Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "High electrode strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative Electrode Material for Lithium Battery, and Lithium Battery

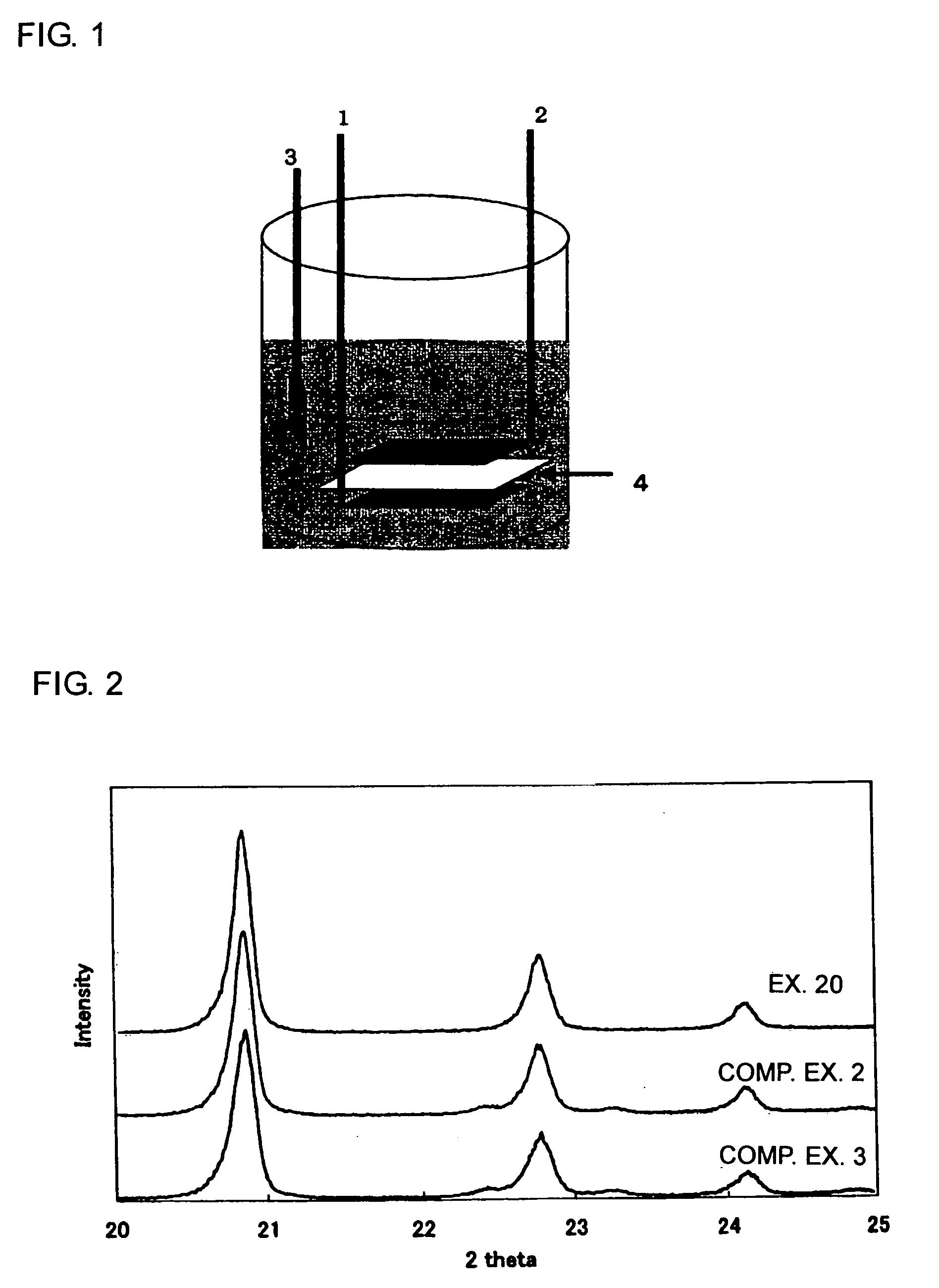

InactiveUS20070275302A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery characterized by comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickner such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:SHOWA DENKO KK +1

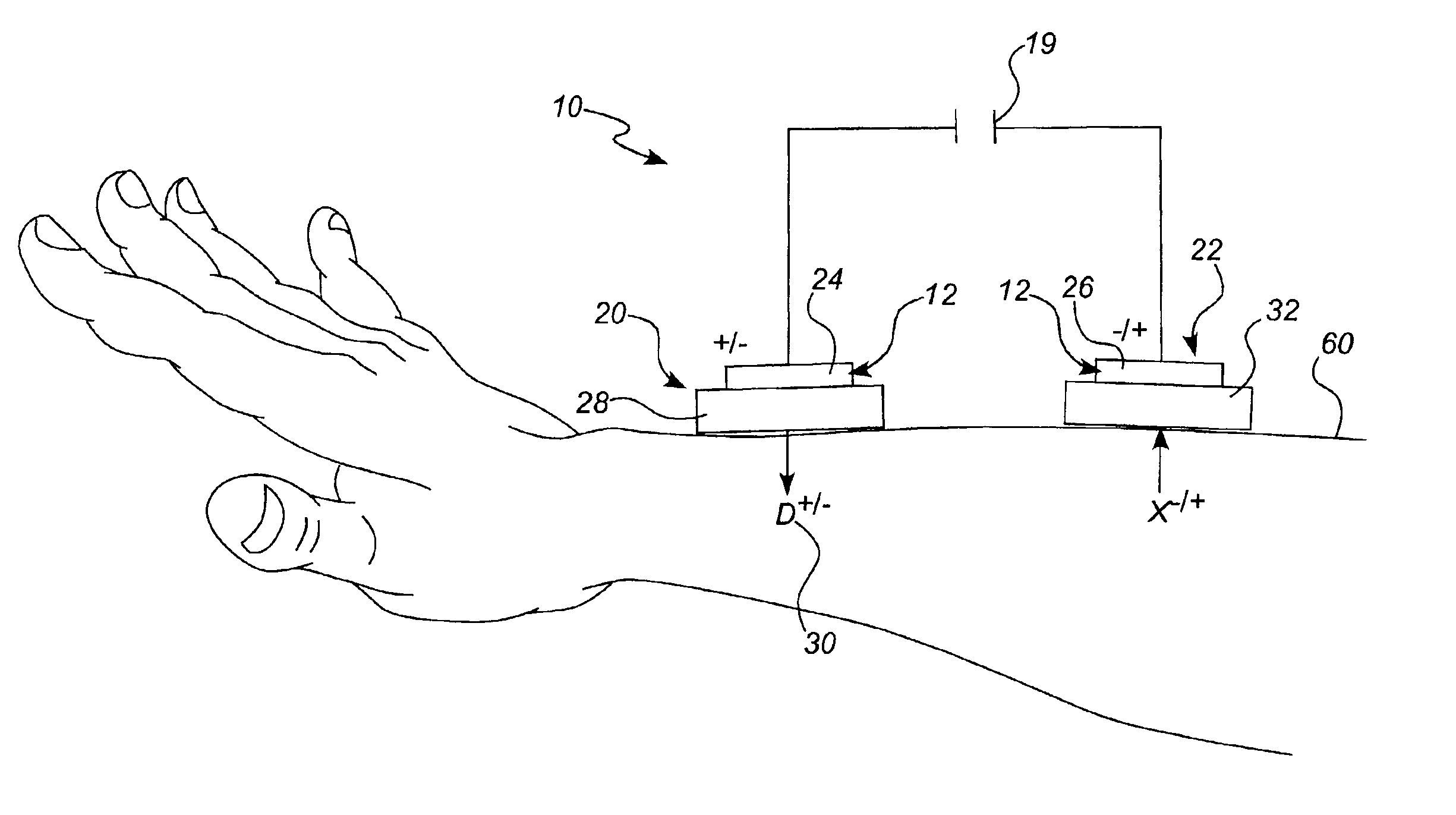

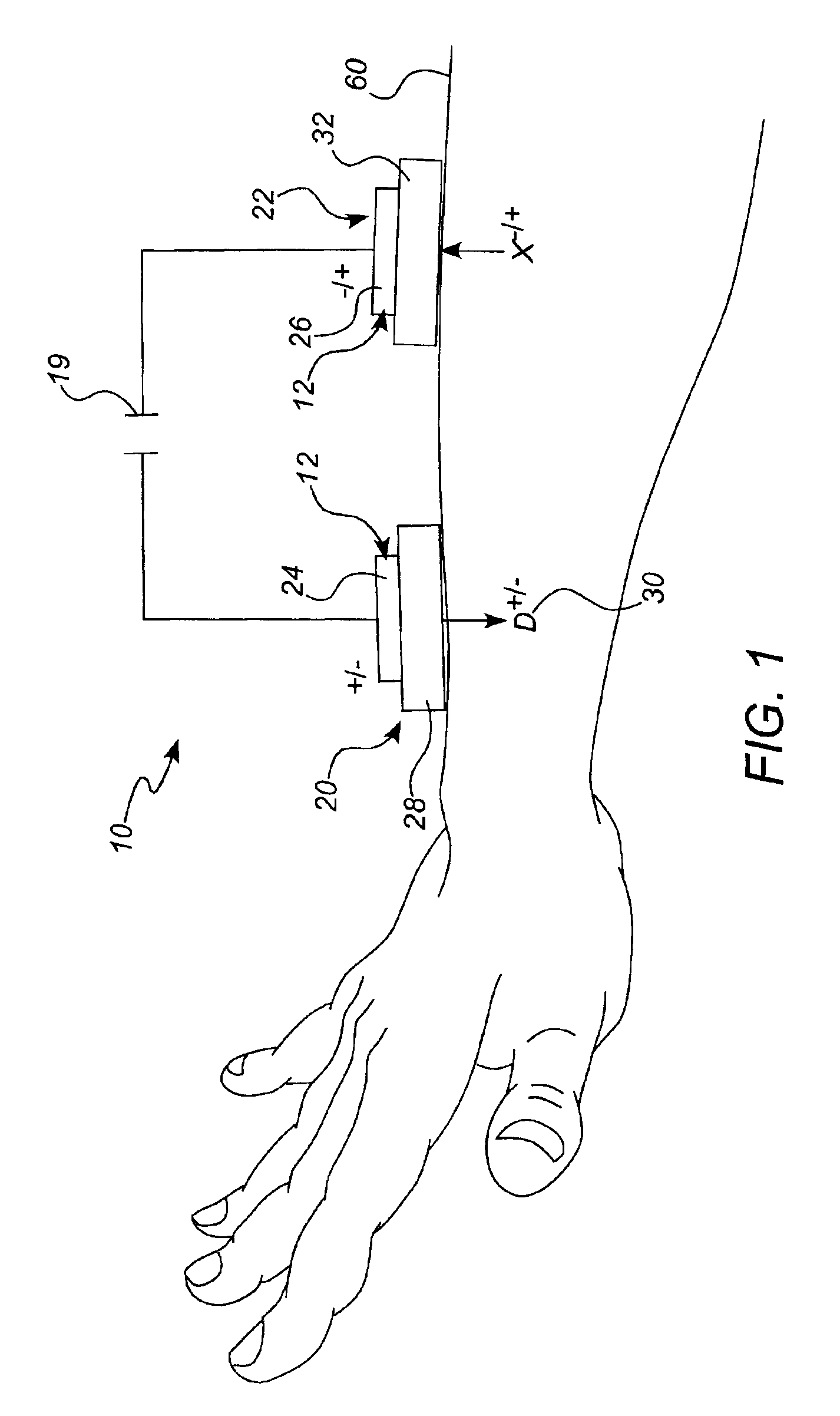

Iontophoretic drug delivery device and reservoir and method of making same

InactiveUS6862473B2Minimize currentReduce availabilityElectrotherapyPharmaceutical delivery mechanismDrugDrug delivery

A reservoir electrode assembly of the present invention for an iontophoretic drug delivery device includes an electrode and a hydrophilic reservoir situated in electrically conductive relation to the electrode. The hydrophilic reservoir is formed from a bibulous hydrophilic cross-linked polymeric material having a first surface and a second surface that is adhesively adherent to the electrode. The first surface of the polymeric material is releasably adhesively adherent when applied to an area of a patient's skin. The polymeric material has a cohesive strength forms an adhesive bond with a bond strength between the second surface of the polymeric material to the electrode that is greater than the cohesive strength of the polymeric material. Additionally, an adhesive bond strength of the first surface of the polymeric material to the applied area of the patient is less than the cohesive strength of the polymeric material so that upon removal of the reservoir assembly of the invention from the applied area of the patient, substantially no polymeric material remains on the applied area and the hydrophilic reservoir remains substantially intact and adhesively adherent to the electrode.

