Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Process controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

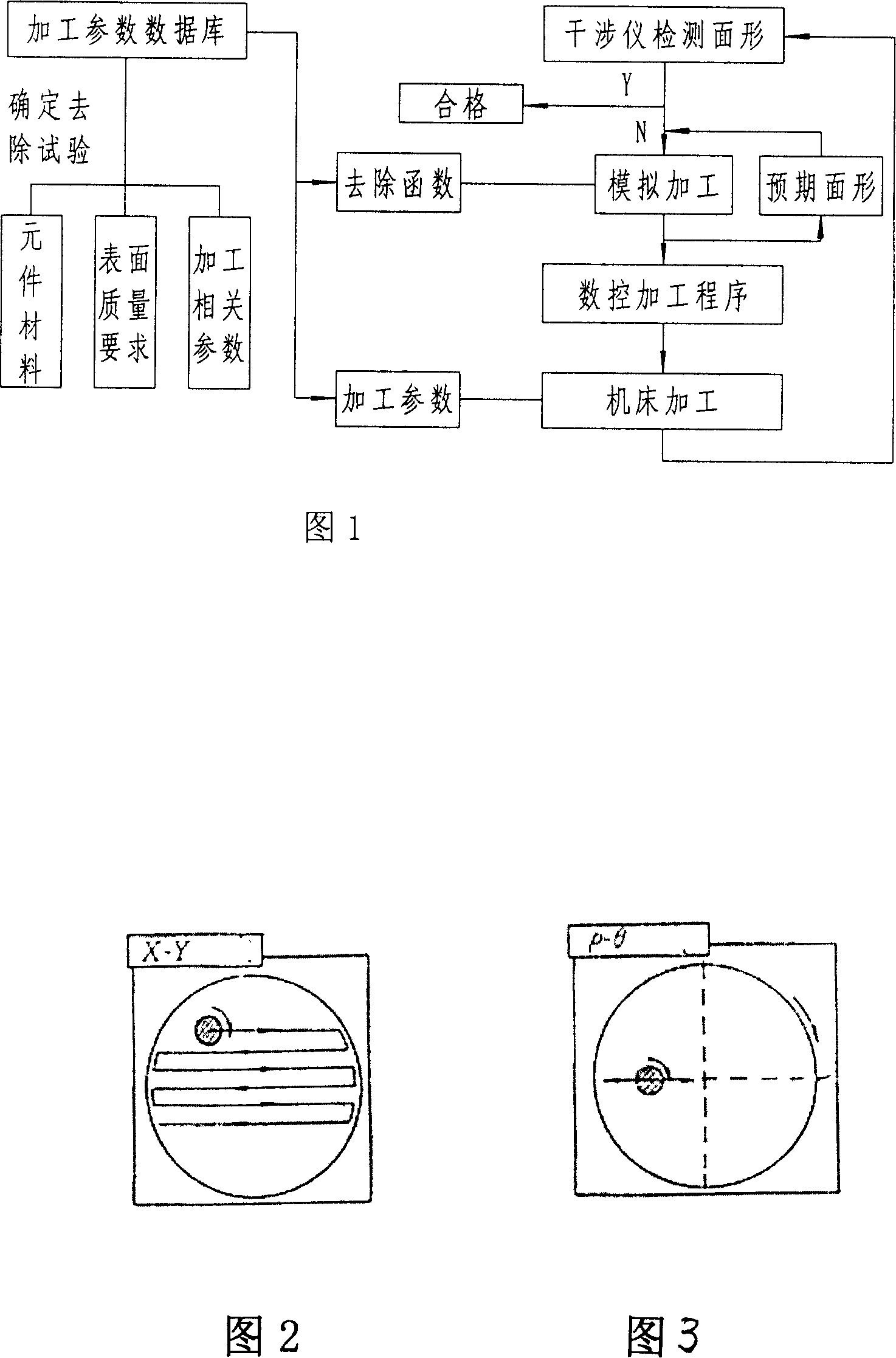

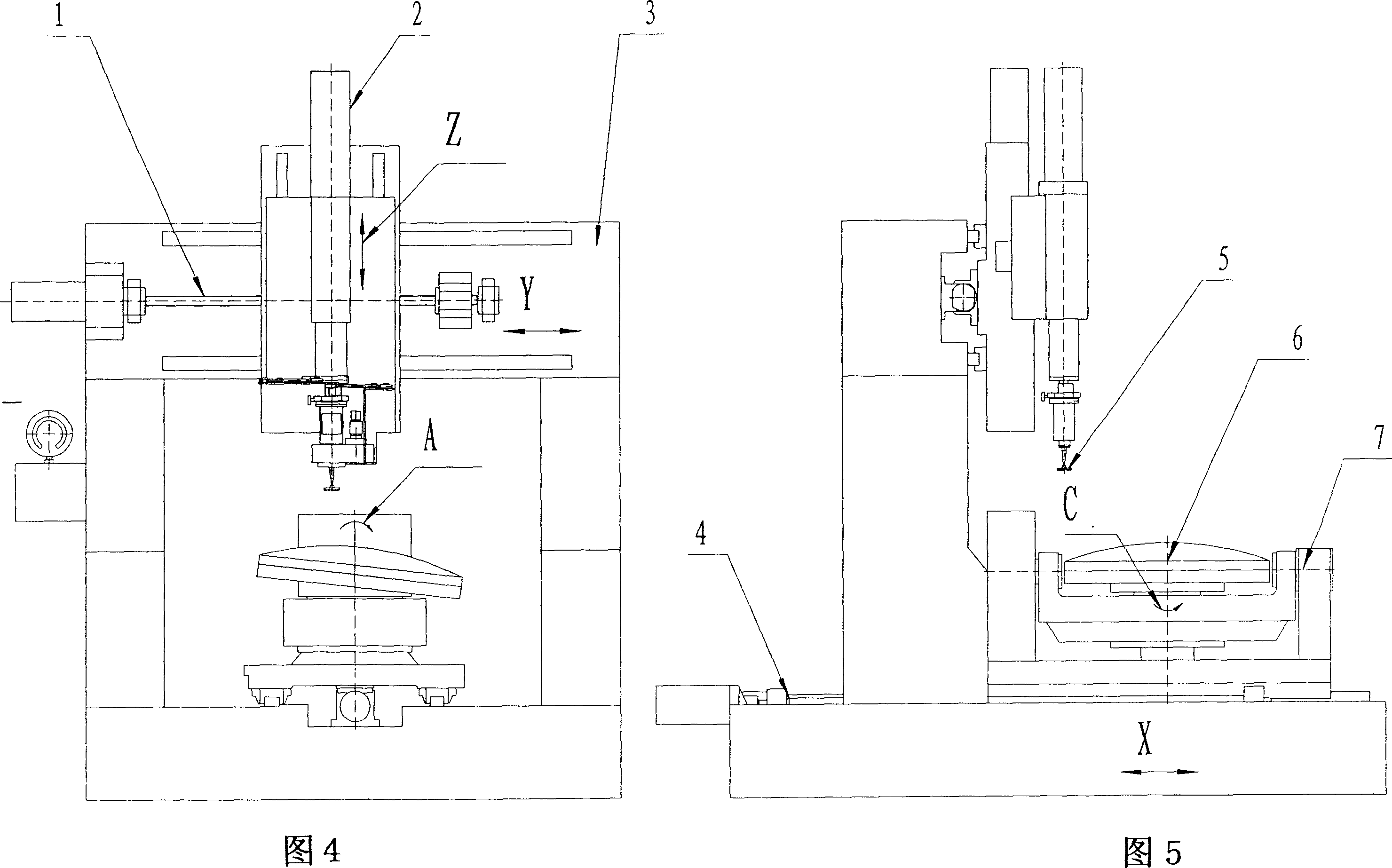

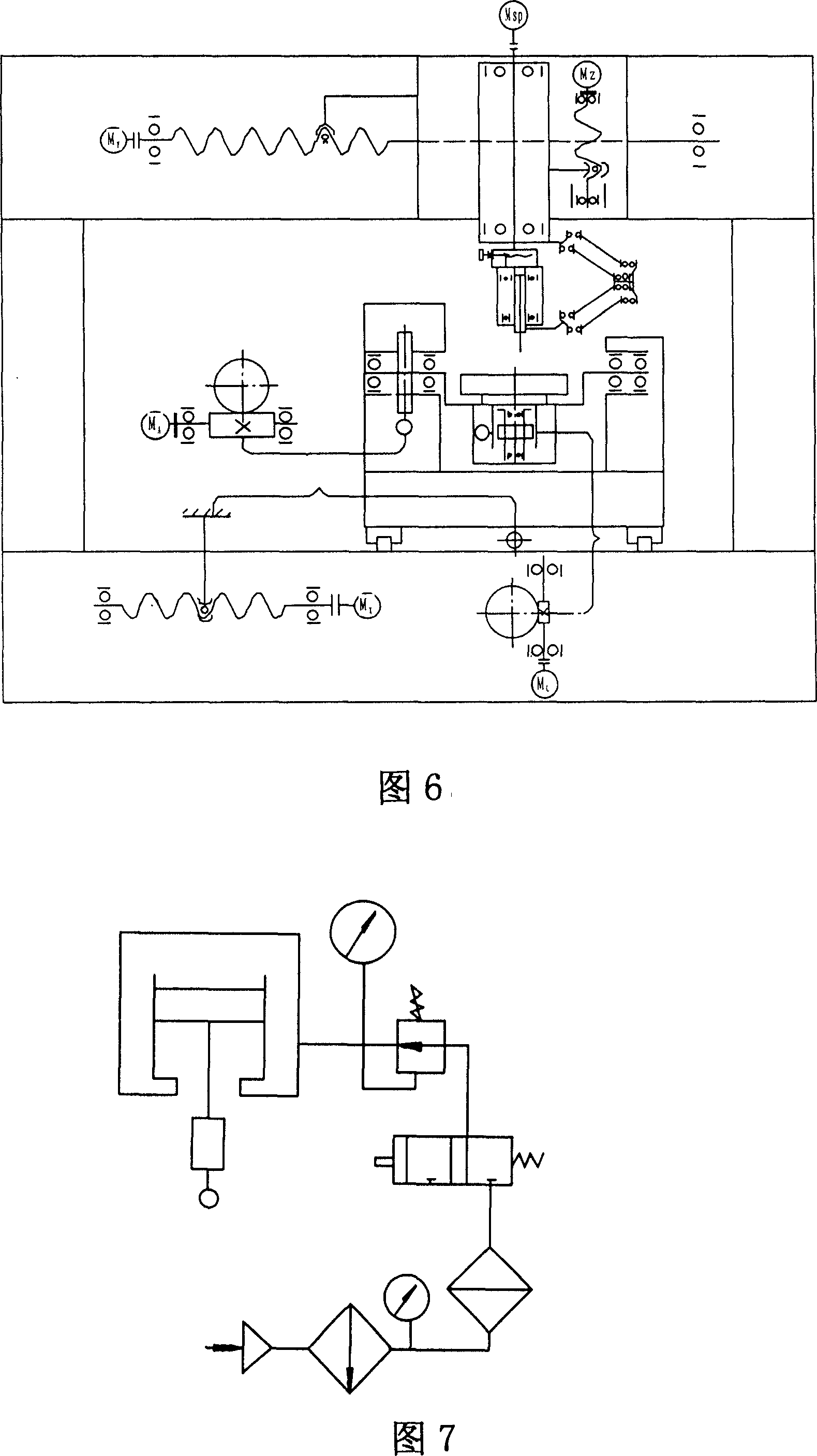

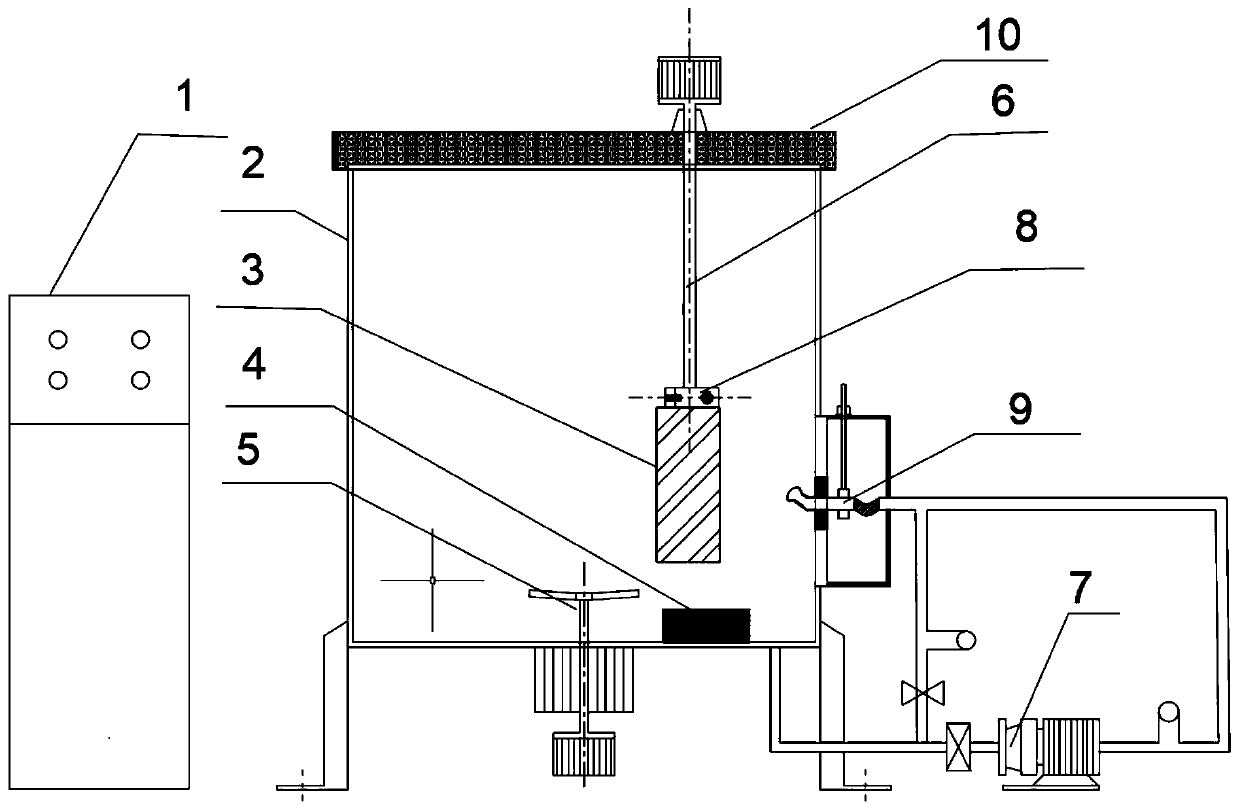

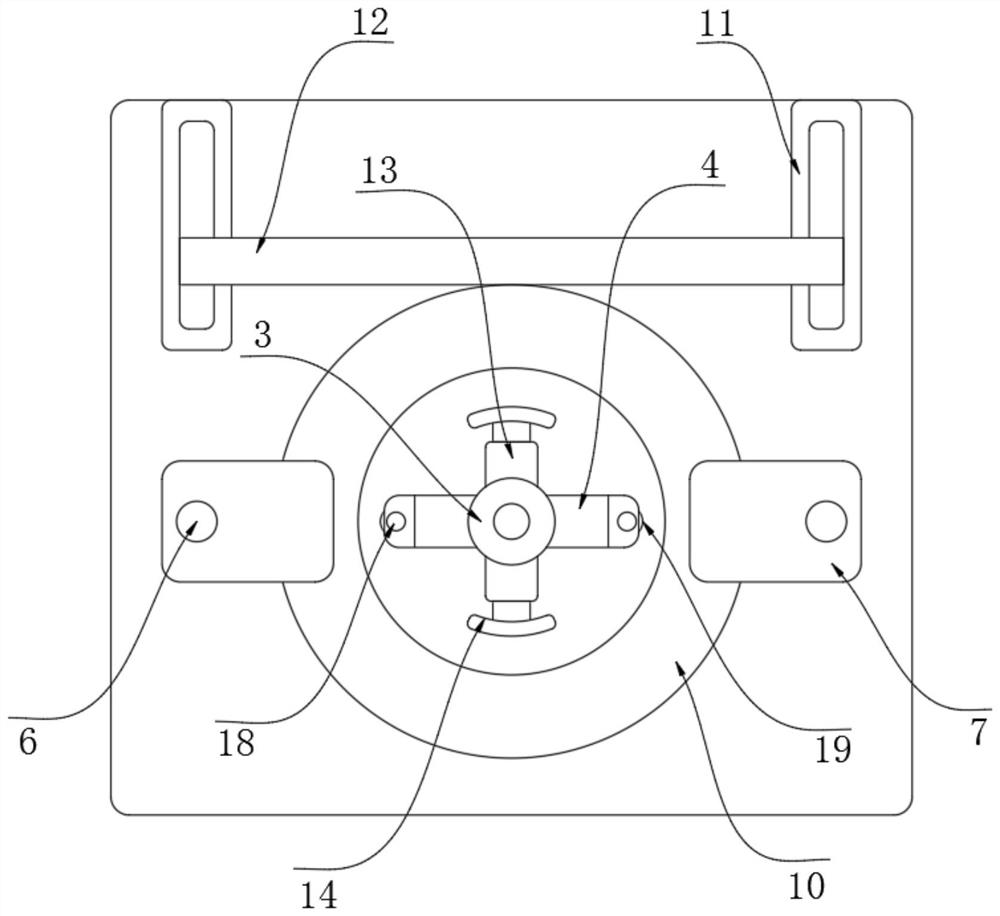

Efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements

InactiveCN101088705AReduce dependenceImprove efficiencyOptical surface grinding machinesOptical surfaceMachining process

The efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements belongs to the field of precise optical machine technology. The polishing process includes: constituting polishing process model based on the profile data obtained through measurement with interferometer or other instrument, determining the machining path, speed, pressure and other parameters of the element under the control of computer to perform simulating machining, verifying the technological parameters based on the simulating machining results and determining the ultimate technological parameters, creating NC program and machining. The present invention has high machining efficiency and high machining precision.

Owner:CHANGCHUN EQUIP TECH RES INST

