Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

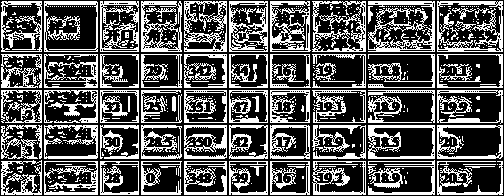

37results about How to "Increase aspect ratio" patented technology

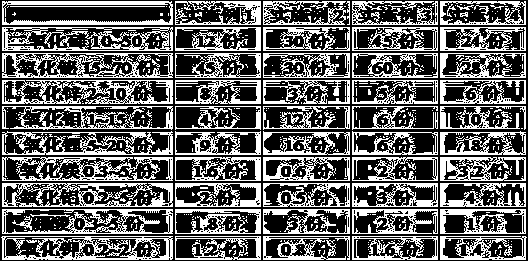

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-viscosity solar cell front side silver paste and method for producing the same

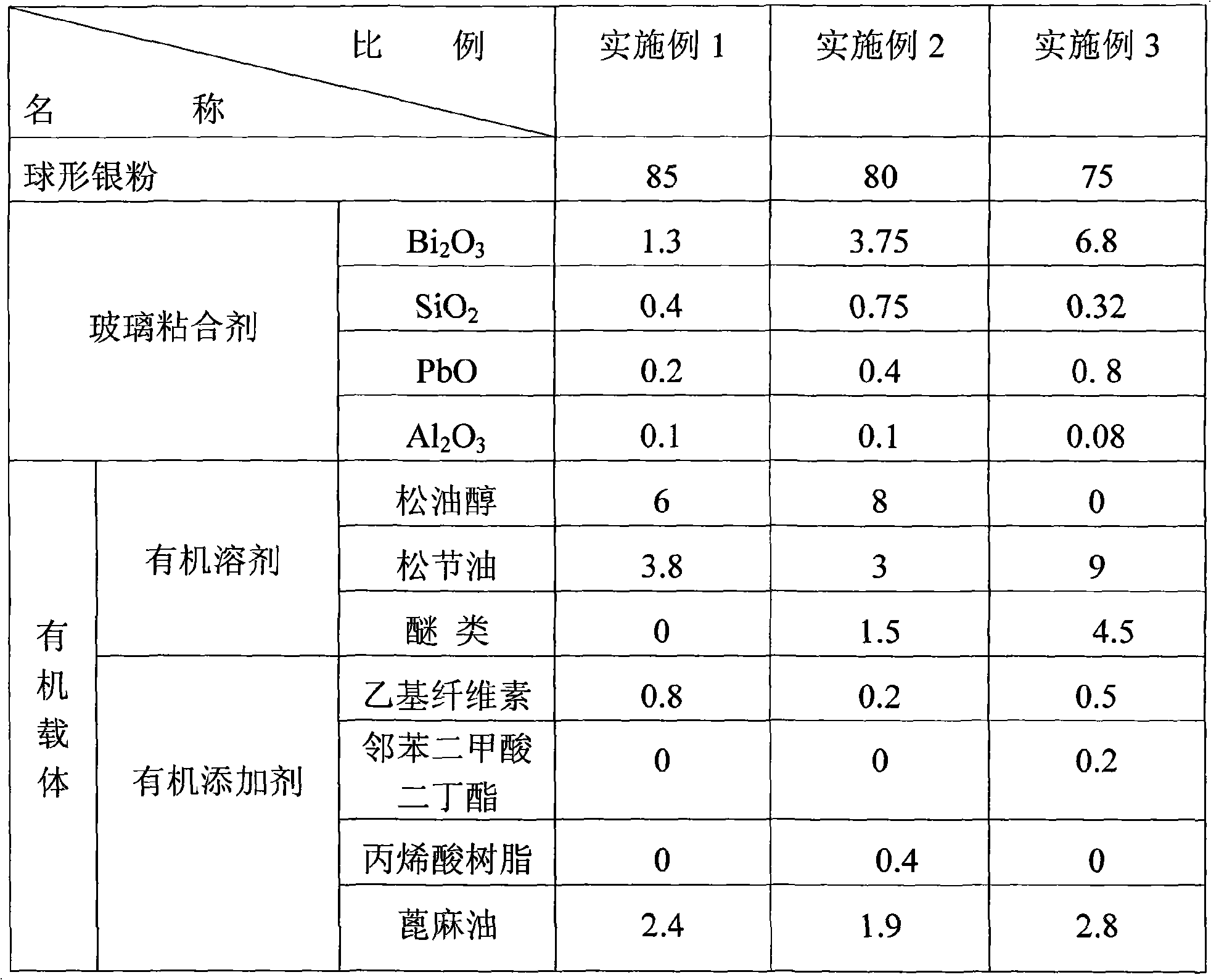

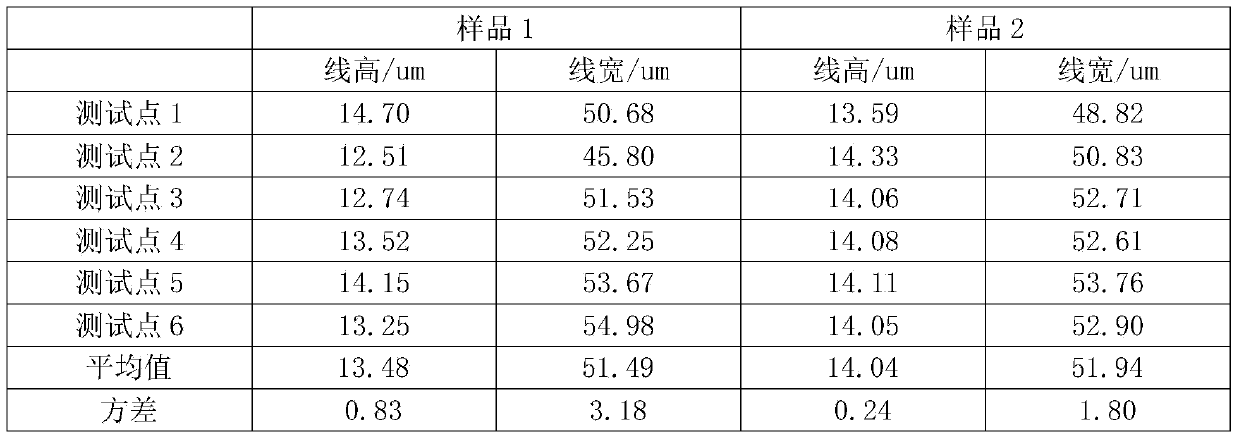

InactiveCN101271928AIncrease aspect ratioImprove photoelectric conversion efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialScreen printingSilver paste

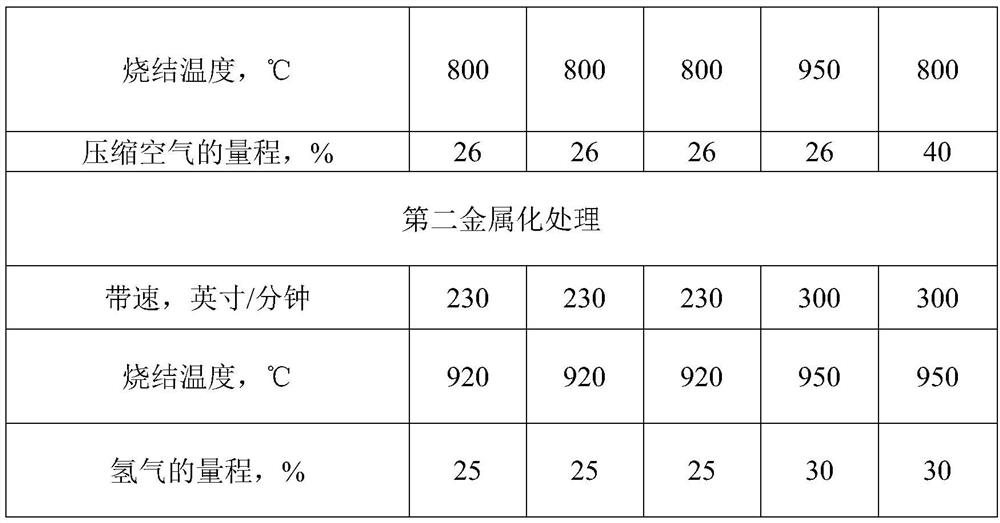

The invention relates to a high viscosity solar cell front silver serum and a preparation method thereof. The composition and the weight ratio of the high viscosity solar cell front silver serum are that conductive silver powder accounts for 75-85 percent, glass glue accounts for 2-10 percent, organic carrier accounts for 5.5-20 percent, the particle size of the conductive silver powder is 0.2-2mum; the composition and the weight ratio of the glass glue are that Bi2O3 accounts for 65-85 percent, SiO2 accounts for 5-20 percent, PbO accounts for 1-15 percent and Al2O3 accounts for 1-5 percent. After such processes are carried out by the serum as screen printing, low temperature drying and high temperature sintering, the aspect ratio of a conducting electrode formed on the surface of solar cell is high, the solar cell produced by using the method has small front shading area and high photoelectric conversion efficiency.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

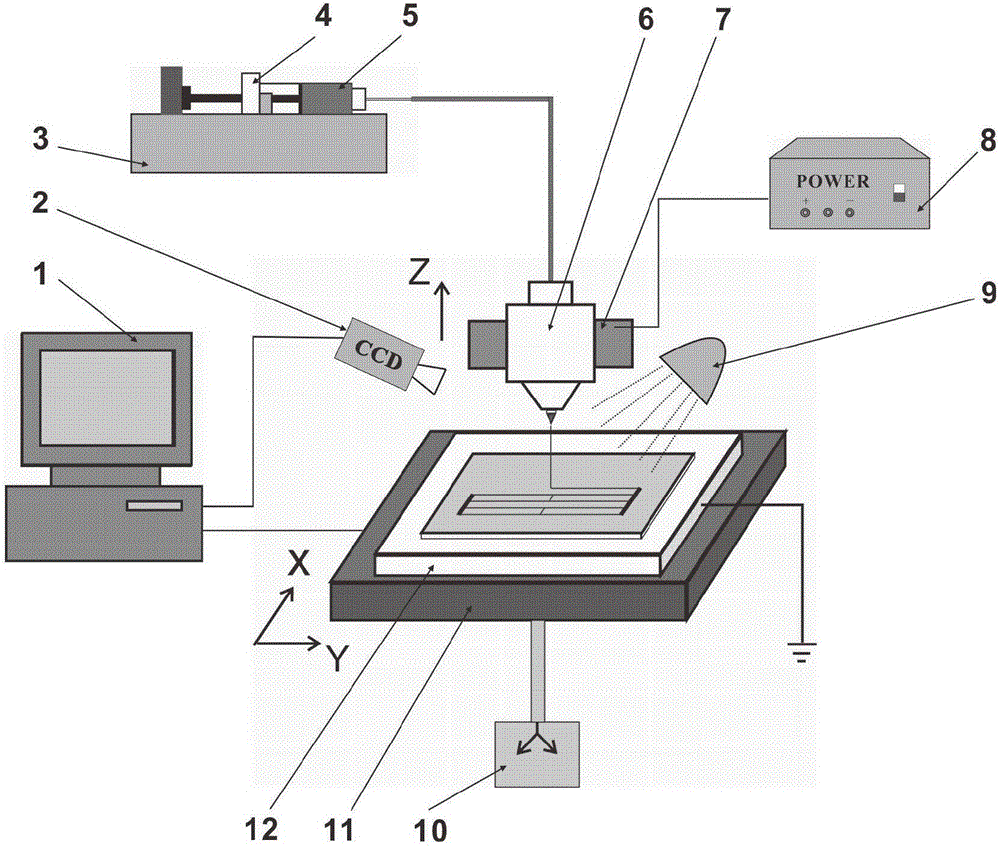

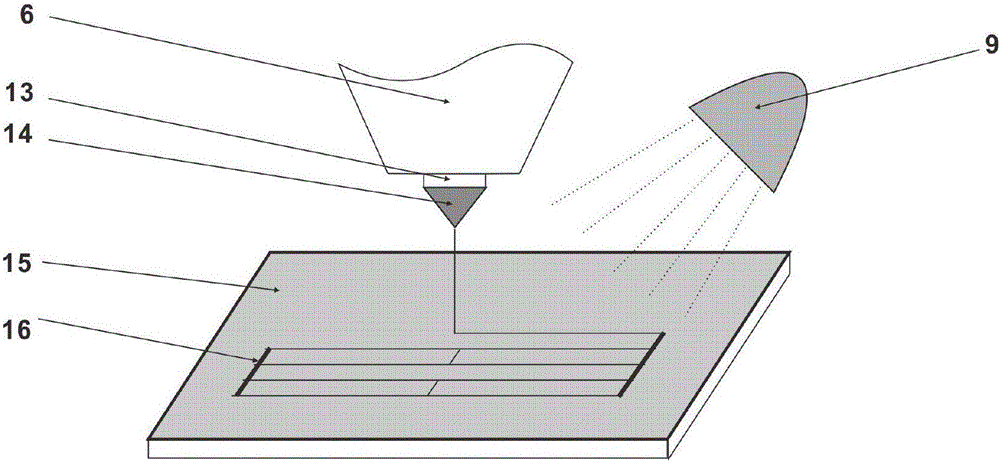

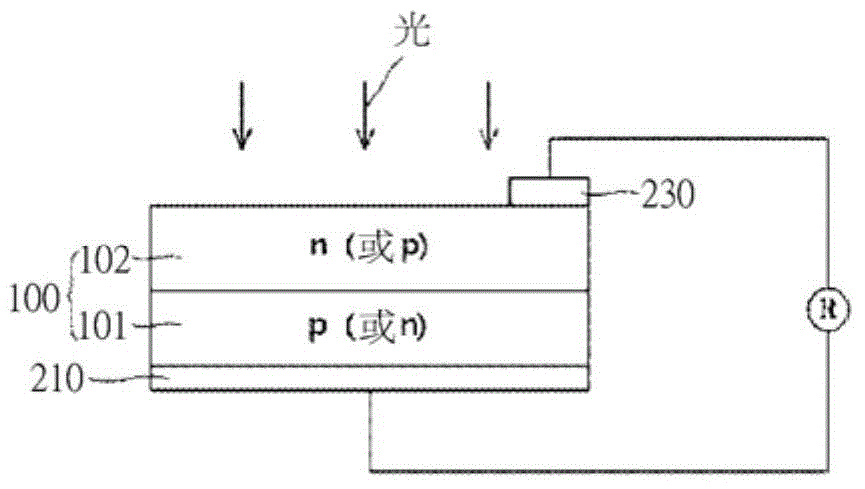

E-jet printing method for solar photovoltaic cell electrode

ActiveCN106653877AImprove photoelectric conversion efficiencyReduce manufacturing costPrintingPhotovoltaic energy generationEngineeringWidth ratio

The invention belongs to the technical field of advanced manufacturing and provides an e-jet printing method for a solar photovoltaic cell electrode. Firstly, fluid pressure is applied to conductive ink, and the conductive ink flows out of a nozzle hole at a certain flow speed; then, a certain electric field is applied to the conductive ink, fine jet far smaller than the inner diameter of the hole is thus formed; the jet is then heated, and the partial solvent of the conductive ink is evaporated; and finally, jet printing of an electrode structure on a heated photovoltaic cell semiconductor sheet is carried out, the conductive ink is quickly cured, and a photovoltaic cell electrode structure is formed. The comprehensive effects on the conductive ink by the electric field-thermal field are used and control on the moving track of the solar photovoltaic cell semiconductor sheet by a moving platform is matched, and thus, the solar photovoltaic cell electrode is made. The electrode structure jet printing technology provided by the invention has the advantages of simple process, easy control, high precision and strong material adaptability, and making of a large-height-width ratio electrode structure in high temperature can be realized.

