Photovoltaic solar cell electrode grid line in-situ secondary printing device and method

A technology of solar cells and electrode grid lines, which is applied in photovoltaic power generation, printing devices, printing and other directions, can solve the problems of difficulty in printing, reduce production efficiency, and visual positioning cost, and achieve convenient operation, high production efficiency, and fast printing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

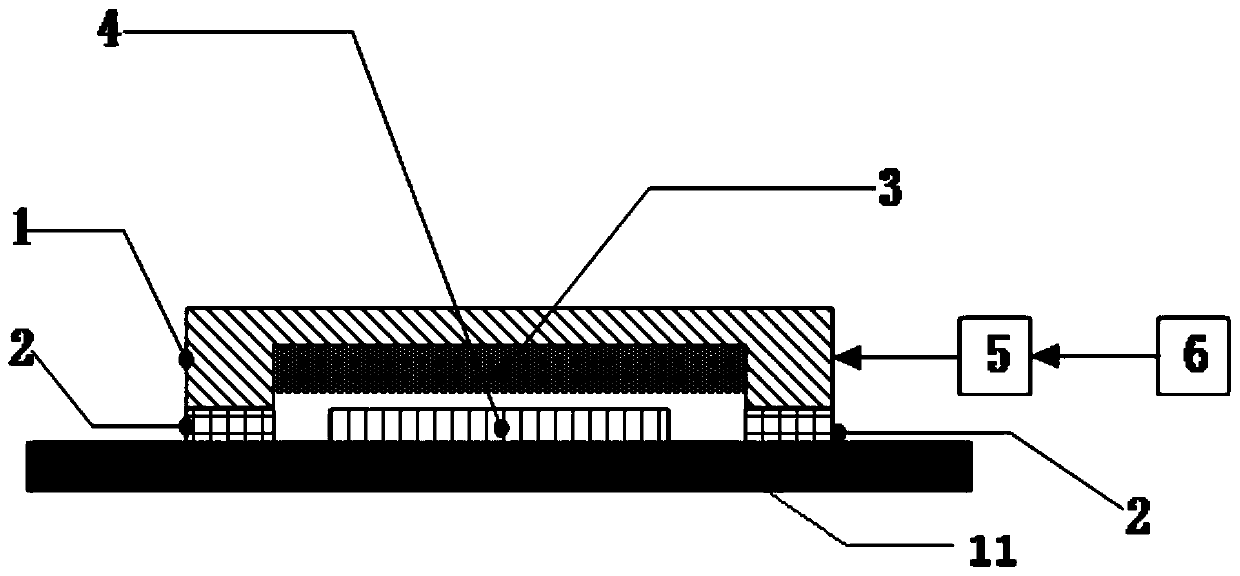

[0036] This embodiment discloses an in-situ secondary printing device for grid lines of photovoltaic solar cells, such as figure 1 As shown, it includes a base 11 , a silver paste carrier 1 and a silver paste carrier motion control device 6 .