Crosslinked alginate-bacterial cellulose sponge and preparation method thereof

ActiveCN103536954AImprove mechanical propertiesSimple structureAbsorbent padsBandagesPolymer scienceFreeze-drying

The invention relates to the field of a biomedical material, and particularly discloses a crosslinked alginate-bacterial cellulose sponge and a preparation method thereof. The crosslinked alginate-bacterial cellulose sponge takes an alginate biomaterial and bacterial cellulose as raw materials. The crosslinked alginate-bacterial cellulose sponge is characterized in that a sponge product is prepared from the alginate biomaterial and the bacterial cellulose in manners of crosslinking and freeze-drying after being compounded, wherein the alginate biomaterial accounts for 80-95% of the sponge product in mass fraction; the bacterial cellulose accounts for 5-20% of the sponge product in mass fraction. The crosslinked alginate-bacterial cellulose sponge is abundant in used material sources, low in cost, controllable to process, and simple in production technology; the prepared crosslinked alginate-bacterial cellulose sponge has good mechanical property, liquid absorption property, water retention capacity and air permeability, and is applicable to bleeding healing of large seepage or a bleeding wound.

Owner:山东颐诺生物科技有限公司

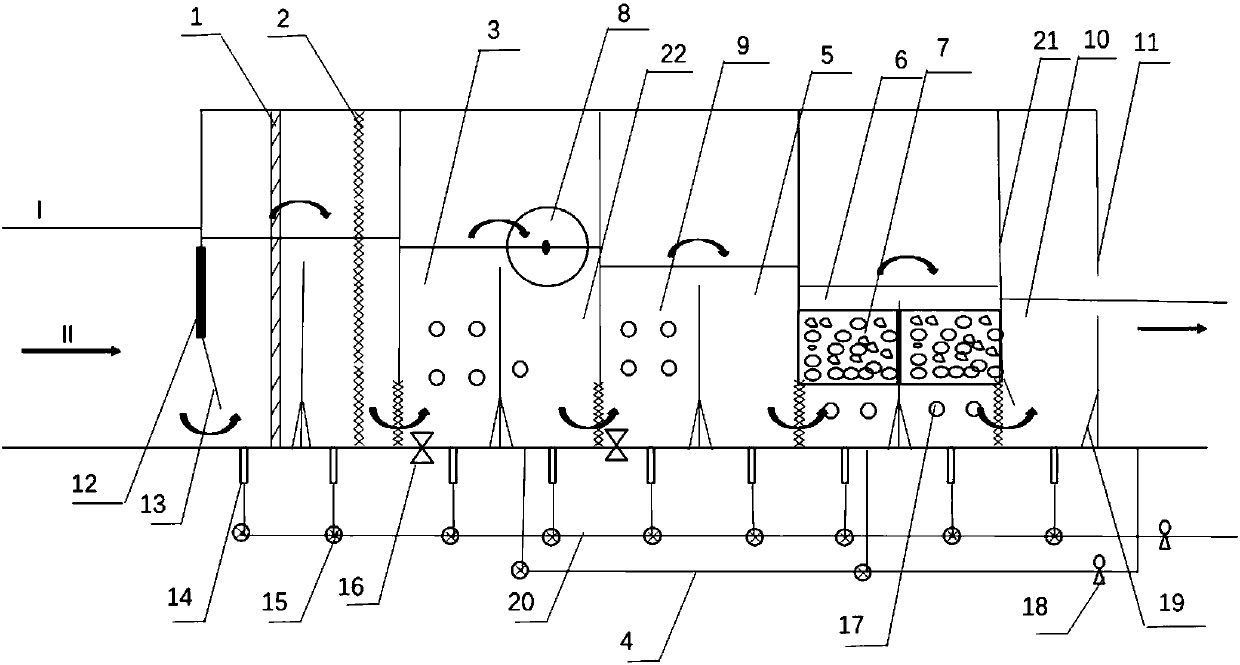

In-situ treatment system and method of black and odorous water

ActiveCN107673561AIncrease concentrationTo achieve the effect of phosphorus removalWater treatment parameter controlWater treatment compoundsWater flowWater quality

The invention provides an in-situ treatment system of black and odorous water and a method of using the system to treat black and odorous water. The in-situ treatment system of black and odorous watercomprises a pretreatment zone, an in-situ treatment zone and a separation zone; a certain section of a river channel is modified, more deflections are added to water flows, the water has longer stayin a unit zone, and the land around is scarcely used; in-situ restoration is mainly dependent on a biological method assisted by physicochemical methods, and the quality of the black and odorous wateris finally improved. In the method, the in-situ restoration of the black and odorous water is confined in a smaller area so that the concentration of microbes in the water of this area is increased,reflow can be achieved, contaminants in the water gain full time to degrade, treatment cost is lowered, and treatment is fast, efficient and free of secondary contamination.