Owner:LINCOLN FAIR LAWN ASSOC

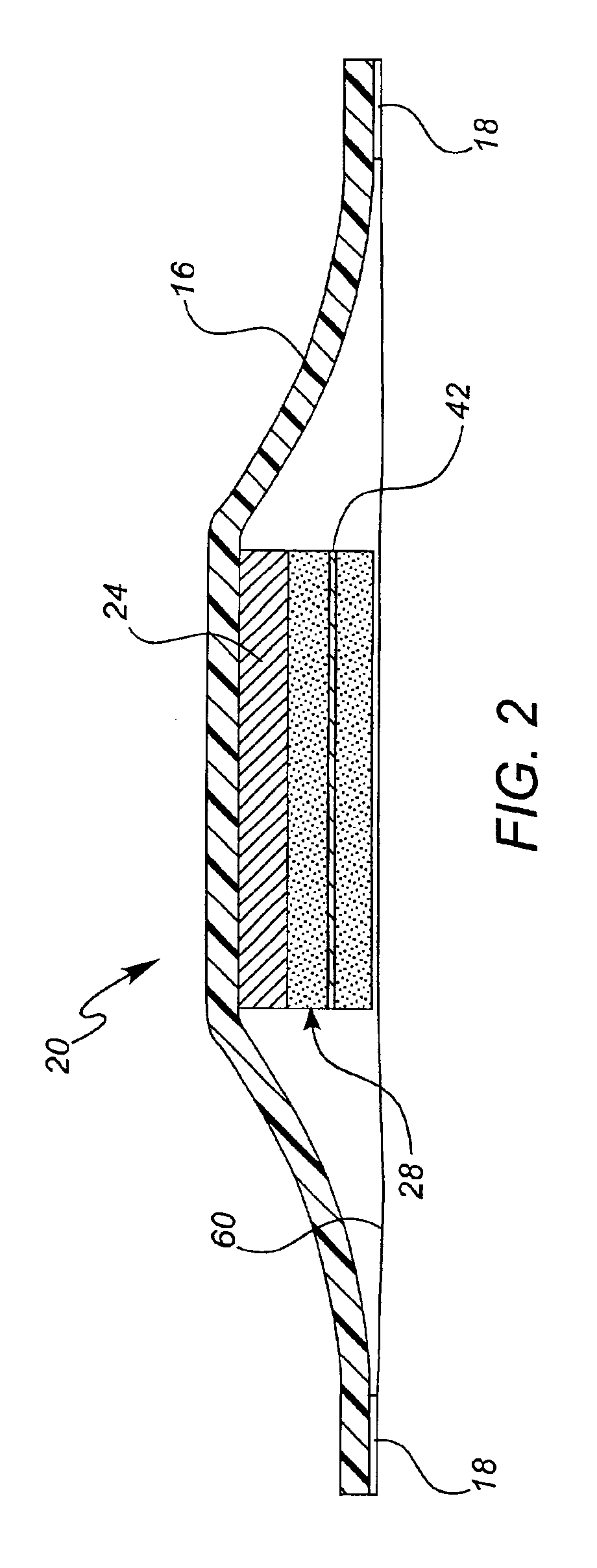

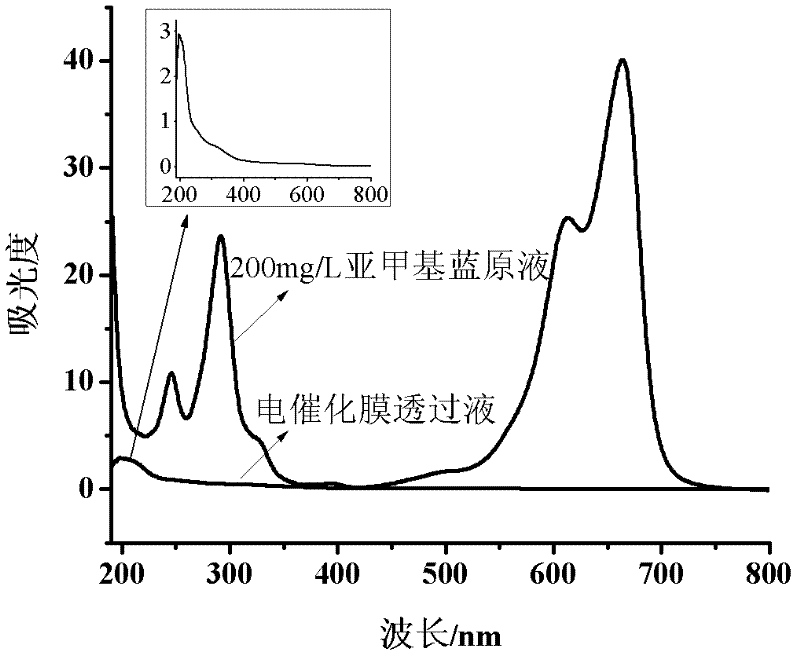

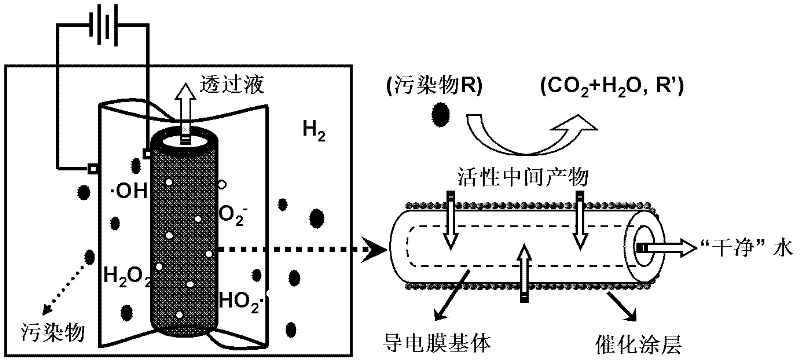

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

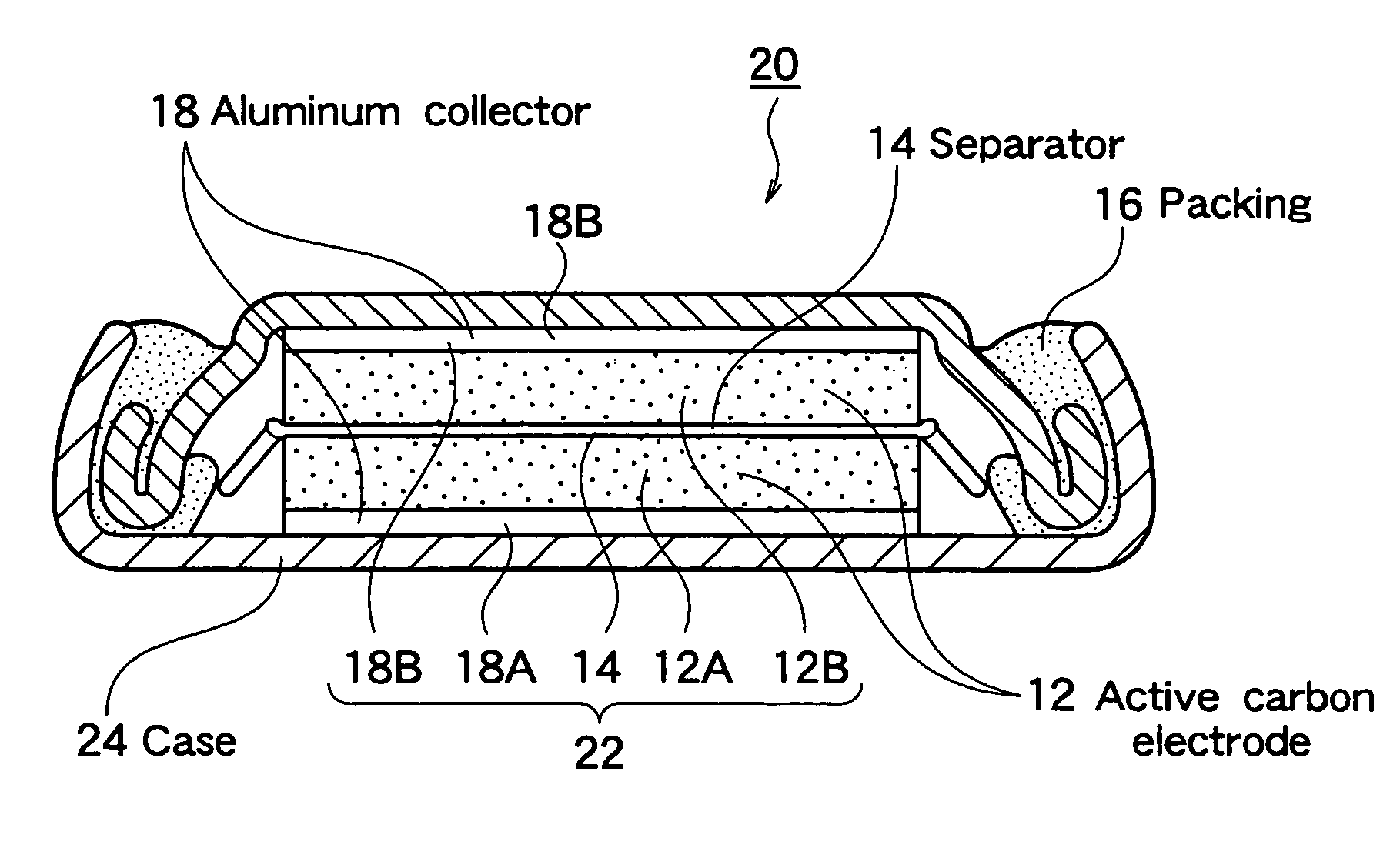

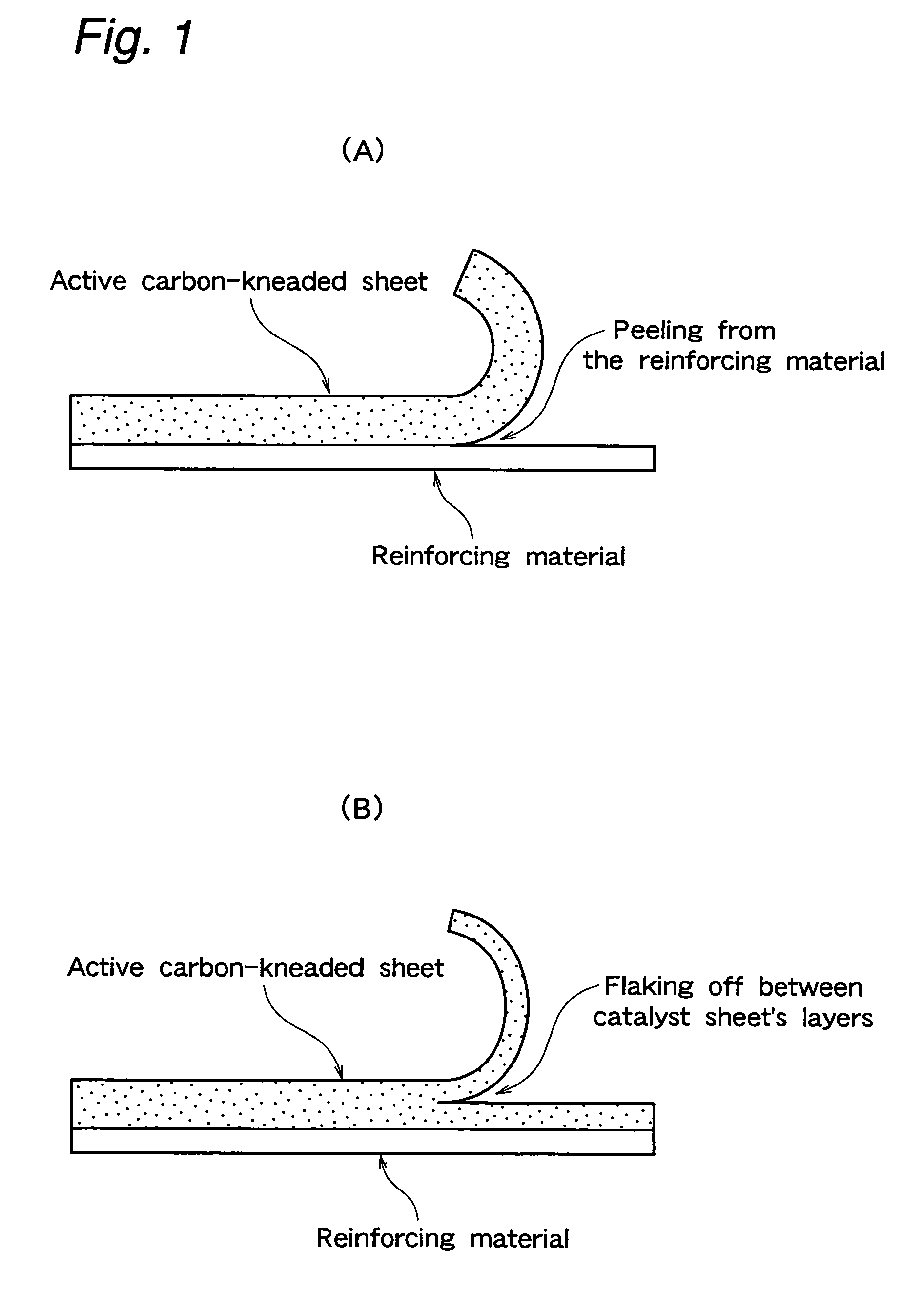

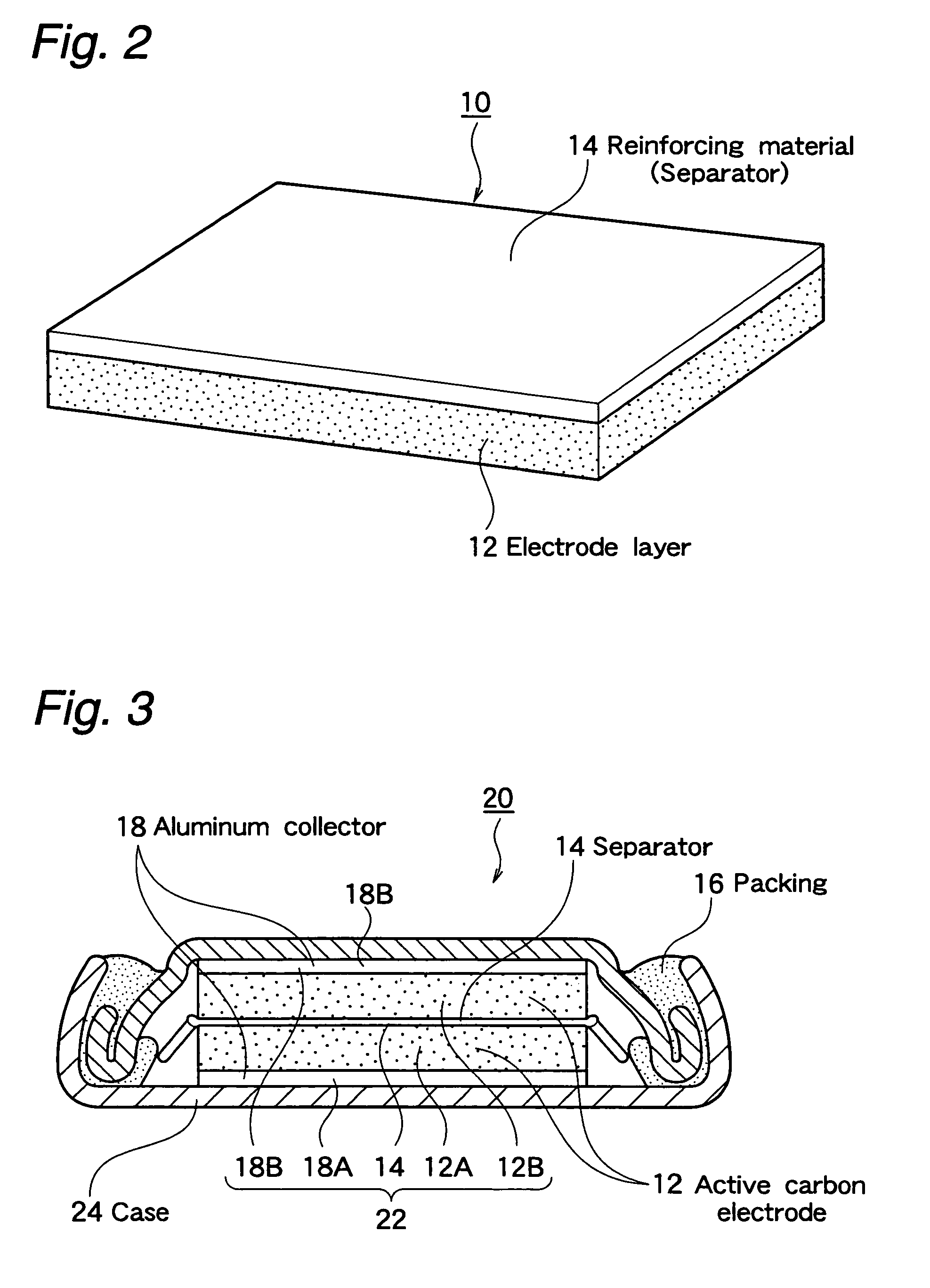

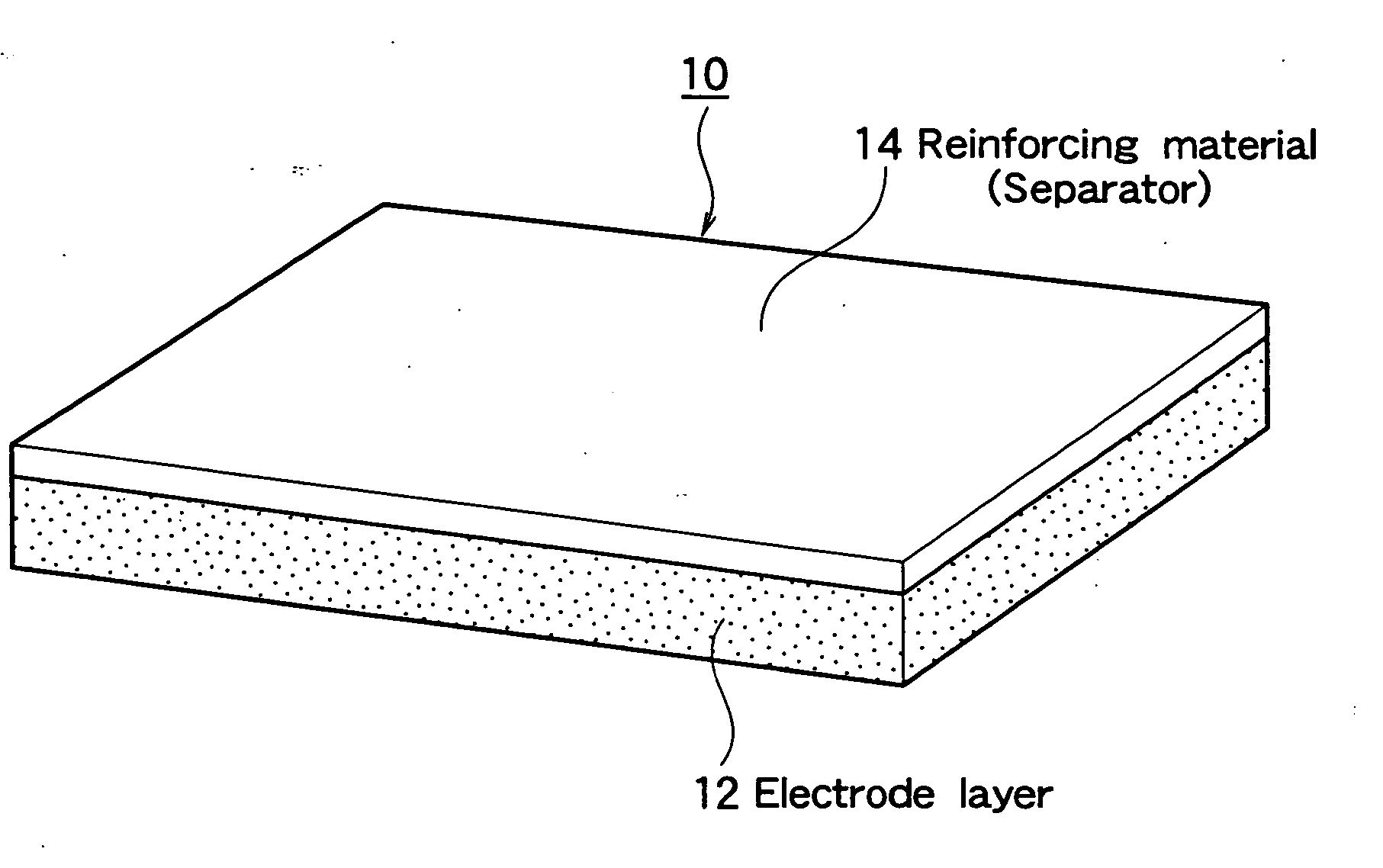

Functional sheet having reinforcing material

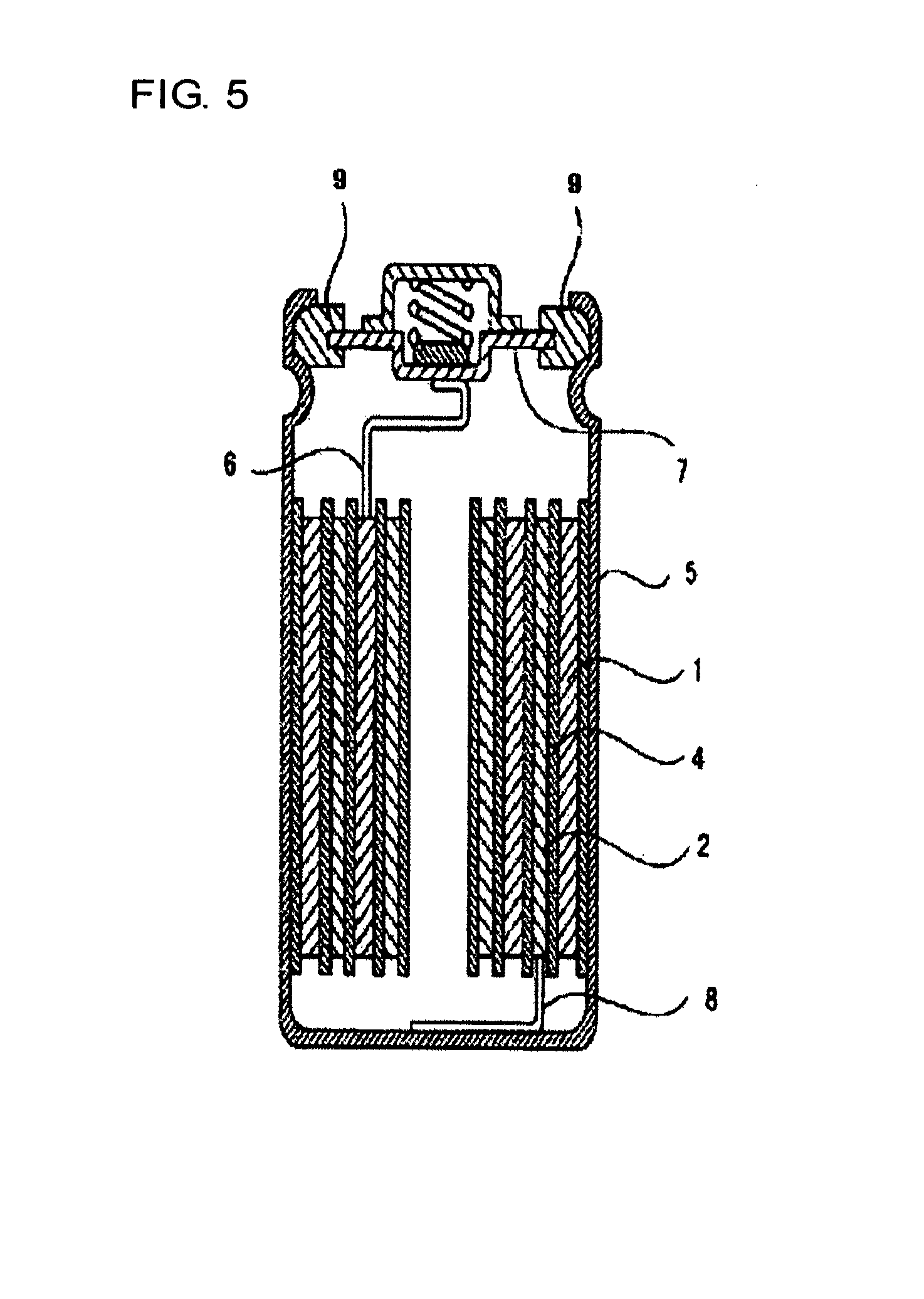

InactiveUS7236348B2High strengthImprove functionalityHybrid capacitor separatorsHybrid capacitor electrodesPolymer resinInternal resistance

A reinforcing material-having functional sheet of a sheet-like functional material including a functional powder and a binder resin and, laminated thereon, a reinforcing sheet comprising a woven fabric or a non-woven fabric, which are bonded, wherein the basis weight of the reinforcing sheet, the fiber diameter of the fiber constituting the reinforcing sheet and the functional sheet thickness are in specific ranges. A sheet-like electrode for electric double layer capacitors, which electrode comprises a sheet-like electrode of carbon fine powder and a fluorine-containing polymer resin and, laminated thereon, the reinforcing sheet, and an electric double layer capacitor having this electrode. The functional sheet has strength and no elimination of the functional material powder, and also efficiently exhibits high functional properties. The sheet electrode can efficiently prepare electric double layer capacitors having strength, remarkably low internal resistance, slight lowering of charging and discharging capabilities, excellent durability and long lifetime.

