High-viscosity solar cell front side silver paste and method for producing the same

A solar cell and high-viscosity technology, applied in cable/conductor manufacturing, circuits, adhesives, etc., can solve the problems of reducing the photoelectric conversion efficiency of solar cells, reducing the light-receiving area of the surface of solar cells, and increasing the shading area of the surface of solar cells to achieve shading The effect of small area, high photoelectric conversion efficiency, and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

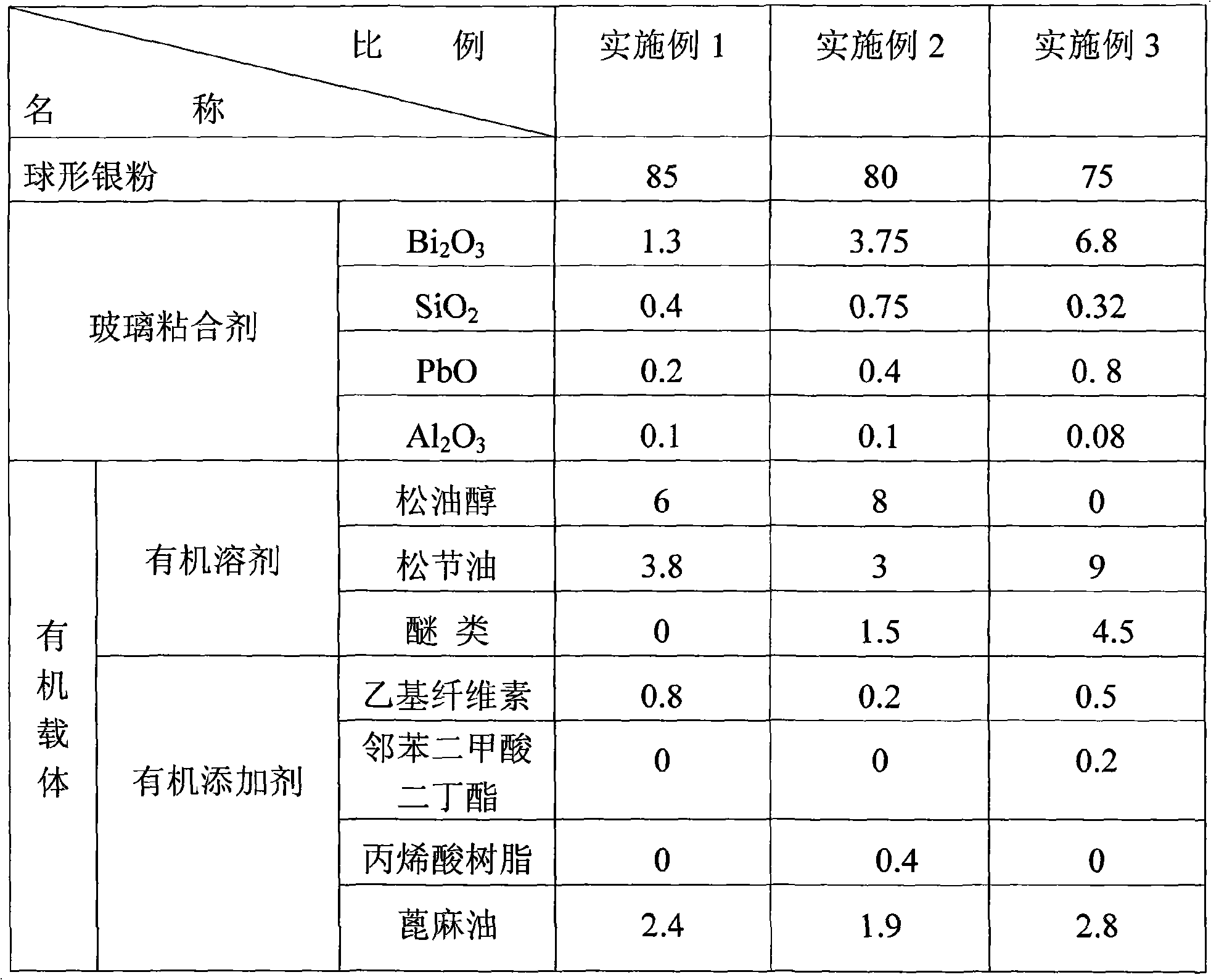

[0019] The embodiment of high viscosity solar cell front silver paste of the present invention is shown in the following table:

[0020]

[0021] The parameters of the high-viscosity solar cell front silver paste produced according to the above-mentioned examples are as follows: maximum particle diameter≤15 μm; average particle diameter≤9 μm; viscosity 220-300Pa.s; solid content 81-83.5wt%; square resistivity≤ 4mΩ / □; sintering temperature 850-950℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com