Owner:中交生态环保投资有限公司

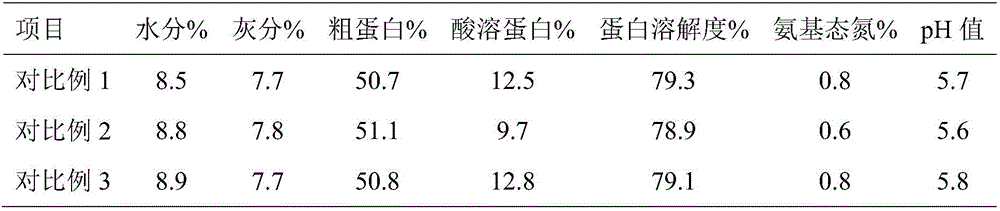

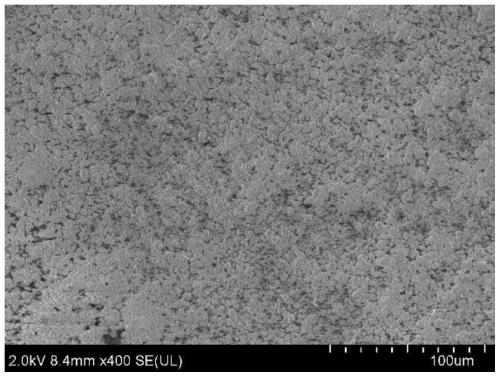

High-quality enzymolysis-fermented bean pulp as well as preparation method and application thereof

ActiveCN106615672AImprove digestibilityImprove palatabilityFood processingAnimal feeding stuffAntigenMetabolite

The invention relates to a high-quality enzymolysis-fermented bean pulp as well as a preparation method and application thereof. The preparation method comprises the steps of crushing peeled bean pulp, sieving by virtue of an 80-mesh sieve, carrying out primary enzymolysis by virtue of alpha-galactosidase and glucoamylase, carrying out secondary enzymolysis by virtue of papain, carrying out enzyme deactivation, inoculating a compound strain of saccharomycetes, bacillus and lactic acid bacteria, sequentially carrying out aerobic fermentation and anaerobic fermentation to obtain a finished product, and carrying out spray drying on the finished product, so as to preserve active components to the greatest extent. The prepared enzymolysis-fermented bean pulp has the special fermentation flavor, the protein content is about 55%, the acid soluble protein content is more than 50%, antinutritional factors such as antigens are fundamentally eliminated, the components are stable, and the enzymolysis-fermented bean pulp has the characteristics of strong hydrophily, high water holding ratio and strong palatability and has an obviously food calling effect on aquatic animals; and the enzymolysis-fermented bean pulp is rich in functional small peptides, probiotics and metabolite of the probiotics, beneficial to the nutrient balance of intestinal tract of bred animals and is suitable for being added into feeds of piglets, poultries, pets, aquatic products and the like, the problem of trophic diarherra of the animals is solved, and the suggested use ratio is 2%-5%.

Owner:岳阳市展翔生物科技有限公司

Highly dielectric composite material containing core-shell structured packing and preparation method thereof

InactiveCN101293986ALow densityAvoid leakage conductanceNon-conductive material with dispersed conductive materialDomestic articlesAcetic acidDielectric loss

The invention belongs to the technology field of composite materials, more particularly relates to a high dielectric composite material containing fillers with a core-@-shell structure and a production method thereof. The composite material contains 10-45 wt% of aluminum and 55-90 wt% of polystyrene. The production method comprises the following steps: subjecting aluminum powder to surface passivation treatment to obtain fillers with a core-@-shell structure, preparing ethyl acetate solution of polystyrene, adding the treated aluminum powder into the ethyl acetate solution at different mass fractions, stirring, casting, sun-drying, oven-drying, molding and shaping to obtain the high dielectric composite material containing fillers with core-@-shell structure. An oxide coating is formed on the surface of the aluminum powder after the surface passivation treatment, so as to efficiently avoid the formation of leakage conductance due to mutual contact between eclectically-conducting additives and thereby to reduce the dielectric loss of the material. The composite material has high dielectric constant, low density and good flexibility. The production method of the composite material has the advantages of simple and controllable process, low hot-pressing temperature, energy conservation and environmental protection.

Owner:TSINGHUA UNIV

Method for preparing delta-MnO2 nanosheet

InactiveCN108298588ASimple preparation processProcess controllableManganese oxides/hydroxidesHigh pressureAlcohol

A method for preparing a delta-MnO2 nanosheet comprises steps as follows: a NaOH solution with the concentration being 0.4-0.8 mol / L is prepared, and a H2O2 solution with the concentration being 9.0-11.0 mol / L is prepared; a Mn(NO3)2 solution with the concentration being 0.20-0.40 mol / L is prepared; the H2O2 solution is rapidly added to the NaOH solution; the mixed solution is rapidly added to theprepared Mn(NO3)2 solution; a produced sediment is washed to be neutral and then dried, and an intermediate product is obtained; the intermediate product is added to the NaOH solution, and the mixture is stirred uniformly and transferred into a high-pressure reactor; after a reaction in the reaction kettle, cooling is performed, the obtained product is washed to be neutral with distilled water, then washed with absolute ethyl alcohol and finally dried by an oven, and the delta-MnO2 nanosheet is obtained. The obtained product has completely developed crystalline phase, high purity and good dispersity.

Owner:SHAANXI UNIV OF SCI & TECH

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1343543AHigh electrode strengthImprove processing efficiencySoldering apparatusLaser beam welding apparatusLaser solderingSoldering

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

Polyimide-zinc organic framework loaded graphene oxide hybrid membrane as well as preparation and application

ActiveCN107866154AEasy to prepareProcess controllableProductsSemi-permeable membranesGas separationHummers' method

The invention discloses a polyimide-zinc organic framework loaded graphene oxide hybrid membrane. A preparation process comprises the following steps: preparing graphene oxide by adopting a Hummer method, preparing dispersing liquid with a mass ratio of methanol to water of (1 to 4) to 1, and performing ultrasonic dispersion; adding the graphene oxide and the dispersing liquid into a mixed solution of zinc nitrate hexahydrate and 2-methylimidazole, and performing a stirring reaction at room temperature, thus preparing a zinc organic framework loaded graphene oxide compound nanosheet; and blending the zinc organic framework loaded graphene oxide compound nanosheet and a polyimide solution to prepare a membrane casting solution, and preparing the hybrid membrane through a tape casting method. The polyimide-zinc organic framework loaded graphene oxide hybrid membrane disclosed by the invention has the advantages that the raw materials of the hybrid membrane are easy to obtain, and the preparation process is simple and controllable; and the prepared compound membrane is used for gas separation, and has excellent separation performance. Particularly, under a humidification condition, the permeability of CO2 pure gas is 238 barrer, and the CO2 / N2 selectivity is 65.

Owner:TIANJIN POLYTECHNIC UNIV

Dialogue system answer generation method and system

InactiveCN110020015ALess freedomProcess controllableDigital data information retrievalNatural language data processingDatabase queryTest sample

The invention relates to a dialogue system answer generation method and system, and the method comprises the following steps of S1) cutting the multiple rounds of dialogue data according to each round, wherein each round of dialogue is expressed as (U, Y); S2) performing THE part-of-speech tagging and named entity identification on each word in the U to find a keyword sequence in the word sequence; and S3) obtaining a target keyword sequence by using a database query or neural network automatic generation method; For each target keyword, searching to obtain a word vector of the keyword; S4) carrying out model training, for all rounds of conversations in the training set, using a seq2seq model to obtain a predicted word sequence Y'; and S5) after the training is completed, inputting a sample into any user in the test sample, and performing the operation in the step S4) to obtain the predicted word sequence Y'. According to the method and the system, the content of the generated answer can be effectively controlled, and the quality of the answer is improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

High-glow-wire-temperature red phosphorus flame-retardant reinforced PA (polyamide) 66 and PPE (polyphenyl ether) alloy material and preparation method thereof

The invention discloses a high-glow-wire-temperature red phosphorus flame-retardant reinforced PA (polyamide) 66 and PPE (polyphenyl ether) alloy material and a preparation method thereof. The high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material includes the following components in each 100 parts of raw materials and content of the components, by weight, 30-50% of PA66, 10-20% of PPE, 5-20% of red phosphorus masterbatch, 20-35% of glass fibers, 5-15% of synergistic agent, 5-10% of compatilizer, 2-5% of antioxidant and 0.1-0.5% of auxiliaries. The high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material can be formed in an extrusion or injection manner by corresponding equipment such as an extruder. Compared with the conventional material, the high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material can pass the test of the GWIT (glow wire ignition temperature) of 850 DEG C, cannot be ignited, is controllable in processing and stable in flame retardant, quite fine in rigidity, high in fire resistance, stable in size and capable of meeting requirements of various electronic and electric products.

