Small-caliber pipe butt-welding method

A welding method and technology for small-diameter pipes, which are applied in welding equipment, tubular articles, arc welding equipment, etc., can solve the problems of concave root and incomplete penetration, so as to speed up the production cycle, speed up the production cycle, reduce the The effect of ancillary workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

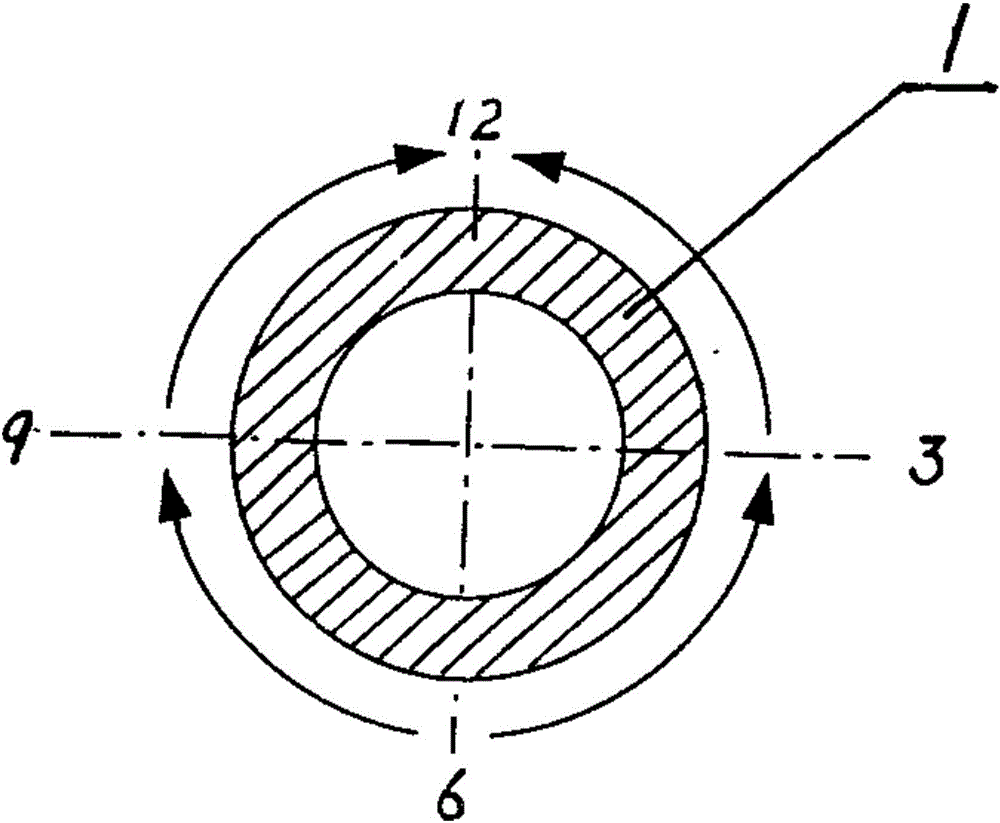

[0028] like figure 1 As shown, it is a schematic diagram of the welding direction in the upright and climbing position of the barrier-free small-diameter pipe butt joint. The described small-diameter pipe welding method adopts the "all-position" welding method, and the entire welding joint 1 is regarded as a clock. It is 6 o'clock, and the left and right are 9 o'clock and 3 o'clock respectively. At this time, the arc is struck from 6 o'clock, and the arc is fired from both sides upwards to 12 o'clock.

[0029] The all-position welding method for barrier-free small-diameter pipes includes the all-position welding method for barrier-free small-diameter tubes and the welding method for barrier-free small-diameter tubes with relatively large welding gaps.

[0030] The barrier-free small-diameter pipe welding adopts the method of all-position welding, and the method is as follows:

[0031] 1. The welding method of the first half circle adopts the method of climbing welding and fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com