Owner:VALQUA LTD

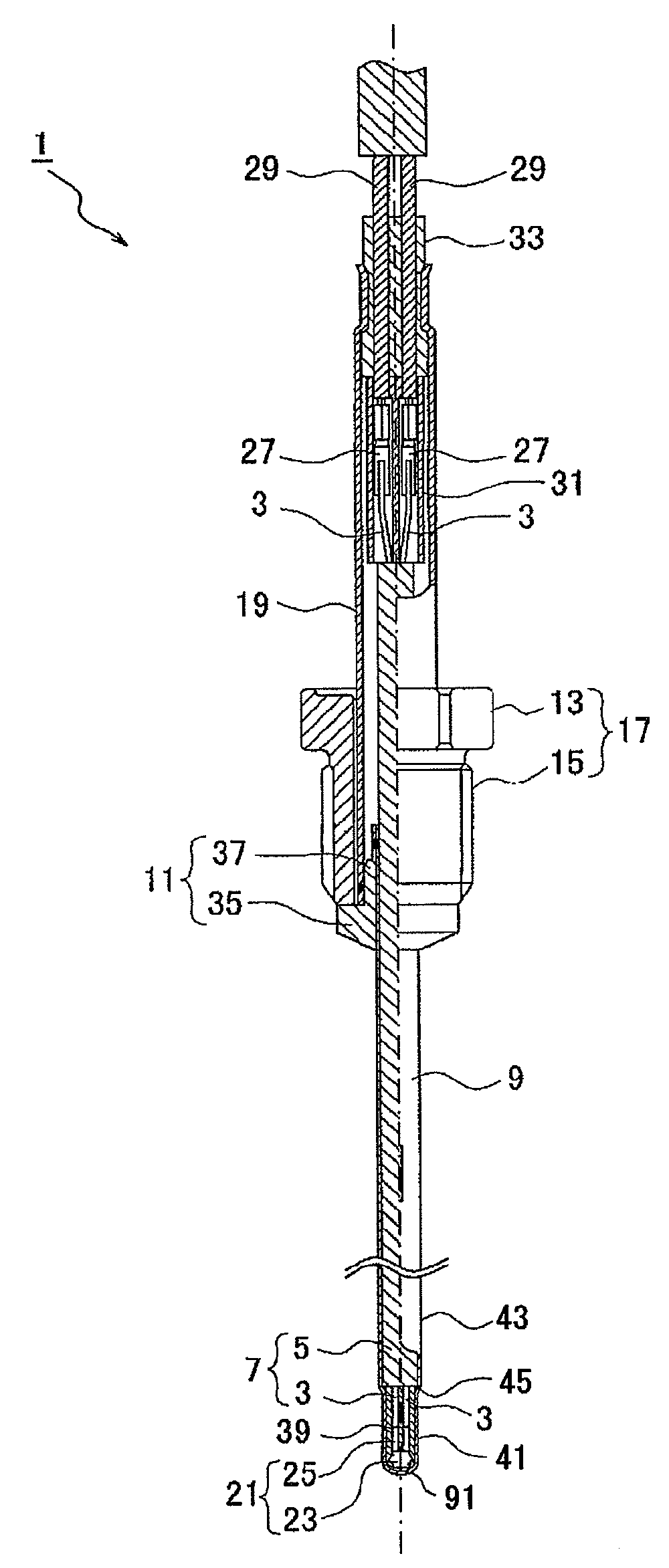

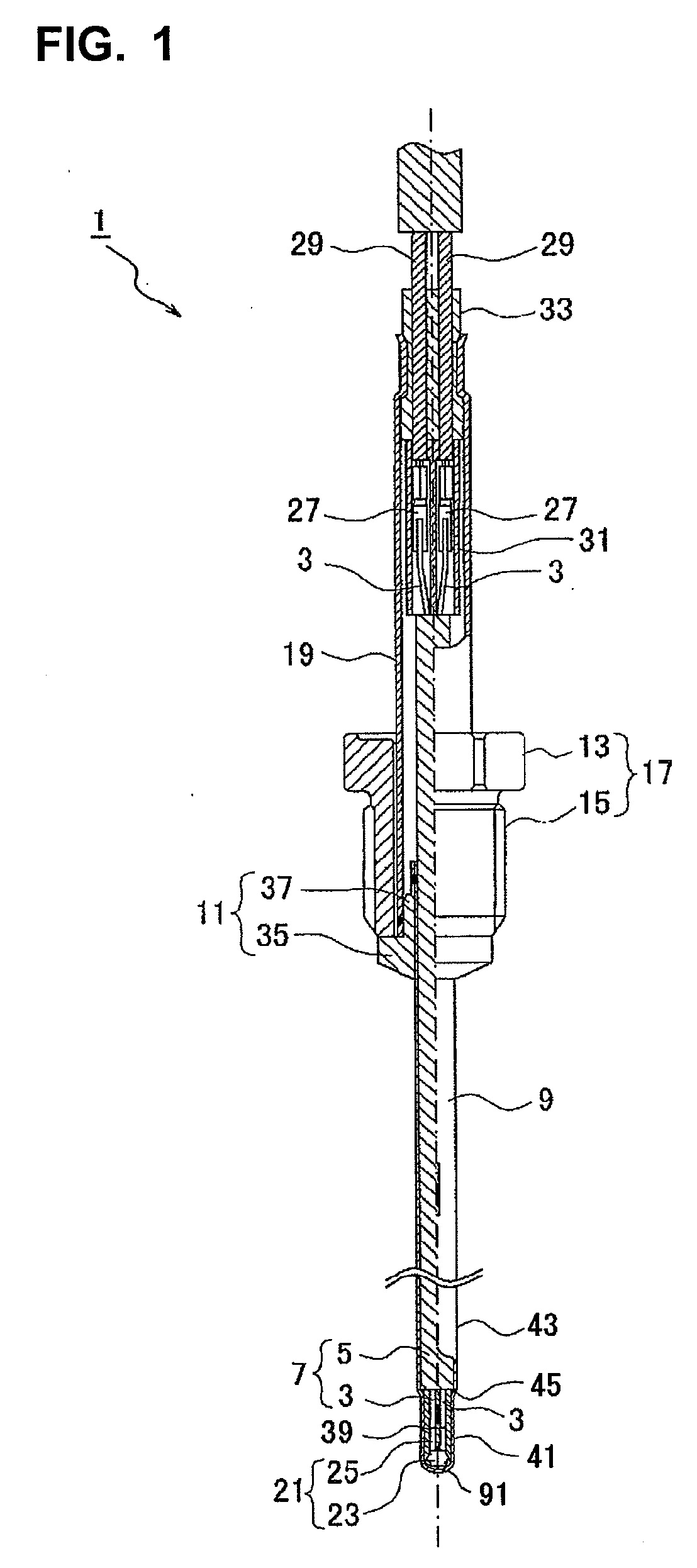

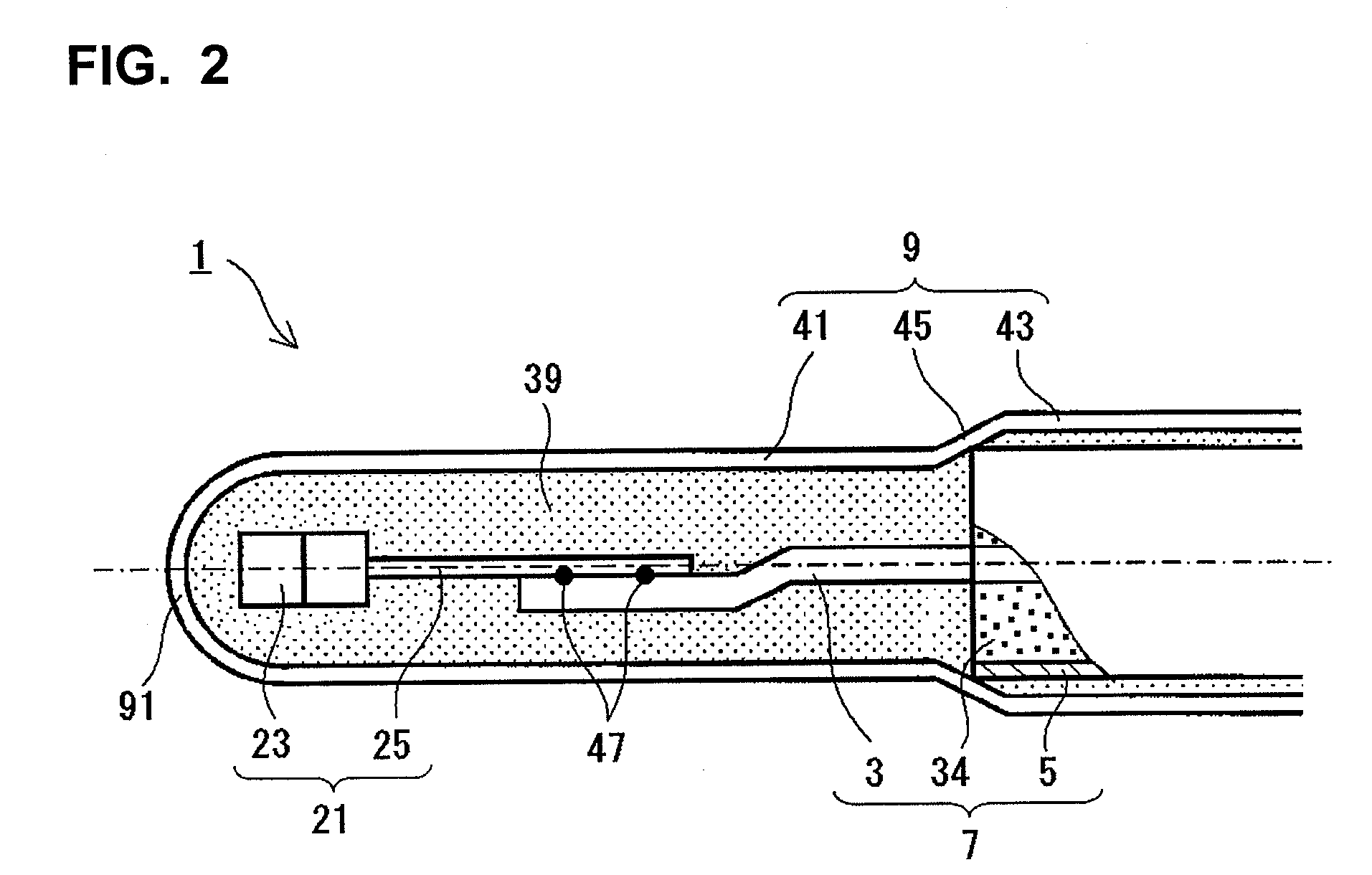

Temperature sensor

ActiveUS20090323765A1Improve solderabilityImprove welding strengthThermometer detailsThermometers using electric/magnetic elementsPlatinumStrontium

In a temperature sensor (1), a pair of electrode wires (25) of a thermistor element (21) are formed of a material prepared by adding strontium to platinum or a platinum alloy and without addition of zirconia or a like oxide. Rear end portions of the electrode wires (25) formed of the above-mentioned material and front end portions of sheath core wires (3) are laser-welded to one another in an overlapping condition.

Owner:NGK SPARK PLUG CO LTD

Reinforcing material-carrying functional sheet

ActiveUS20060039100A1Good mass production propertySufficient strengthHybrid capacitor separatorsHybrid capacitor electrodesWoven fabricElectric double-layer capacitor

A reinforcing material-having functional sheet which comprises a sheet-like functional material comprising a functional powder and a binder resin and, laminated thereon, a reinforcing sheet comprising a woven fabric or a non-woven fabric, which are bonded, wherein the basis weight of the reinforcing sheet, the fiber diameter of the fiber constituting the reinforcing sheet and the functional sheet thickness are in specific ranges. A sheet-like electrode for electric double layer capacitors which electrode comprises a sheet-like electrode of carbon fine powder and a fluorine-containing polymer resin and, laminated thereon, the reinforcing sheet, and an electric double layer capacitor having this electrode. The functional sheet has strength and no elimination of the functional material powder, and also efficiently exhibits high functional properties. The sheet electrode can efficiently prepare electric double layer capacitors having strength, remarkably low internal resistance, slight lowering of charging and discharging capabilities, excellent durability and long lifetime.

Owner:VALQUA LTD

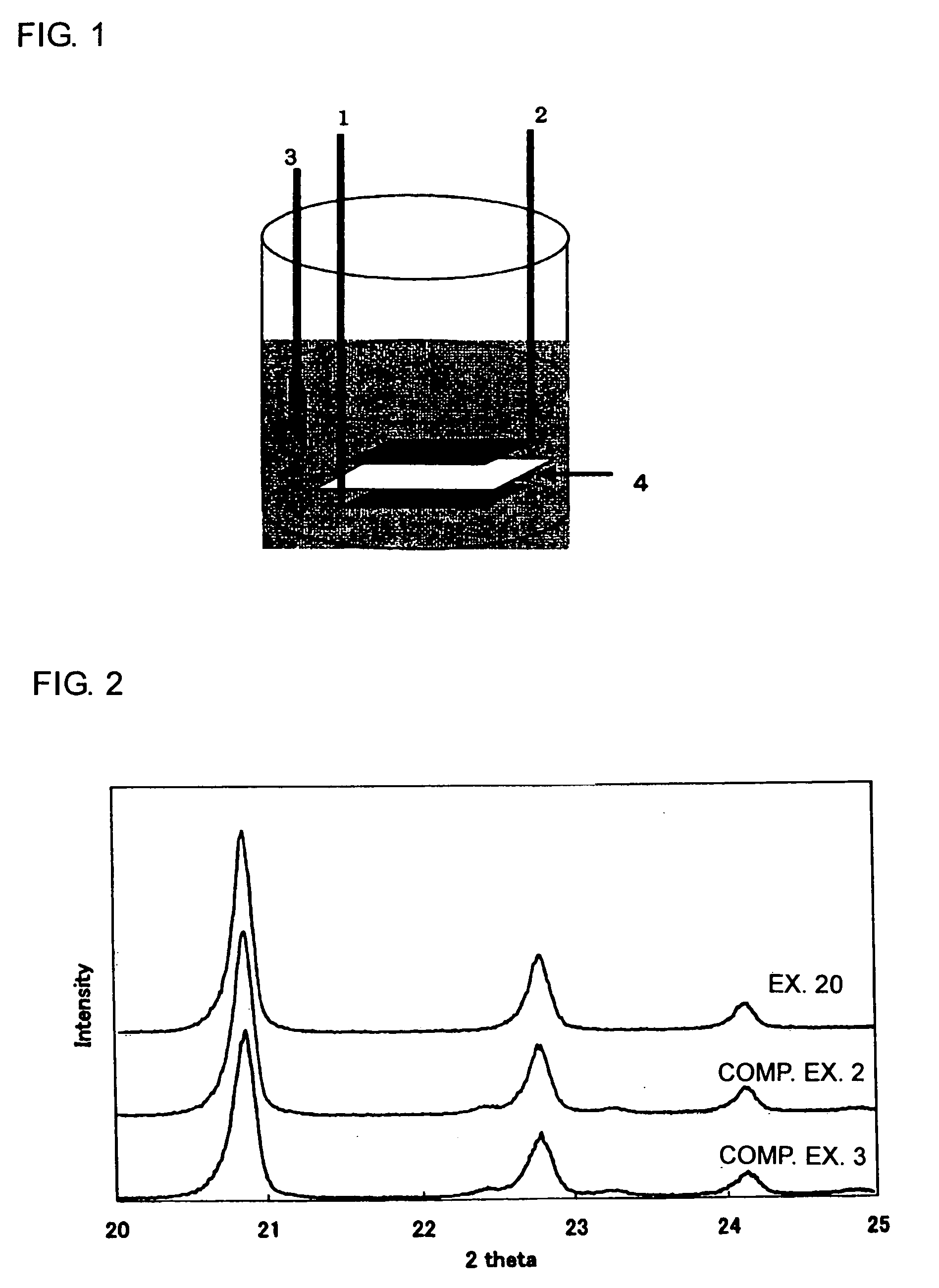

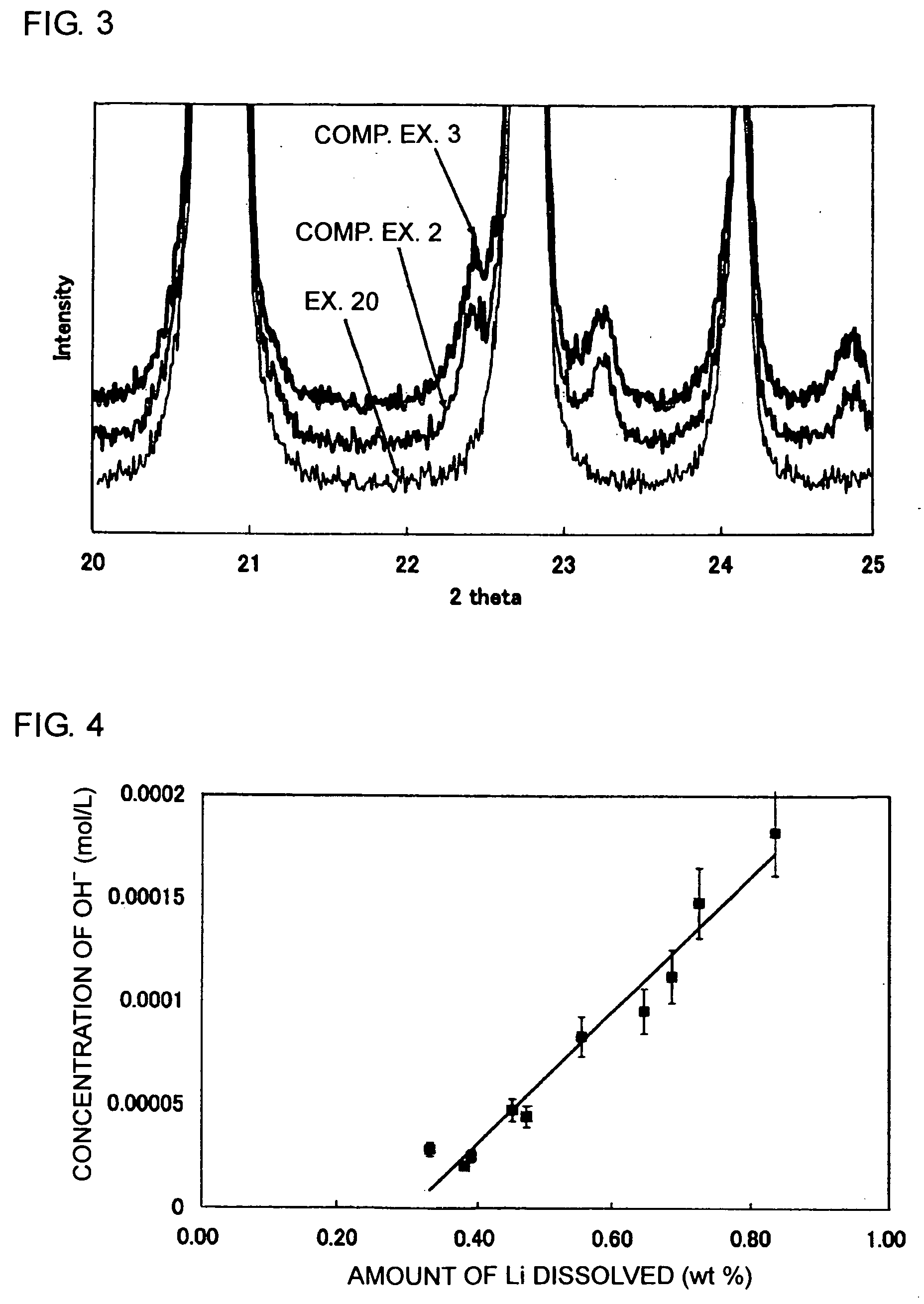

Method of producing active material for lithium secondary battery, method of producing electrode for lithium secondary battery, method of producing lithium secondary battery, and method of monitoring quality of active material for lithium secondary battery

ActiveUS20080222881A1High sensitivityQuality improvementOptical radiation measurementParticle separator tubesLithiumOxyanion

A method of producing an active material for a lithium secondary battery, by which impurities causing problems in synthesizing an active material for a lithium secondary battery, including a lithium transition metal oxyanion compound are removed efficiently and enhancement of an energy density is realized, is provided. By cleaning the active material for a lithium secondary battery, including a lithium transition metal oxyanion compound, with a pH buffer solution, for example, it is possible to efficiently remove just only impurities such as Li3PO4 or Li2CO3, or a substance, other than LiFePO4, in which the valence of Fe is bivalent such as FeSO4, FeO or Fe3(PO4)2 without dissolving Fe of LiFePO4.

