Preparation method of Bacillus licheniformis powder and microbial ecological agent

A technology of bacillus licheniformis and probiotics, applied in the field of preparation of bacillus licheniformis, can solve the problems of low production efficiency, high production cost, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation process of the present invention is as follows:

[0015] 1. Preparation of culture medium

[0016] (1) Nutrient broth medium: dissolve 1.0% peptone, 0.5% beef extract, and 0.5% sodium chloride in purified water, and adjust the pH to 7.0-7.4 with sodium hydroxide.

[0017] (2) Nutrient agar medium: dissolve 1.0% peptone, 0.5% beef extract, 0.5% sodium chloride, and 1.6% agar powder in purified water, and adjust the pH to 7.0-7.4 with sodium hydroxide.

[0018] 2. Recovery of Bacillus licheniformis freeze-dried bacteria

[0019] 2.1. Open the ampoule where the freeze-dried bacteria are stored (disinfect the outer wall of the bacteria tube before opening, generally use alcohol cotton with a concentration of 70%), and inject a small amount of nutrient broth medium (about 0.3ml) into it with a straw , and shake the freeze-dried bacteria suspension dissolved therein.

[0020] 2.2. Add an appropriate amount (about 50-100ml) of nutrient broth medium into a 20...

Embodiment 1

[0054] Example 1. Open a portion of 63516 strains of Bacillus licheniformis freeze-dried bacteria (its microorganism preservation number is CGMCC NO: 0183), which is equally divided into five parts and marked as A, B, C, D and E respectively.

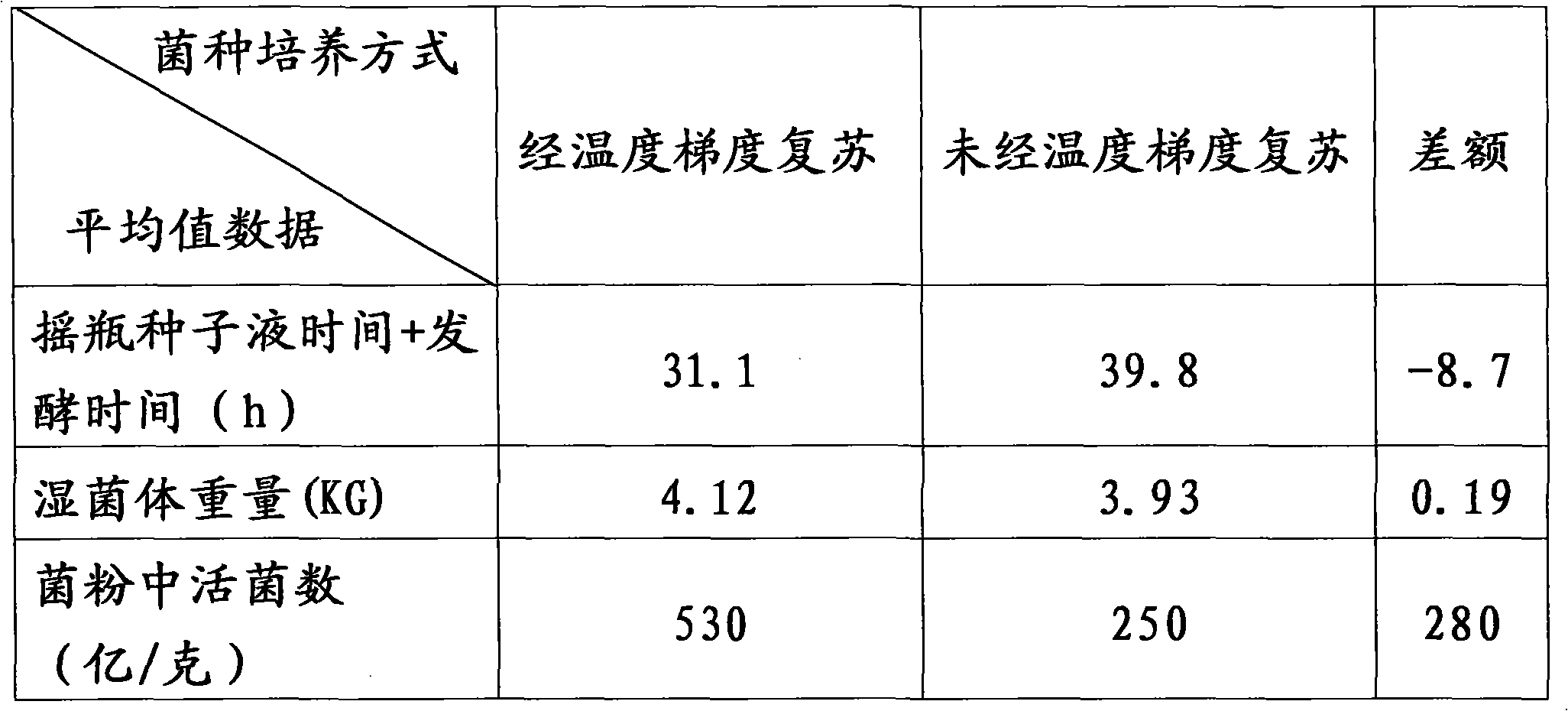

[0055] Perform temperature gradient recovery culture on A, the temperature of each gradient stage is 25±1°C, 30±1°C, 37±1°C, and the corresponding culture time is 4h, 4h, 12h respectively; select three groups of dominant colonies with similar characteristics , marked as 1, 2 and 3 respectively, after the cultivation of the shake flask seed liquid and the fermentation culture time are not exactly the same, the fermented liquid is centrifuged to obtain the wet thallus; the wet thallus and anhydrous calcium carbonate The ratio is mixed and dried to make bacterial powder, and the results obtained are shown in Table 1. Wherein, the pH of the culture medium used in the cultivation process is 7.0-7.4.

[0056] Table 1:

[0057] Grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com