Front electrode and preparation method thereof

A front electrode and silver electrode technology, applied in the field of electrodes, can solve the problems that silicon solar cells cannot be promoted vigorously, the aspect ratio of thin grid lines is small, and the loss of large front electrodes, etc., to achieve reduced shading loss, small shading loss, and low contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The second aspect of the present invention provides a method for preparing the front electrode, the method comprising:

[0025] (1) Print a trapezoidal silver electrode on the front surface of the silicon substrate that has been processed through texturing, diffusion, post-cleaning, coating and printing the back electrode process (it can be understood that the trapezoidal silver electrode is the same as the aforementioned first The dimensions of the trapezoidal silver electrodes in the middle and lower layers are exactly the same);

[0026] (2) carrying out the first metallization treatment to the silver electrode printed on the front surface of the silicon substrate;

[0027] (3) Triangular copper electrodes are printed on the surface of the silver electrodes after metallization (it can be understood that the triangular copper electrodes are exactly the same size as the upper small triangular copper electrodes in the aforementioned first aspect), forming electrode sta...

Embodiment approach

[0036] According to a preferred embodiment of the present invention, the preparation method of the front electrode comprises:

[0037] (1) Print a trapezoidal silver electrode on the front surface of the silicon substrate after the process of texturing, diffusion, post-cleaning, coating and printing the back electrode;

[0038] (2) carrying out the first metallization treatment to the silver electrode printed on the front surface of the silicon substrate;

[0039] (3) Print triangular copper electrodes on the surface of the silver electrodes after metallization to form electrode stacks;

[0040] (4) Performing a second metallization treatment on the copper electrode to form a front electrode of copper-silver alloy.

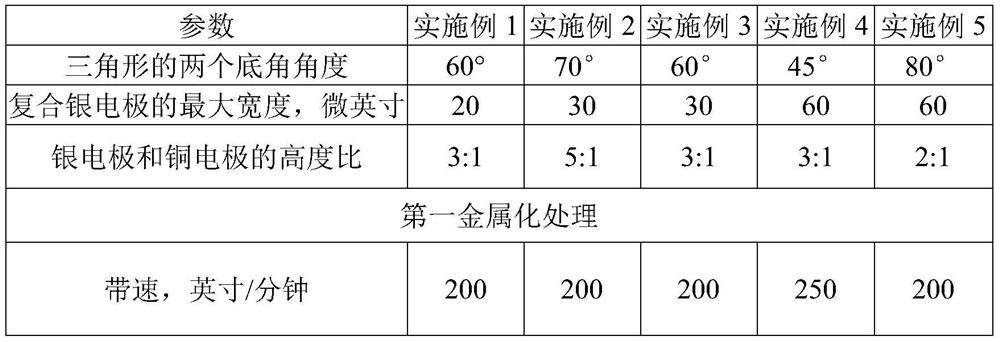

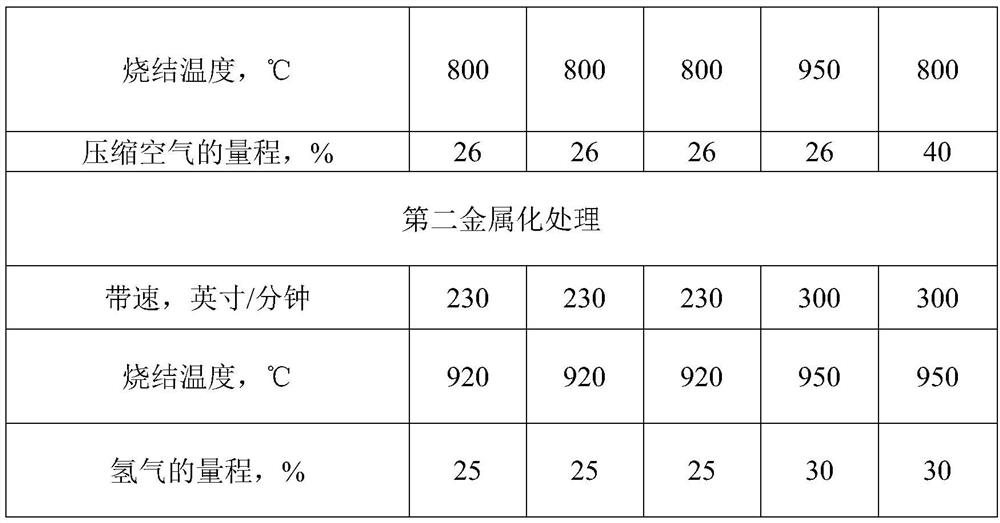

[0041] The present invention will be described in detail below by way of examples.

Embodiment 1

[0043] (1) Print a trapezoidal silver electrode on the front surface of the silicon substrate after the process of texturing, diffusion, post-cleaning, coating and printing the back electrode;

[0044] (2) carrying out the first metallization treatment to the silver electrode printed on the front surface of the silicon substrate;

[0045] (3) Print triangular copper electrodes on the surface of the silver electrodes after metallization to form electrode stacks;

[0046] (4) Performing a second metallization treatment on the copper electrode to form a front electrode of copper-silver alloy.

[0047] The above mentioned parameters are listed in Table 1. Test its photoelectric conversion rate according to the test method of Example 1 in CN103021510B, as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com