Owner:SANYO ELECTRIC CO LTD

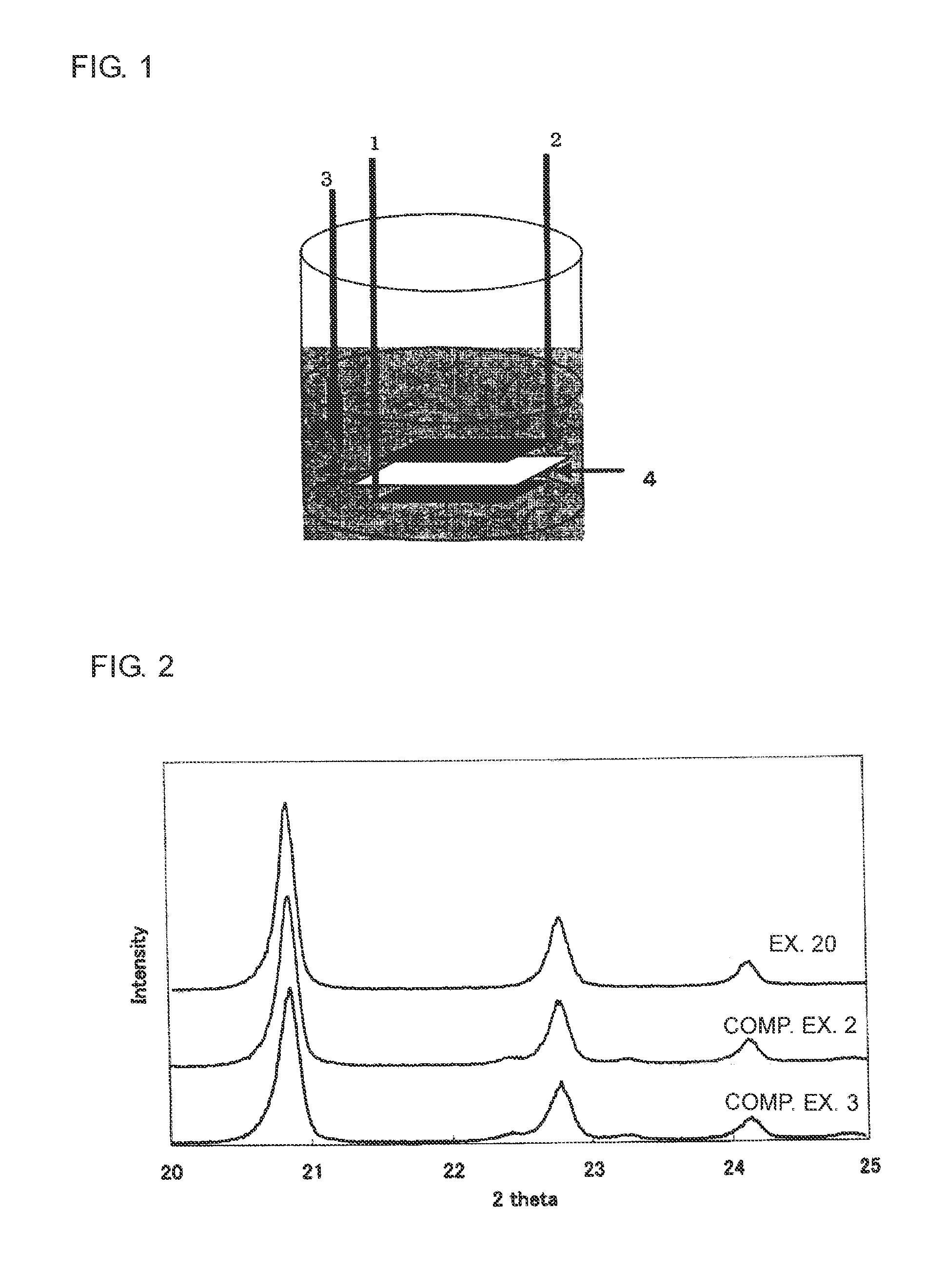

Manufacturing method for all-solid-state battery and all-solid-state battery

InactiveUS20150349379A1High electrode strengthHigh strengthSolid electrolytesLarge-sized flat cells/batteriesAll solid stateEngineering

A manufacturing method for an all-solid-state battery including a positive electrode layer, a negative electrode layer, a solid electrolyte layer, a positive electrode current collector layer, and a negative electrode current collector layer is provided. At least one of the positive and negative electrode layers is an electrode layer containing a sulfide-based solid electrolyte and having a first main surface and a second main surface. The manufacturing method includes: shielding at least a central portion of the first main surface and at least a central portion of the second main surface from an ambient atmosphere; and exposing an outer peripheral portion of the electrode layer to an atmosphere having a dew-point temperature of −30° C. or higher, with at least the central portion of the first main surface and at least the central portion of the second main surface shielded from the atmosphere.

Owner:TOYOTA JIDOSHA KK

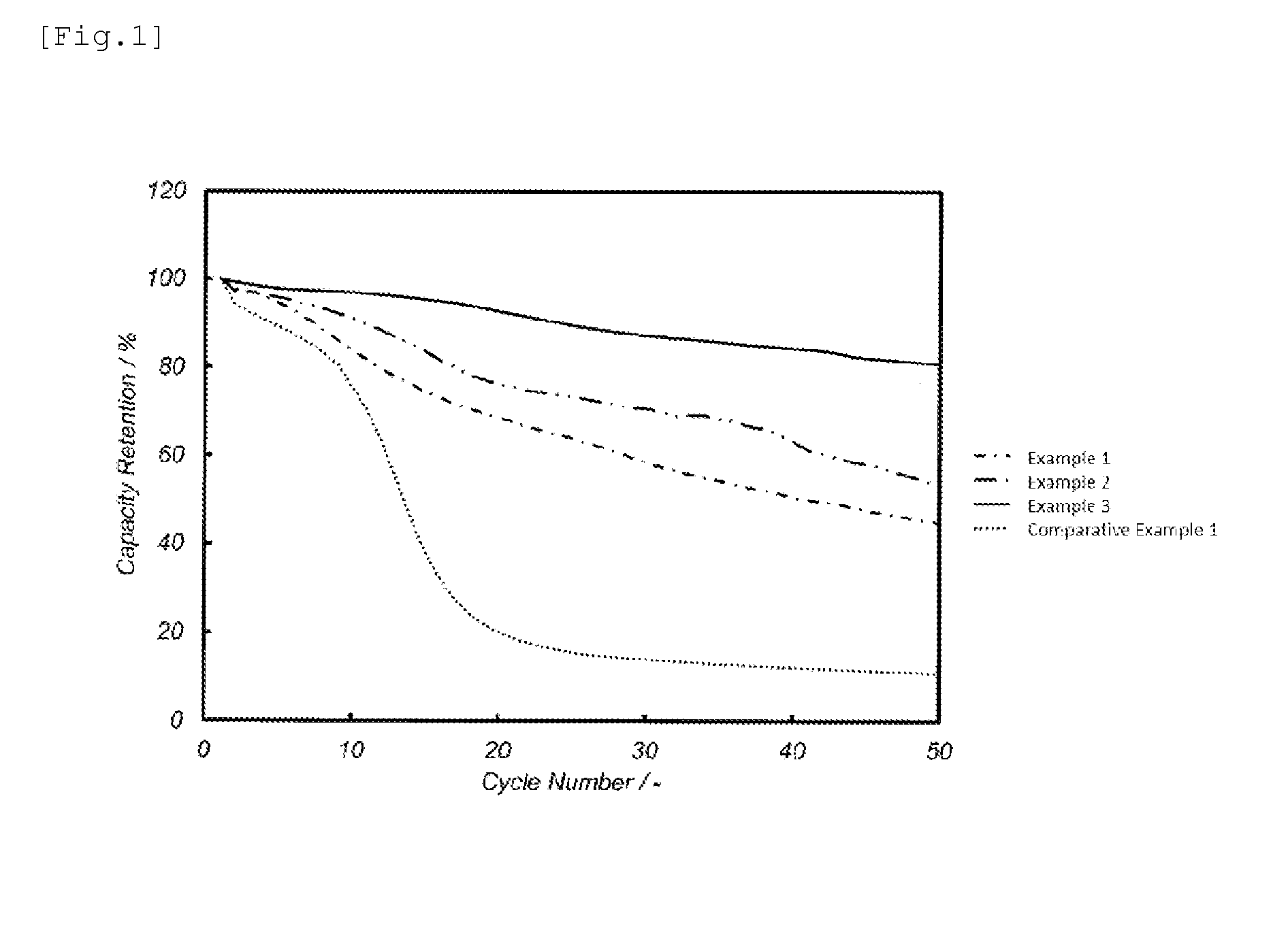

A modified lithium-ion battery cathode material, cathode and battery

ActiveCN1670991AImprove performanceImprove dynamic performanceActive material electrodesSecondary cellsFiberCarbon fibers

A modified negative electrode material, negative electrode and cell of lithium ion cell, the negative electrode material made of modified quasi one dimension nano carbon material with average diameter of 1nm-500nm which is 0.1 %-50 % of total weight of negative electrode material selected from natural graphite, intermediate phase char microsphere, amorphous carbon, hard carbon, pyrolytic carbon, petroleum coke, asphalt base carbon fiber etc carbon material, and one or plurality of kinds of stannum base and silicon base material. Said invention raises the service life, charge capacity and discharge rate and effectively improves the performance of lithium ion cell.

Owner:四川金泰能新材料有限公司

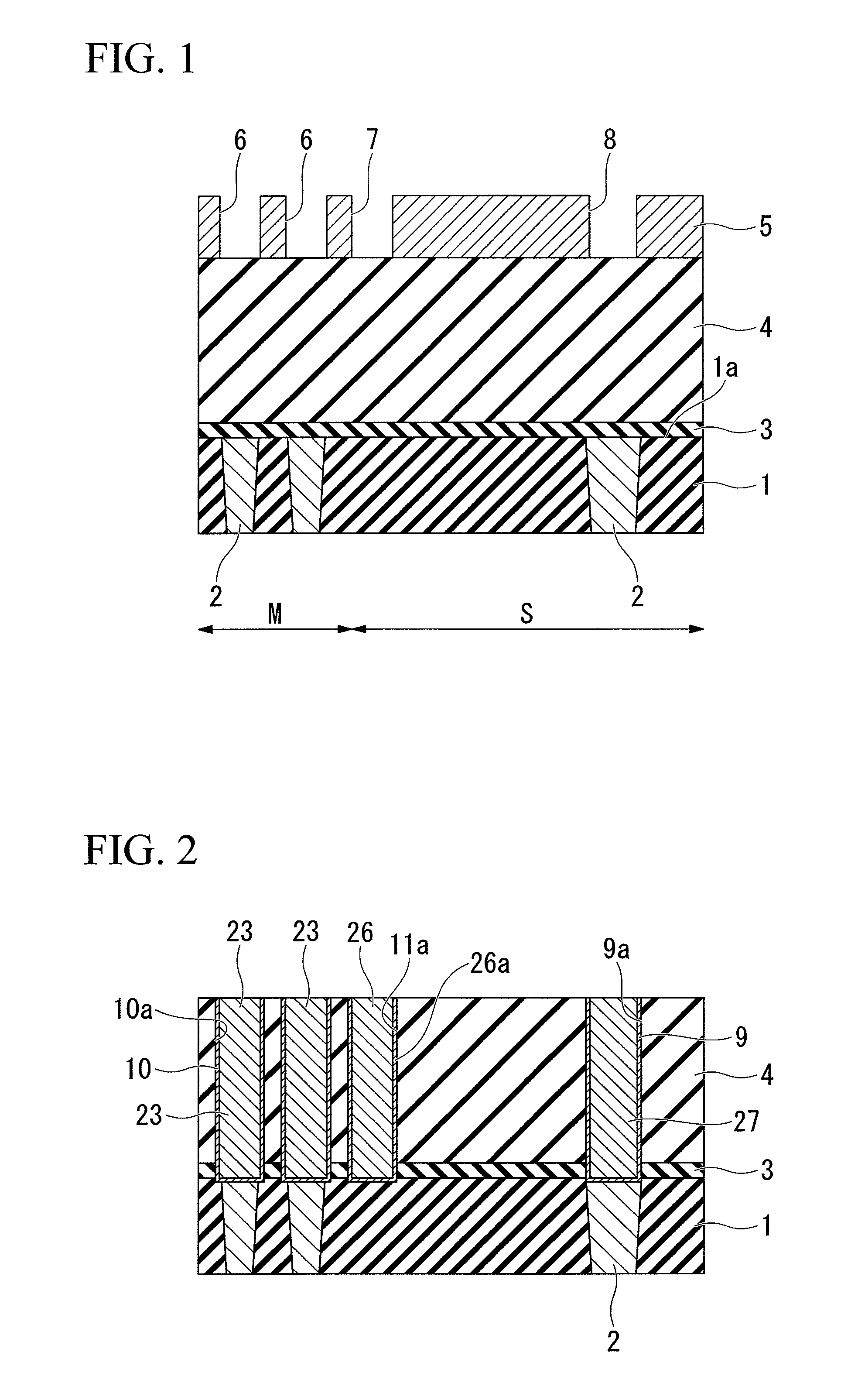

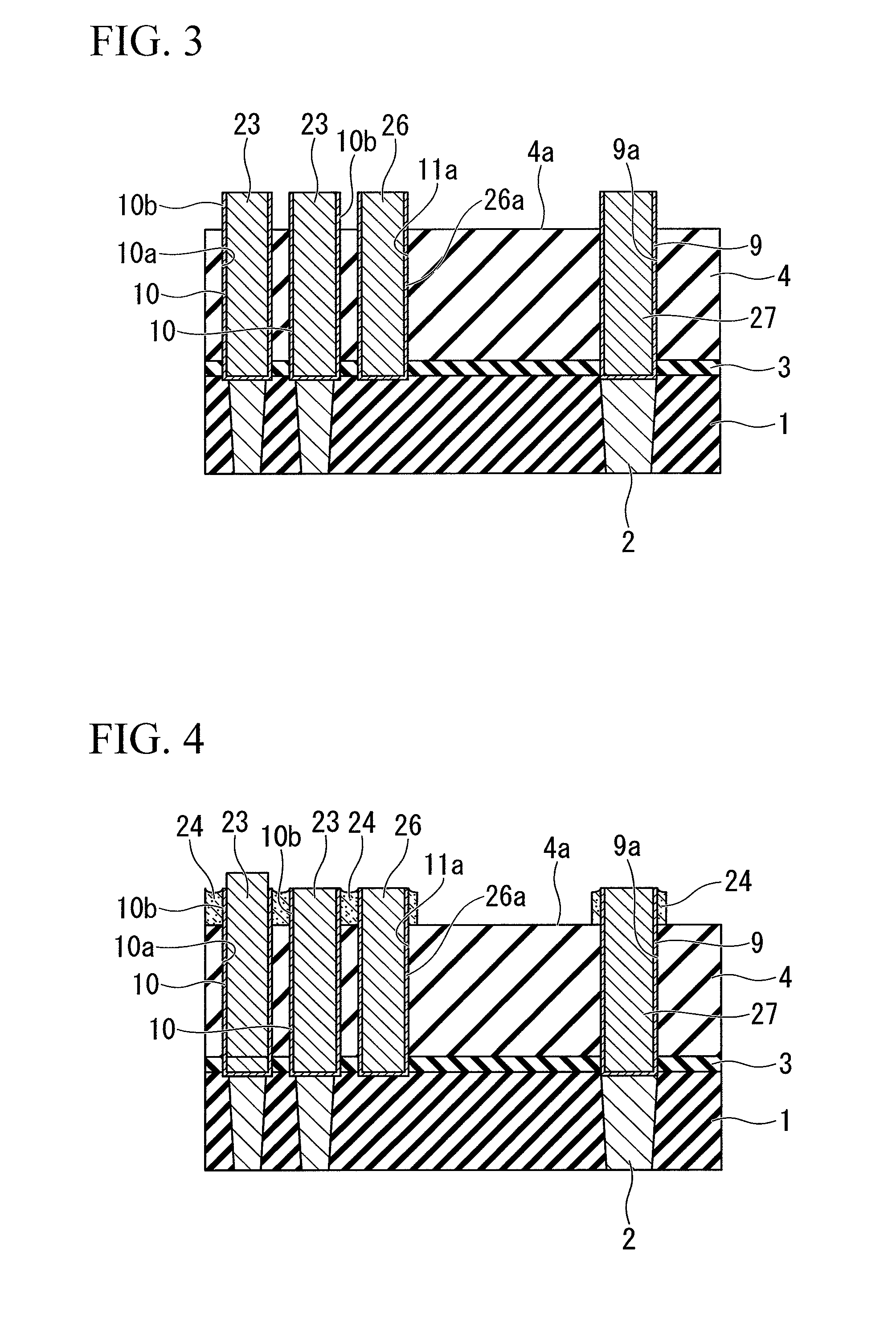

Semiconductor device and manufacturing method therefor

InactiveUS20090140397A1High aspect ratioHigh strengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor device includes capacitors formed on the surface of an interlayer insulating film in connection with capacitive contact plug, wherein capacitors are constituted of base-side lower electrode films having hollow-pillar shapes, metal plugs embedded in hollows of base-side lower electrode films, and top-side lower electrode films having hollow-pillar shapes engaged with the upper portions of the hollows as well as dielectric films and upper electrode films which are sequentially laminated so as to cover the peripheral surfaces of the base-side and top-side lower electrode films and the interior surfaces of the top-side lower electrode films. Side walls are further formed to connect together the adjacent base-side lower electrode films. Thus, it is possible to control the aspect ratio of a capacitor hole for embedding the metal plug from being excessively increased, and it is possible to increase the capacitive electrode area of each capacitor.

