Method for manufacturing solar cell positive electrode grid line

A technology of solar cells and positive electrodes, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increased grid line width, improvement, and unfavorable cell efficiency, etc., and achieves low series resistance, simple process, and ideal shape of the seed layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

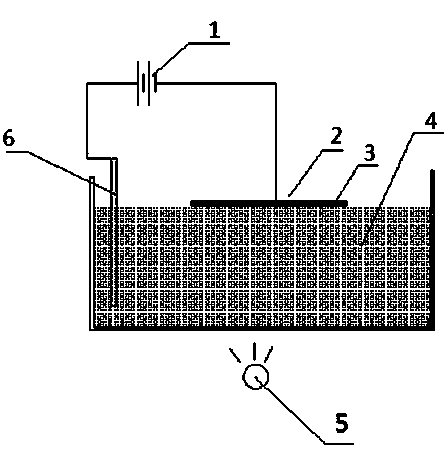

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of preparation method of solar cell positive electrode grid line, specific process is:

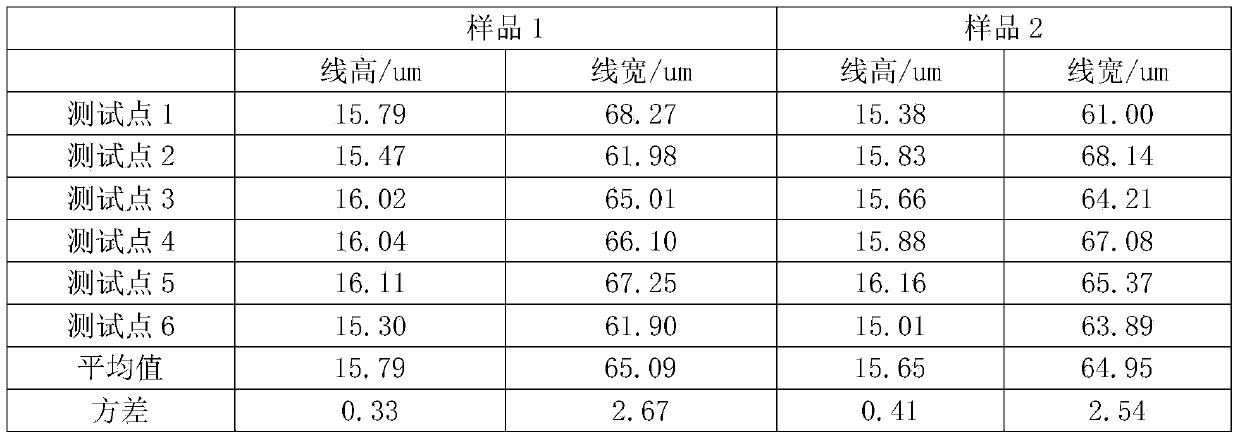

[0021] a. On the silicon wafer that has undergone previous processes such as texturing, diffusion, edge insulation, PSG removal, and anti-reflection coating, and has printed the back electrode and the back electric field, screen-print the positive electrode grid line and sinter it quickly to form an ohmic Contact; specifically, the screen parameters used in screen printing are: the number of fine grid lines is 88, the mesh is 360 mesh, the opening of the fine grid lines is 36um, the wire diameter is 16um, and the thickness of the photosensitive film is 15um; It is 80mg of silver paste dedicated to the positive electrode of solar cells, and it is required that there is no broken grid after printing. The line height and line width after sintering are shown in the following table:

[0022] Table 1 Line height and line width of grid lines after sintering

[0023] ...

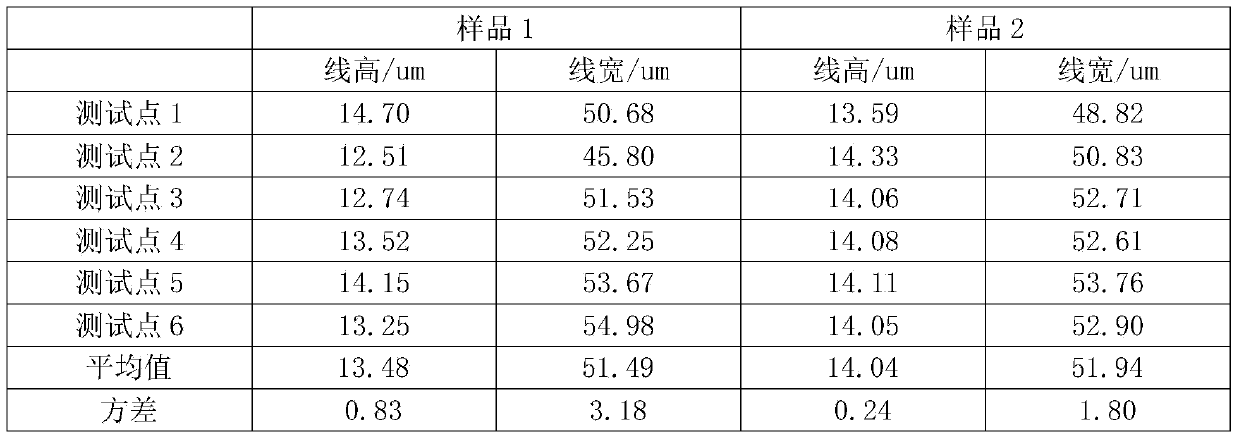

Embodiment 2

[0039] Example 2: roughly the same as Example 1, the difference is that the amount of silver paste printed in step a is 60mg; the applied voltage in step b is 1.5V, the light intensity is 6000lux, the reaction temperature is 20°C, the reaction time is 5min, the dissolution of the positive electrode The amount is 15 mg; the light intensity in step c is 6000 lux, the reaction temperature is 20° C., and the amount of silver plating on the positive electrode is 20 mg.

Embodiment 3

[0040] Example 3: roughly the same as Example 1, the difference is that the amount of silver paste printed in step a is 100mg; the applied voltage in step b is 2V, the light intensity is 15000lux, the reaction temperature is 60°C, the reaction time is 10min, and the amount of positive electrode dissolved is 30 mg; in step c, the light intensity is 15000 lux, the reaction temperature is 60° C., and the amount of silver plating on the positive electrode is 50 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com