Owner:DALIAN UNIV OF TECH

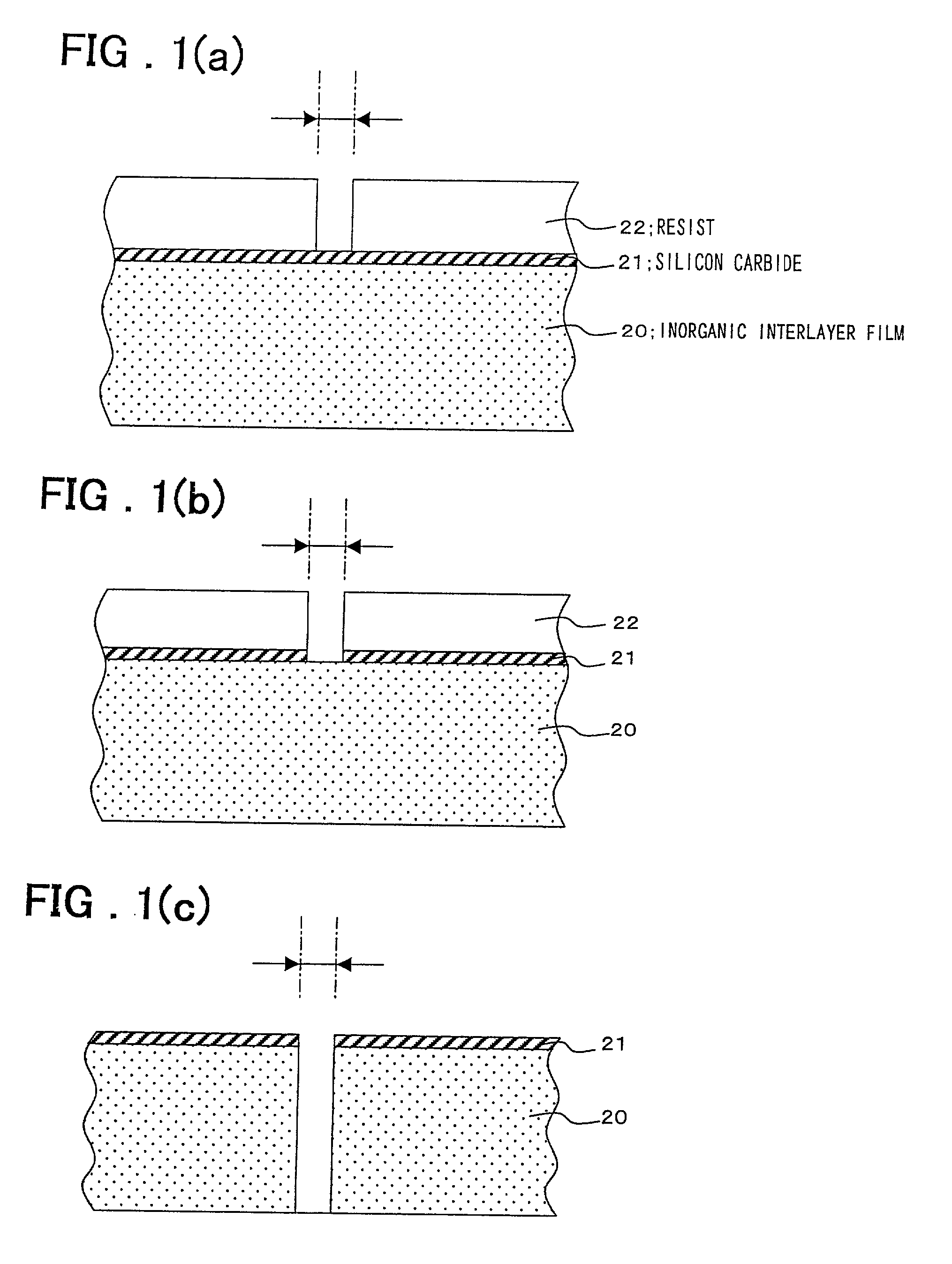

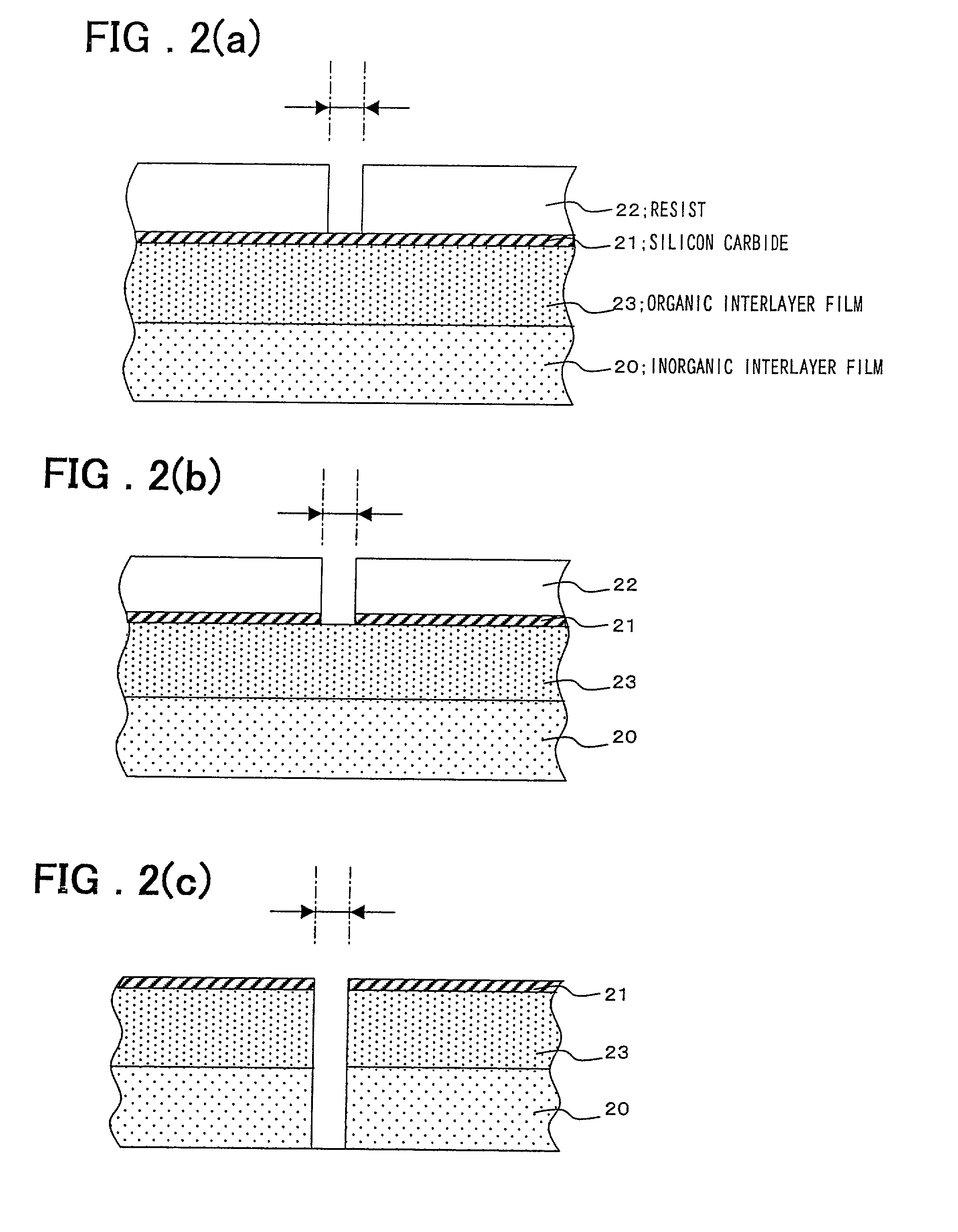

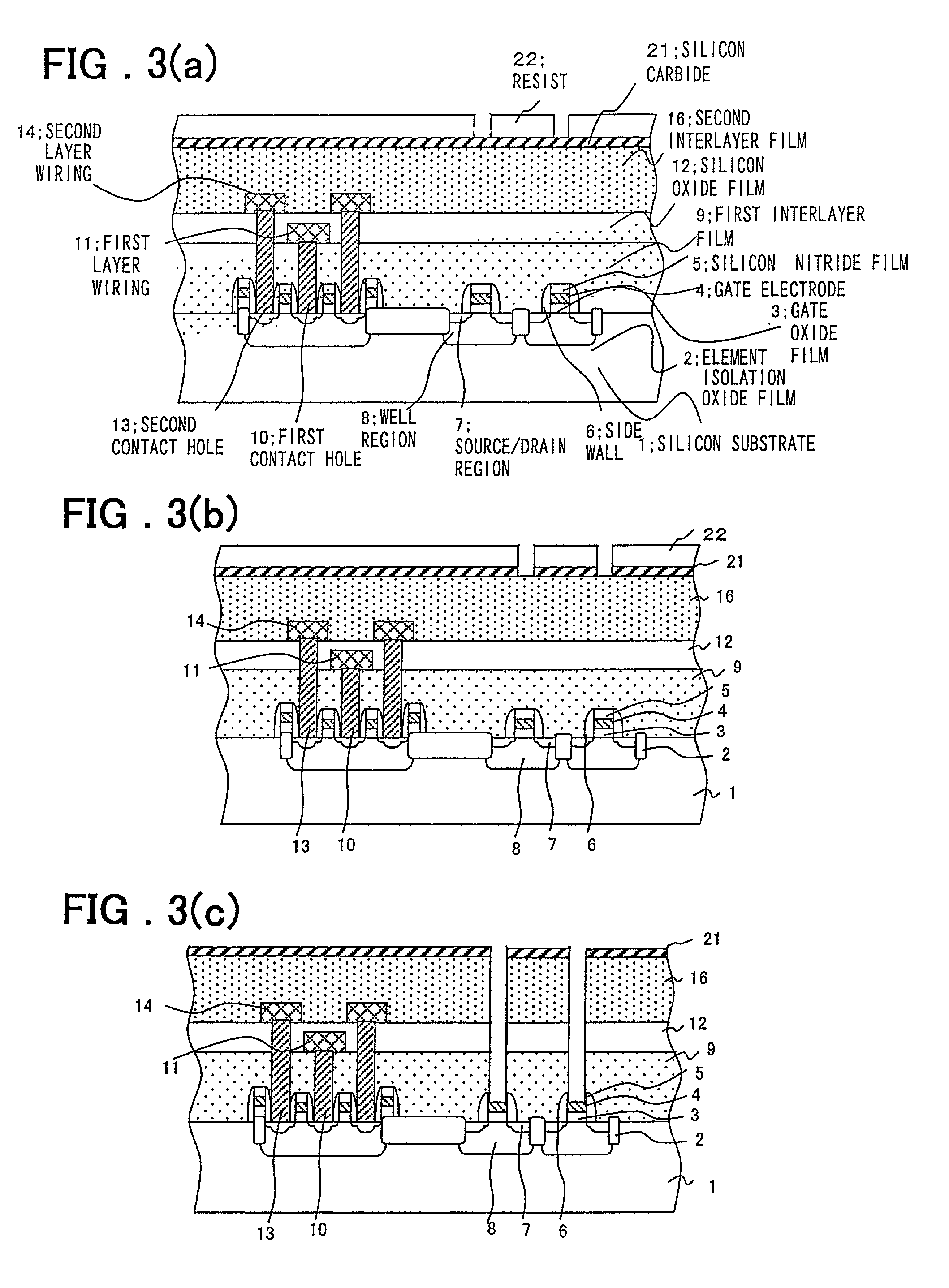

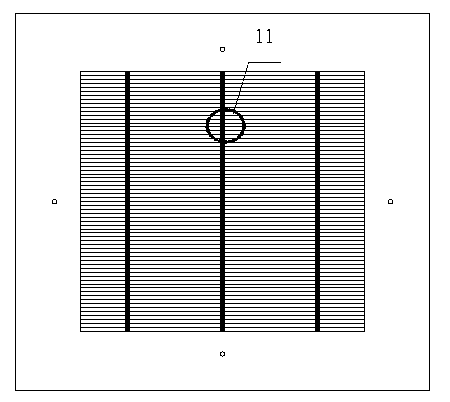

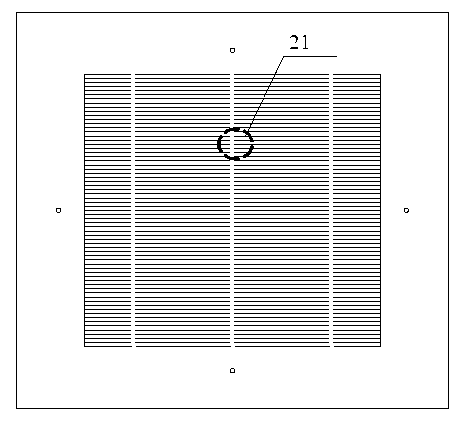

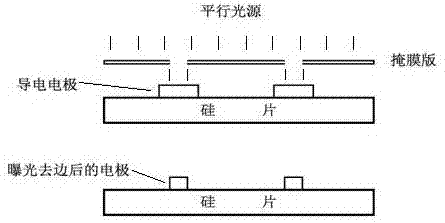

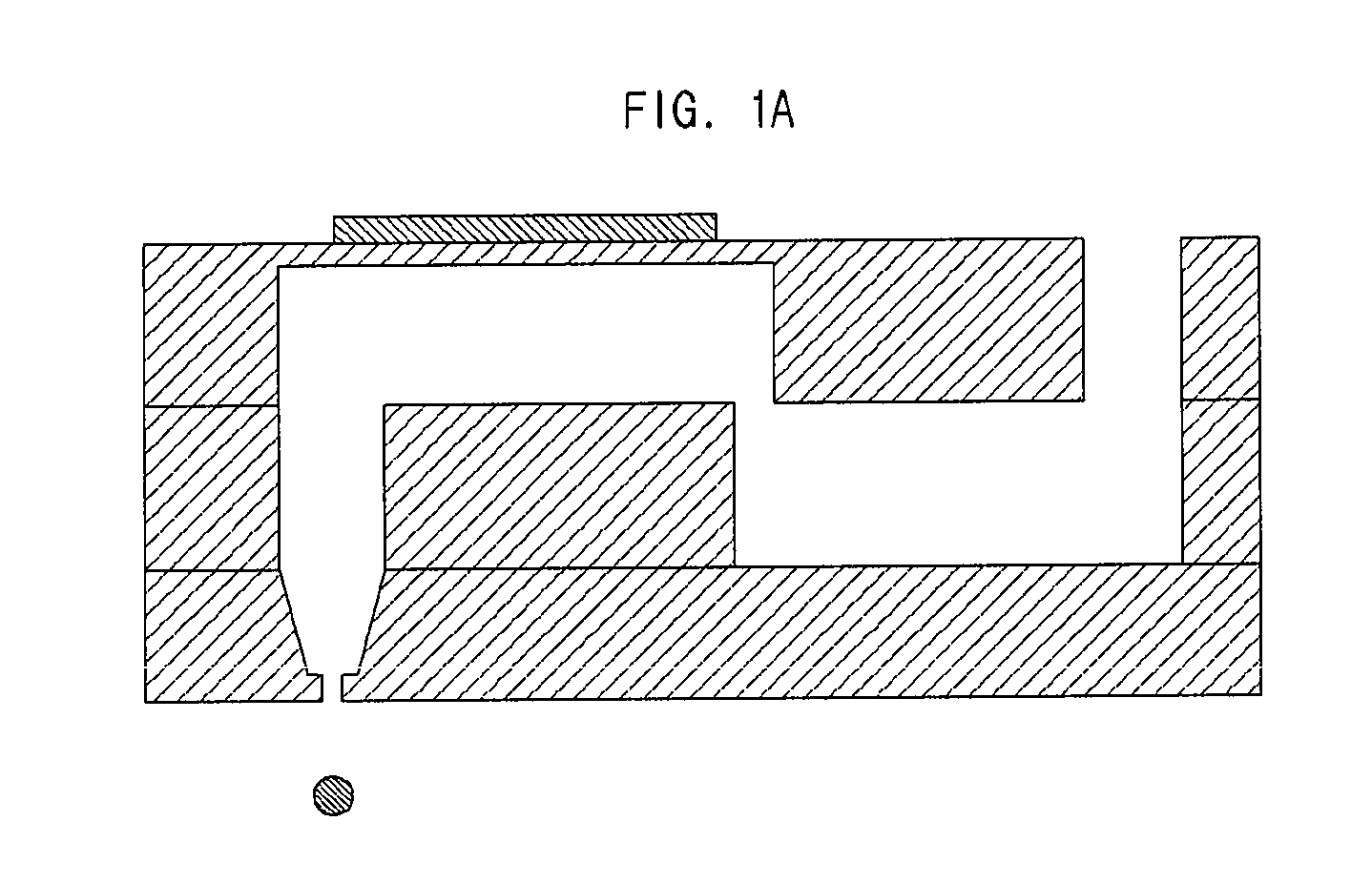

Etching mask, process for forming contact holes using same, and semiconductor device made by the process

InactiveUS20010002731A1Increase aspect ratioReduce in sizeSemiconductor/solid-state device detailsSolid-state devicesEtching selectivityResist

An etching mask having high etching selectivity for an inorganic inter layer film of SiO2 or Si3N4, an organic interlayer film such as ARC and an electrically conductive film and a contact hole using such an etching mask, a process for forming same and a resultant semiconductor device. On formation of contact holes for connecting wirings disposed through interlayer films of inorganic or organic material (20, 23 in FIG. 2), a thin film of silicon carbide (21 in FIG. 2) having high etching selectivity for any of the inorganic and organic materials is deposited on an interlayer film, and a mask pattern of silicon carbide is formed using a resist pattern (22 in FIG. 2). Thereafter, high aspect ratio contact holes having a size which is exactly same as that of the mask is formed by etching the interlayer film using the silicon carbide mask.