Owner:ELPIDA MEMORY INC

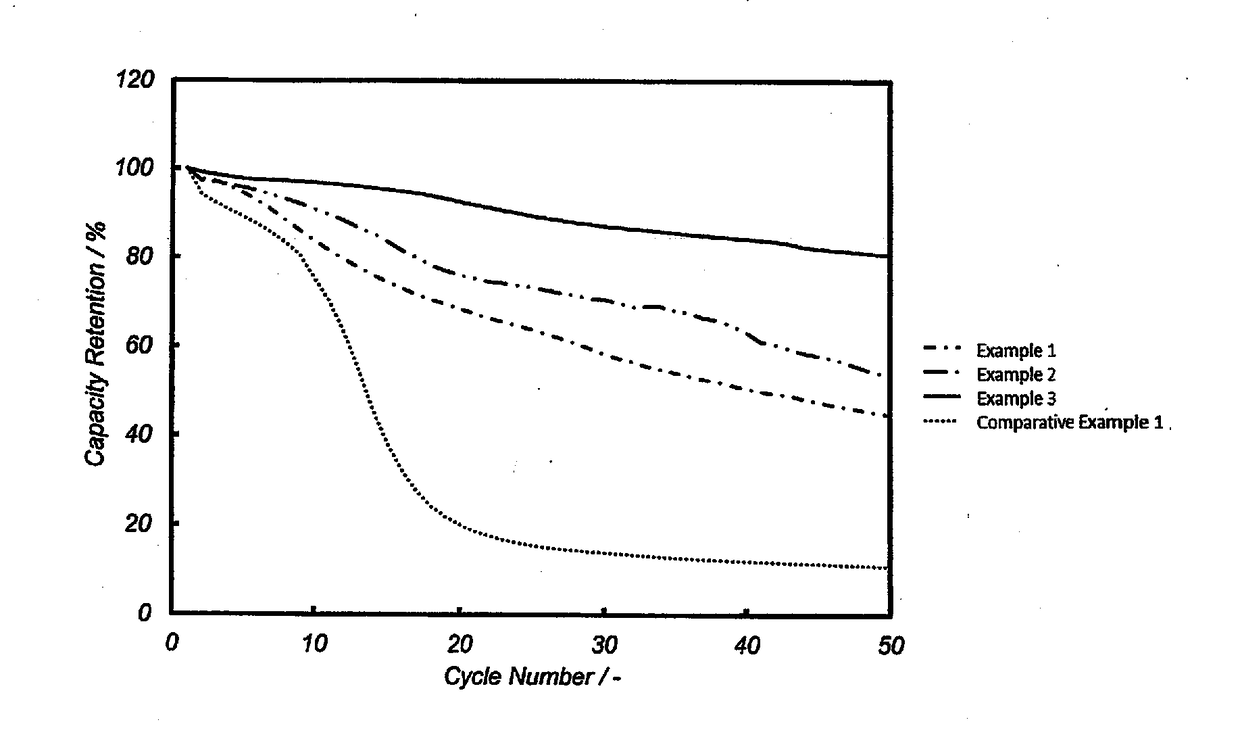

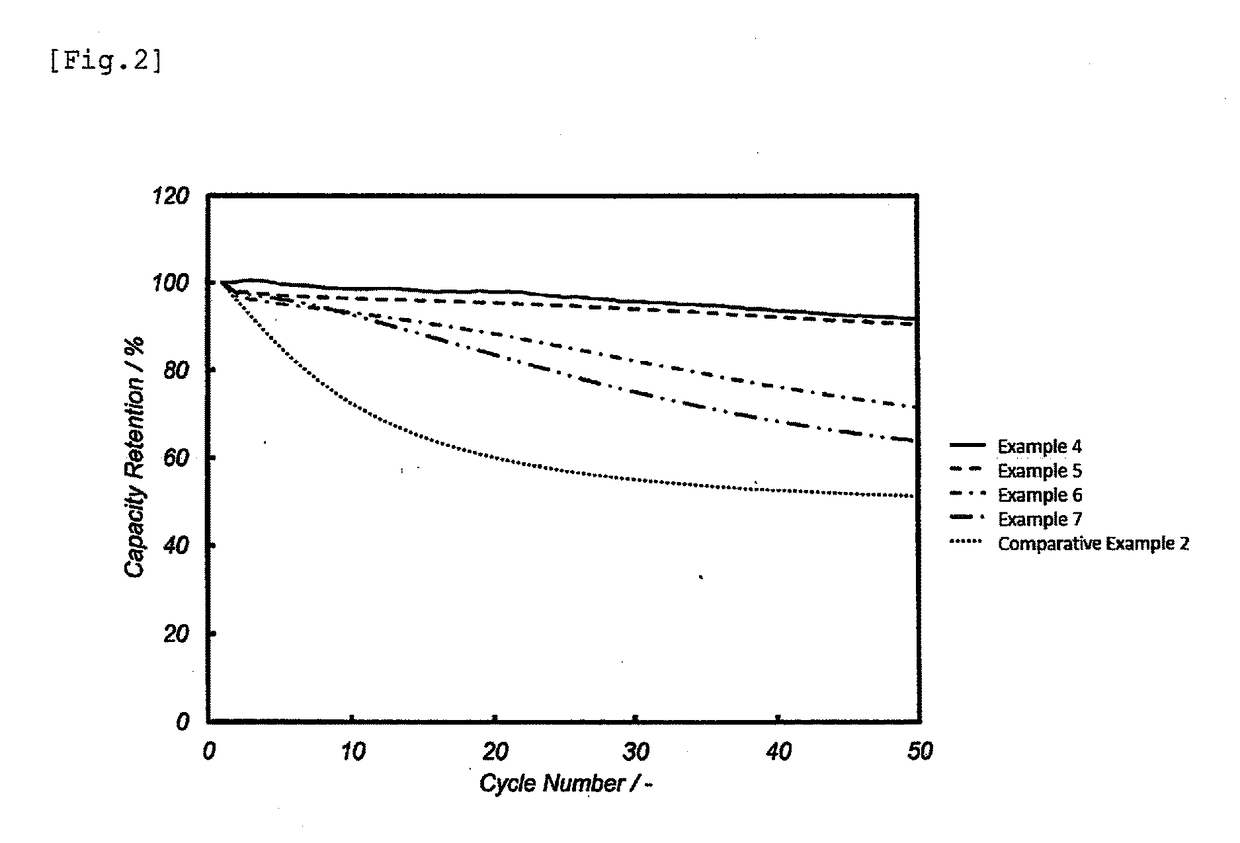

Negative electrode material for lithium battery, and lithium battery

ActiveUS20110193014A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickener such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:RESONAC HOLDINGS CORPORATION +1

Method for preparing high-tungsten-content tungsten-zirconium alloy

The invention relates to a method for preparing high-tungsten-content tungsten-zirconium alloy. The method comprises the following steps that (1) powder is prepared and mixed, tungsten powder and zirconium-titanium powder are mixed and then pelletized, and the proportion, by weight, of the added tungsten powder is 50%-70%; (2) pressing and sintering are carried out, pressing is carried out through a cold isostatic pressing molding press, and pressure is relieved in a graded mode; degreasing sintering is carried out through a high-vacuum resistance furnace, peeling is carried out through finish turning, and a consumable electrode is obtained; and (3) consumable electric arc melting is carried out for at least one time to obtain the high-tungsten-content tungsten-zirconium alloy with uniform ingredients. The consumable electrode is prepared through powder metallurgy, the strength of the electrode is high, and the phenomenon of slag falling is avoided in smelting; the distribution state of tungsten and other elements in the electrode is well improved through powder sintering, the uniformity of ingredients and the structure of cast ingots is facilitated, and therefore the smelted-state tungsten-zirconium alloy with the tungsten content reaching up to 70% is obtained. In addition, through the consumable smelting process, the alloy can be purified, inclusions are eliminated, and the density and the toughness of the alloy are further improved compared with powder-metallurgy-state alloy.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

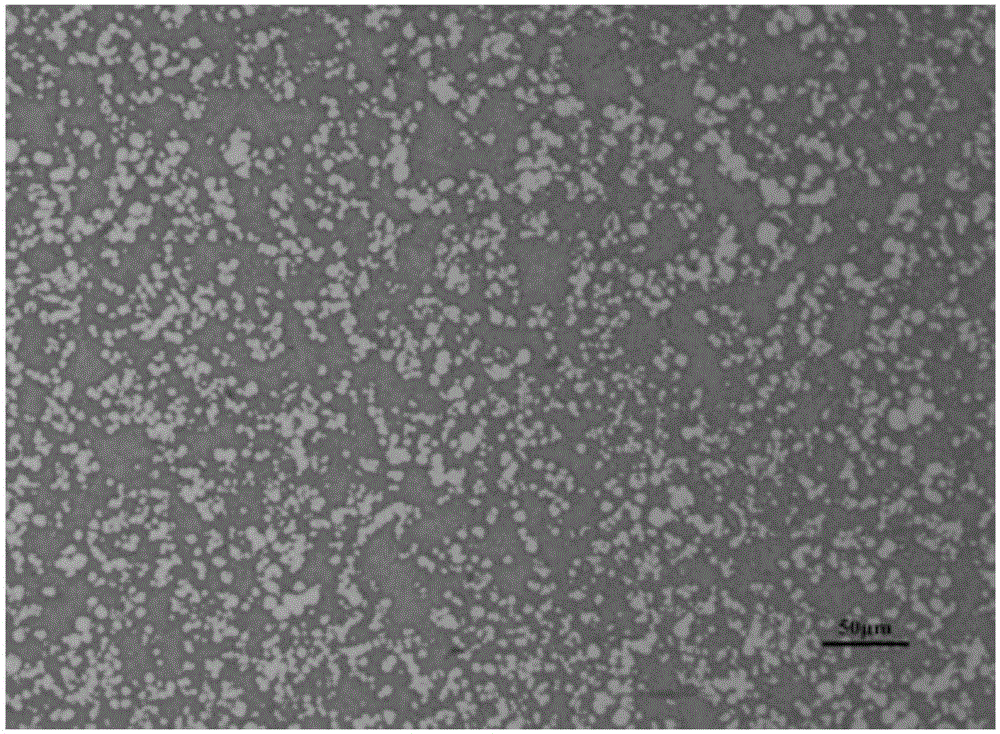

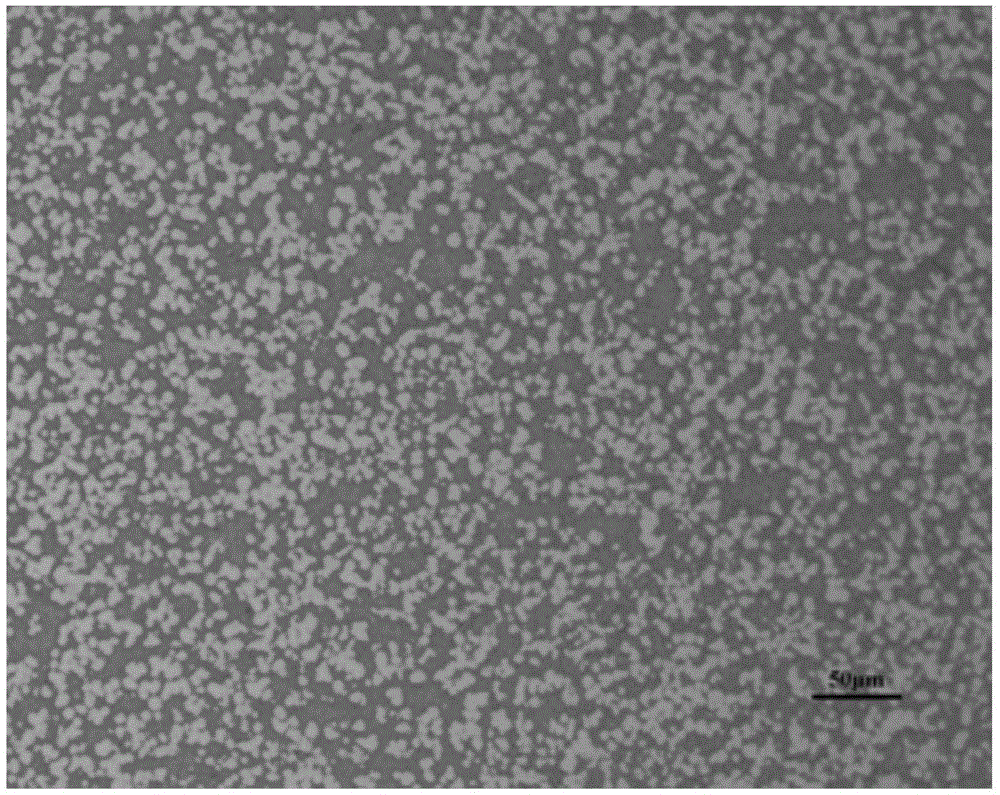

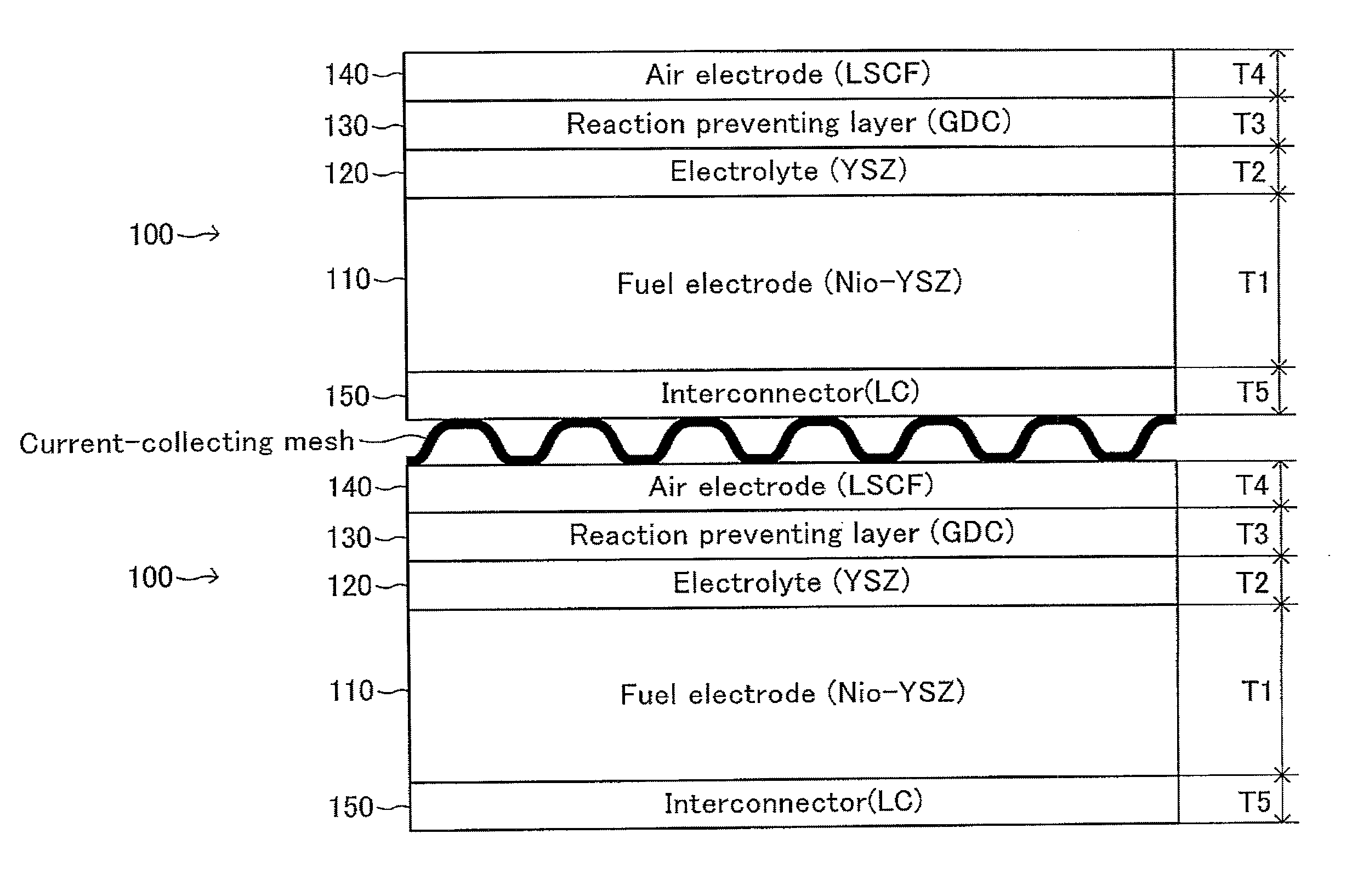

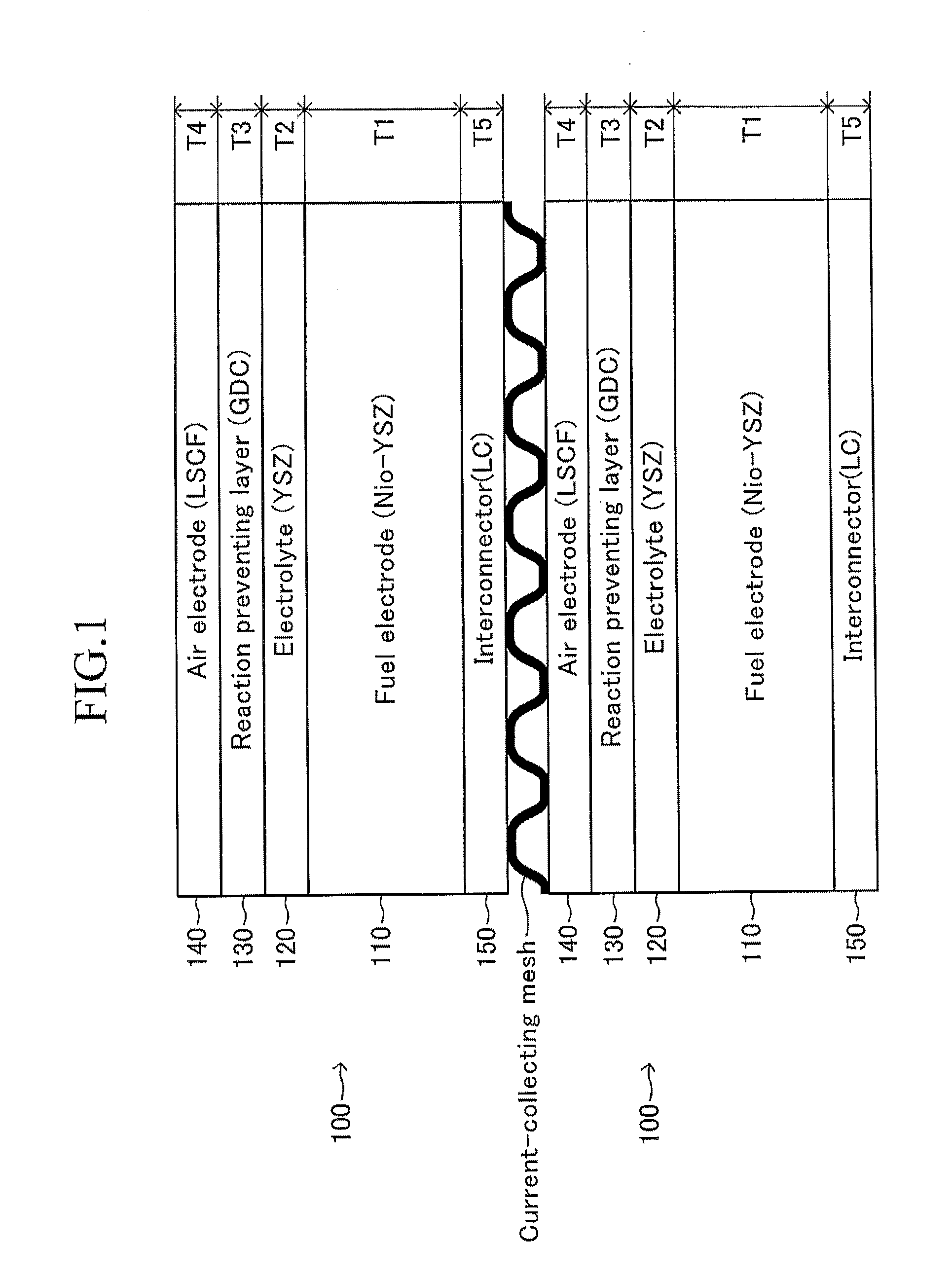

Solid oxide fuel cell

ActiveUS20120164552A1Reduced responseIncrease productionFinal product manufactureElectrode carriers/collectorsPorosityFuel cells

A solid oxide fuel cell having a fuel electrode, a solid electrolyte film, an air electrode, and a conductive current-collecting mesh bonded to an upper surface, opposite to a lower bonding surface with the solid electrolyte film, of the air electrode. Plural bonding portions that are bonded to the current-collecting mesh and plural non-bonding portions that are not bonded to the current-collecting mesh are present on the upper surface of the air electrode. In the air electrode, regions having a porosity smaller than a porosity of the other region are respectively formed on the position in the middle of the thickness of the air electrode from each bonding portion. The average of the porosity of the dense portion is 20% or more and less than 35%, while the average of the porosity of the porous portion is 35% or more and less than 55%.