Owner:5ELEM HI TECH CORP

Reinforced skateboard and production thereof

A reinforced slide board for sliding on snow, grass and sand is composed of a core board made of at least one foamed board, the top and bottom surface boards with a pattern printed film and a foamed upper liner layer adhered by a ultralow-density adhering metallocene film, a solid board with low friction coefficient, and a reinforcing high-density edge clad. Its advantages are high bending strength, low weight and high adhesion.

Owner:张广基

Device for taking up and paying off cable automatically

The invention provides a device for taking up and paying off a cable automatically. The device for taking up and paying off the cable automatically comprises a control device, a motor and a winch. The winch comprises a cable winding drum and a rotating shaft. The cable winding drum is fixed to the rotating shaft. The rotating shaft is supported on a rack. An output shaft of the motor is connected with the rotating shaft of the winch through a clutch. A braking device is further arranged on the winch. The control device is connected with the motor. The motor drives the winch to rotate, and thus the cable can be wound on the cable winding drum of the winch or unwound from the cable winding drum; in addition, the clutch is arranged between the output shaft of the motor and the rotating shaft of the winch, and thus power transmission between the motor and the rotating shaft can be cut off or recovered at any time according to the situation; and the braking device is arranged on the winch, and thus rapid braking of the winch can be achieved through the braking device. In this way, by adoption of the device for taking up and paying off the cable automatically, the cable can be taken up or paid off conveniently, the taking-up or paying-off process can be controlled, and operation is safe.

Owner:SINOPEC SSC +1

Manufacturing method of fish skin glue jellies

The present method provides a manufacturing method of fish skin glue jellies. The manufacturing method comprises the following steps: quick-frozen fish skins are thawed; the scales of the thawed fish skins are removed and the scale removed fish skins are washed for standby application; water is added into the fish skins, and the fish skins are heated to a temperature of 30-40 DEG C and boiled for 15-30 minutes; the boiled fish skins are screened using a 40-mesh screen, the fish skins are collected, and the collected fish skins are prepared into blocks or strips; water at 1-5 times of the mass of the fish skins is added, and the fish skins are heated to a temperature of 60-80 DEG C and boiled for 1-3 hours; the boiled fish skins are screened using a 60-mesh screen to collect a liquid phase and to obtain skin fish glue liquid; and the fish glue liquid is cooled and shaped to obtain the fish skin glue jellies. Diced fish flesh is also added into the fish skin glue liquid to prepare the fish skin glue liquid containing the fish flesh; and or white granulated sugar, fresh ginger water, Chinese prickly ash water and vitamin C are added to obtain the flavored fish skin glue liquid. The method is simple in technology, energy saving and environmentally protective, not high in requirements for the equipment in the production line, easy to control in processes and suitable for industrialized production. Besides, the obtained products are high in product added value and strong in plasticity, can be directly edible or matched with other seasoning for consumption, and are high in security and suitable for a wide range of populations.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Synthesis process of paliperidone palmitate

Belonging to the technical field of pharmaceutical compositions, the invention relates to a synthesis process of paliperidone palmitate. Through synthesis of P (paliperidone), refinement of P synthesis of PP (paliperidone palmitate) and refinement of PP, the paliperidone palmitate can be prepared. According to the invention, the process is controllable, the cost is low, the impurities are controllable, the refining process is simple and convenient, the product purity is high, and the yield is high.

Owner:HUAYU WU XI PHARMA

Electrochemical treatment method of copper foil and composite copper foil material

ActiveCN111197176ARapid responseProcess controllableElectrolytic organic material coatingElectrochemical responseCopper foil

The invention discloses an electrochemical treatment method of copper foil and a composite copper foil material. The electrochemical treatment method comprises the following steps of jointly constructing an electrochemical reaction system by at least using a plasma surface-treated copper foil as the cathode, an anode and an electrolyte; and then electrifying the electrochemical reaction system toperform an electrochemical reaction, thereby forming a silane polymer film layer on the surface of the copper foil through polycondensation, wherein the electrolyte comprises a mixed solution of sodium sulfate, dodecyltrimethoxysilane and an acid solution. The plasma surface treatment and the electrochemical alkylation reaction have the advantages of fast reaction and controllable process, and canmeet the needs on rapid passivation treatment of the surface in the actual production of the copper foil; a silane polymer film generated through two-step treatment of the copper foil has high stability and high oxidation resistance; and at the same time, compared with the traditional chromium-containing passivation process, the method has the advantages of environmental protection and no pollution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Cationic chain transfer agent and application thereof

The invention belongs to the technical field of organic catalysis and polymer materials, and particularly relates to a cationic chain transfer agent and application thereof. The chain transfer reagentcan be used for continuous reaction to prepare a polyvinyl ether polyester block copolymer, and the chain transfer reagent has the advantages of simple and convenient process, low cost, controllableprocess, high reaction rate, narrow molecular weight distribution and large-scale application.

Owner:NANJING UNIV OF TECH

Multifunctional radar wave reflection soft protective material and preparation method thereof

PendingCN108174593ASimple preparation processProcess controllableShielding materialsSizingPlasticizer

The invention relates to the field of radar wave reflection, in particular to a multifunctional radar wave reflection soft protective material and a preparation method thereof. The soft protective material comprises a PVC coating layer I, a bonding layer I, a piece of carbon fiber base cloth, a bonding layer II and a PVC coating layer II. The first layer and the fifth layer on the upper and lowersurfaces are respectively the PVC coating layer I and the PVC coating layer II, the third layer in the middle is the carbon fiber base cloth, and the second layer and the fourth layer are respectivelythe bonding layer I and the bonding layer II coating the upper and lower surfaces of the carbon fiber base cloth. The raw materials of the PVC coating layers include polyvinyl chloride resin, plasticizer, flame retardant, filler, stabilizer and anti-ultraviolet agent. The soft protective material is prepared by the steps of slurry preparing and grinding, base cloth drying, soaking, rolling, scrape coating and sizing, plasticizing and drying, and the like. The soft protective material of the invention has good radar wave reflection performance, and has the advantages of low weight, high strength, water proofing, flame retardancy, ultraviolet protection, and the like.

Owner:辽宁山磊航空装备制造有限责任公司 +2

Ablation-resistant material preparation method

The invention relates to an ablation-resistant material preparation method which includes the steps: 1) preparing a carbon fiber prefabricated body by a three-dimensional needling weaving method, anddepositing a carbon interface layer on carbon fiber surface of the carbon fiber prefabricated body to form a carbon billet; 2) leading a ceramic phase into the carbon billet, filling inner space of the carbon billet with the ceramic phase. The carbon interface layer is provided with pyrolytic carbon formed on the carbon fiber surface by a chemical vapor deposition process, the ceramic phase is anHfC ceramic, and the carbon billet is soaked into HfC ceramic precursor solution and cross-linked, cured, pyrolyzed and treated at high temperature to obtain the ceramic phase. According to the method, a preparation technology is simple, controllable in process and relatively low in cost, and the quality and the line ablation rate of a sample is 1.64 milligrams / second and 2.77 micrometers / second when a prepared ablation-resistant material is ablated for 120 seconds at the temperature of 2500 DEG C.

