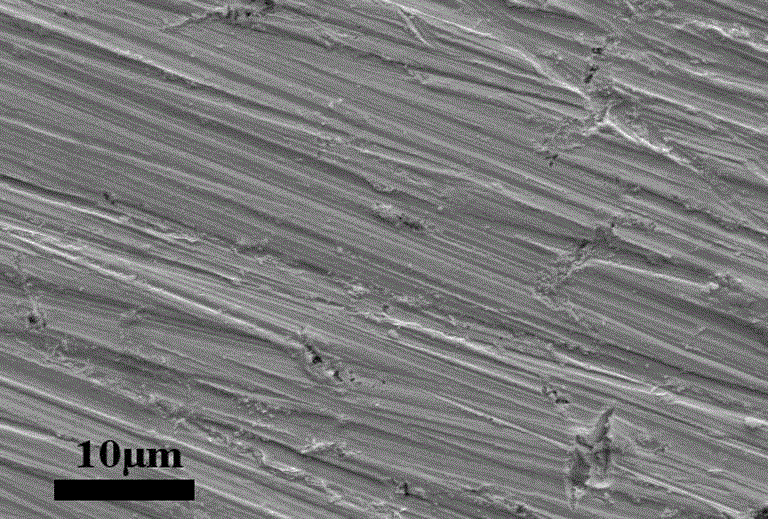

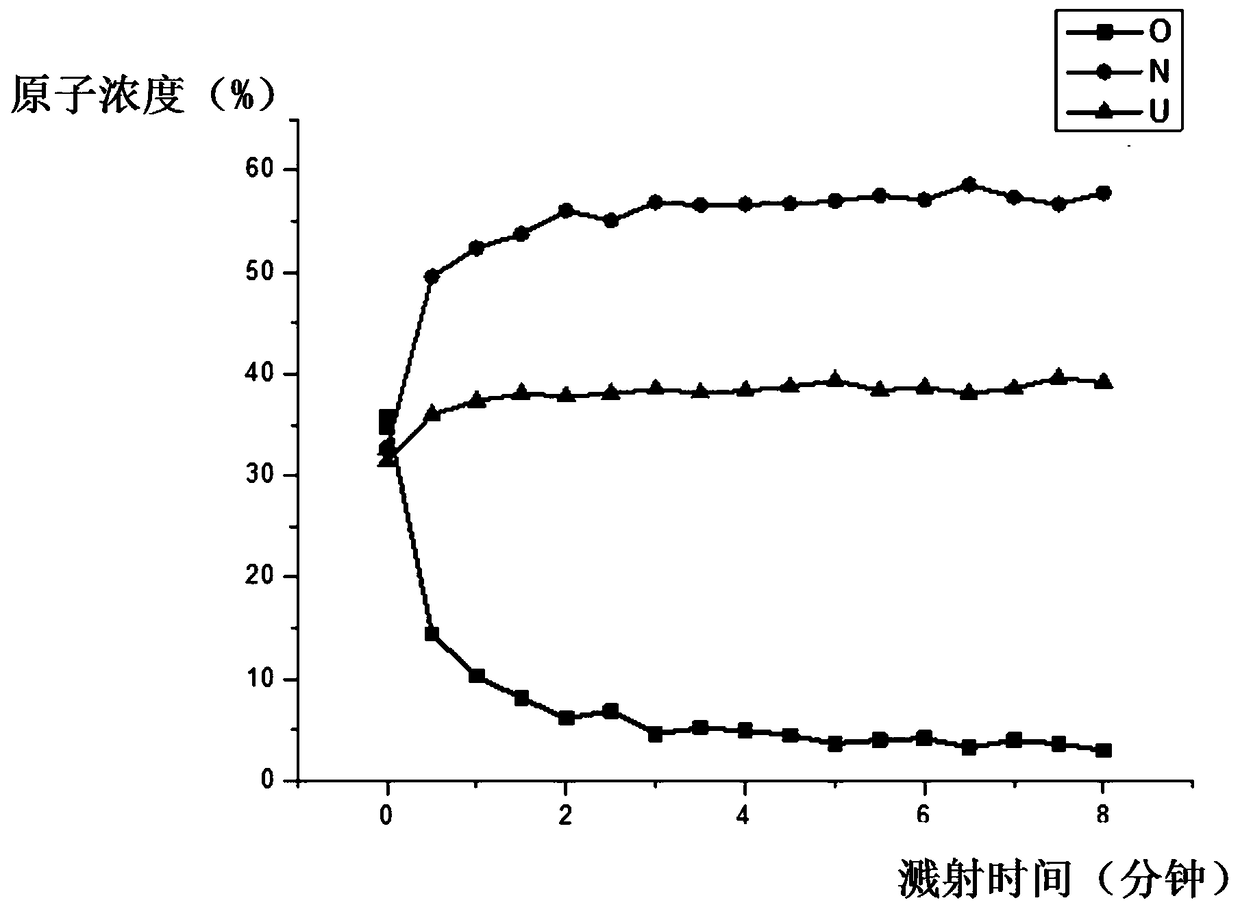

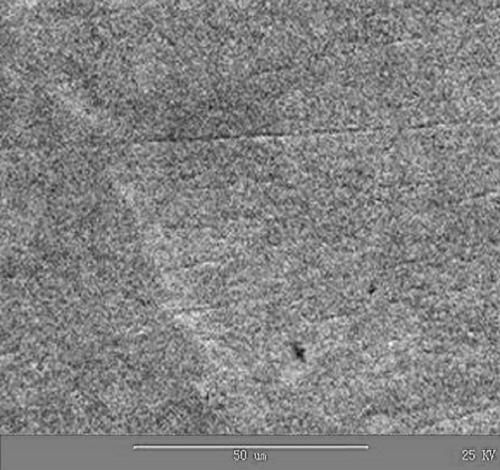

A thin film used for thermoelectric power generation devices under strong irradiation environment and its preparation method

ActiveCN106058033BStable in natureImprove efficiencyThermoelectric device manufacture/treatmentVacuum evaporation coatingThermoelectric materialsNitrogen oxides

The invention discloses a thin film used for a thermoelectric power generation device in a strong irradiation environment. The main material of the thin film is a uranium nitrogen oxide compound thermoelectric material. The preparation method comprises the following steps: 1) taking high-purity metal uranium flakes, pretreating the metal uranium flakes, and nitriding the treated metal uranium to generate uranium nitrogen oxides on the surface of the metal uranium flakes; 2) making metal uranium The uranium nitride oxide compound formed on the surface of the sheet is deposited on the substrate surface of the electric insulator by magnetron sputtering to obtain the uranium nitride thermoelectric material, and then the uranium nitride thermoelectric material is made into a thin film. The invention adopts uranium nitrogen oxide compound thermoelectric material as the main material of the film, so that the film can realize functions such as refrigeration and thermoelectric power generation in a special radiation-resistant environment, and can be used as a thermoelectric power generation device in a strong radiation environment; its preparation method The method is simple and easy to operate, and the obtained thermoelectric material has stable properties, high efficiency and low cost.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

An integrated uranium nitride thermoelectric conversion device

ActiveCN108123026BReduce volumeReduce weightThermoelectric device with peltier/seeback effectThermoelectric device junction materialsThermoelectric materialsSemiconductor structure