Owner:NGK INSULATORS LTD

Hydrogen-absorbing alloy electrode for alkaline secondary battery and method of manufacture thereof

InactiveUS6242133B1Battery capacity be reduceImprove low-temperaturePrimary cellsElectrode carriers/collectorsHigh rateMetal

A hydrogen-absorbing alloy electrode for an alkaline secondary battery. The electrode is prepared by adding a transition metal salt to a paste comprising a hydrogen-absorbing alloy powder and binder. The electrode improves charge-discharge cycle performance and high rate discharge capacity at low temperature of an alkaline secondary battery.

Owner:SANYO ELECTRIC CO LTD

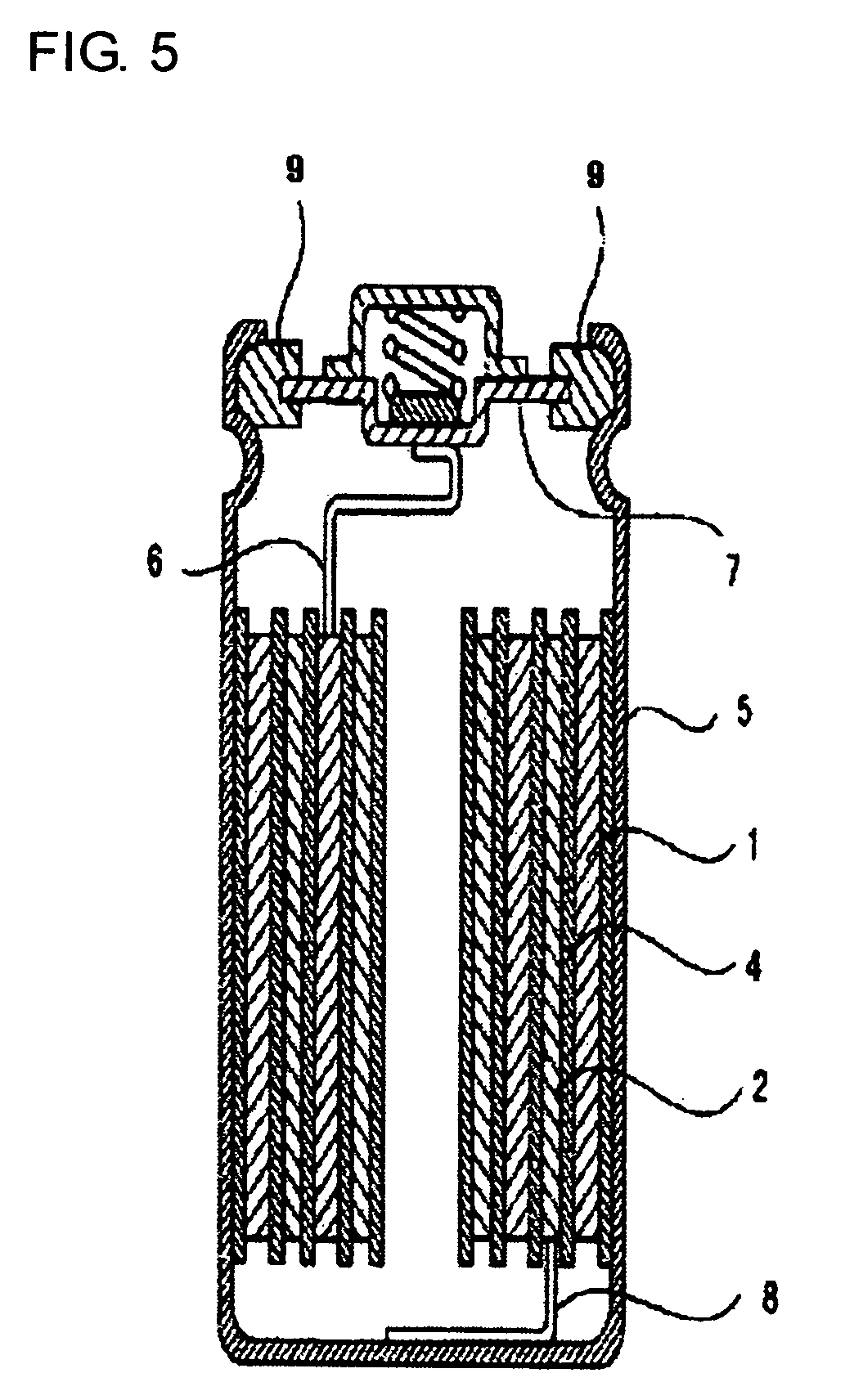

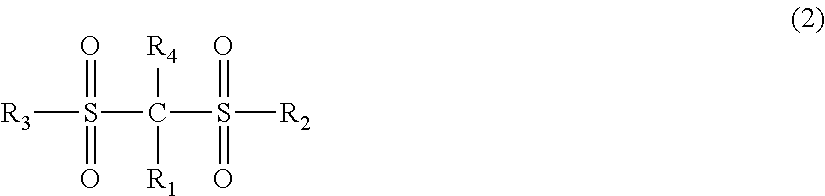

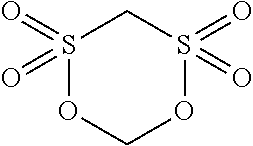

Lithium ion secondary battery and charging method therefor

ActiveUS20150380777A1Solve problemsGuaranteed specific surface areaCell electrodesFinal product manufactureLithiumCarboxymethyl cellulose

A method for charging a lithium ion secondary battery including at least a positive electrode, a negative electrode provided with a negative electrode active material layer that includes carbon as a negative electrode active material, an electrolytic solution, and a sheathing material that encloses the positive electrode, the negative electrode and the electrolytic solution; the negative electrode active material layer including carboxymethyl cellulose and the electrolytic solution including an additive that can be decomposed at a predetermined voltage includes: preliminary charging including constant-current charging in which charging is performed at a fixed current value and, following the constant-current charging, constant-voltage charging in which charging is performed at a fixed voltage; degassing in which gas is removed from within the sheathing material after the preliminary charging; and main charging that follows the degassing in which the lithium ion secondary battery is charged. The fixed voltage during the constant-voltage charging is at least 3.3 V per cell.

