A continuous metal mold split-type bending structure and bending forming method thereof

A metal mold, split-type technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of flatness of the bottom surface of the side wall outreach, affecting the quality of assembled products, and insufficient, so as to reduce the auxiliary workload and save The effect of manpower and material resources and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

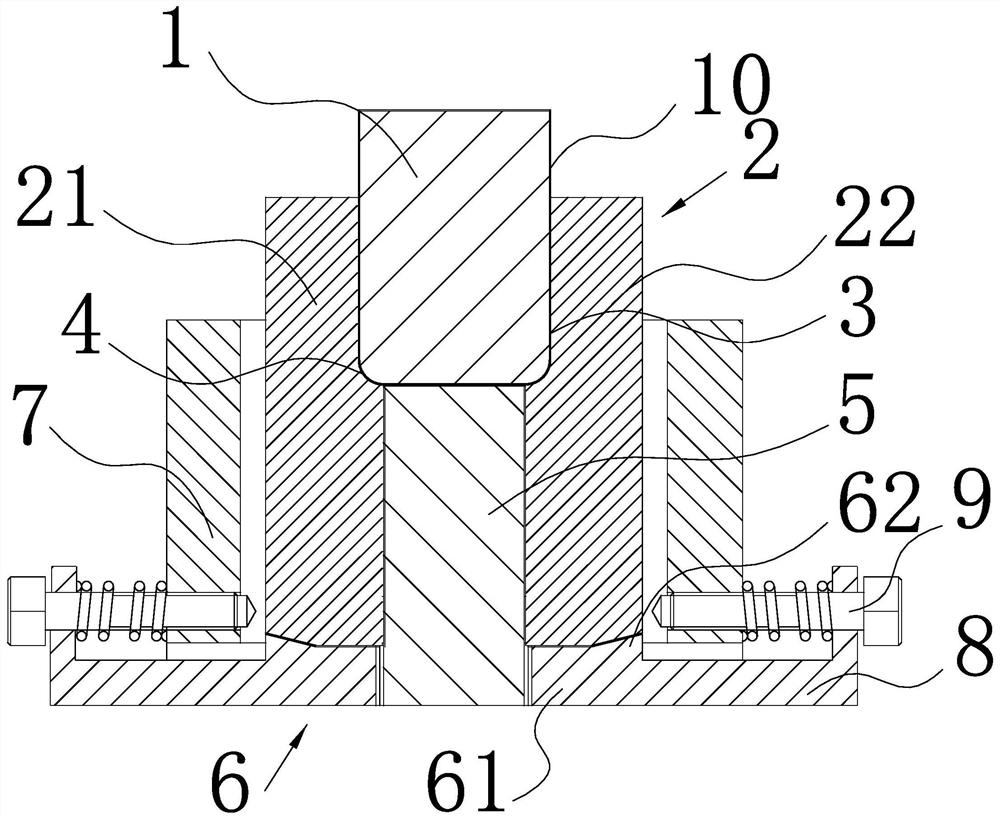

[0023] Such as figure 1 As shown, a continuous metal mold split-type bending structure of the present invention includes a forming bending die 2 composed of a left lifting die 21 and a right lifting die 22, a left lifting die 21 and a right lifting die 22 It is distributed symmetrically on the left and right, and the lower ends of the two clamp the lifting pusher block 5, and the upper ends of the left lifter die 21, the right lifter die 22 and the lifter pusher block 5 jointly enclose the synthetic molding cavity 3, and the lifter pusher The inner surfaces of the left lifting die 21 and the right lifting die 22 corresponding to the two sides of the material block 5 respectively form a straight line forming fillet 4, and the inner surfaces of the left lifting die 21 and the right lifting die 22 are formed by the linear forming fillet 4 and the inner surface of the right lifting die 22 respectively. The two ends of the top surface of the lifting pusher block 5 form a fillet tra...

Embodiment 2

[0034] The adjusting screw rod 9 is screwed horizontally on the longitudinal edge of the L-shaped tie rod 8, and the screw-in end of the adjusting screw rod 9 is abutted on the outer surface of the lower formwork 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com