Owner:RENESAS ELECTRONICS CORP

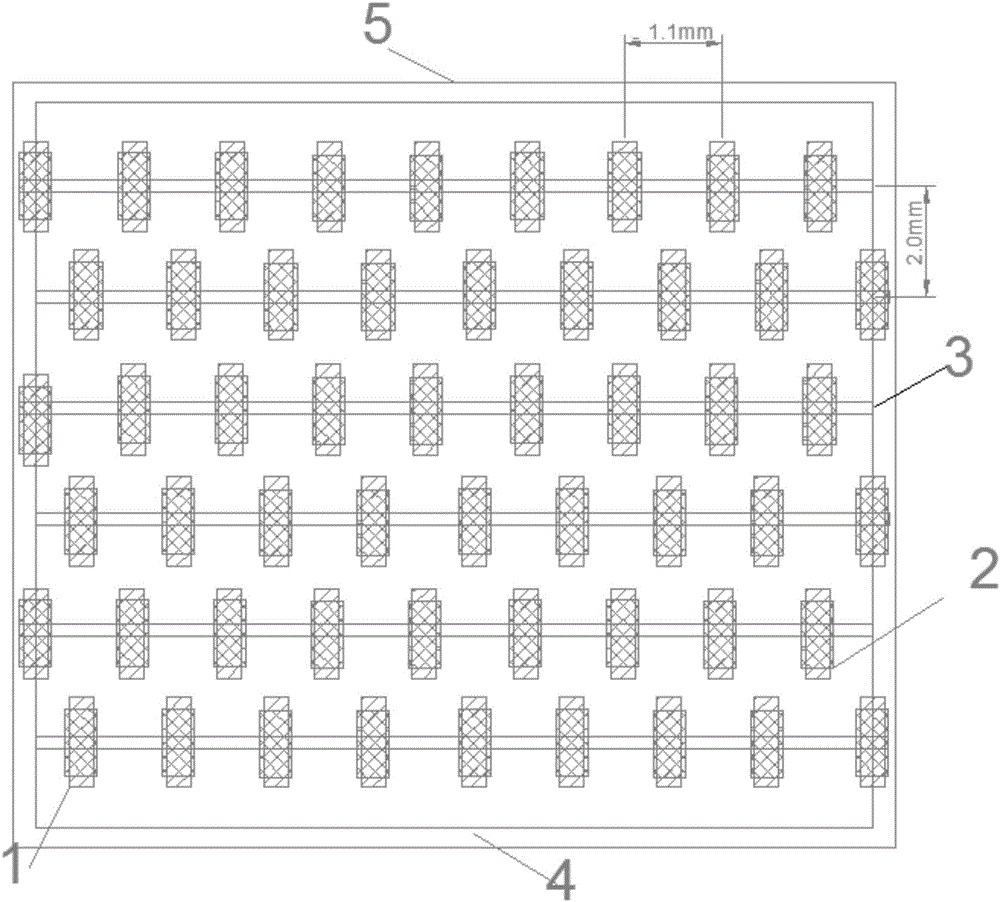

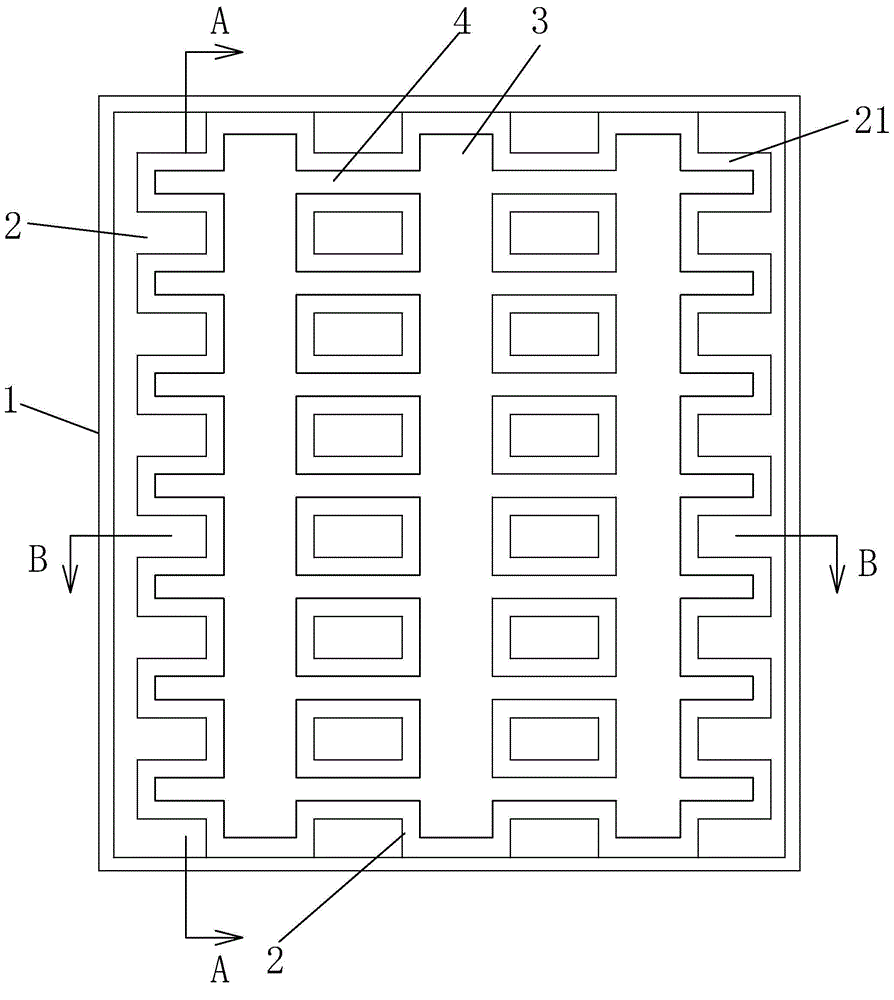

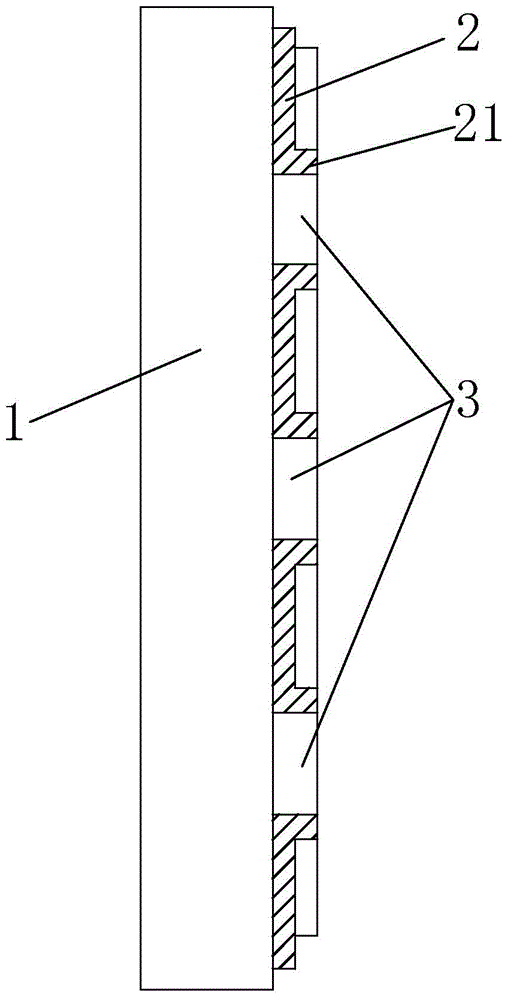

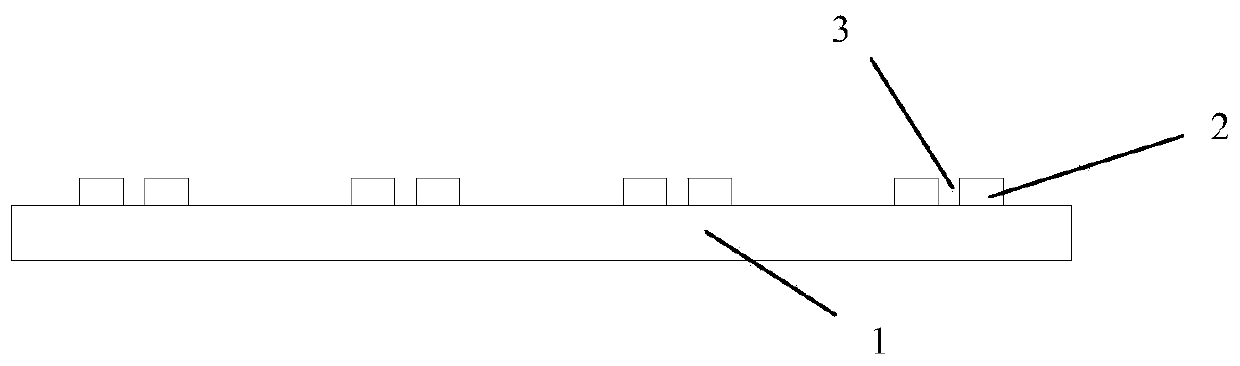

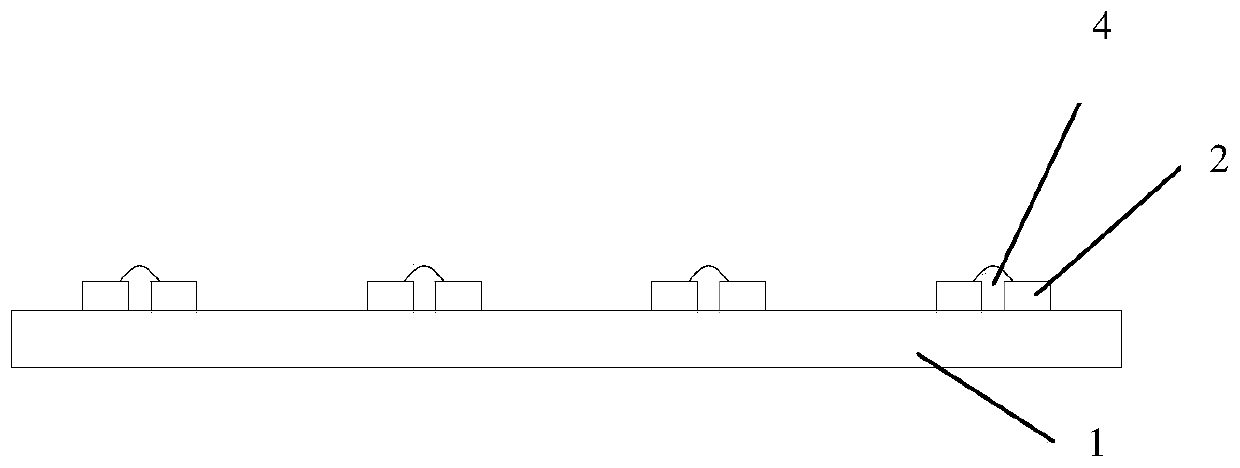

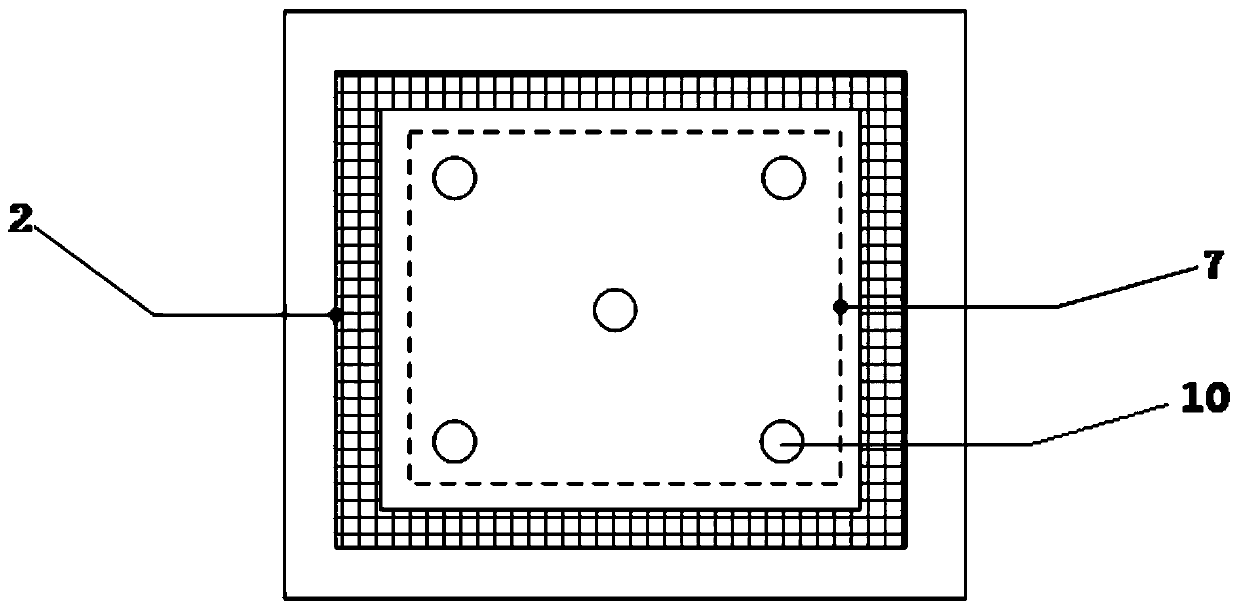

Matched screen board of solar cell electrode and printing method thereof

InactiveCN103171260AClosely connectedImprove conversion efficiencyFinal product manufactureScreen printersSolar cellElectrode Grid

The invention discloses a matched screen board of a solar cell electrode and a printing method thereof. The matched screen board of the solar cell electrode comprises two screen boards which are matched. A first screen board of the two screen boards is of a complete grid line structure and comprises a plurality of thin grid lines and a plurality of main grid lines. A second screen board of the two screen boards is of a thin grid line structure. After accurate counterpoint of the two screen boards is achieved, overlapping of the thin grid lines on the two screen boards is guaranteed. According to the matched screen board of the solar cell electrode and the printing method thereof, a 'camel peak' which can appear with a traditional printing method occurs to the electrode thin grid lines after primary printing is carried out. The 'camel peak' disappears after secondary printing. The electrode grid lines obtained after the two printing are even, smooth, and large in depth-width ratio. And meanwhile, the problem of empty printing is solved, and conversion efficiency of a solar cell is improved.

Owner:KUN SHAN POWER STENCIL

Solar cell front electrode with combination of points and lines and preparation method

ActiveCN105762202AReduce dosageReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesCopper electrodeSilicon solar cell

The invention discloses a solar cell front electrode with combination of points and lines and a preparation method. The front electrode includes point-like silver electrodes printed on a front surface of a P type silicon matrix, metal wires are printed on the metalized point-shaped silver electrodes, and the metal wires are connected with the point-shaped silver electrodes through a transparent conductive adhesive. The preparation method adopts a silk-screen printing technology to print point-shaped silver electrodes on a front surface of a P type silicon matrix which is subjected to texturing, diffusion, post cleaning, film coating, laser film opening and back electrode back field printing process treatment, then a metal wire printing machine is adopted to print metal wire electrodes on surfaces of the silver electrodes after metallization treatment, and the metal wires and the silver electrodes are connected together through a transparent conductive glue. The solar cell font electrode provided by the invention has the advantages that copper electrodes are utilized to replace part of silver electrodes on the front electrode, thereby reducing the silver electrode usage amount of the front electrode of a silicon solar cell, and reducing manufacturing cost of the silicon solar cell; and in addition, the copper electrodes have higher height, thereby improving the aspect ratio of grid lines, and improving efficiency.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD +1

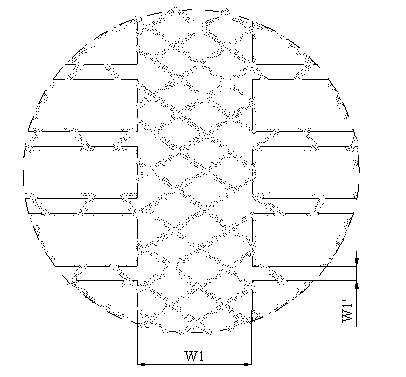

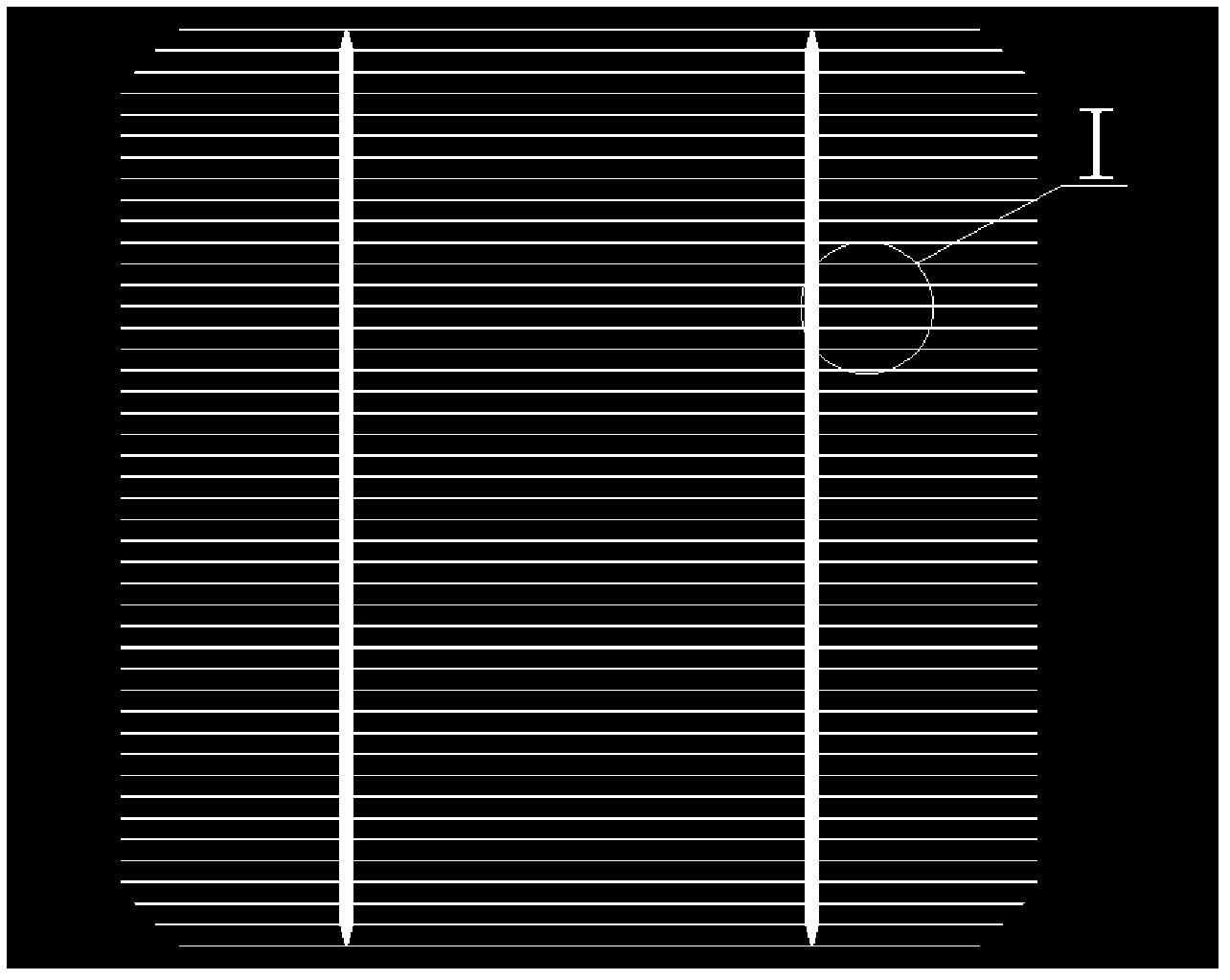

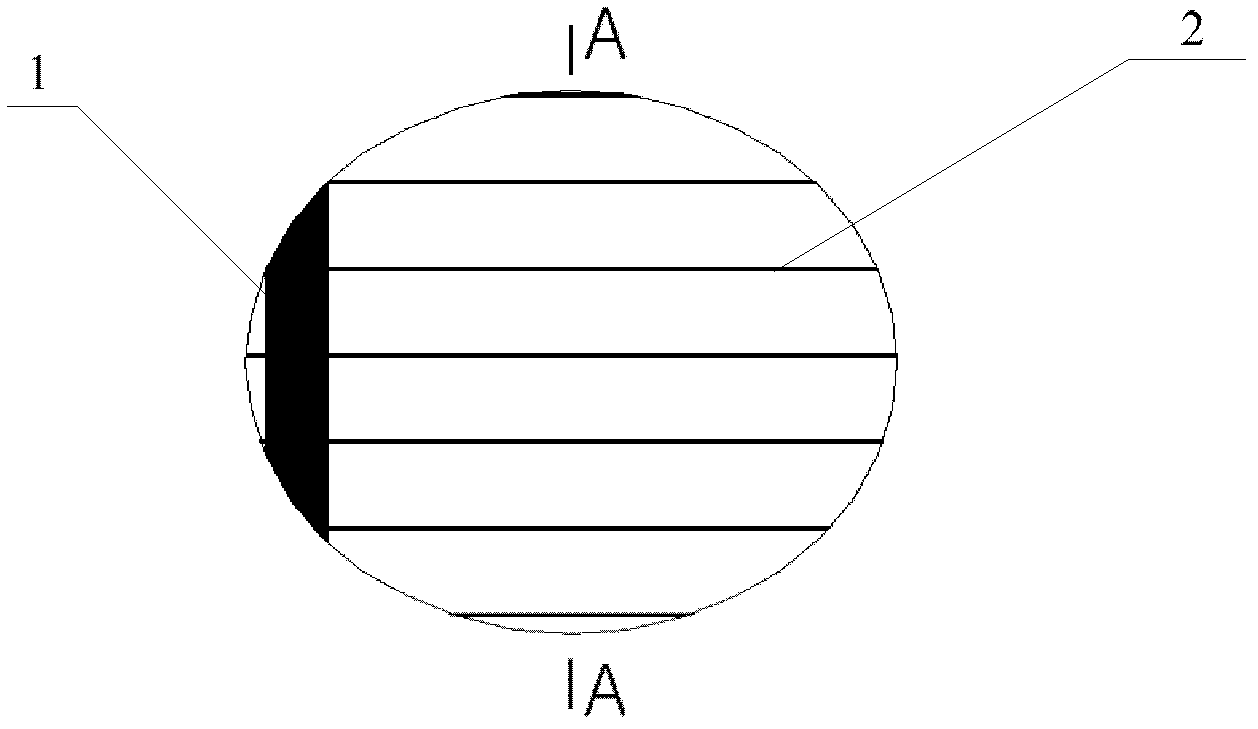

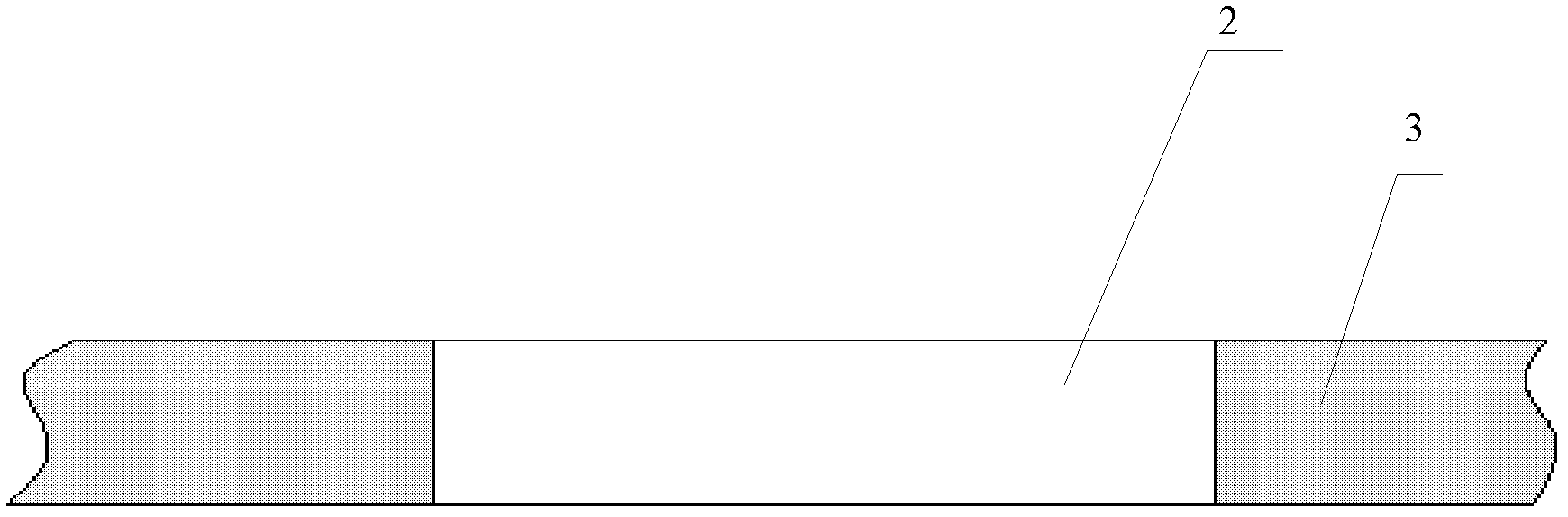

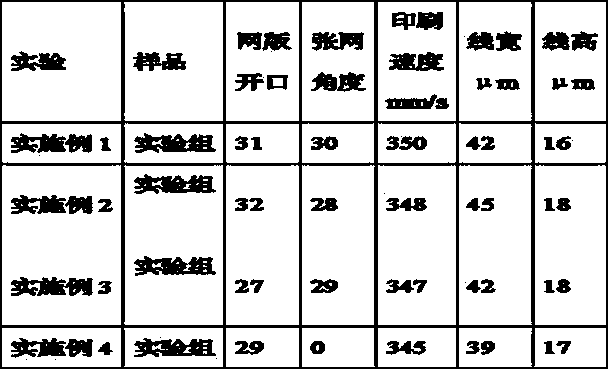

Crystalline silicon solar battery positive electrode screen printing plate

InactiveCN105977346AReduce widthIncrease aspect ratioFinal product manufactureScreen printersScreen printingYarn

The invention discloses a crystalline silicon solar battery positive electrode screen printing plate and belongs to the technical field of a solar battery. The crystalline silicon solar battery positive electrode screen printing plate comprises a screen frame and a plurality of mesh yarns arranged on the screen frame, wherein the mesh yarns are coated with a latex film layer, the latex film layer is provided with a positive electrode pattern, and the positive electrode pattern comprises a plurality of crossed primary grid wires and secondary grid wires; the mesh yarns comprise a plurality of vertical mesh yarns and transversal mesh yarns which are vertically crossed, the vertical mesh yarns are successively arranged on the screen frame in parallel at equal intervals, the transversal mesh yarns are successively arranged on the screen frame in parallel at equal intervals, and the interval between adjacent two vertical mesh yarns and the interval between adjacent two transversal mesh yarns are the same; and the primary grid wires are arranged in parallel between adjacent two transversal mesh yarns, the secondary grid wires are arranged in parallel between adjacent two vertical mesh yarns, and the quantity of the primary grid wires is smaller than that of the secondary grid wires. The solar battery positive electrode screen printing plate, while improving the electrode conductivity, improves the photoelectric conversion efficiency of a battery, can reduce EL broken grid proportion of a secondary grid at the same time, and improves the appearance qualified rate of the battery.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Organic adhesive composite used for silicon solar cell silver paste and preparation method thereof

InactiveCN102304287AGood dispersionEasy to wrapInksNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides an organic adhesive composite used for silicon solar cell silver paste, comprising the following raw materials according to parts by weight: 5-13% of polyamide resin, 8-25% of abietic resin or phenolic aldehyde modified terpene resin, 65-80% of organic solvent and 0-1% of wetting dispersant. The organic adhesive composite exists in silver paste to serve as a carrier or dispersion medium, proper fluid performance is endowed to slurry to fully wet silver powder or inorganic adhesive powder in the wetting silver paste, and the slurry can be dissolved with other accessory ingredients in a mixed mode.