Owner:ENVISION AESC ENERGY DEVICES LTD

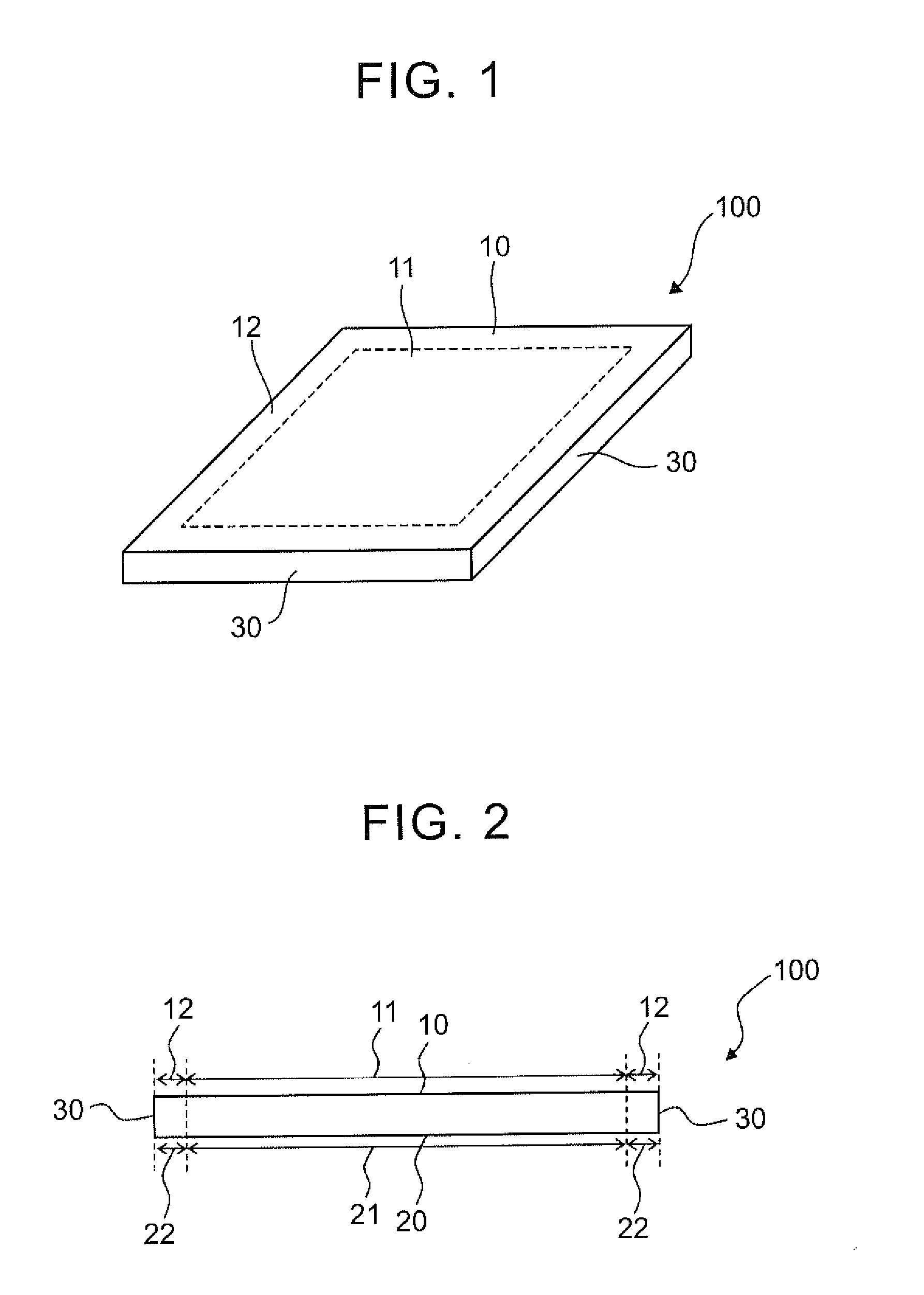

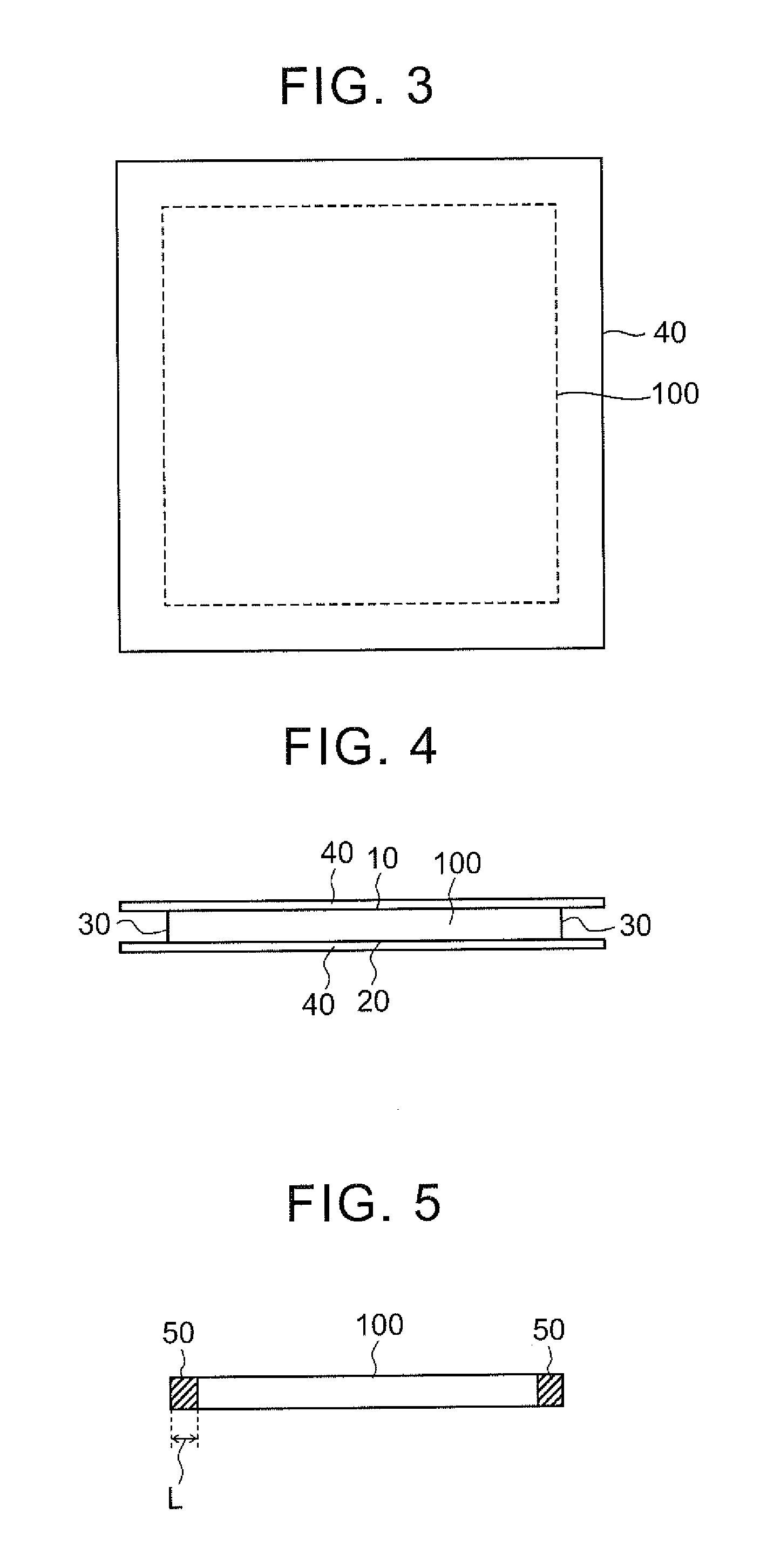

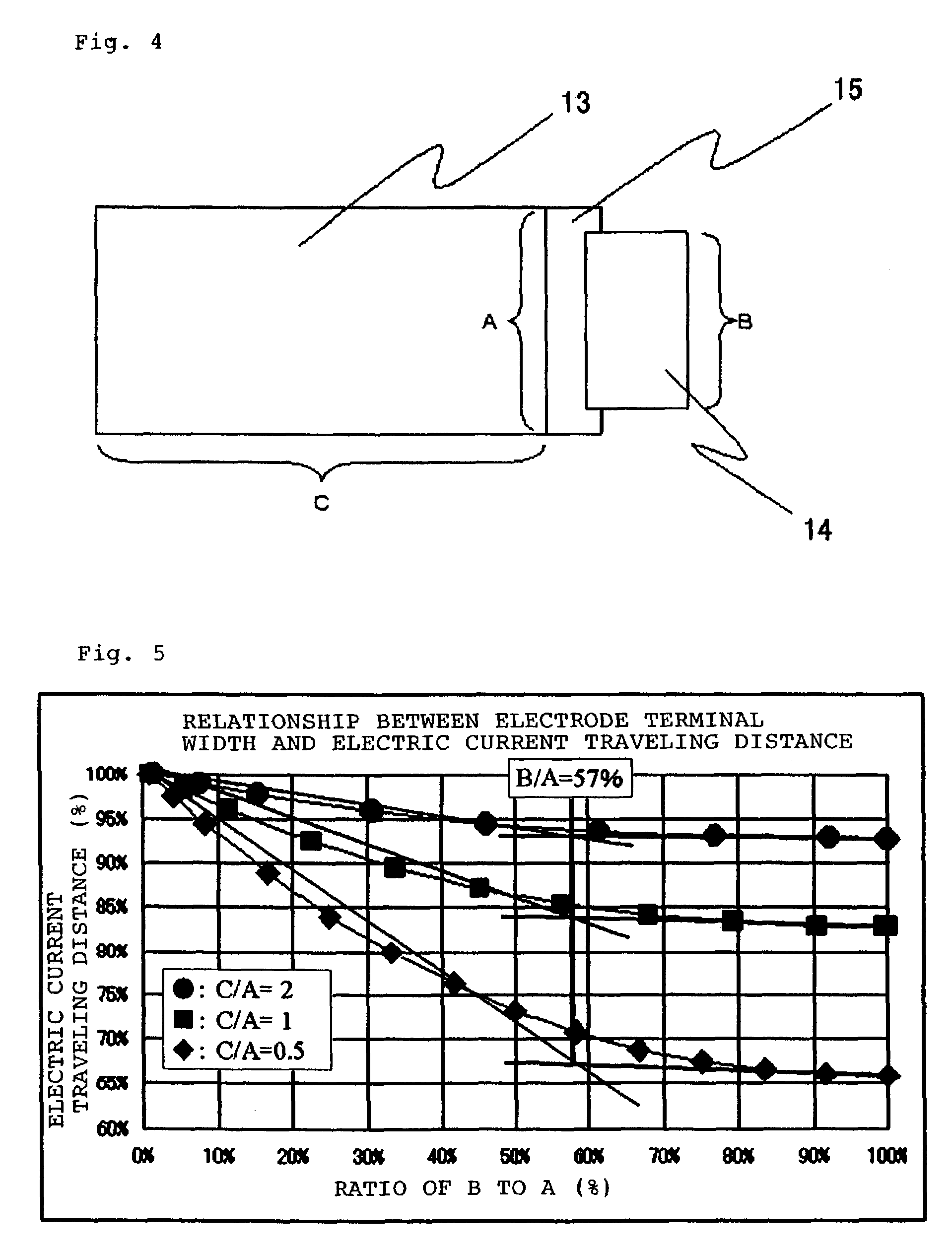

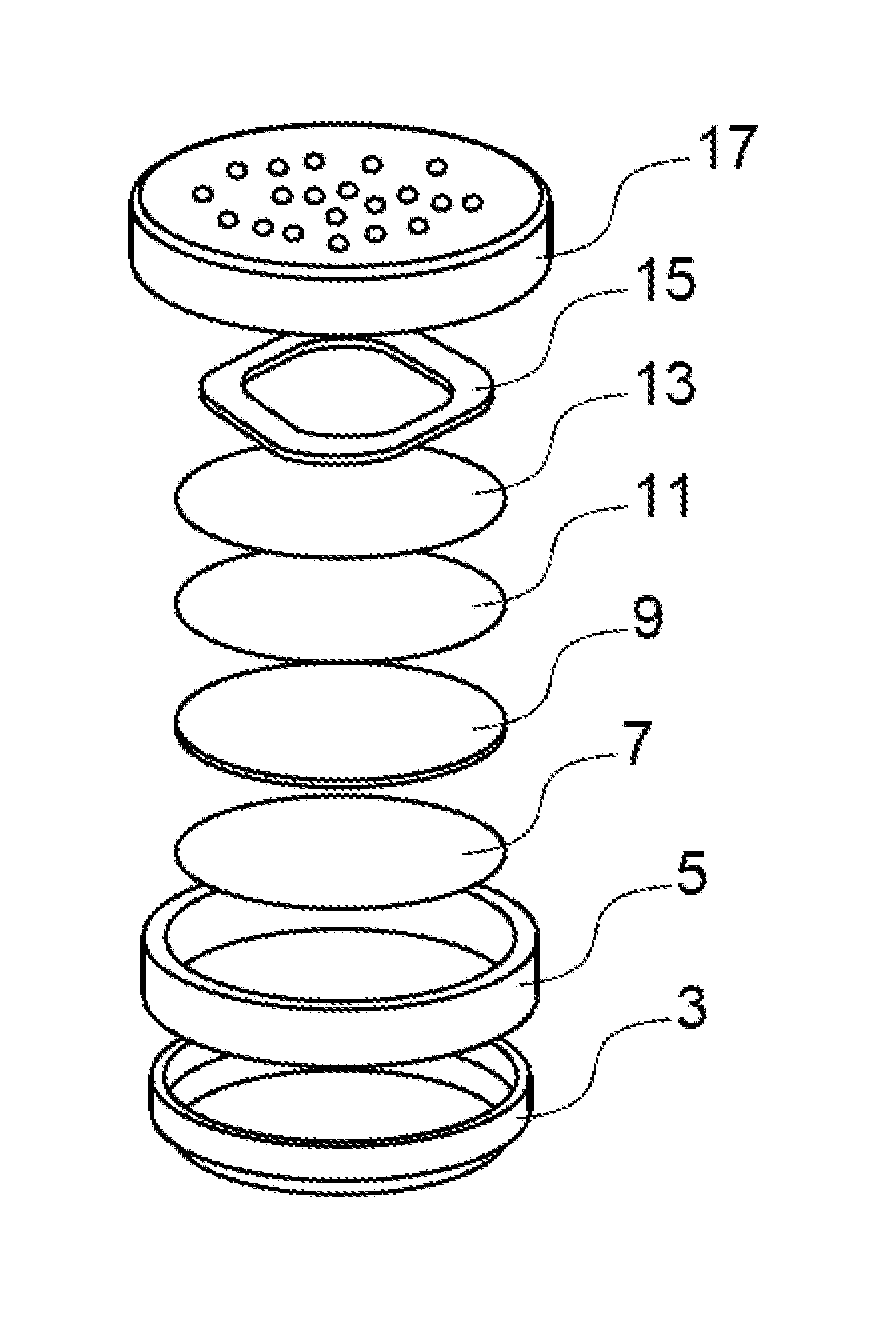

Flat-type cell and combined battery utilizing the same

ActiveUS7029789B2Effective restriction of heat generationReduce temperature riseCurrent conducting connectionsFinal product manufactureEngineeringBattery cell

The battery is constituted to satisfy B / A≧0.57, wherein “A” represents a width of an active material region and “B” represents a width of each electrode terminal.

Owner:NEC CORP

Conductive adhesive composition for electrochemical element electrode, collector with adhesive layer, and electrochemical element electrode

InactiveCN103718355APainted smoothlyIncreased durabilityElectrode thermal treatmentHybrid capacitor electrodesParticulatesPolymer science

The invention provides a conductive adhesive composition for an electrochemical element electrode and used in forming a conductive adhesive layer that is highly uniform and is interposed between a collector and an electrode composition layer, being able to contribute to increased adhesion between the two. The conductive adhesive composition for an electrochemical element electrode is characterized by containing: conductive carbon; a particulate copolymer (A) containing a dibasic acid monomer unit; a particulate copolymer (B) containing an ethylenically unsaturated carboxylic acid amide derivative unit; and a dispersing agent.

Owner:ZEON CORP

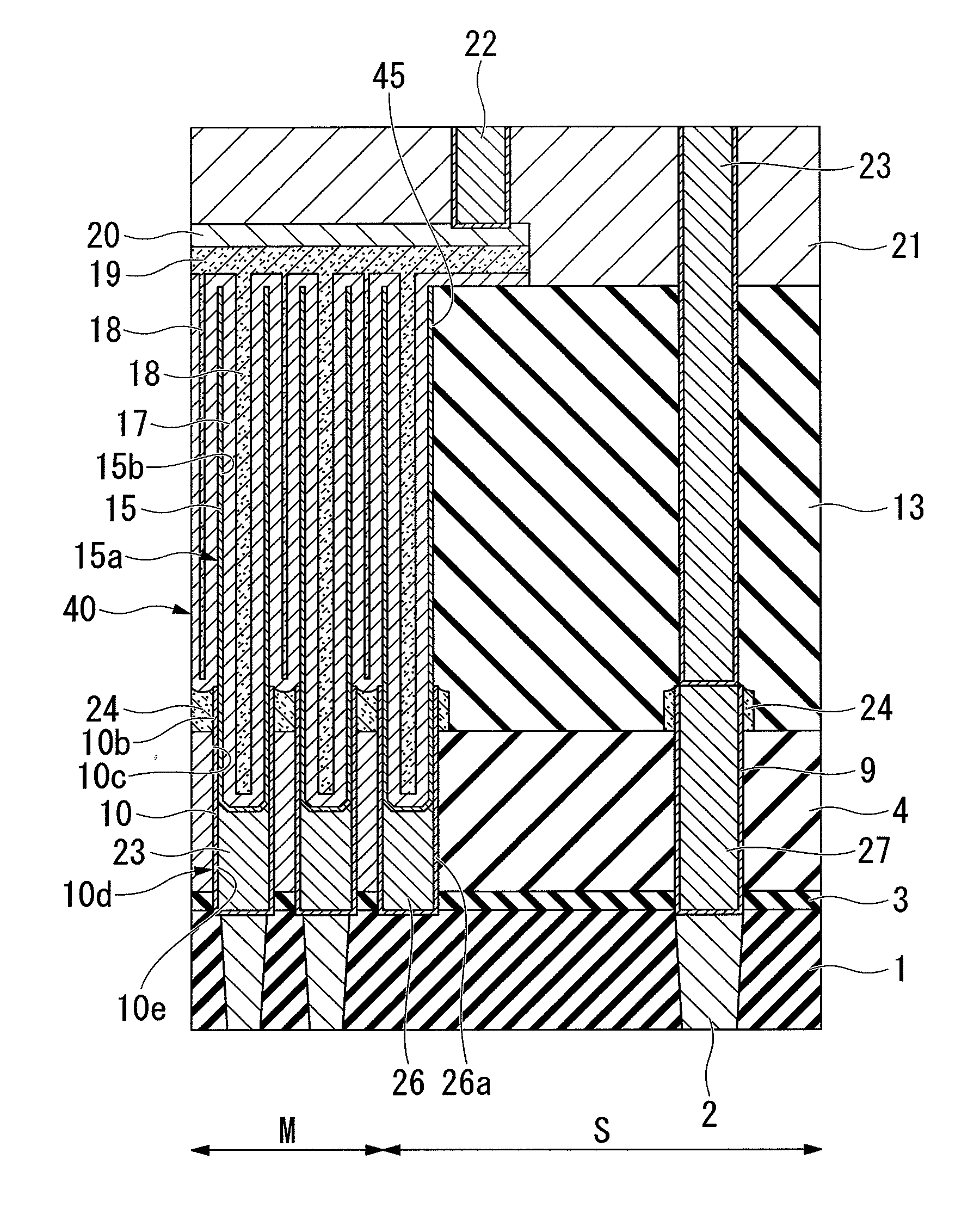

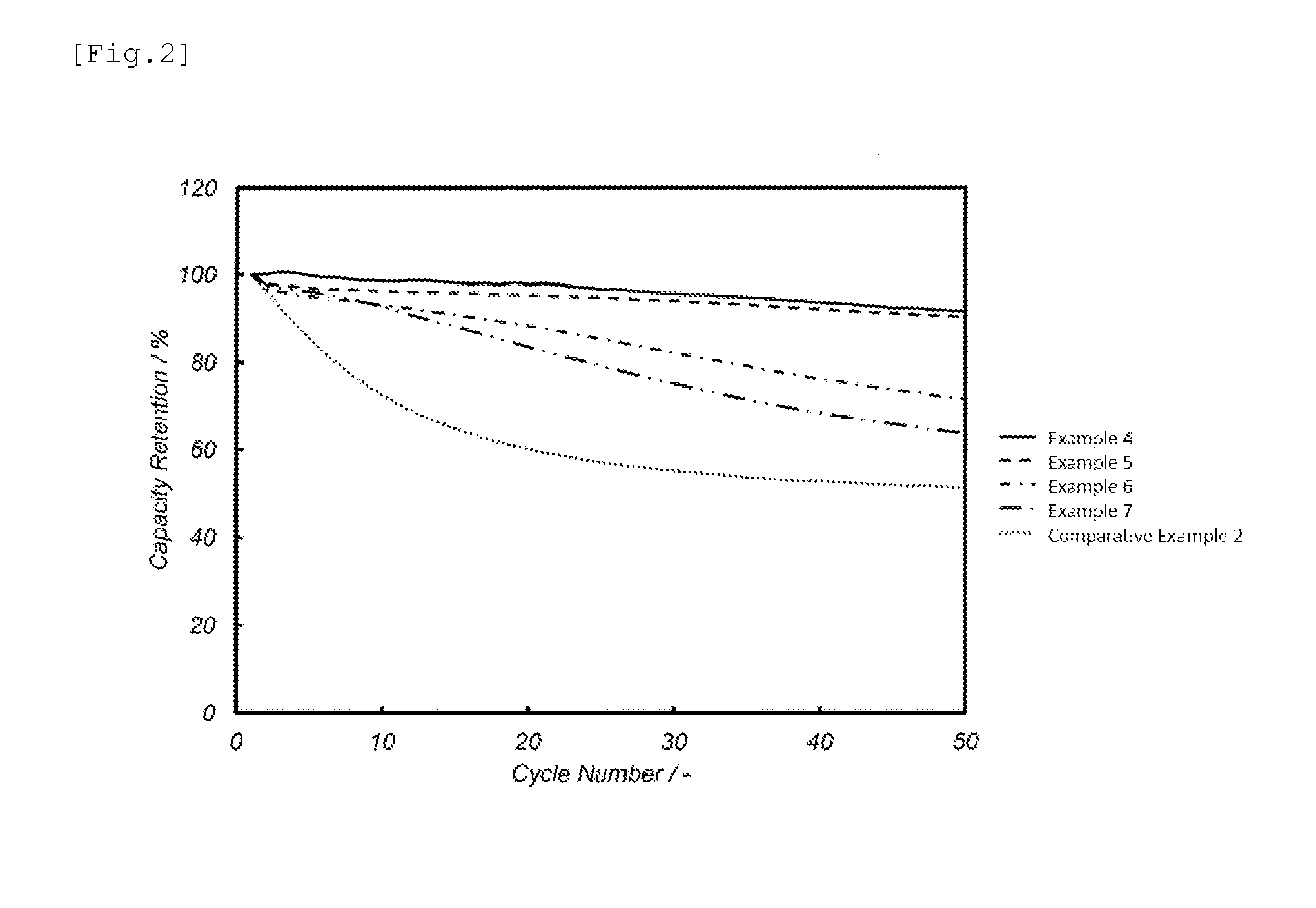

All solid-state battery and method for producing same

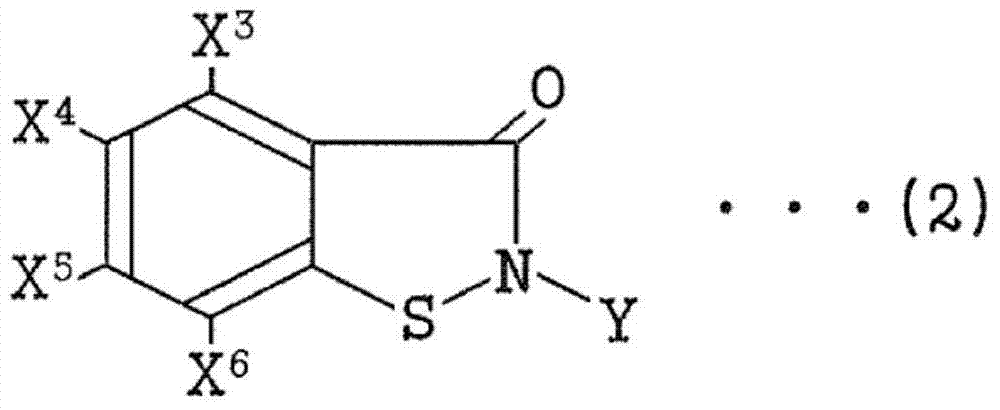

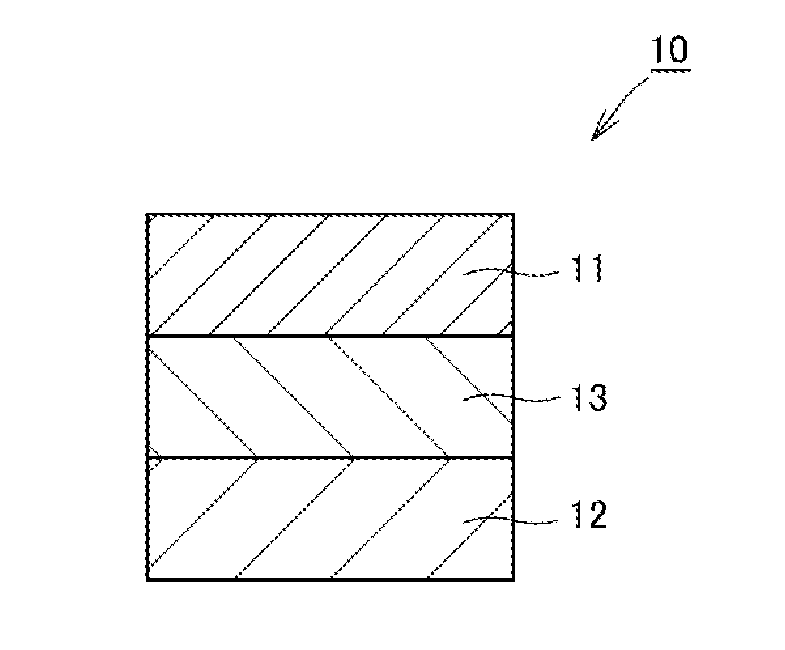

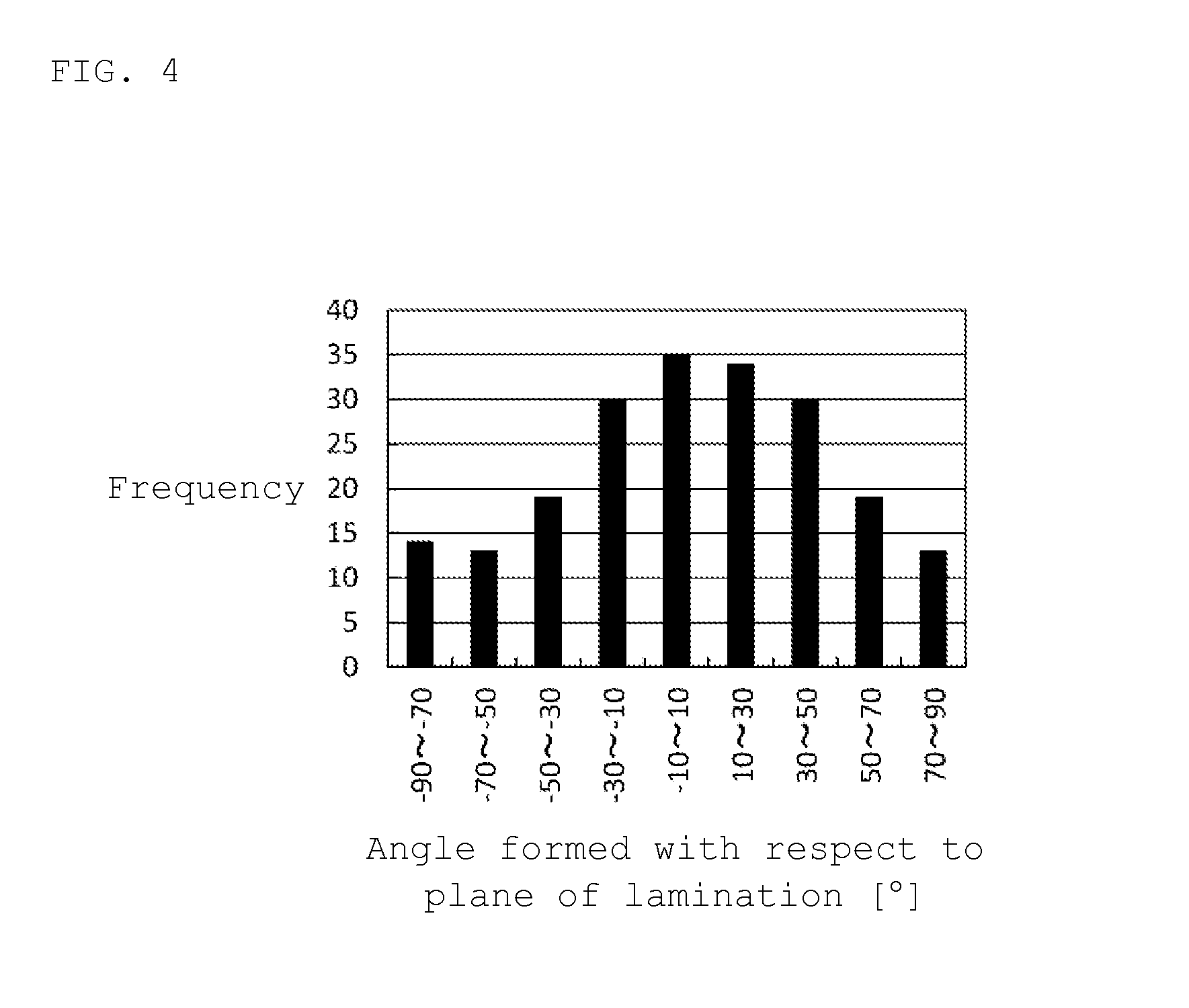

InactiveUS20150249265A1High strengthHigh electrode strengthSolid electrolytesFinal product manufactureAll solid stateOptoelectronics

An all-solid-state battery that includes a positive electrode layer, a negative electrode layer and a solid electrolyte layer interposed between the positive electrode layer and the negative electrode layer. At least one electrode layer selected from the positive electrode layer and the negative electrode layer contains an electrode active material, a sulfide solid electrolyte and fibrous carbon. The fibrous carbon includes at least fibrous carbon components that extend in the direction of lamination of the positive electrode layer, the solid electrolyte layer and the negative electrode layer.