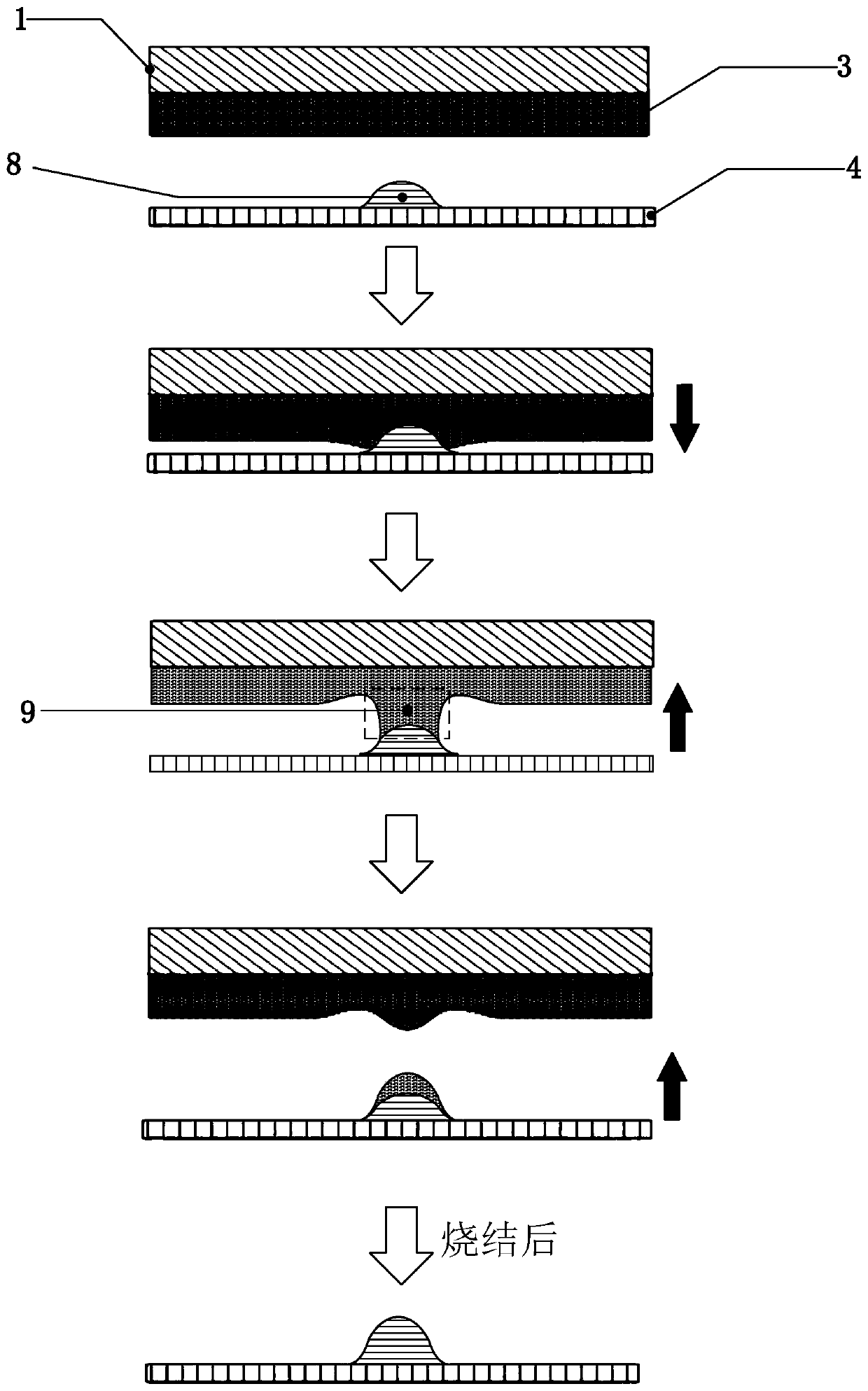

[0037] Wherein, the base 11 is used to place the printed silicon wafer 4 . Such as image 3 As shown, the silicon wafer is printed once or more than once, and there are gate lines 8 generated by printing on the silicon wafer.

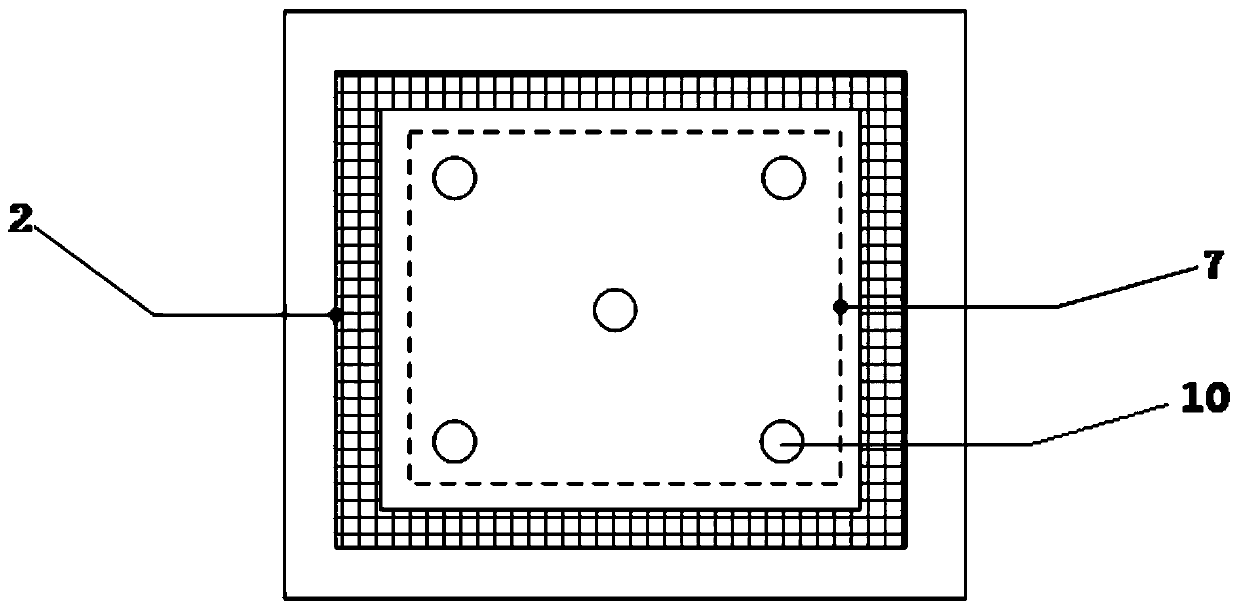

[0038] Such as figure 2 As shown, the base 11 is provided with an adsorption device 10 through which the silicon wafer is adsorbed on the base. The adsorption device in this embodiment is a suction cup, and the adsorption force of the suction cup can ensure that the silicon wafer can be tightly attached to the base. The number and distribution position of the suction cups are not unique, as long as the stress on each part of the silicon wafer is uniform and can be fixed on the base.

[0039] The silver paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com