Owner:IRICO

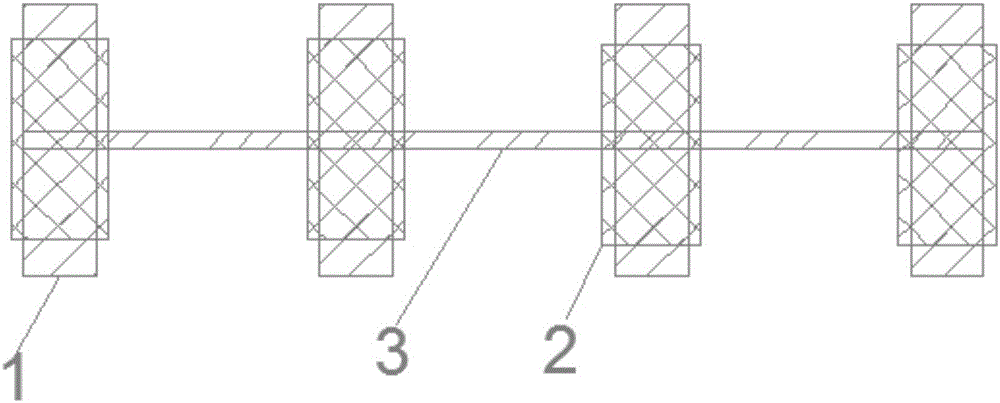

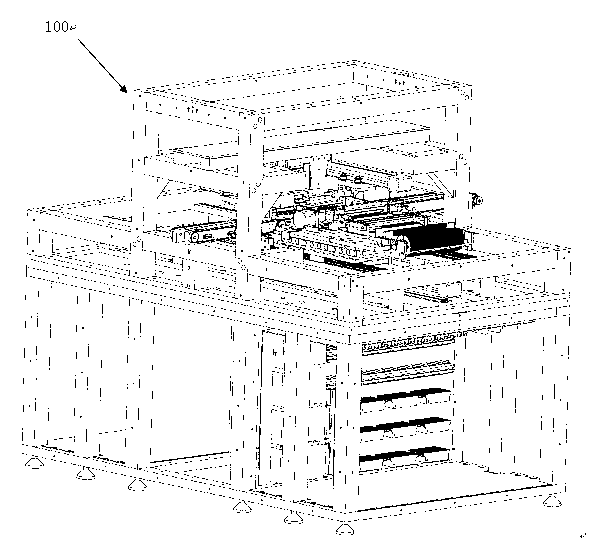

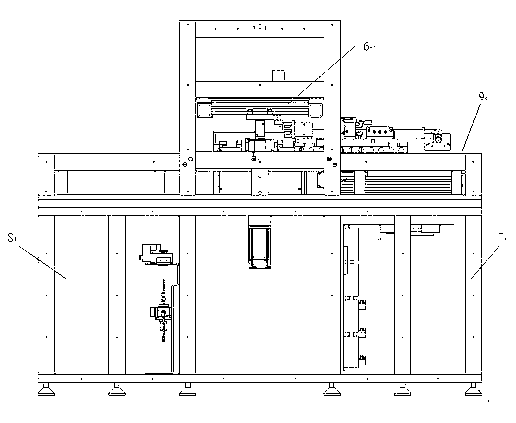

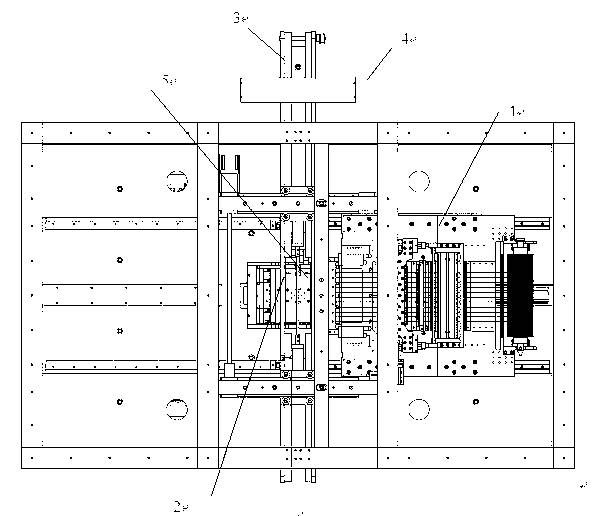

Equipment and method for manufacturing solar cell positive electrode

InactiveCN102800748AReduce grid widthIncrease aspect ratioScreen printersPhotovoltaic energy generationWire cuttingWidth ratio

The invention discloses equipment and a method for manufacturing a solar cell positive electrode. The manufacturing equipment comprises a frame, a wire feeding mechanism, a wire drawing mechanism, a paste coating mechanism and a wire attachment mechanism, wherein the wire feeding mechanism provides a conductive wire; the wire drawing mechanism draws the conductive wire out of the wire feeding mechanism so as to penetrate through the paste coating mechanism; the paste coating mechanism is used for coating the conductive wire on conductive paste; and the wire attachment mechanism attaches the conductive wire coated with the paste to the positive side of the solar cell, so that the manufacture of the cell positive electrode is finished. The invention also discloses a method for manufacturing the cell positive electrode. The method comprises the following steps of: wire drawing, paste coating, wire attachment, wire cutting and wire head processing. The manufacturing equipment and method have the beneficial effects that according to the cell positive electrode manufactured by the equipment and method, the diameter of the conductive wire and the paste coating mechanism are adjusted, so that the width of the grid line can be effectively reduced, the height-width ratio of the positive electrode is improved, the manufacturing cost is reduced, and the conversion efficiency is improved.

Owner:HANGZHOU SILARS TECH

Preparation method of organic carrier containing cellulose nanocrystals and application of organic carrier in silver paste

InactiveCN108641123AImprove printing performanceIncrease aspect ratioNon-conductive material with dispersed conductive materialCable/conductor manufactureSolventWidth ratio

The invention discloses a preparation method of an organic carrier containing cellulose nanocrystals. The organic carrier consists of 1-5% of resin, 1.5-6% of an auxiliary agent, 59-92.5% of an organic solvent and 5-30% of cellulose nanocrystal hydrogel. The invention also provides a method for preparing front-surface silver paste of a solar cell by using the carrier. The silver paste comprises 5-9% of the organic carrier, 2-3% of glass powder, 86-90% of silver powder and 1-2% of a solvent / auxiliary agent. According to the invention, cellulose-containing nanocrystals (CNC) are added into the organic carrier, and the printing performance of the front-surface silver paste is improved through changing the content of the CNC in the organic carrier, namely the proportion of the CNC to a conventional organic carrier, so that the height-width ratio of the grid line is increased, collapse does not occur in a sintering process, and the electrical property after sintering is improved. The front-surface silver paste of the solar cell prepared by the organic carrier provided by the invention has good printing performance, and after the sintering, the height-width ratio of the grid line is large, the filling factor is large, the series resistance is small, and the cell conversion efficiency is high.

Owner:山东建邦胶体材料有限公司

Film transistor, display substrate and display device

InactiveCN105826396AIncrease aspect ratioReduce widthTransistorSolid-state devicesEngineeringDisplay device

The invention discloses a film transistor, a display substrate and a display device. The film transistor comprises an active layer, a source electrode and a drain electrode, wherein the drain electrode is half surrounded by the source electrode, the first portion of the drain electrode is at an inner portion of an opening of the source electrode, and the second portion of the drain electrode extends from the inner portion of the opening of the source electrode to an outer portion of the opening of the source electrode. Through the film transistor, parasitic capacitance between a grid electrode and the source electrode can be reduced and stabilized, so adverse phenomena such as splash screen display can be avoided.

Owner:BOE TECH GRP CO LTD +1

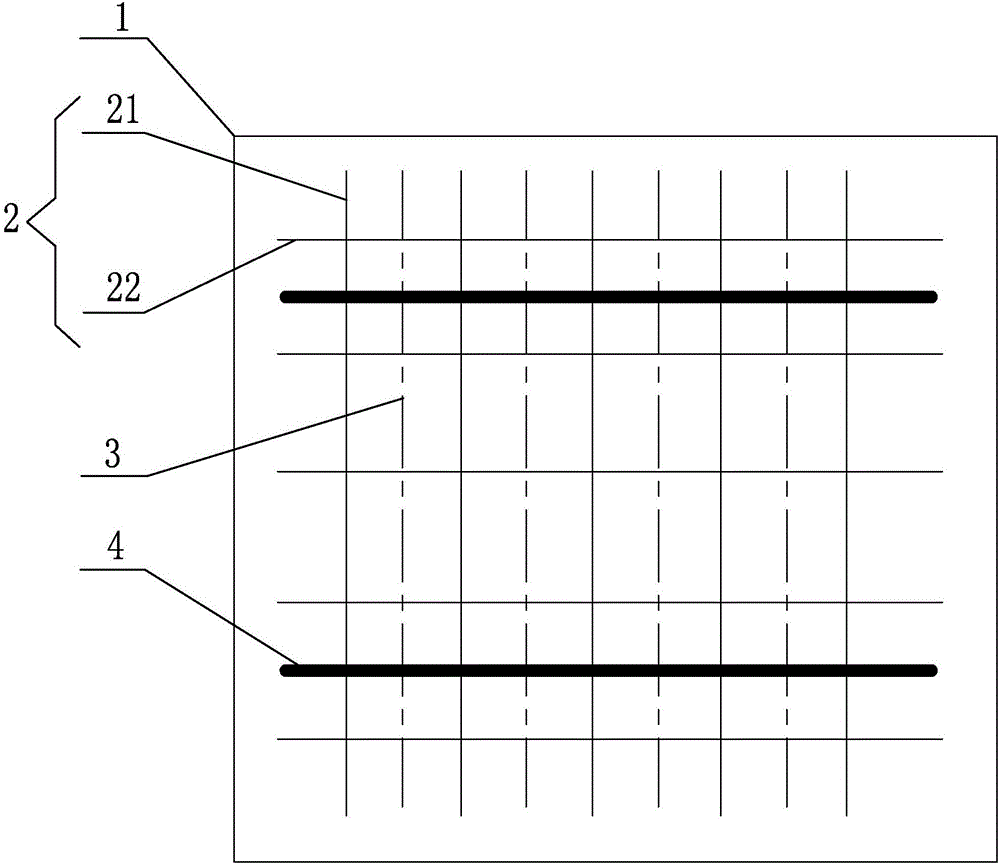

Positive electrode printing screen

ActiveCN102991101AReduce width differenceLow conversion efficiencyScreen printersRenewable energy productsSolar batteryWidth ratio

The embodiment of the invention discloses a positive electrode printing screen, which comprises stop membranes and secondary gate line holes formed by adjacent stop membranes; the stop membranes and the secondary gate line holes are cut in the thickness direction of the stop membranes; the cross sections of the formed secondary gate line holes are of inverted trapezoids, wherein each inverted trapezoid is a trapezoid longer in upper bottom side and shorter in lower bottom side. By adopting the positive electrode printing screen provided by the invention, in the printing process, the position pressed by squeegee is sunken, so that the secondary gate line holes in the printing screen are distorted; through controlling the size of the top angle (or bottom angle) of the inverted trapezoids, the widths of the upper and lower openings when the secondary gate line holes are pressed can be almost the same, and finally, the longitudinal section of the formed secondary gate lines is of a rectangular shape; thus, the phenomenon that the printing is poor can be improved; on the other hand, the width of the finally formed secondary gate lines can be reduced, thereby increasing the height width ratio of the finally formed secondary gate lines, and improving the conversion efficiency of a solar battery.

Owner:JETION SOLAR HLDG

Organic adhesive for electrode paste of silicon solar cell and preparation method thereof

InactiveCN101864251AEnsure uniformity of dispersionIncrease aspect ratioAldehyde/ketone condensation polymer adhesivesCellulose adhesivesWater bathsGrating

The invention discloses an organic adhesive for the electrode paste of a silicon solar cell and a preparation method thereof. The preparation method comprises the following steps: (1) weighting the raw materials of the organic adhesive according to the raw material composition and weight percentages thereof; (2) adding the weighted components in a reaction tank using water bath, heating and stirring to ensure that resin powder is completely dissolved to form a yellowish and transparent solution, then keeping the temperature; and (3) cooling the yellowish and transparent solution, using a silkscreen to filter, and obtaining the organic adhesive for the electrode paste of the silicon solar cell. By using the paste prepared from the organic adhesive, the dispersion uniformity of solid powder material can be maintained, the paste can be stored for long time without layering, and the printed grating has larger height-width ratio and can not cause casting.

Owner:IRICO

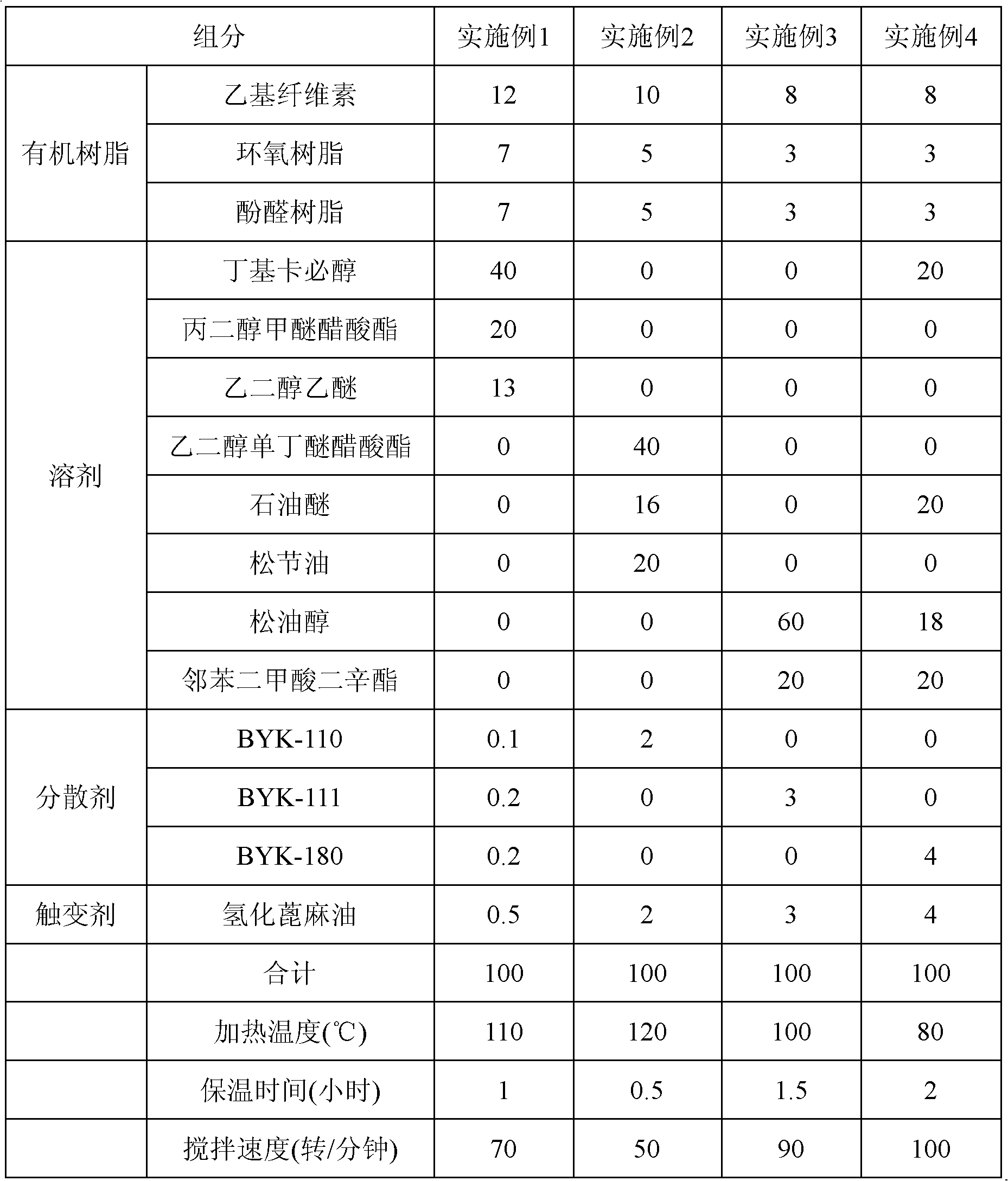

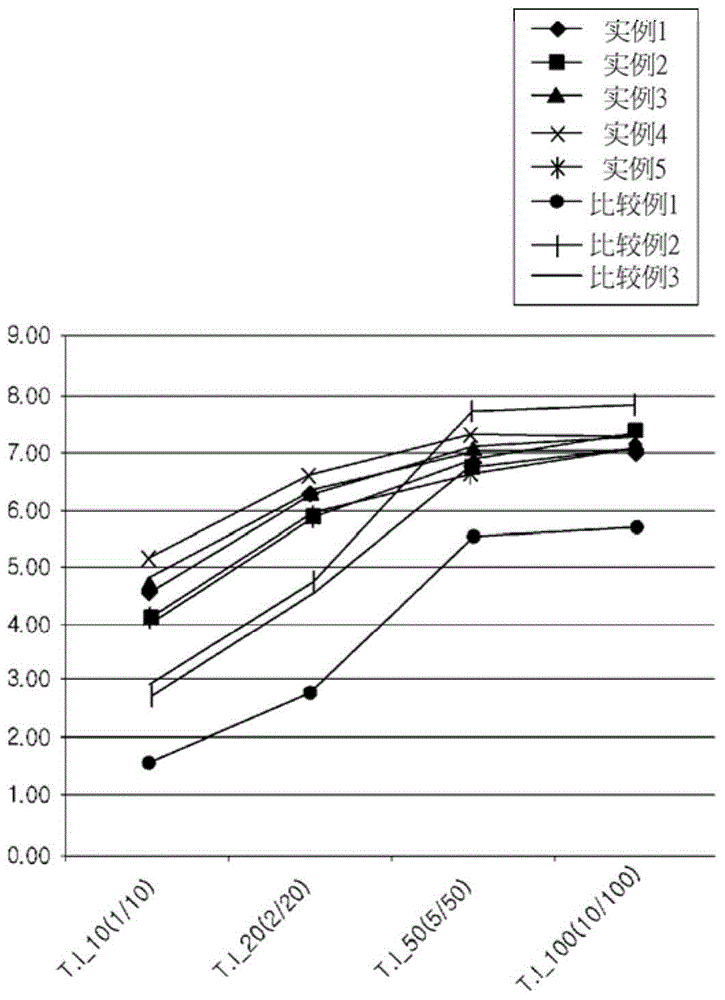

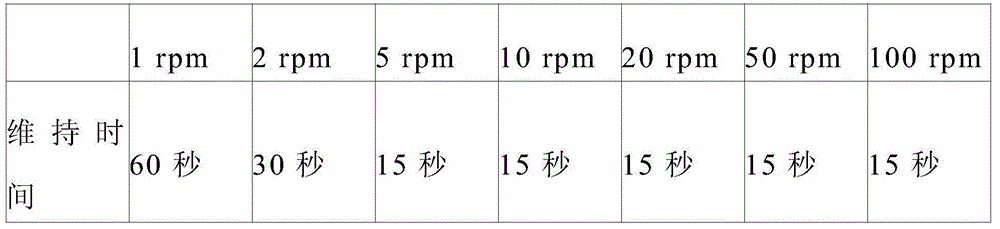

Composition for forming solar cell electrode, and electrode produced from composition

ActiveCN104903973AIncrease aspect ratioHigh aspect ratioNon-conductive material with dispersed conductive materialPhotovoltaic energy generationChemistryComposite material

The present invention relates to a composition for forming a solar cell electrode which is characterized by including a conductive powder, a glass frit, an organic vehicle, and a thixotropic agent, and satisfying 3<TI 10=(viscosity at 1 rpm) / (viscosity at 10 rpm)<5.5, 4<TI 20=(viscosity at 2 rpm) / (viscosity at 20 rpm)<7, 6<TI 50=(viscosity at 5 rpm) / (viscosity at 50 rpm)<7.5, 6<TI 100=(viscosity at 10 rpm) / (viscosity at 100 rpm)<7.5, 1<¦TI 10-TI 20¦<2, 0.5<¦TI 20-TI 50¦<1.5, and 0<=¦TI 50-TI 100¦<0.8. Here, thixotropic index (TI) is a value calculated by substituting viscosity measured at each revolution (rpm) with a spindle number 14 by using a rotation viscometer at 23°C. The composition for forming a solar cell electrode can realize a print pattern having a fine line width and high aspect ratio, and has excellent conversion efficiency.