Owner:XIAN AVIATION BRAKE TECH

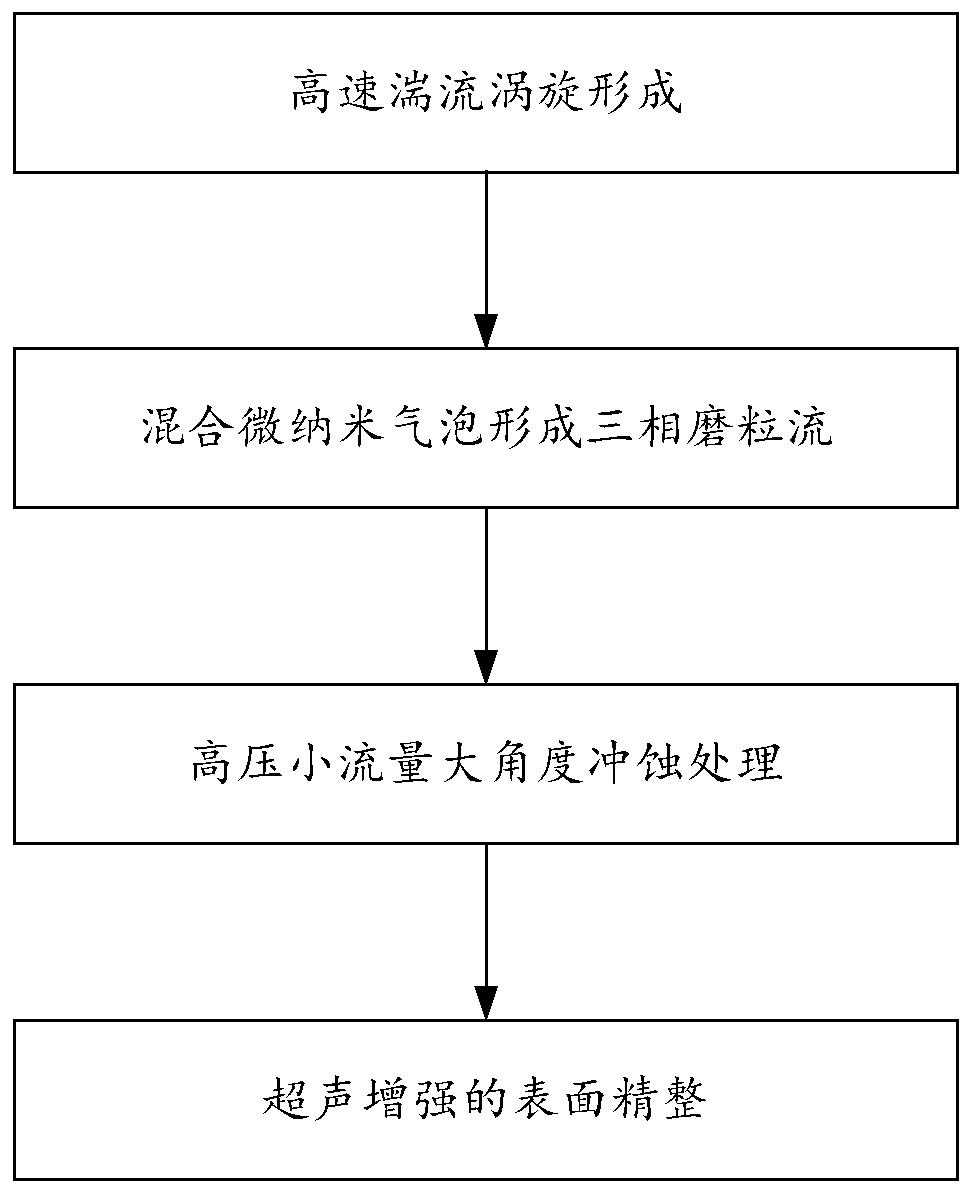

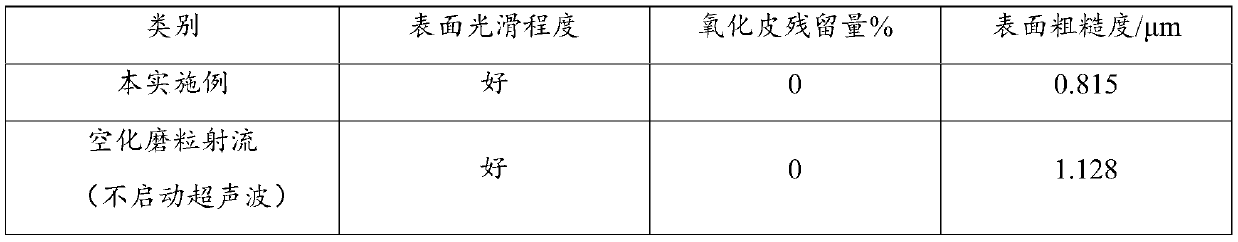

Ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers

ActiveCN110948398AImprove removal efficiencyRealize integrated enveloping processingAbrasive feedersAbrasive machine appurtenancesMicro nanoUltrasonic assisted

The invention provides an ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers. The method comprises the following steps: stirring a solid-liquidtwo-phase mixed fluid to form high-speed turbulence vortex; extracting the solid-liquid two-phase mixed fluid, mixing the solid-liquid two-phase mixed fluid with micro-nano bubbles to form a high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow; spraying the high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow to a workpiece in a tank body for staged surface treatment; meanwhile, emitting ultrasonic waves by an ultrasonic device configured below the workpiece to form an ultrasonic cavitation effect, and forming a negative fluctuation environment with positive and negative pressure alternating rapidly in the high-speed fluid in the tank body to cause expansion and compression of micro-nano bubbles in the high-speed fluid. Under the comprehensive action of turbulence, jet, cavitaiton and ultrasonic waves, a manner of combining cavitation abrasive grain jet and turbulence integrated surrounding type processing and ultrasonic enhancement isadopted, synchronous stripping of different in-situ defects of oxide scale and derivative and chain stripping of new defect points can be realized, the removal efficiency is high, and the processinguniformity is good.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

New-generation information technology machining device capable of achieving rapid clamping, automatic clamping, perforating and cleaning

InactiveCN111590681ARealize the clamping effectEasy to handleMetal working apparatusMachiningIndustrial engineering

The invention relates to the field of the new-generation information technology, and discloses a new-generation information technology machining device capable of achieving rapid clamping, automatic clamping, perforating and cleaning. The device comprises a machining machine. The right side of the machining machine is movably connected with a feeding belt. A machining belt is movably connected inthe machining machine. A transmission wheel is movably connected in the machining belt. The bottom in the machining machine is movably connected with fixed rails. The left side of the fixed rail on the right side is movably connected with a power rail. A power wheel is movably connected to the bottom in the machining machine. A control pipe is movably connected in the machining machine. A gas inlet pipe starts to input gas into a machining pipe, a locating rod movably connected in a locating pipe is pushed to move upwards to be clamped into a groove of a feeding belt wheel, the feeding belt isprevented from continuing to transport circuit board raw materials into the machining machine, and therefore the effects of automatic transporting and raw material clamping are achieved, and meanwhile it is guaranteed that no raw material continues to be fed in while machining is carried out.

Owner:郭琦

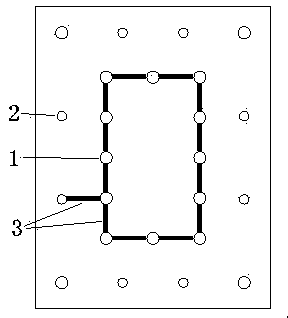

Blind rivet arrangement and joint

Blind rivet arrangement (10) for producing a blind rivet joint (64), said blind rivet arrangement having a rivet body (12) and having a mandrel (14), wherein the rivet body (12) comprises a rivet head (20), a rivet shank (26) and a continuous rivet bore (30), wherein the mandrel (14) comprises a mandrel head (32) and a mandrel shank (36) which is inserted in the rivet bore, wherein the rivet bore (30) comprises a first bore cross section (D1) in the region of an end of the rivet shank (26) which is opposite the rivet head (20), wherein the mandrel shank(36) comprises a first shank cross section (D2) in a first mandrel region (B1) adjacent to the mandrel head (32), and wherein the first shank cross section (D2) is adapted to the first bore cross section (D1). In this case, in a second mandrel region (B2) which projects out of the rivet bore (30), the mandrel shank (36) comprises a second shank cross section (D3) which is smaller than the first shank cross section (D2).

