Method for preparing surface modified stainless steel as biplar plate for proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, which is applied to fuel cell parts, battery electrodes, metal material coating processes, etc. The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

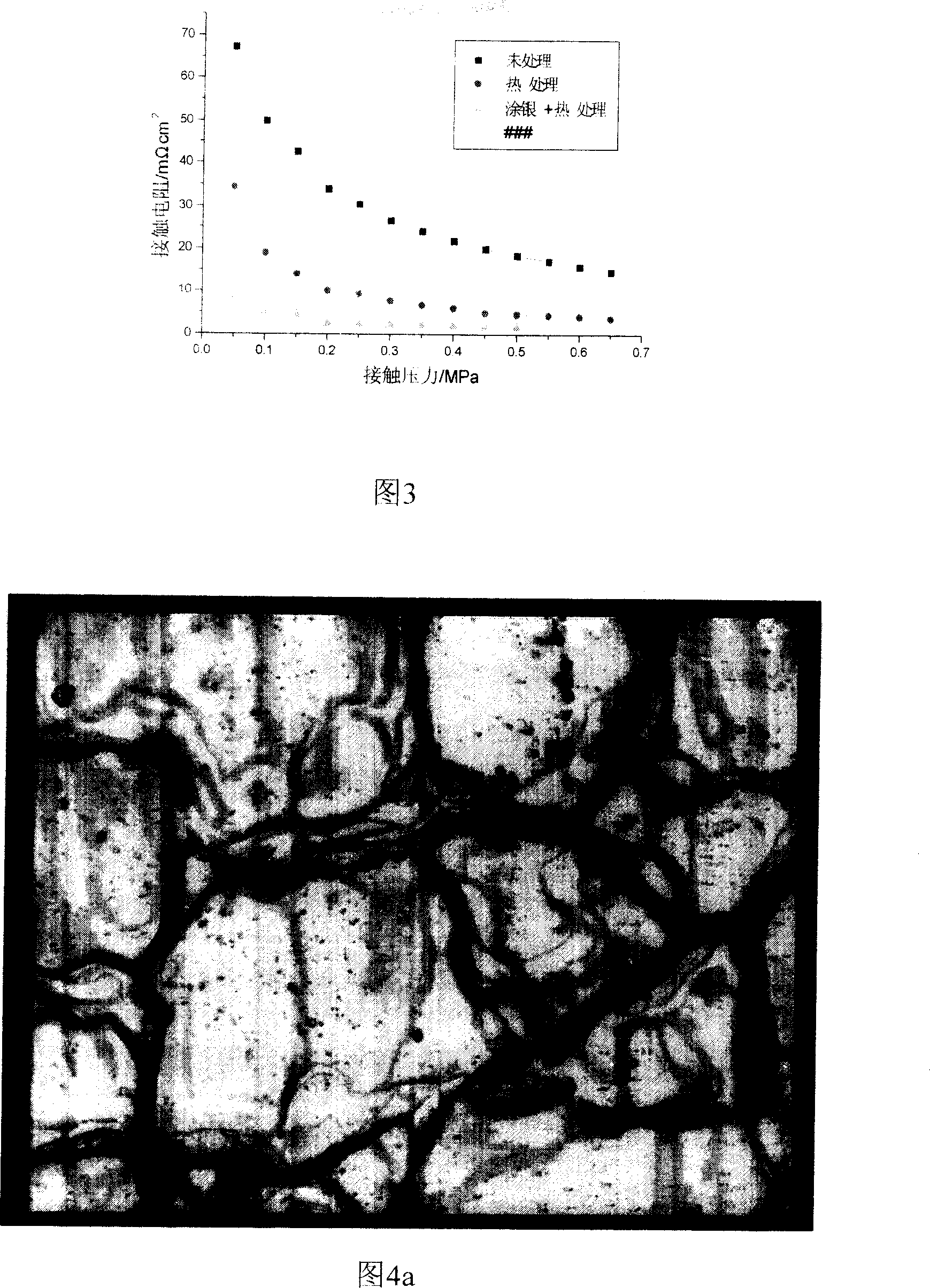

[0034] Degrease the 304 stainless steel with a thickness of 0.1~0.3mm with petroleum ether, and then use 0.5~1.0mol·L -1Wash it with dilute nitric acid for 15-20 minutes, apply a layer of saturated silver nitrate aqueous solution on the surface, dry it, put it into the muffle furnace and heat it to 780°C, keep it warm for 30 minutes, take it out, and wash it with dilute hydrochloric acid; The comparison test of the contact resistance was carried out under pressure. The results are shown in Figure 3. Compared with the stainless steel with only heat treatment and untreated stainless steel, the contact resistance between the stainless steel with the heat treatment and the silver salt coating process is significantly reduced. . Then passivate with potassium dichromate passivation solution for 20 minutes, the surface microstructure is shown in Figure 4a, and the comparative test results of corrosion resistance are shown in Figure 4b, after passivation, the contact resistance increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com