Owner:上海匠聚新材料有限公司

Method for manufacturing positive electrode of solar cell in printing manner

InactiveCN102544218AIncrease aspect ratioSolve bottlenecksFinal product manufacturePattern printingScreen printingElectrical battery

The invention discloses a method for preparing an electrode, in particular to a method for manufacturing a positive electrode of a solar cell in a printing manner. The method comprises the following steps of: locating an solar cell sheet on a printing platform to be fixed; moving the solar cell sheet to be under a printing head; applying a pressure onto an electrode slurry in the printing head so that the electrode slurry flows out of a nozzle of the printing head and is in contact with the upper surface of the solar cell sheet; printing a discontinuous high-aspect-ratio electrode grid line with a shape consistent with a shape of the nozzle of the printing head on the solar cell sheet after the printing platform and the printing head do motions in opposite directions; and subsequently, repeating the steps above after the printing plate and the printing head do relative motions to a proper position so as to print a continuous high-aspect-ratio electrode grid line on the solar cell sheet. The method for manufacturing the positive electrode of the solar cell in the printing manner, disclosed by the invention, has the advantages of breaking through the limitation of a traditional screen printing manner, being capable of manufacturing a positive grid line with the width of 20-80 microns, and having important industrial application prospect.

Owner:浙江搏路尚新能源有限公司 +1

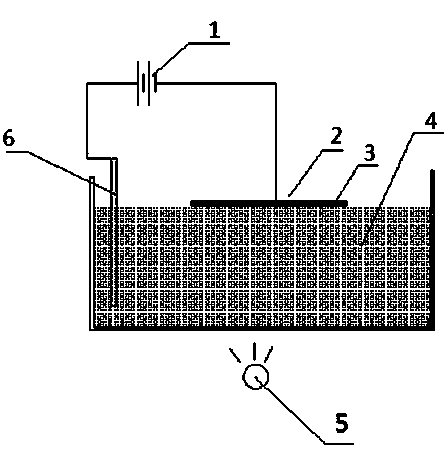

Method for manufacturing solar cell positive electrode grid line

ActiveCN103996752AReduce line widthIncrease aspect ratioFinal product manufacturePhotovoltaic energy generationWidth ratioOhmic contact

The invention discloses a method for manufacturing a solar cell positive electrode grid line. Through the wool manufacturing, diffusion, edge insulation, PSG removing and reflecting film plating and reducing technology, a positive electrode grid line graph is printed on a silicon wafer in a silk-screen mode, the silicon wafer is printed with a back electrode and a back electric field, rapid sintering is performed to form ohmic contact, a sintered cell piece is placed in a light induction plating tank, the cell piece is taken as a positive electrode, a silver stick is taken as a negative electrode, part of the grid line is dissolute to be manufactured into a seed layer, light induction plating is adopted, silver plating and thickening are performed on the seed layer, the silk-screen printing technology and rapid sintering technology are adopted on a solar positive electrode to form the good ohmic contact, on the basis of the grid line graph with the qualified tensile force, plating dissolving is performed on the deckle edge area of the grid line, the width of the grid line cannot be increased due to the deckle edge, afterwards, silver is electroplated on the grid line, and the cross section of the manufactured grid line is quasi-semi-circular. The line width is small, the depth-width ratio is large, the seed layer form is ideal, the grid line structure is compact, the series resistance is low, and the conversion efficiency of a cell piece can be effectively improved.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

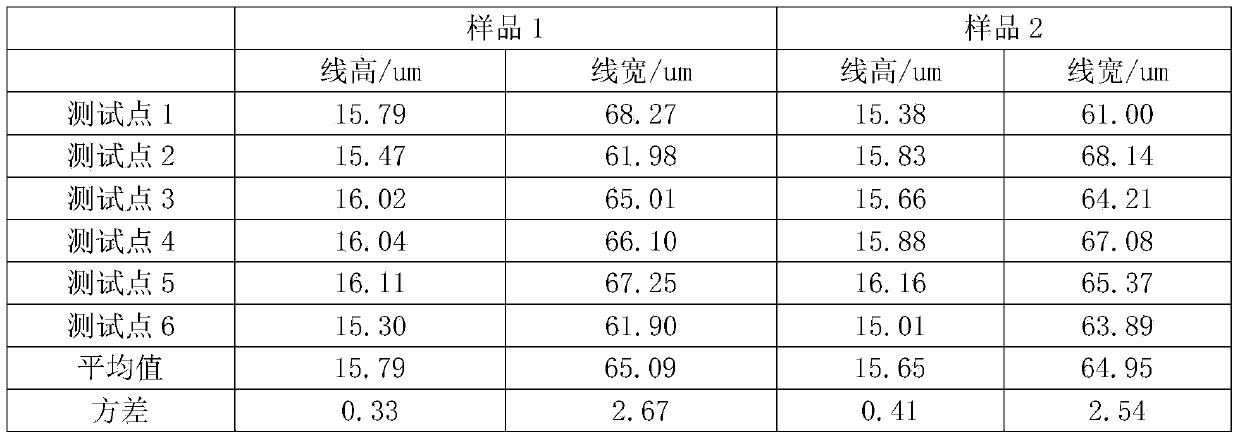

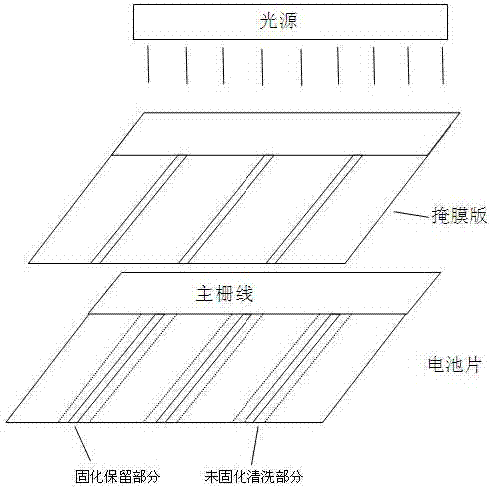

Method for preparing front electrode of crystalline silicon photovoltaic cell

InactiveCN107275419AImprove conversion efficiencyIncrease the cross-sectional areaFinal product manufacturePhotovoltaic energy generationSilver pasteScreen printing

The invention relates to the technical field of crystalline silicon photovoltaic cells and in particular to a method for preparing the front electrode of a crystalline silicon photovoltaic cell. The method comprises the following steps of: firstly, forming an electrode by using silk screen printing photosensitive silver paste and drying the electrode; secondly, covering the top of the cell with a mask plate provided with an electrode pattern and irradiating the mask plate with a UV light source to cure a part to be retained, wherein the retained part is any part of the electrode pattern, the un-retained part is uncured, and unexposed and uncured part required to be cleaned is any part of the electrode pattern; thirdly, cleaning the uncured part of an electrode gate line by using a photosensitive silver paste developing solution; and fourthly, sintering the electrode gate line. The method for preparing the front electrode of the crystalline silicon photovoltaic cell can prepare thin electrode gate lines with high height-to-width ratios, reduces light shielding area, increases electrode cross-sectional area so as to reduce power loss and greatly improve the conversion efficiency of the cell.

Owner:北京市合众创能光电技术有限公司

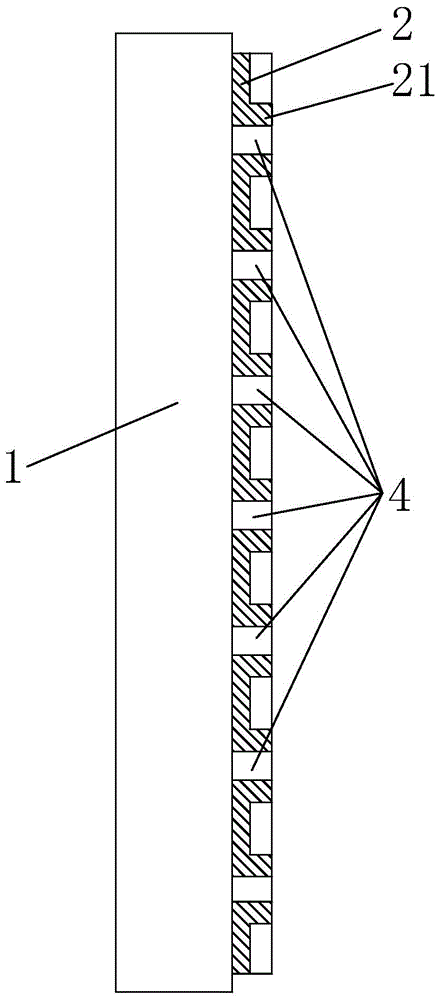

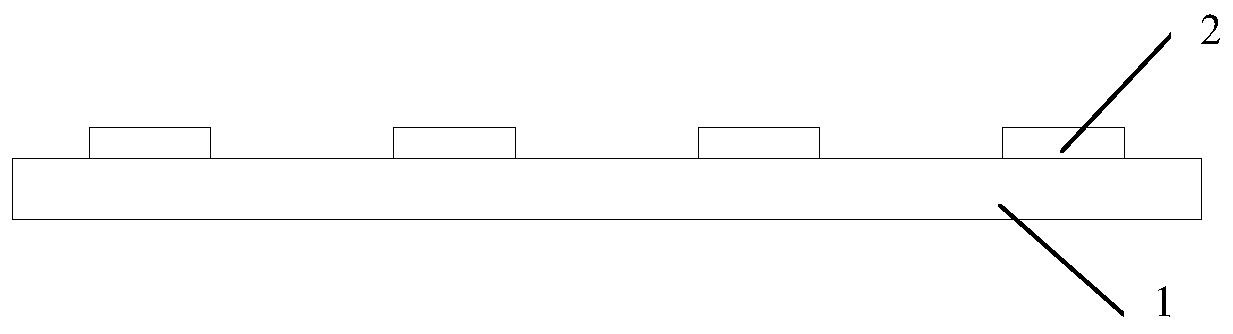

Crystalline silicon solar cell positive electrode preparation device

InactiveCN104960322AIncreasing the thicknessImprove conductivityScreen printersSemiconductor devicesScreen printingSilver paste

The invention discloses a crystalline silicon solar cell positive electrode preparation device, comprising a positive electrode screen printing plate and a printing head with air holes. The positive electrode screen printing plate comprises a screen printing plate basic body formed by a silk screen, and a latex film layer adhered to the basic body. The latex film layer is provided with positive electrode patterns. The positive electrode patterns are formed by M positive electrode main grids and N positive electrode secondary grids. The width of the positive electrode main grid is larger than the width of the positive electrode secondary grid. The latex film layer on the opening of the positive electrode secondary grid is provided with raised convex ribs. When the printing head prints, the air holes of the printing head release airflow, assisting silver paste output by the printing head to smoothly pass through the screen printing plate basic body and enter the positive electrode main grids and positive electrode secondary grids. Compared with the prior art, the device does not increase light shading area of the electrodes while improving conductivity of the electrodes, so as to improve photoelectric conversion efficiency of a cell, and the device is advantaged by effectively reducing broken lines of the positive electrode main grids and the positive electrode secondary grids.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Method for preparing crystalline silicon solar cell electrode

InactiveCN111584654AWon't collapseWon't expandPhotovoltaic energy generationSemiconductor devicesElectrical batterySilicon solar cell

The invention discloses a method for preparing a crystalline silicon solar cell electrode. The method comprises the steps that S1, cured film layers are prepared at the positions, corresponding to allthe electrodes, of a silicon wafer substrate; S2, a groove is formed in the cured film layer in the electrode extending direction, the groove penetrates through the cured film layer, and the width ofthe groove is smaller than that of the cured film layer; S3, the groove is filled with the electrode slurry; and S4, drying and sintering are carried out, the cured film layer is volatilized, the electrode slurry is melted, and through cooling, the electrode slurry is recrystallized to form the electrode. In the process of preparing the electrode, the electrode slurry is supported and blocked bythe cured film layer, the slurry does not collapse or expand, the electrode grid line can be ensured to have a higher depth-to-width ratio, and the electrical performance of the cell is improved; theviscosity of the used electrode slurry can be lower than that of conventionally used slurry, so that the grooves can be filled with the electrode slurry by means of printing or ink jetting and the like, ink passing performance and good flowability are guaranteed, and the electrical performance of the cell is improved.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD

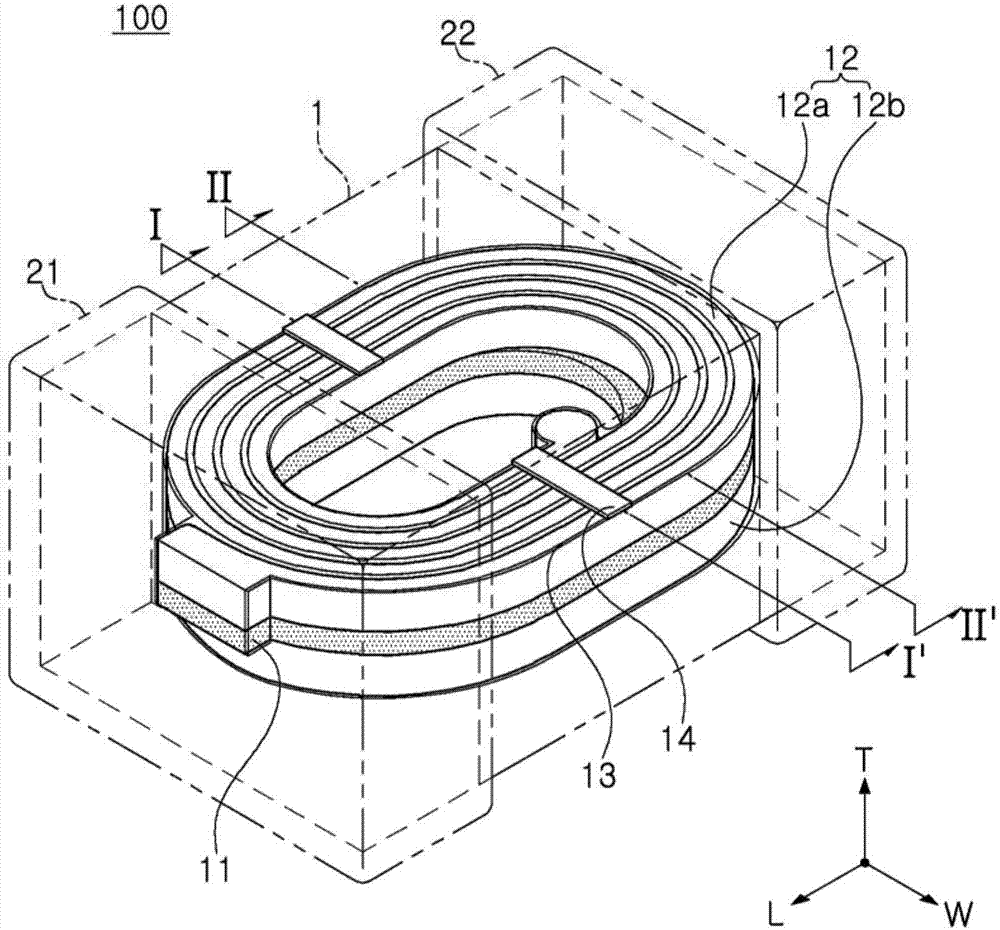

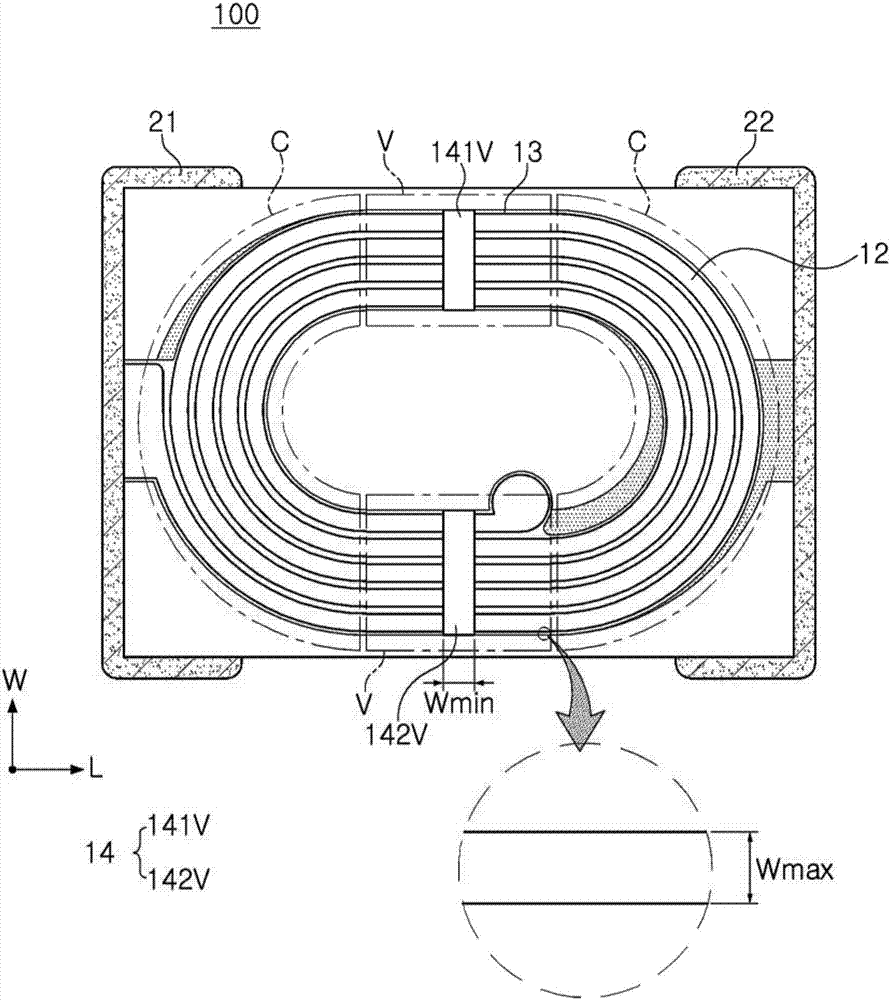

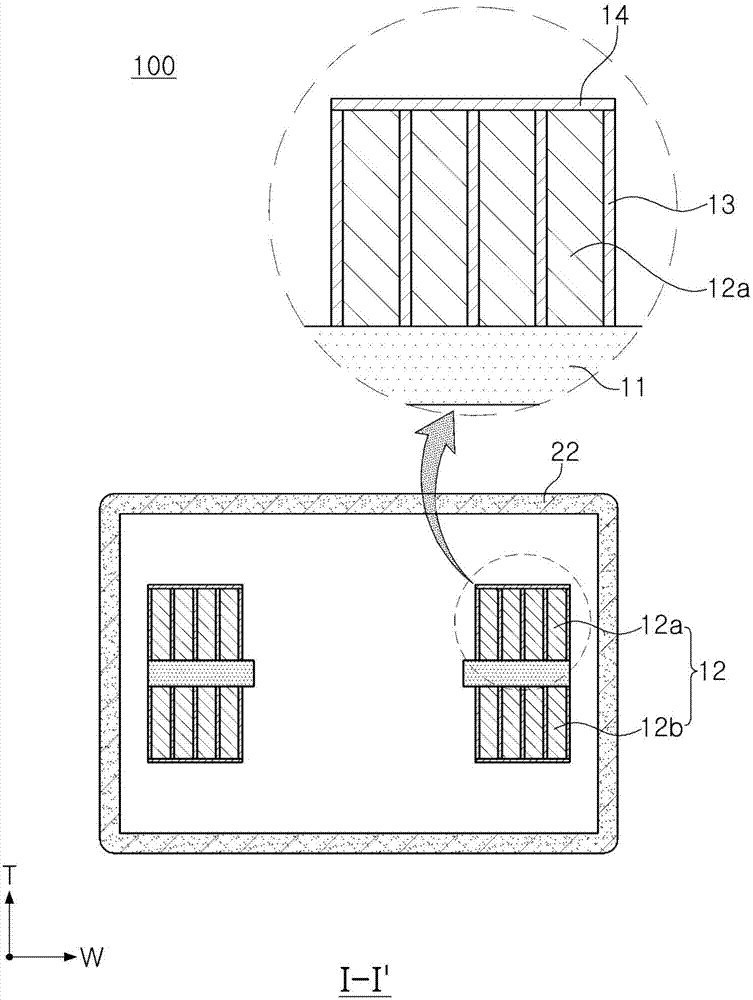

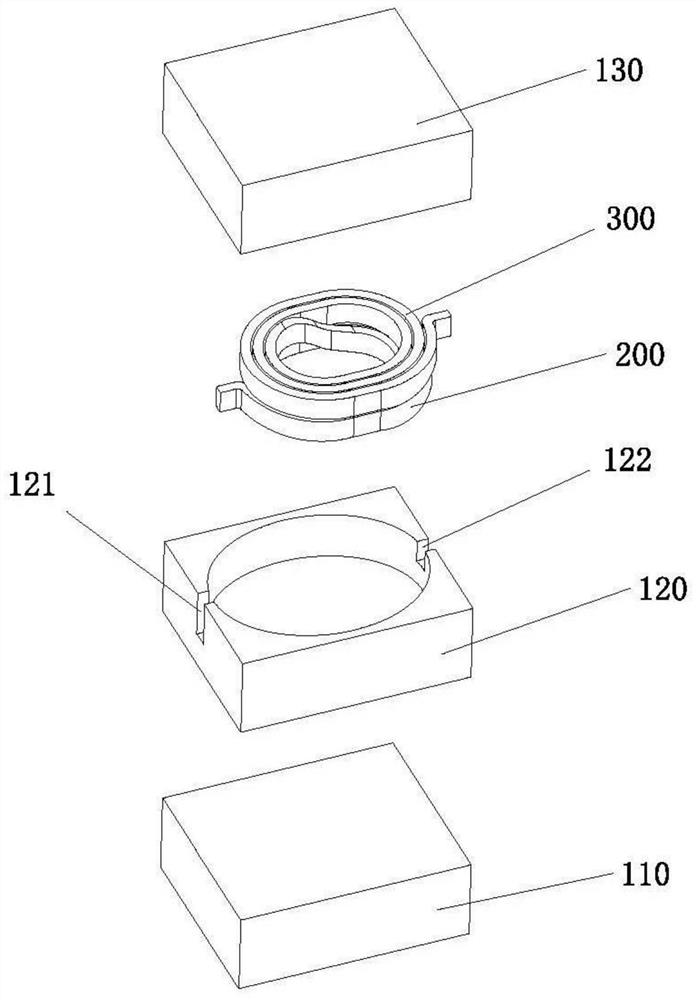

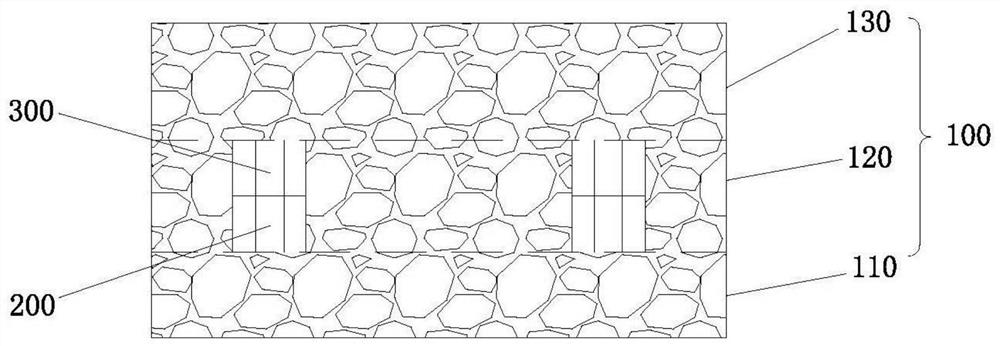

Inductor

ActiveCN107978421AIncrease aspect ratioWith structural stabilityTransformers/inductances coils/windings/connectionsThin magnetic filmsEngineeringInductor

An inductor includes: a body including a coil and a magnetic material, and external electrodes disposed on an outer surface of the body. The coil is supported by a support member, and the support member may also support an insulating wall including an open-hole pattern having a shape corresponding to a pattern of the coil. An insulating ribbon formed so that a length thereof is greater than a width thereof may be additionally disposed on at least a portion of an upper surface of the insulating wall.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

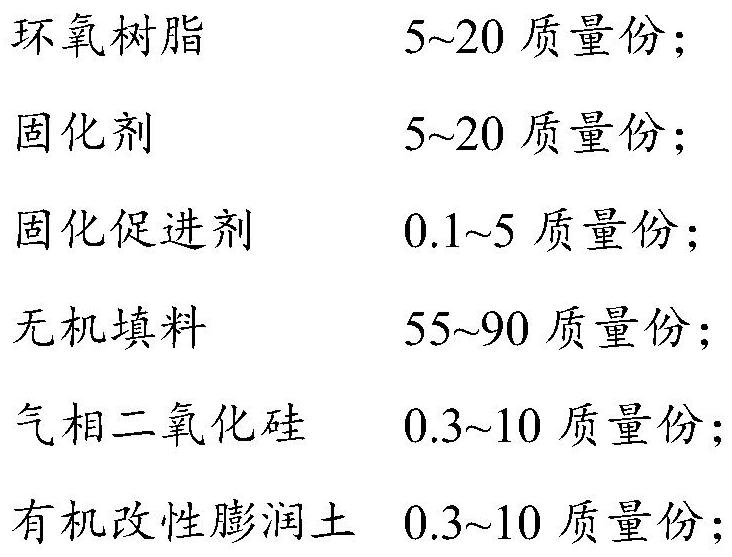

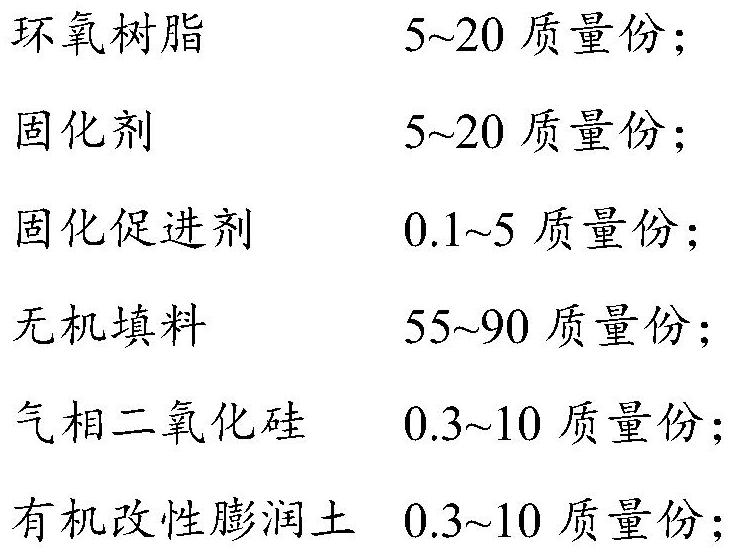

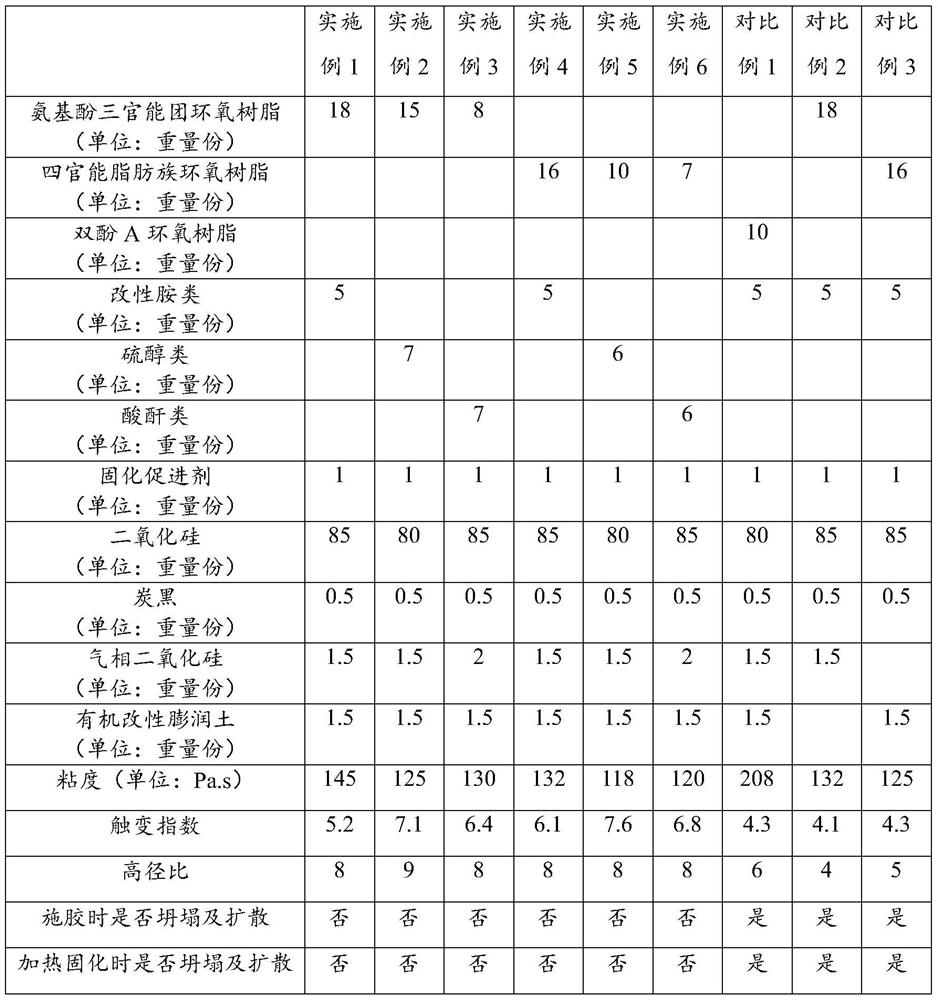

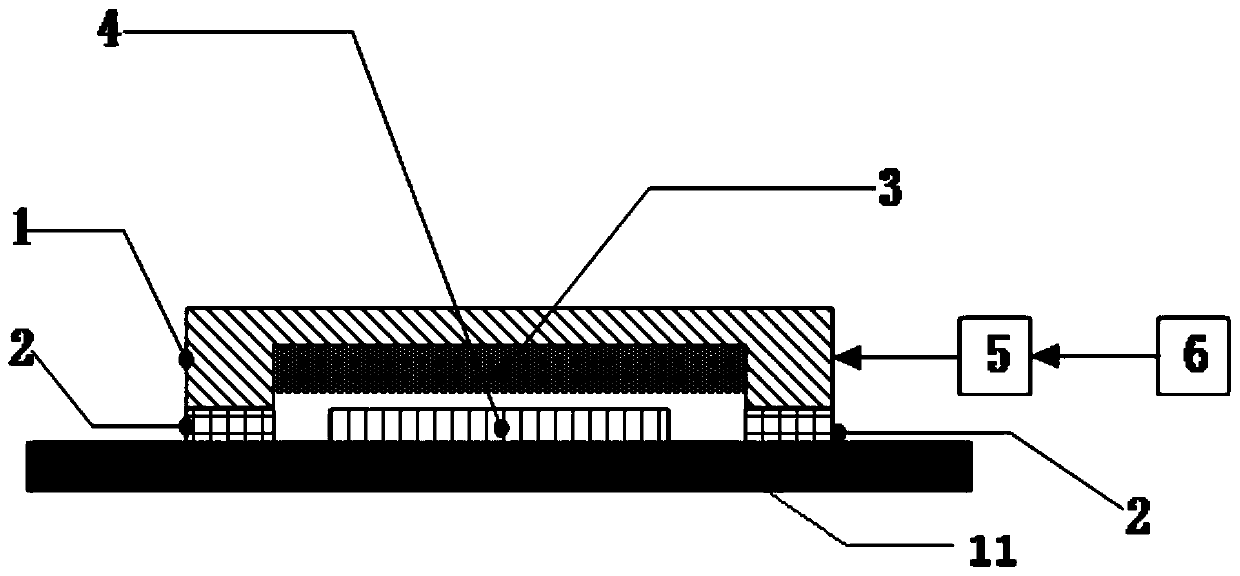

Single-component dam material composition and preparation method thereof

ActiveCN111635723AIncrease aspect ratioGood viscosityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsFirming agentPolymer chemistry

The invention discloses a single-component dam material composition and a preparation method thereof. The single-component dam material composition comprises the following components in parts by mass:5-20 parts of epoxy resin, 5-20 parts of a curing agent, 0.1-5 parts of a curing accelerator, 55-90 parts of an inorganic filler, 0.3-10 parts of fumed silica and 0.3-10 parts of organic modified bentonite, wherein the epoxy resin is one or more of aminophenol trifunctional epoxy resin or tetrafunctional aliphatic epoxy resin. According to the invention, with the combination of aminophenol trifunctional epoxy resin or tetrafunctional aliphatic epoxy resin, fumed silica and organic modified bentonite, the height-diameter ratio and thixotropy are significantly improved, the viscosity under highshearing force is maintained, the sizing is easy, and the dam material does not collapse and diffuse during sizing and heating curing.

Owner:WUHAN CHOICE TECH CO LTD

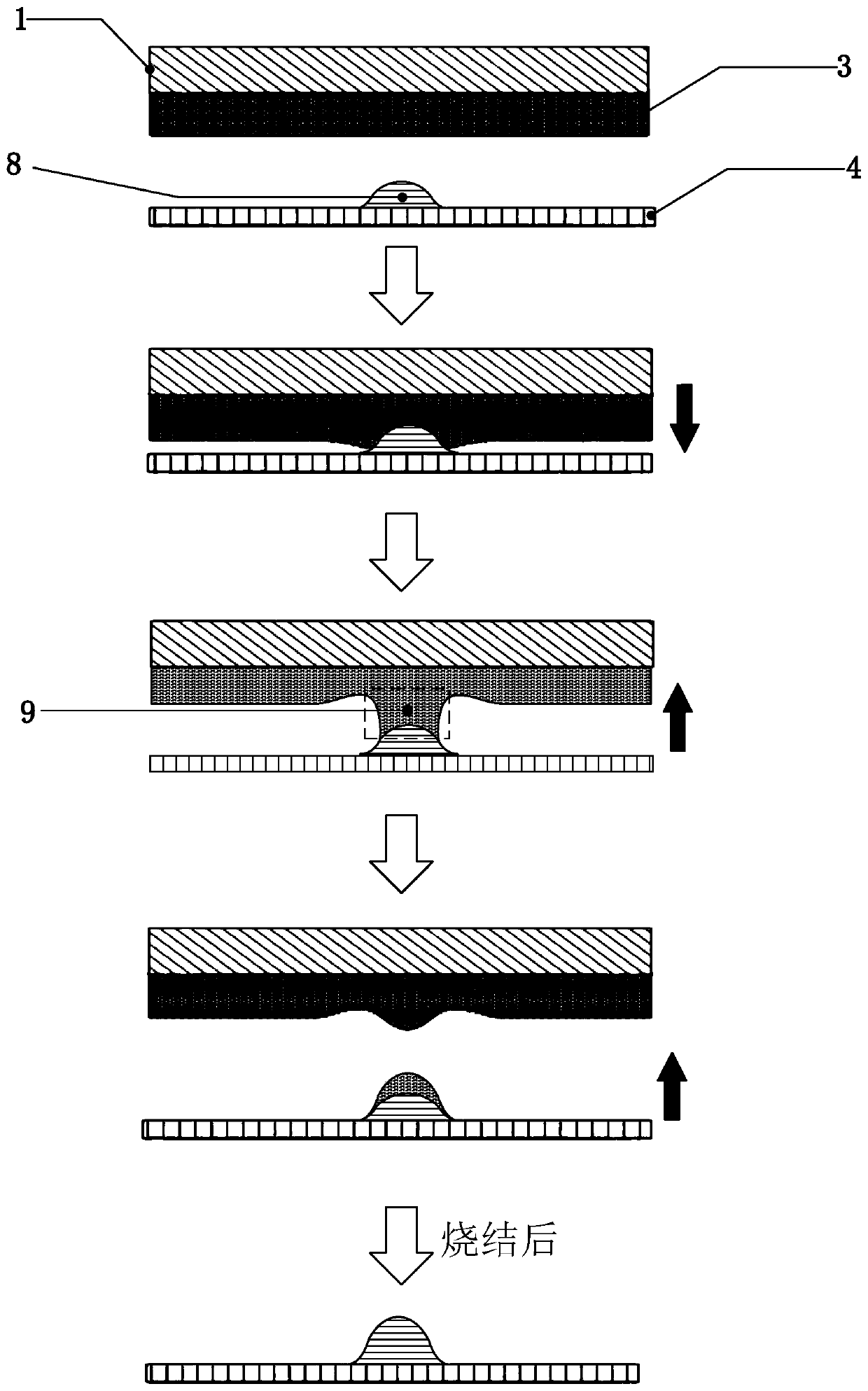

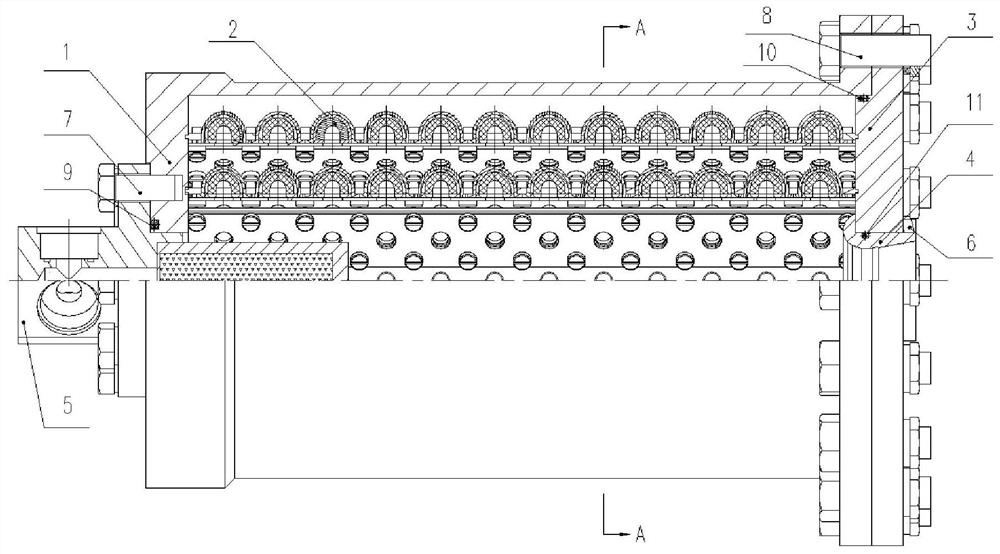

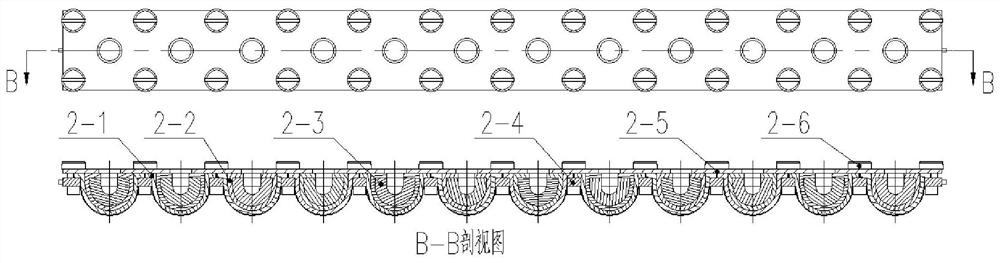

Photovoltaic solar cell electrode grid line in-situ secondary printing device and method

PendingCN110690299AIncrease heightIncrease aspect ratioScreen printersOther printing apparatusPhysicsSilicon chip

The invention discloses a photovoltaic solar cell electrode grid line in-situ secondary printing device and method. The device comprises a base, a silver paste carrier and a silver paste carrier motion control device. The base is used for placing a printed silicon wafer; the silver paste carrier is arranged above the base, a groove used for smearing a silver paste film with a certain thickness isformed in the silver paste carrier, and the opening of the groove faces the base; the silver paste carrier is installed on the silver paste carrier motion control device, and the silver paste carriermotion control device controls the silver paste carrier to move up and down relative to the base above the base. According to the invention, in-situ secondary printing of the silicon wafer can be achieved, a grid line with a higher depth-to-width ratio is obtained, the printing speed is high, and the production efficiency is high.

Owner:SOUTH CHINA UNIV OF TECH

Micro-bead glass for conductive silver paste and preparation method of micro-bead glass

InactiveCN109422463ASpeed up the flowImprove the lubrication effectCoatingsSemiconductor devicesLithium oxideFine line

The invention discloses micro-bead glass for conductive silver paste and a preparation method of the micro-bead glass. The micro-bead glass is composed of the following components in parts by weight:10-50 parts of tellurium dioxide, 15-70 parts of bismuth oxide, 2-10 parts of zinc oxide, 1-15 parts of molybdenum oxide, 5-20 parts of lithium oxide, 0.3-5 parts of magnesium oxide, 0.2-5 parts of aluminum oxide, 0.3-5 parts of boric acid and 0.2-2 parts of potassium oxide. The particle size D50 of glass micro-bead powder is 1-2 microns; the glass micro-bead powder is fed into a mixed solution formed by terpilenol, butyl carbitol acetate, oleic acid and polyvinylpyrrolidone; and stirring is carried out for 3-6 hours under a heat preservation condition at 80 DEG C, so that the spherical glassbeads with an organic coating layer is obtained. According to the micro-bead glass disclosed by the invention, lubricity of a slurry system is improved, ink permeability is increased, a problem of material shortage in fine grid lines is avoided, molten glass cannot flow easily when the slurry is sintered, and a fine line shape is kept.