Owner:NEWFREY

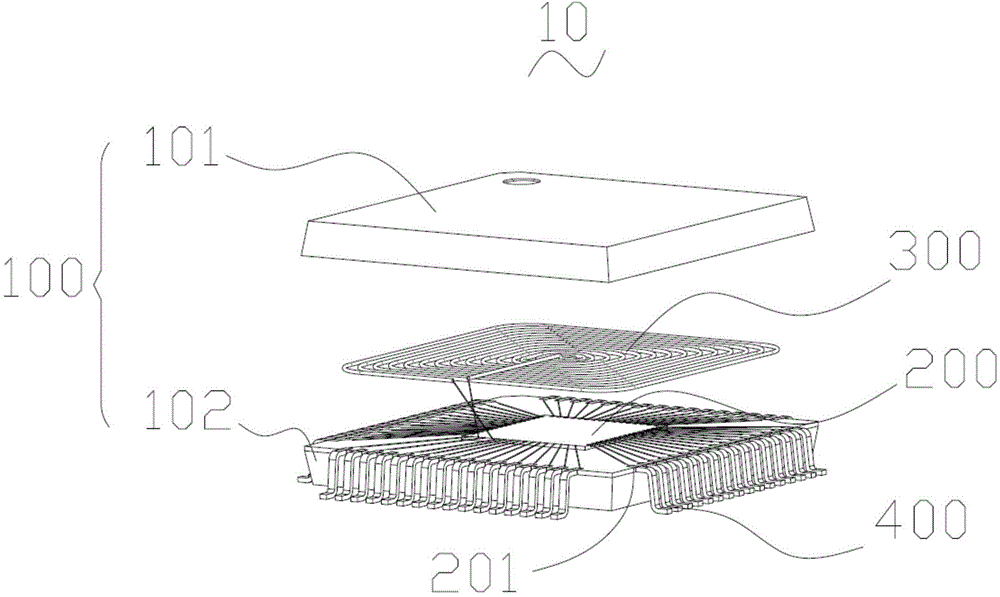

Wireless charging device

ActiveCN104821641ASimple structureReduce volumeBatteries circuit arrangementsElectric powerFailure rateControl circuit

The invention relates to a wireless charging device, including a packaging shell, a coil and a control circuit. The coil is electrically connected with the control circuit, the coil and the control circuit are packaged in the packaging shell, the control circuit is integrated on a wafer, and the wafer is packaged in the packaging shell. Through integral packaging, the wireless charging device has the characteristics of high integration, simple structure and small volume, the failure rate of the packaged wireless charging device is greatly reduced in a working process, machining of the control circuit is facilitated, and production cost is reduced.

Owner:SHENZHEN TITAN MICRO ELECTRONICS

Small and medium-sized traditional Chinese medicine drying assembly, drying equipment and drying method

ActiveCN113028758AReduce moisture contentProcess controllableDrying gas arrangementsDrying solid materialsMedicinal herbsProcess engineering

The invention discloses a small and medium-sized traditional Chinese medicine drying assembly, drying equipment and a drying method. The small and medium-sized traditional Chinese medicine drying assembly comprises a drying bin which is a drying tank capable of being sealed; the drying tank is used for accommodating medicinal materials and forming a drying space; the drying tank comprises a support, a tank body, a protective shell, an electric heating part, a connector, a ventilation plug, an air inlet pipe and an exhaust pipe; the tank body comprises a sealing cover and a containing part, and the sealing cover is detachably connected with the containing part in a sealed manner; the protective shell is fixed to the bottom face of the inner side of the sealing cover or the containing part and used for preventing the medicinal materials from making direct contact with the electric heating part. the electric heating part is an electric heating rod or an electric heating wire and is fixed into the protective shell; the connector is used for positioning with the support and is used as a channel for gas to enter and exit from the tank body; the connector is hollow, and the two ends of the connector are open; an air pump is further included; and an air treatment tank is further included and used for cooling air in the tank body and discharging condensate water for later use again. The assembly, the equipment and the method can improve the drying rate, and the process is controllable.

Owner:哈尔滨松山堂药业有限公司

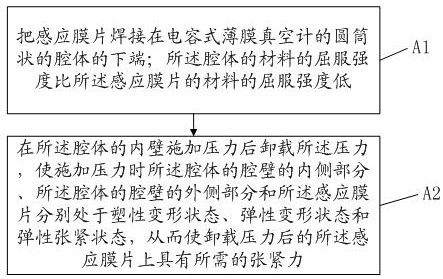

Method for controlling post-welding tensile force of induction diaphragm of capacitive film vacuum gauge

ActiveCN113739989AProcess controllableReliable workmanshipVacuum gaugesMachiningUltimate tensile strength

The invention belongs to the technical field of machining and discloses a method for controlling post-welding tensile force of a induction diaphragm of a capacitive film vacuum gauge. The method comprises the following steps that an induction diaphragm is welding at a lower end of a cylindrical cavity of the capacitive film vacuum gauge; the yield strength of the material of the cavity is lower than that of the material of the induction diaphragm; after pressure is applied to the inner wall of the cavity, the pressure is unloaded, so the inner side part of the cavity wall of the cavity, the outer side part of the cavity wall of the cavity and the induction diaphragm are respectively in a plastic deformation state, an elastic deformation state and an elastic tensioning state when the pressure is applied, and the induction diaphragm after the pressure is unloaded has required tensioning force; the post-welding tensile force control method for the induction diaphragm of the capacitive film vacuum gauge is beneficial to realizing accurate control on the tensile force after the induction diaphragm is welded.