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

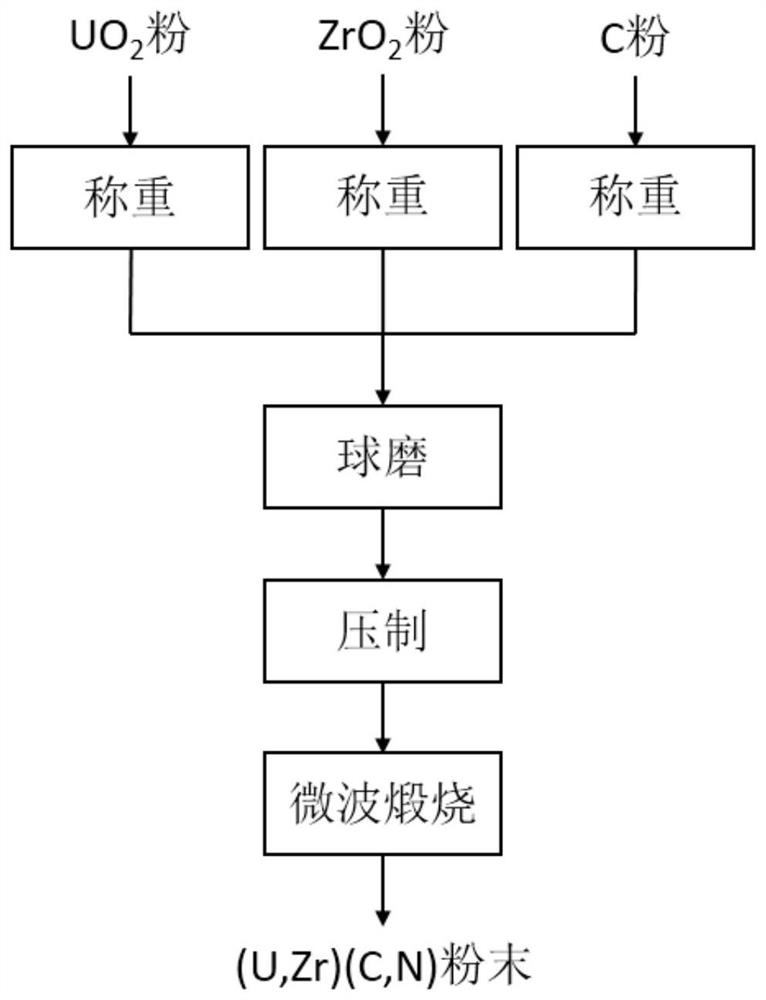

A microwave synthesis method of uranium-zirconium carbonitride powder

ActiveCN110156475BHigh powder activityLow costNuclear energy generationZirconium compoundsUranium nitrideCalcination

The invention belongs to the technical field of nuclear fuel preparation, and relates to a microwave synthesis method for zirconium uranium carbonitride powder. The microwave synthesis method sequentially comprises the following steps: (1) ball-milling: weighing UO2 powder, ZrO2 powder and carbon powder, performing uniform mixing, pouring the obtained mixture into a mill pot, adding grinding balls, and performing ball milling; (2) pressing: pouring out the ball-milled material, separating the balls and the material, sieving the material, and pressing the ball-milled raw material powder in a hydraulic machine to form a green body; and (3) performing microwave calcination: placing the green body in a microwave high-temperature furnace, vacuumizing the furnace, introducing an atmosphere gas,carrying out microwave heating to 1300-1600 DEG C, and performing heat insulation calcining to obtain the zirconium uranium carbonitride powder. The synthesis method for zirconium uranium carbonitridepowder is used to directly obtain a (U,Zr)(C,N) single solid solution phase at a low reaction temperature, and the synthesized (U,Zr)(C,N) powder has a high activity, and can be directly used in thesubsequent pellet sintering process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A kind of preparation method of uranium nitride pellet

ActiveCN108305693BExcellent surface appearanceImprove power densityNuclear energy generationReactor fuel susbtancesChemical compositionNuclear reactor

The invention relates to the technical field of preparation of nuclear fuel pellets, and particularly discloses to a method for preparing a uranium nitride pellet. The method comprises the following steps: 1, preparing a hydrogenation-dehydrogenation sample; 2, performing hydrogenation-dehydrogenation to prepare uranium powder; 3, preparing uranium sesquinitride powder; 4, molding a uranium sesquinitride green body; step 5, sintering the green body to form the uranium nitride pellet. The uranium nitride pellet obtained by the method has good surface appearance, and the density and the chemicalcomposition of the pellet meet the requirements of technical indexes, so the pellet can be used in a novel nuclear reactor to improve the core power density and reduce the release of fission products.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com