Owner:SUZHOU ISILVER MATERIALS

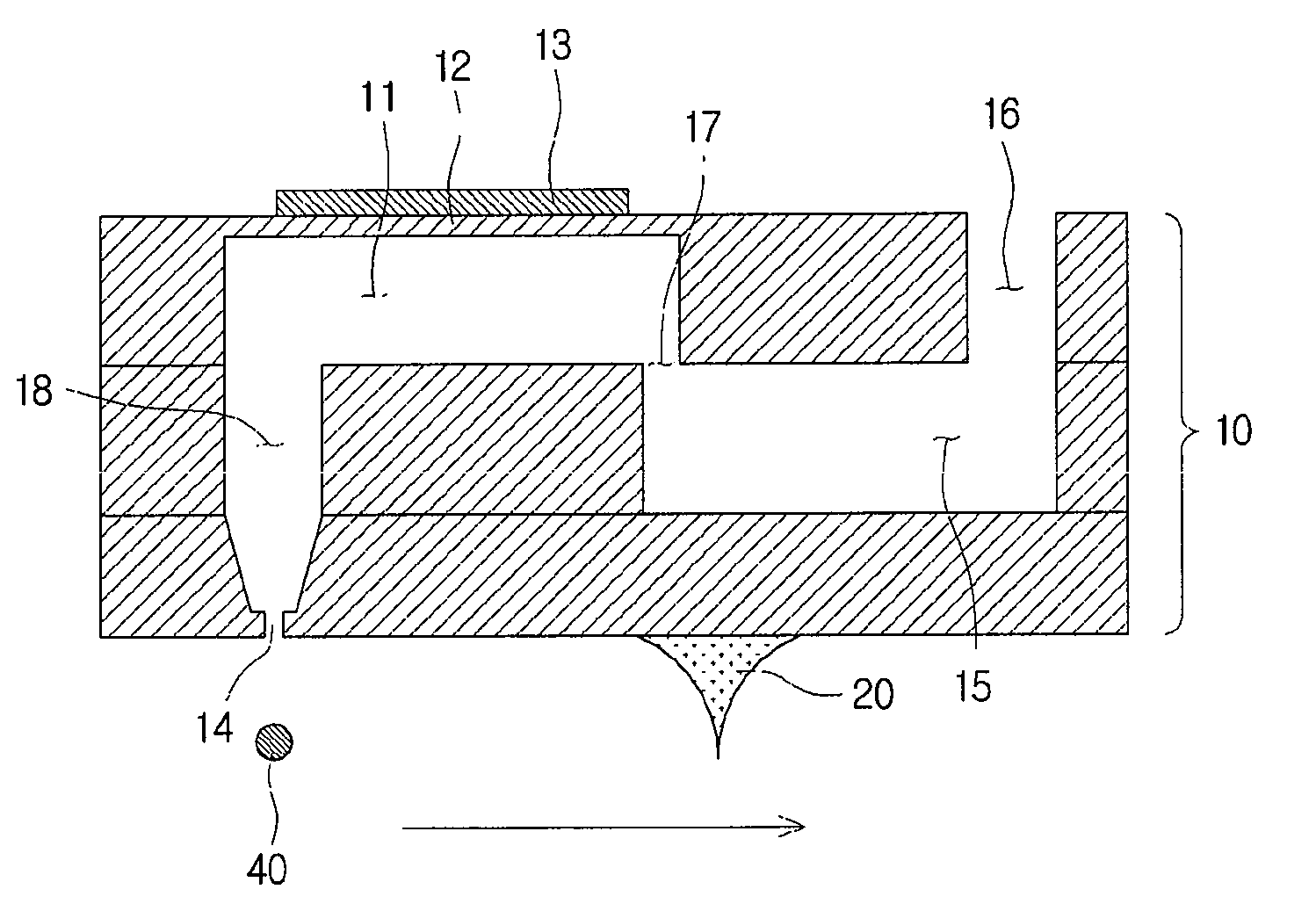

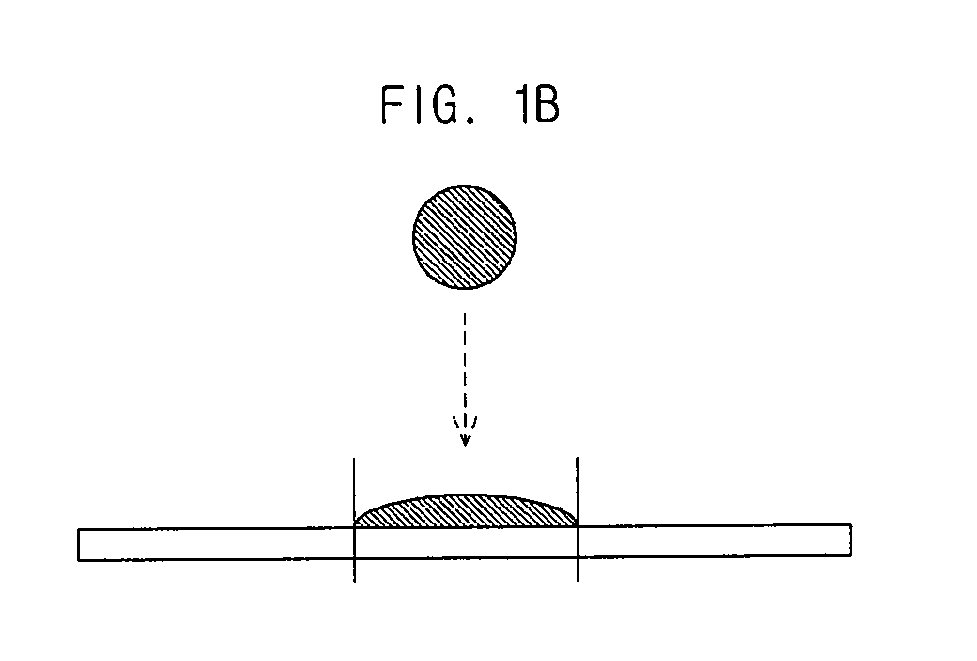

Inkjet head

InactiveUS20100103222A1Increase aspect ratioHigh aspect ratioPrinted circuit aspectsTypewritersAspect ratioEngineering

An inkjet head is disclosed. The inkjet head, which include a head body, having one side, in which a nozzle is formed to discharge ink; and a protrusion, formed in one side of the head body, spaced from the nozzle, can form a groove on the surface of a printing target in the printing and then discharge ink in the groove, thereby increasing the aspect ratio of a printed line.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

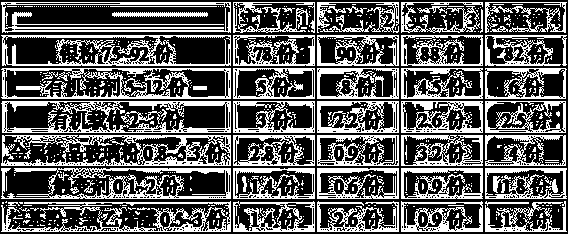

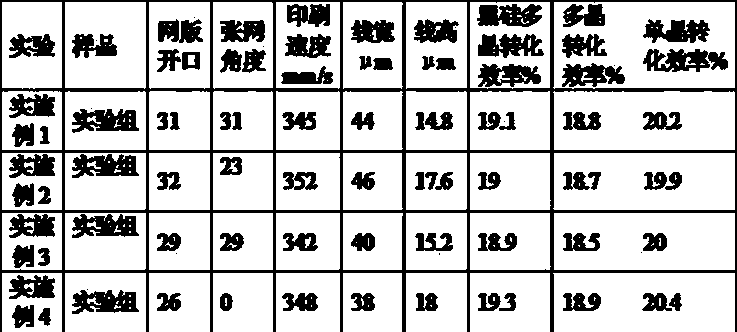

Conductive silver paste for crystalline silicon solar energy gate line

InactiveCN109427918AImprove stabilityImprove continuityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFine lineSlurry

The invention discloses a conductive silver paste for a crystalline silicon solar energy gate line. The conductive silver paste consists of the following components in parts by weight: 75-92 parts ofsilver powder, 5-12 parts of organic solvent, 2-3 parts of organic carrier, 0.8-5.3 parts of glass bead powder, 0.1-2 parts of thixotropic agent and 0.5-3 parts of alkylphenol polyoxyethylene ether; the particle diameter D50 of the glass bead powder is 1 to 2 [mu]m; the glass bead powder consists of the following components: tellurium dioxide, bismuth oxide, zinc oxide, molybdenum oxide, lithium oxide, magnesium oxide, aluminum oxide, boric acid and potassium oxide; and the glass bead powder is put into a mixed solution formed by terpineol, butyl carbitol acetate, oleic acid and polyvinyl pyrrolidone to obtain spherical glass beads with an organic coating layer through heat preservation. The conductive silver paste improves the lubricity of the slurry system, increases the ink permeability, and avoids the problem of material loss in fine gate lines; the molten glass is not liable to flow when the slurry is sintered, and the fine line shape is maintained; the conductive silver paste issuitable for fine line printing of narrow opening screen plates; and the slurry system has no material loss, the line width is narrow, and the height to width aspect ratio is large.

Owner:SUZHOU ISILVER MATERIALS

Conductive paste suitable for high-speed printing

InactiveCN109427429AIncrease high temperature viscosityIncrease surface tensionNon-conductive material with dispersed conductive materialSemiconductor devicesFine lineSilicon oxide

The invention discloses conductive paste suitable for high-speed printing. The conductive paste is formed by the following components in parts by weight: 75-92 parts of silver powder, 5-12 parts of organic solvents, 2-3 parts of organic carriers, 0.8-5.3 parts of glass bead powder and 0.1-2 parts of thixotropic agents, wherein the particle size D50 of the glass bead powder is 1-2 microns; the glass bead powder is formed by the following components of tellurium dioxide, bismuth oxide, zinc oxide, tungsten oxide, lithium oxide, molybdenum oxide, aluminum oxide, boric acid and silicon oxide; andthe glass bead powder is put into a mixed solution formed by terpilenol, butyl carbitol acetate, oleic acid and polyvinylpyrrolidone, and a spherical glass bead with an organic coating layer is obtained after thermal insulation. According to the conductive paste, the lubricity of a paste system is improved, the ink permeability is increased, a problem of material shortage in the fine grid lines isavoided, the molten glass is difficult to flow when the paste is sintered, the fine line shape is kept, the conductive paste is suitable for fine line printing of a narrow-opening screen plate, a material shortage situation cannot exist, the line width is narrow, and a height-width ratio is large.

Owner:SUZHOU ISILVER MATERIALS

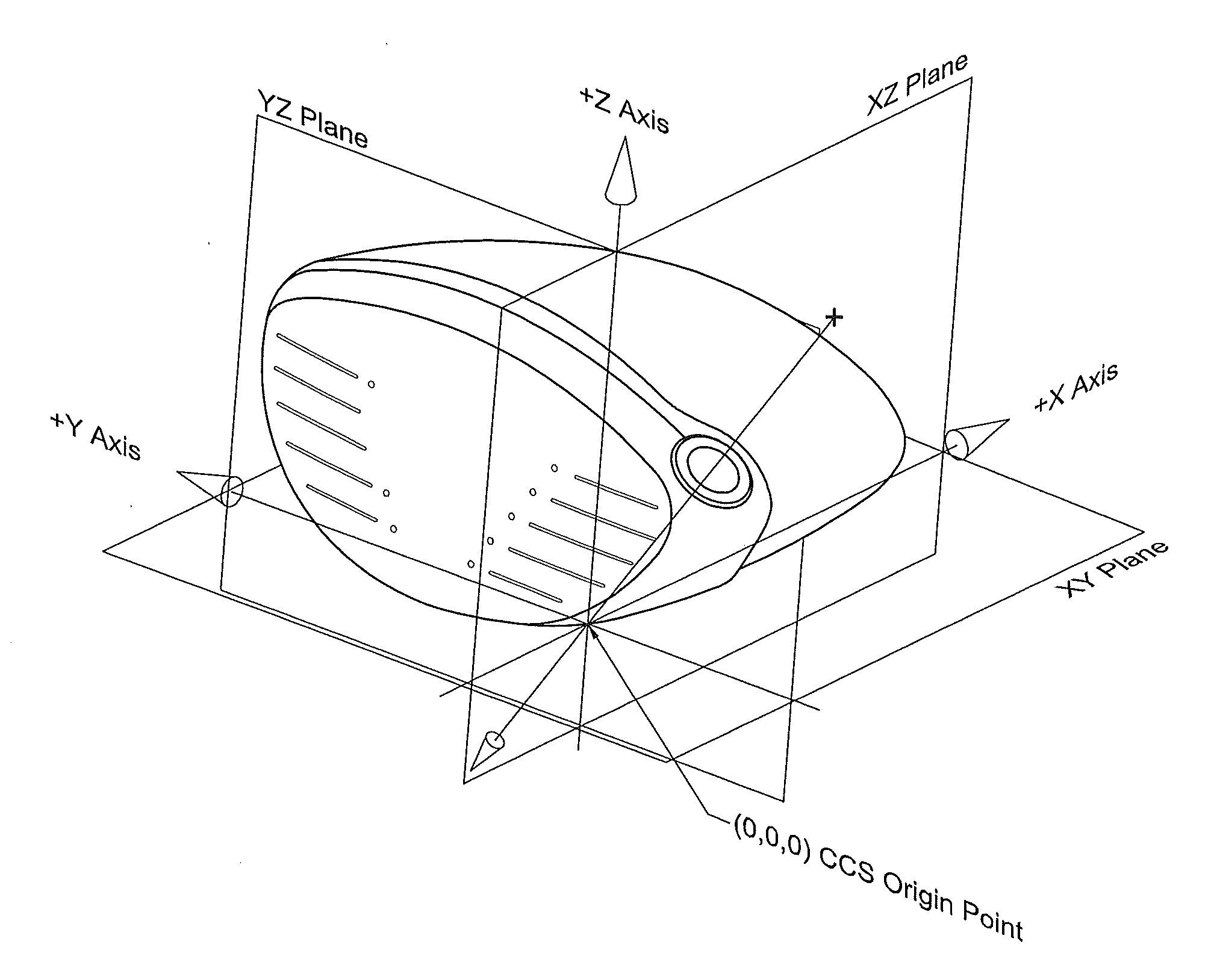

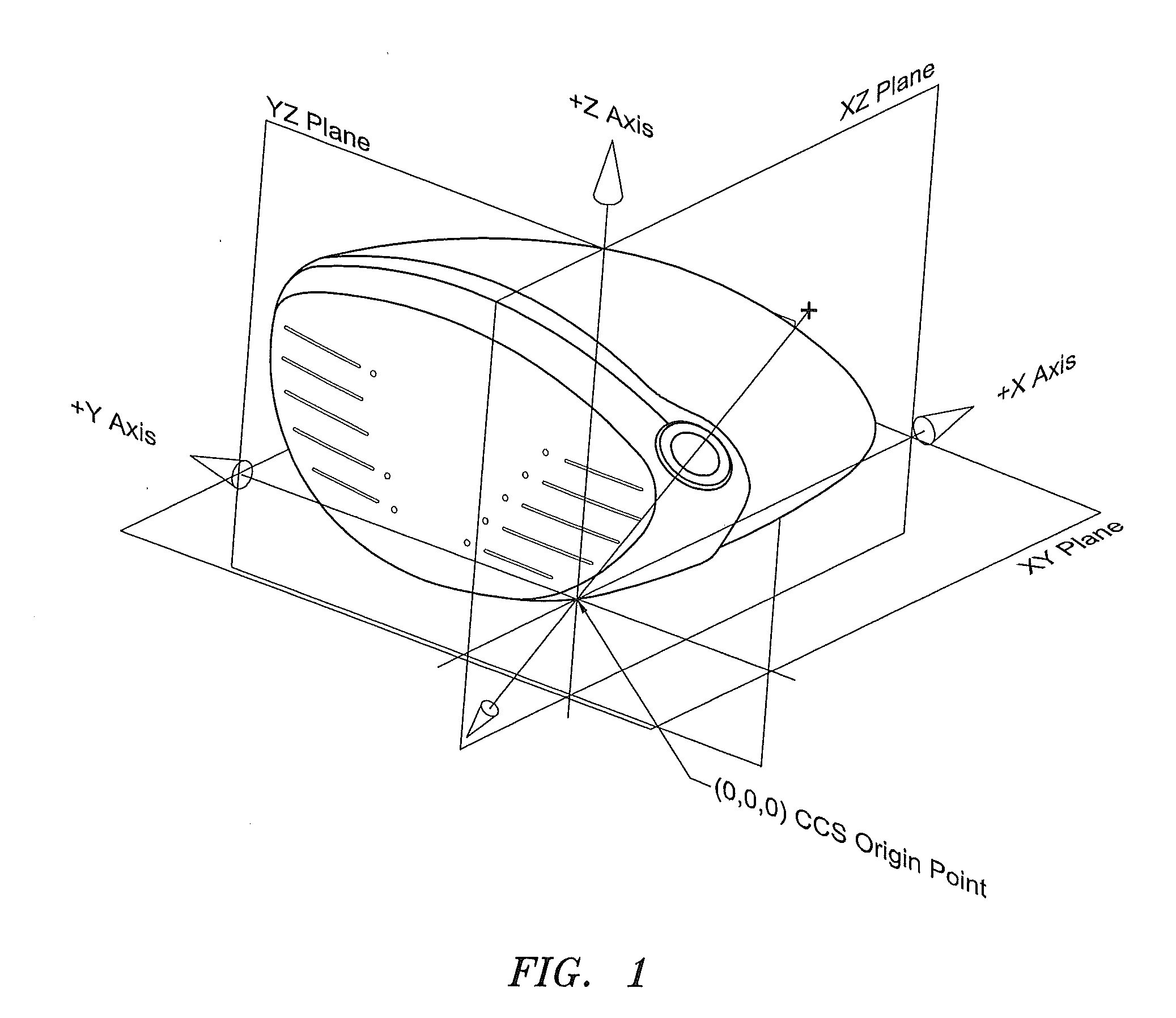

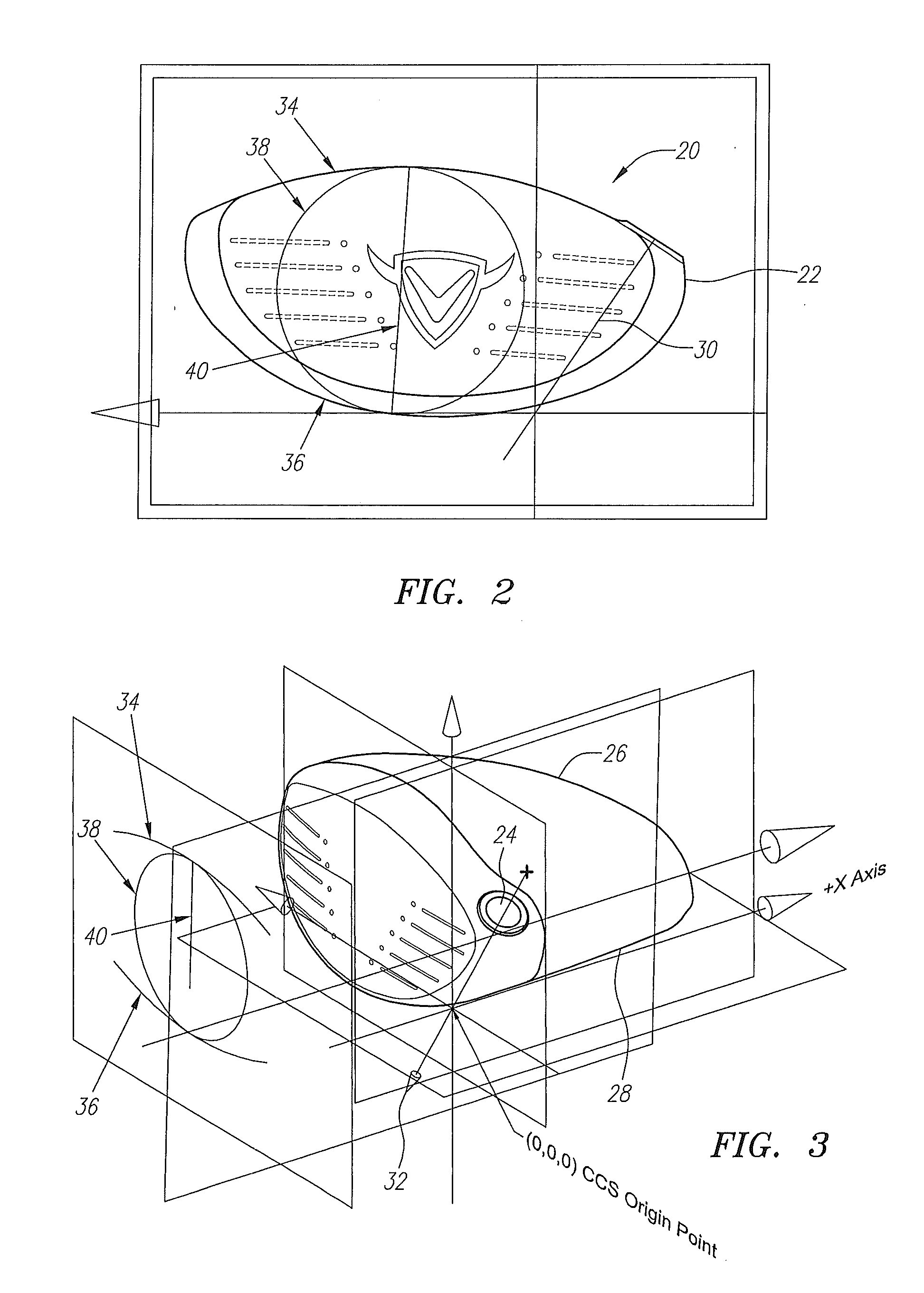

Golf club head with improved aerodynamic characteristics

A driver type golf club head comprising a body having a face, a crown and a sole, wherein the highest point of the crown surface is located within a crown apex zone, and the club head has a depth, the depth being at least twice the length as a height of the club head, wherein the depth is at least 4.600 inches.