Owner:JIHUA LAB

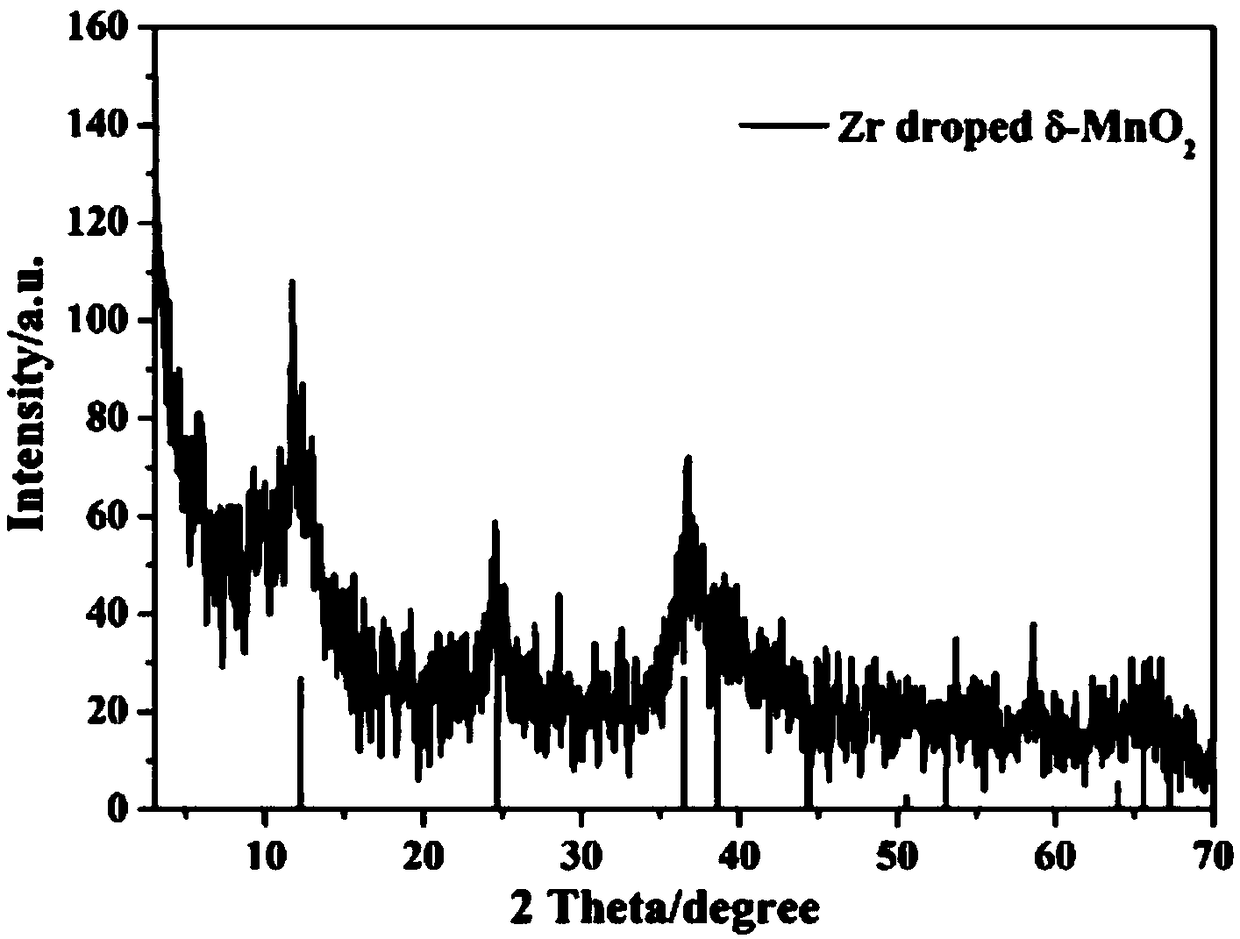

A method for preparing Zr4+-doped delta-MnO2 nanoporous material

InactiveCN109148849ASimple preparation processProcess controllableMaterial nanotechnologyCell electrodesHigh pressureEthanol

A method for preparing a Zr4+-doped delta-MnO2 nanoporous material is provided. The concentration of MnSO4*H2O is 0.002-0.008 mol / L, the concentration ratio of MnSO4*H2O to KMnO4 is 1: 2-1:10, the total volume of the mixed solution is 30-40mL, stirring for 5 min to make that mixture homogeneous; 0.0033-0.132 mmol of Zr(NO3)2*5H2O is added to the mixed solution and stirred for 5 min to make the mixture homogeneous; the obtained mixed solution is transferred to a high-pressure reaction kettle; After reaction in the reaction kettle, cooling, washing the obtained product with distilled water to neutrality, then washing with absolute ethanol, and finally drying in an oven to obtain the Zr4+-doped delta-MnO2 nanoporous material. Zr4+-doped delta-MnO2 nanosheets are prepared by a simple hydrothermal method, the preparation process is simple and the process is controllable. In addition, the product has complete crystal phase, high purity and good dispersibility.

Owner:SHAANXI UNIV OF SCI & TECH

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1159130CGuaranteed requirements for fatigue strengthEnsure proper heatingSoldering apparatusLaser beam welding apparatusMetallic materialsOptoelectronics

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

Starch foaming packaging inner foamed component and preparation method thereof

The invention discloses a starch foaming packaging inner foamed component which is prepared from the following raw materials in parts by mass: 30-50 parts of starch, 30-50 parts of PVA, 5-8 parts of glycerol, 3-6 parts of polyethylene glycol and 1-4 parts of a foaming agent. According to the preparation method, the starch, a plasticizer and the adhesive PVA are introduced, a fully-degradable starch composite material suitable for production of the special-shaped packaging inner foamed component is prepared through a chemical foaming method, the foaming molding process is adopted, and the density of the prepared foamed inner foamed component is 0.6-0.9 g / cm < 3 >. The foaming conditions are mild, the treatment process is controllable, and no adverse effect is caused to the environment.

Owner:HUNAN UNIV OF TECH

Hose boxing mechanism and method

PendingCN110271700AProcess controllableGood effectIndividual articlesEngineeringMechanical engineering

The embodiment of the invention discloses a hose boxing mechanism. The boxing mechanism comprises a rack, a pre-boxing mechanism, a material pushing mechanism, and a mechanism for pushing hoses into a box, wherein a workbench is arranged on the rack, and the plurality of hoses which are continuously placed are arranged on the workbench; the pre-boxing mechanism is positioned on one side of the workbench, and is provided with a cuboid-shaped containing cavity, an opening is formed in the containing cavity in the direction facing the workbench, and the containing cavity can be lifted relative to the workbench; the material pushing mechanism is used for pushing the hoses on the workbench to the containing cavity, and is positioned on the other side of the workbench; and the mechanism for pushing the hoses into the box is positioned at the bottom of the containing cavity and is used for pushing the hoses in the containing cavity into the packaging box at a time. According to the embodiment, the hoses filling the containing cavity can be kept in order by arranging the containing cavity, and the process is controllable; and compared with the prior art where the hoses directly fill the packing box row by row, the hose boxing mechanism is more reliable, the hose boxing mechanism is particularly suitable for the automatic boxing of the hoses with small diameters, and the effect is remarkable.

Owner:ZHONGSHAN CHANGJIAN MEDICINE PACKAGING TECH CO LTD

Future dismantling considered reinforced concrete structure reinforcement method

InactiveCN103790397AProcess controllableLittle environmental disturbanceStrutsBuilding repairsRebarReinforced concrete

The invention provides a future dismantling considered reinforced concrete structure reinforcement method and belongs to the construction technical field. The future dismantling considered reinforced concrete structure reinforcement method specifically comprises the following steps of selecting a plurality of columns which are arranged in a structure to serve as destroy objects; adding a group of steel bars to the selected columns within the range of core area concrete of the selected columns on the basis of normal reinforcement; cutting off the steel bars which are arranged at the positions of the cross sections of the column top and the column bottom located in every column when a building needs to be dismantled; performing insulation treatment and drilling on cut-off surfaces of the steel bars to form a circuit with external power supplies; winding the columns a circle through an iron chain and connecting with an electric pull rod; starting every direct current power supply to enable the steel bars arranged in the columns to rapidly rust; shutting down every power supply and applying lateral tension to every column to enable every column to be destroyed and the structure to be collapsed towards the preset direction. According to the future dismantling considered reinforced concrete structure reinforcement method, the targeted treatment is performed on the building before the building is built so as to bring a great convenience to the dismantling in the future, the implementation process is convenient and feasible, and the economic value is great.

Owner:YUANYI CONSTR TECH SHANGHAI

A special sander for ring parts

ActiveCN111604767BConsistent processingEasy to processDispersed particle filtrationGrinding drivesSanderFixed frame

The invention discloses a special sander for ring parts, which includes a processing table, a main motor is fixed on the upper end of the processing table, a driving disc is fixed on the output shaft of the upper end of the main motor, and two Two telescopic discs and two telescopic cylinders, the inside of the two telescopic discs are equipped with internal processing mechanism, the ends of the two telescopic cylinders away from the driving disc are fixed with laminating plates, and the upper end of the processing table is fixed with a ring The supporting platform and two symmetrically arranged fixed frames, the upper ends of the two fixed frames are rotatably connected with rotating plates. The advantages are: the main motor drives the telescopic disc to rotate, so that the sanding column rotates around the inner wall of the plate, and the sanding motor drives the sanding column to rotate, so that the sanding column itself rotates to complete the processing, and the sanding column rotates around the inner circle of the plate to make the plate The processing degree of each position of the inner ring is consistent, so that the processing effect of the inner ring of the plate is better, and the occurrence of uneven processing is avoided.

Owner:宁波索思机械设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com