Equipment and method for manufacturing solar cell positive electrode

A technology of solar cells and front electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of silver paste consumption, large shading area, thin grid line width, etc., to reduce production costs, improve conversion efficiency, reduce The Effect of Grid Width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention adopts a solar cell front electrode manufacturing equipment completely different from the prior art. In the prior art, fine grid lines are printed on the cell through a screen on a screen printing machine. The improvement of the prior art is also to Improvements to screen printing machines, or improvements to conductive pastes. The invention adopts very effective alternative equipment and manufacturing method to replace the screen printing machine and the screen printing process, so that the manufacturing cost is reduced and the photoelectric conversion efficiency of the solar cell is further improved.

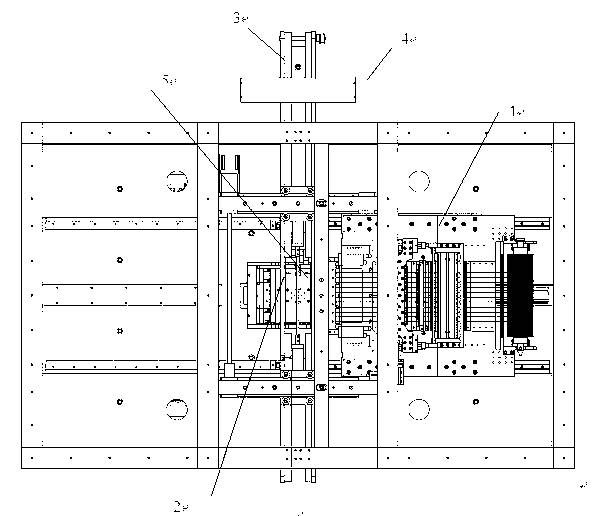

[0054] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

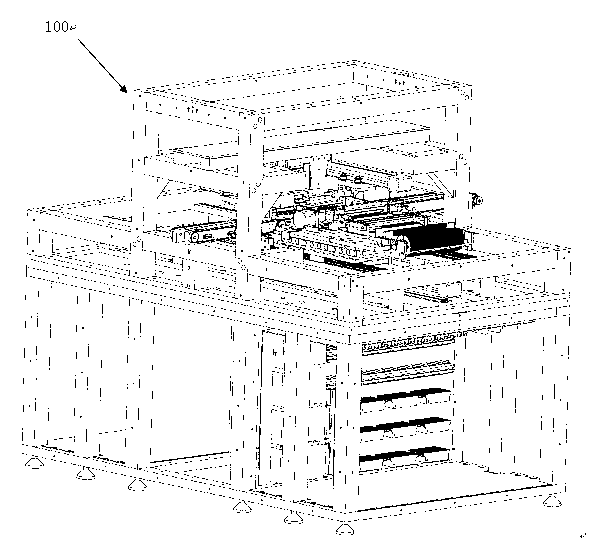

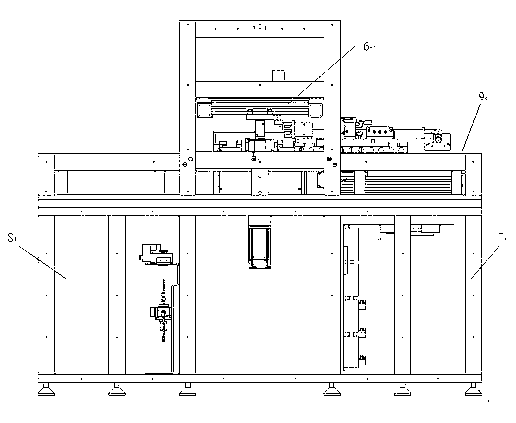

[0055] like Figure 1 to Figure 2 As shown, it shows an embodiment of a new solar cell front electrode manufacturing equipment. The manufacturing equipment 100 mainly includes a frame 9, a wire feeding mechanism 10, a coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com