Owner:CALLAWAY GOLF CO

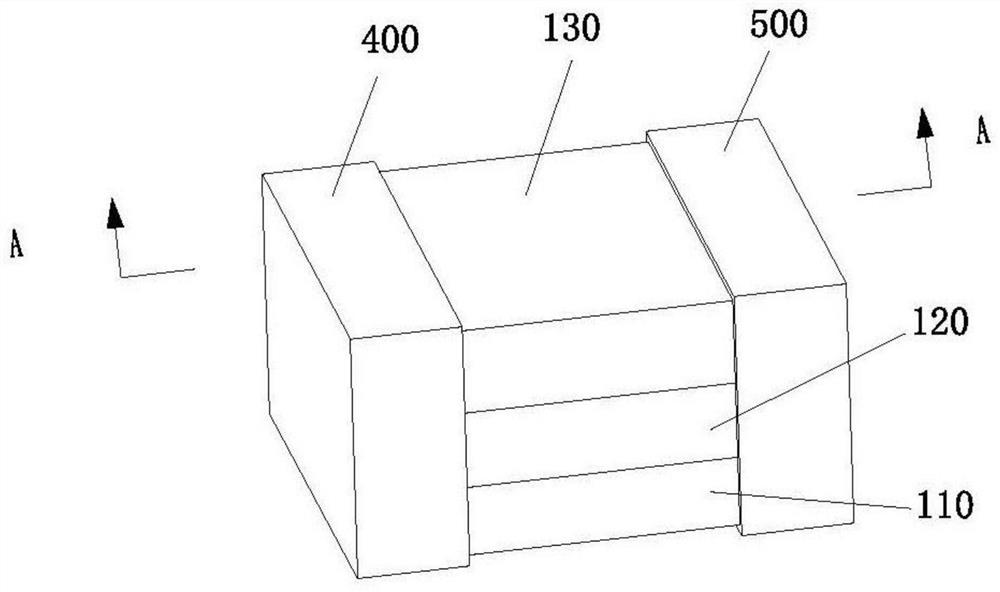

Inductor and manufacturing method thereof

PendingCN113990629ASimple structureIncrease aspect ratioTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureCopper wireEngineering

The invention belongs to the technical field of inductors, and discloses an inductor and a manufacturing method thereof. According to the inductor, a first coil and a second coil are manufactured through enameled flat copper wires, on one hand, the thickness-width ratio of the coils can be increased, meanwhile the production processes of vacuum coating, photoetching, electroplating copper deposition and the like can be omitted, and the production process is effectively simplified, and the production cost is reduced; and on the other hand, a copper wire adopts an enameled structure, so that the insulation effect of the coils is directly realized, one end face of the first coil can be attached to one end face of the second coil, the other end face of the first coil can be attached to the inner wall of a substrate-containing cavity, the other end face of the second coil can be attached to the inner wall of the substrate-containing cavity, and an insulating substrate and an insulating film are omitted, so the structure of the inductor is effectively simplified, meanwhile, the production process is simplified, and the production cost is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

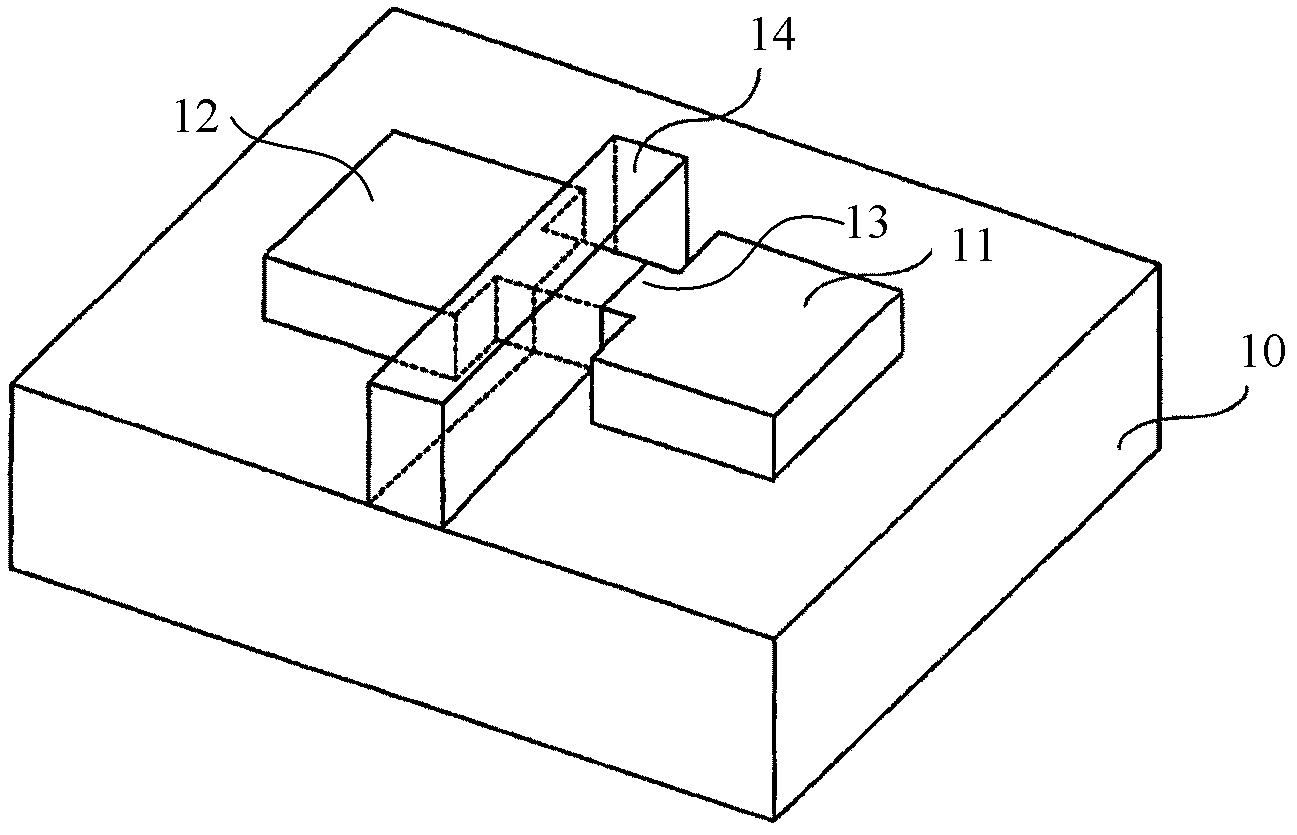

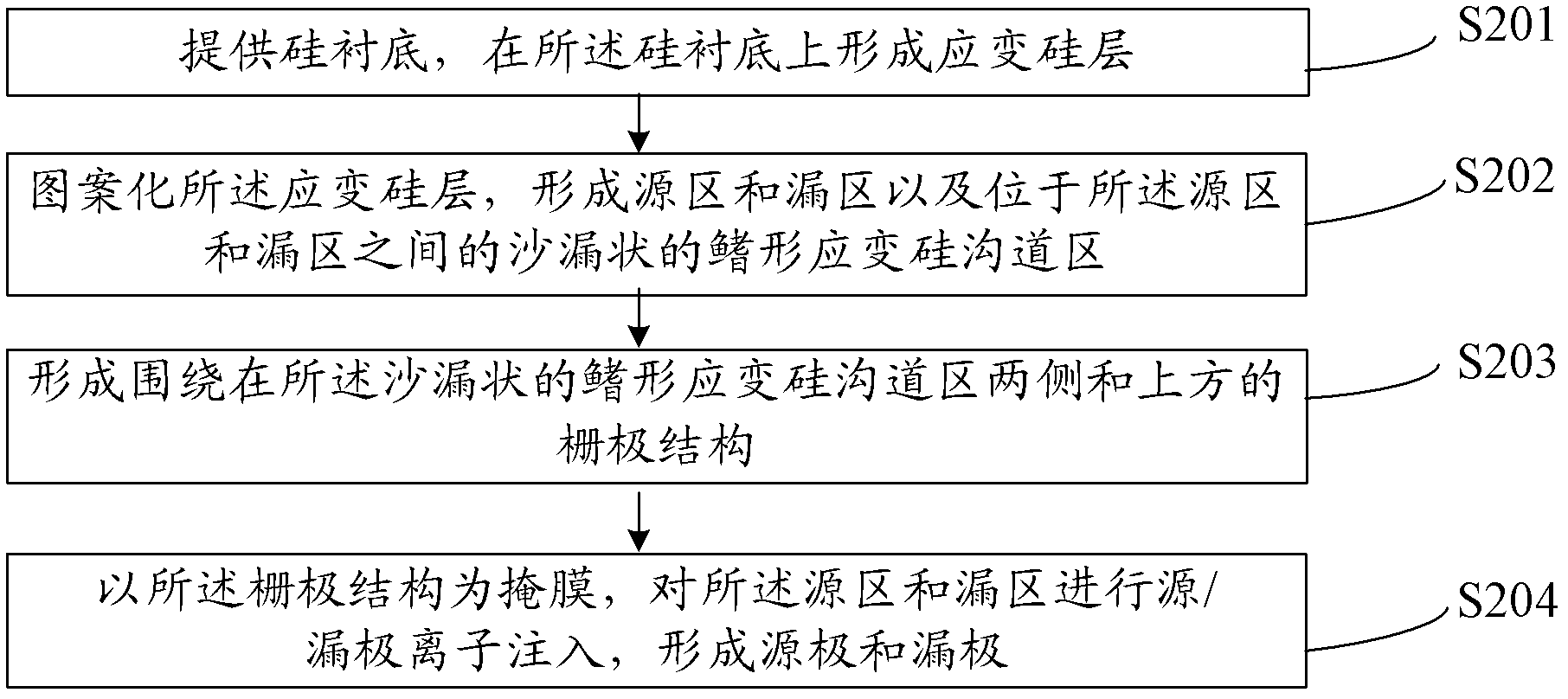

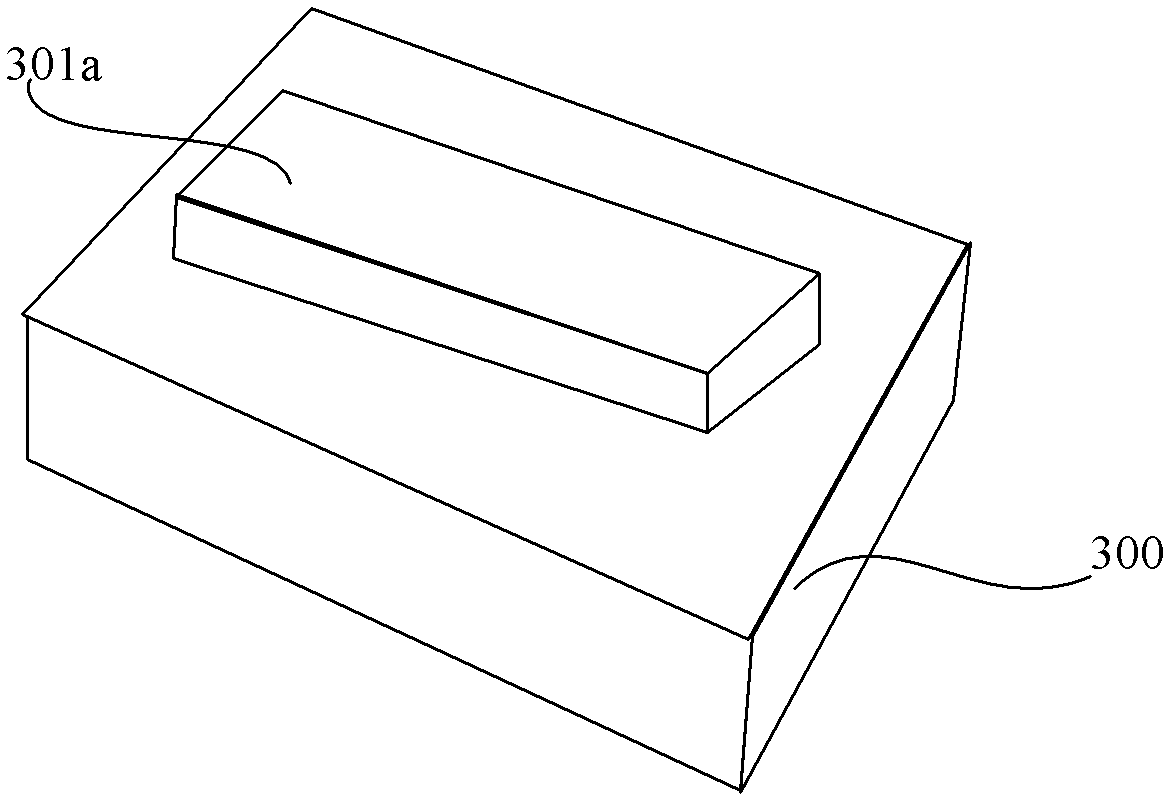

Manufacturing method and structure of fin field-effect transistor (FinFET) device

InactiveCN103137478AIncrease aspect ratioIncrease drive currentSemiconductor/solid-state device manufacturingSemiconductor devicesSquare ShapeStrained silicon

The invention provides a manufacturing method and structure of a fin field-effect transistor (FinFET) device. A fin-shaped strained silicon channel region in an hourglass shape is adopted to replace a fin-shaped strained silicon channel region in a traditional rectangular or square shape, breadth-length ratio of a fin-shaped strained silicon channel is increased, driving current of the FinFET device is remarkably improved, and a manufacturing process is simple.

Owner:SEMICON MFG INT (SHANGHAI) CORP

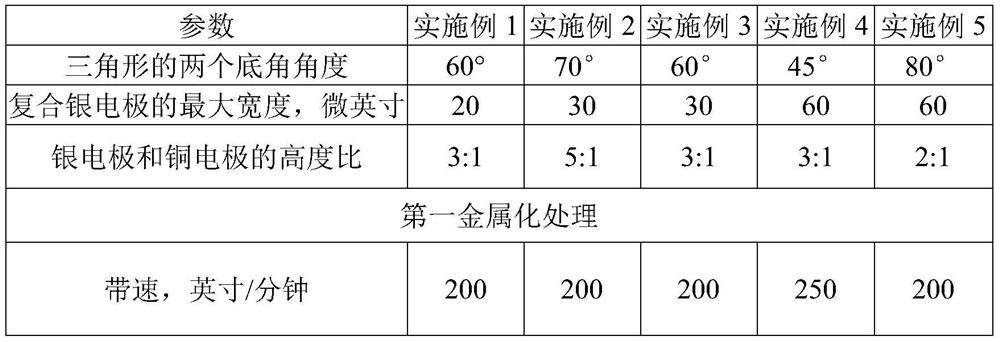

Front electrode and preparation method thereof

PendingCN113035974AReduce silver usageOn the basis of less silver consumption, it also has less aspect ratioFinal product manufacturePhotovoltaic energy generationSilver electrodeCopper electrode

The invention relates to the technical field of electrodes, in particular to a front electrode and a preparation method thereof. The front electrode comprises strip-shaped composite silver electrodes evenly distributed on the front face of a silicon substrate at equal intervals, wherein the cross section of each composite silver electrode is in a triangle shape, the angles of the two base angles of each triangle are 45-80 degrees, the maximum width of the composite silver electrode is 15-60 [mu]inches, the composite silver electrode is of a composite structure of an upper layer and a lower layer, the lower layer is a silver electrode, the upper layer is a copper electrode, and the height ratio of the upper layer to the lower layer is (2-5):1. The front electrode is low in silver consumption, large in height-width ratio, small in shading loss and low in contact resistance, so that the photoelectric conversion rate of the solar cell is high.

Owner:JIANGSU RIYU PHOTOVOTTAIC NEW MATERIAL TECH CO LTD

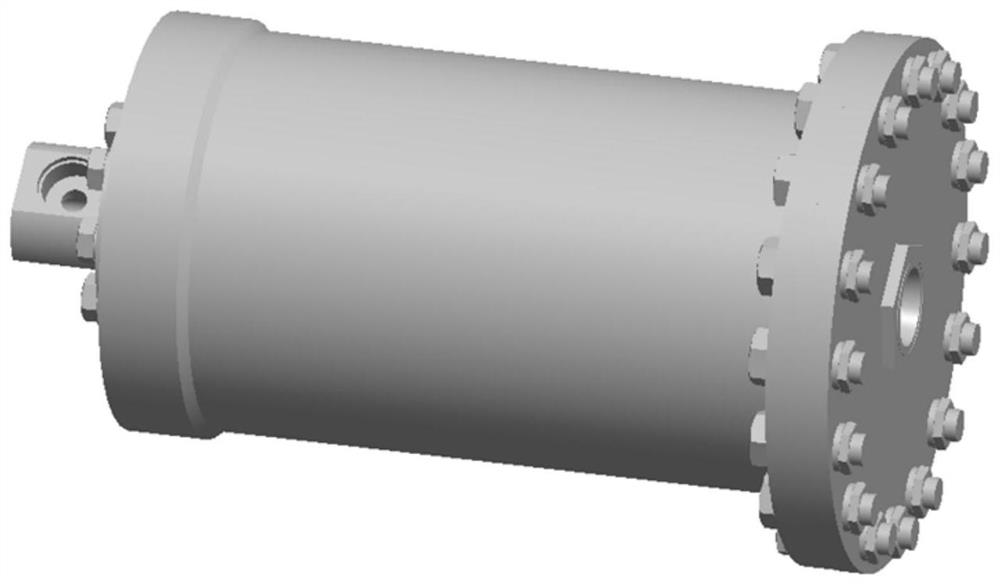

Catapulting engine

ActiveCN111852689AIncrease aspect ratioHigh synchronization of burning surface ignitionRocket engine plantsCombustion chamberRocket

The invention relates to a catapulting engine. The catapulting engine comprises a shell body, charging assemblies, a rear top cover, a spray pipe, an igniting device, a volution, a front bolt, a rearbolt, a from top cover sealing ring, a rear top cover sealing ring, and a spray pipe sealing ring. The catapulting engine has the advantages of large increased area ratio, simple structure, mature process, wide working temperature range, and good trajectory performance. Two rows of charging assemblies are evenly distributed in a combustion chamber shell body, and after ignition of the engine, fuelgas amount of the catapulting engine is gradually increased with time. A two-path ignition tube is installed at the head part, redundancy design is conducted, reliable ignition energy is provided, and spherical propellant is ignited. The volution is used to fix the spray pipe at the tail part, and the process is mature, simple and convenient. The catapulting engine can be applied to of missile orcarrier rocket emission in a wide temperature range, the initial overload is low, and the stability and reliability of missile or carrier rocket emission are improved.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com