Owner:MURATA MFG CO LTD

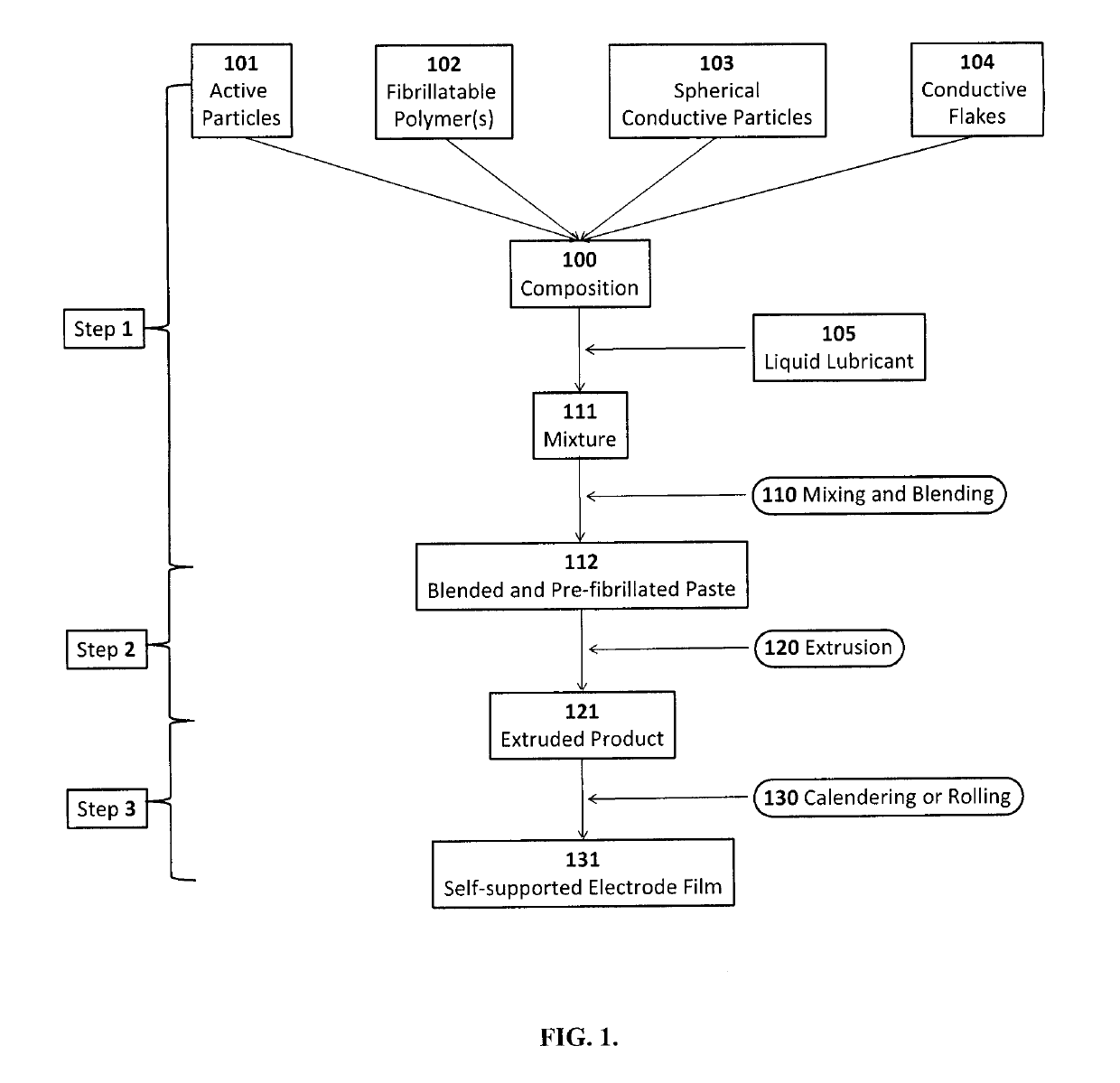

Conductive-Flake Strengthened, Polymer Stabilized Electrode Composition And Method Of Preparing

ActiveUS20190280289A1Low energy-consuming methodsEasy to manufactureElectrode rolling/calenderingHybrid capacitor electrodesUltimate tensile strengthPolymer chemistry

An electrode film with a high tensile strength and a low electrical resistance is fabricated by using conductive flakes to strengthen polymer stabilized particle electrode. The new compositions and low energy methods are disclosed in this invention. The method includes mixing and blending the particulate materials and fibrilltable polymers with conductive flakes into a paste, fibrillating the polymers, and extruding and rolling the paste into self-supported electrode films.

Owner:ADVEN IND INC

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1343543AHigh electrode strengthImprove processing efficiencySoldering apparatusLaser beam welding apparatusLaser solderingSoldering

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

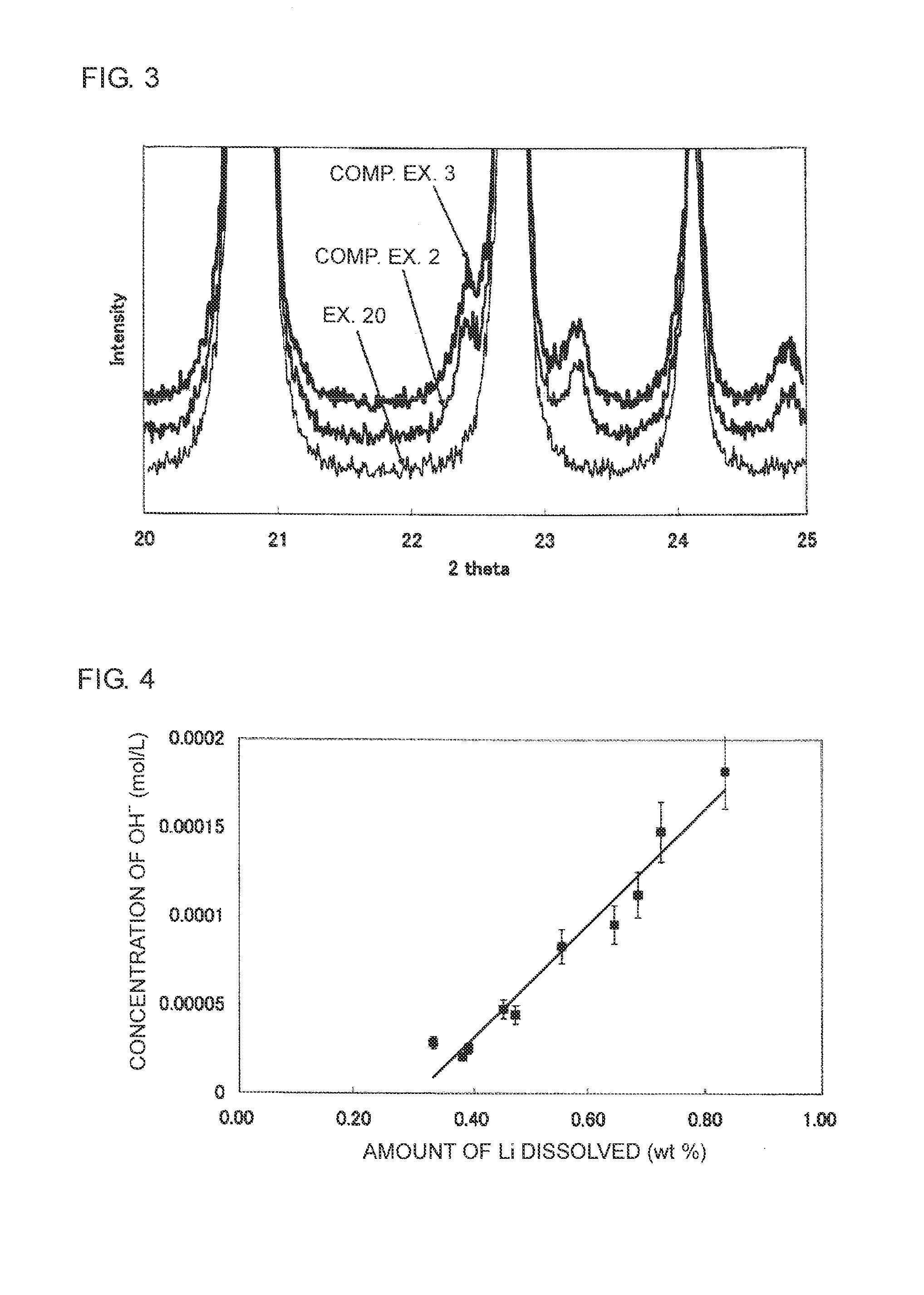

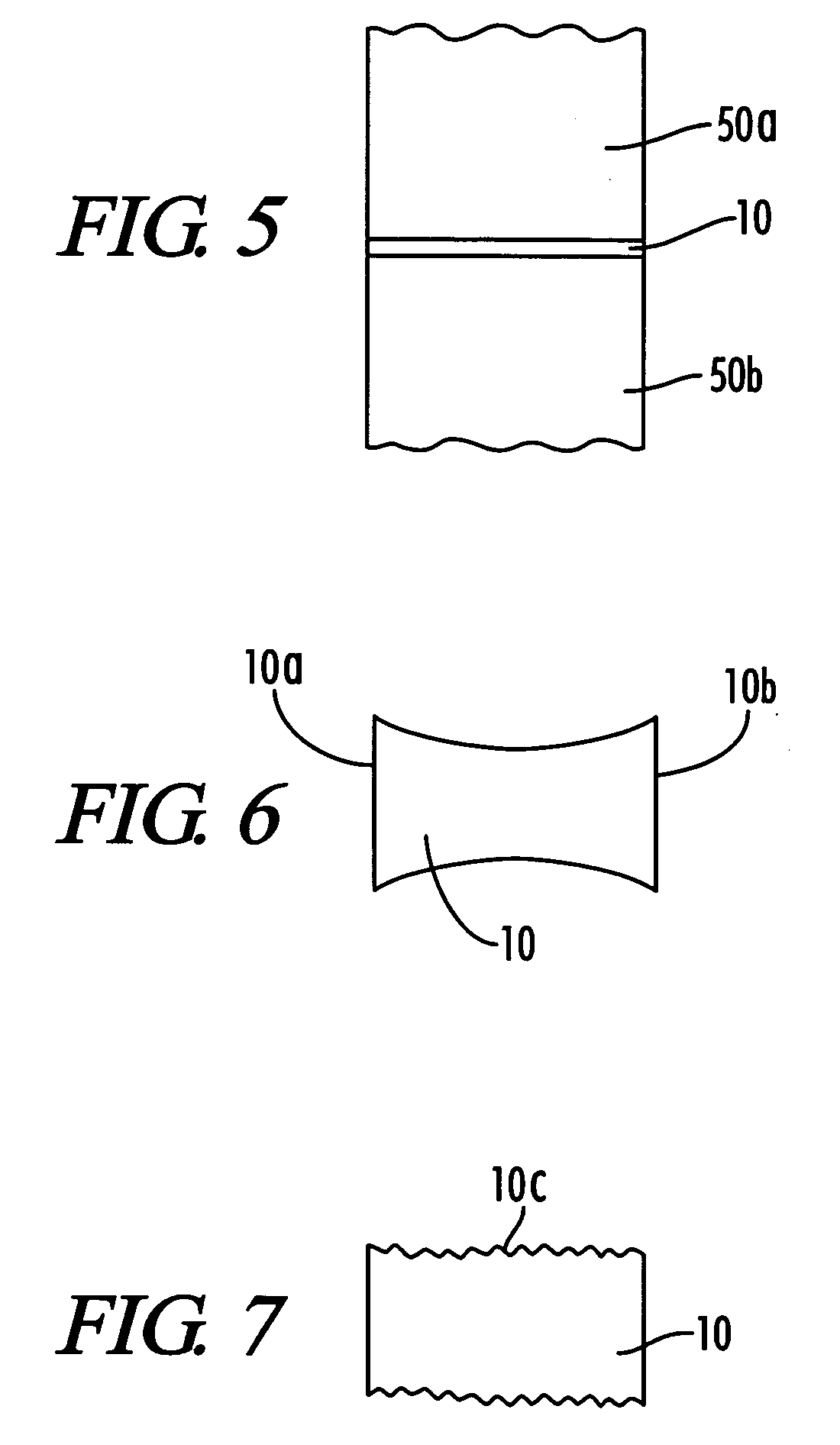

Method of producing active material for lithium secondary battery, method of producing electrode for lithium secondary battery, method of producing lithium secondary battery, and method of monitoring quality of active material for lithium secondary battery

ActiveUS8153302B2Increase energy densitySuppression voltageOptical radiation measurementParticle separator tubesLithiumBuffer solution

A method of producing an active material for a lithium secondary battery, by which impurities causing problems in synthesizing an active material for a lithium secondary battery, including a lithium transition metal oxyanion compound are removed efficiently and enhancement of an energy density is realized, is provided. By cleaning the active material for a lithium secondary battery, including a lithium transition metal oxyanion compound, with a pH buffer solution, for example, it is possible to efficiently remove just only impurities such as Li3PO4 or Li2CO3, or a substance, other than LiFePO4, in which the valence of Fe is bivalent such as FeSO4, FeO or Fe3(PO4)2 without dissolving Fe of LiFePO4.

Owner:PANASONIC ENERGY CO LTD

Negative Electrode Active Material for Nonaqueous Electrolyte Secondary Batteries

ActiveUS20150064555A1Increase battery capacityExcellent uniform reactivitySilver accumulatorsNegative electrodesSlurrySilicon

Provided is a novel negative electrode for nonaqueous electrolyte secondary batteries, which is capable of improving cycle characteristics and is also capable of suppressing aggregation of active material particles in a slurry. The negative electrode active material for nonaqueous electrolyte secondary batteries, which contains silicon and has a D50 of 0.1 μm to 5 μm, and the amount of water measured at 120° C. to 300° C. by the Karl-Fischer method (referred to as “amount of water”) per specific surface area (referred to as “CS”), that is, the amount of water / CS, of 0.1 to 80 ppm / (m2 / cc).

Owner:MITSUI MINING & SMELTING CO LTD

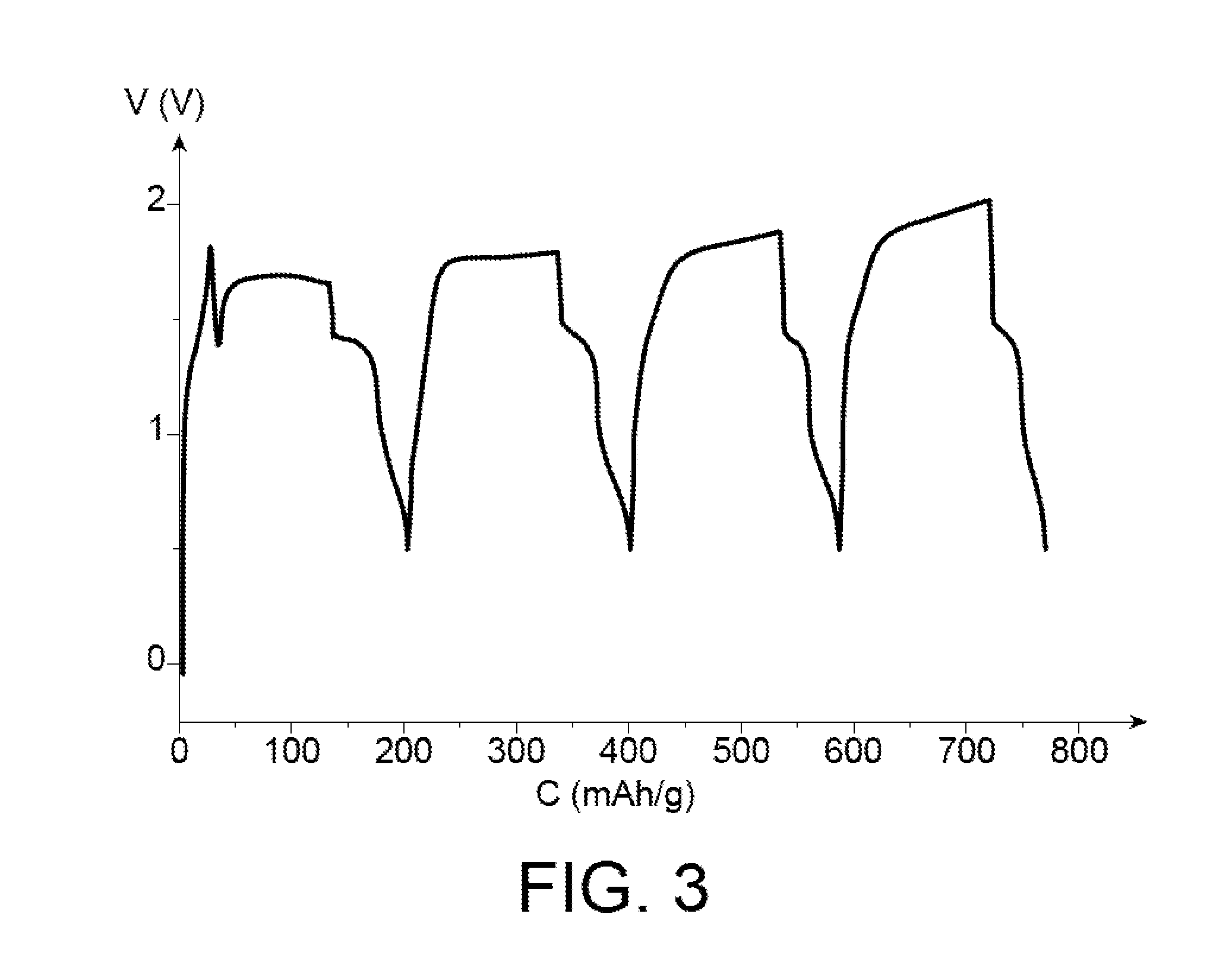

Lithium electrochemical storage battery of the lithium/air type

InactiveUS20150125762A1High mechanical strengthLarge Young modulusFuel and primary cellsFuel and secondary cellsLithiumPotential difference

A lithium-air storage battery having at least one electrochemical cell witha negative electrode, which is an air electrode;a positive electrode, which comprises a material for insertion of lithium; andan organic electrolyte conducting lithium ions, positioned between the negative electrode and positive electrode, the electrolyte not degrading, when it is subject to a voltage ranging from 3V to 5.5V expressed relatively to the Li+ / Li pair and the storage battery having a potential difference between the electrochemical potential of the positive electrode and the electrochemical potential of the negative electrode greater than 4.5V expressed relatively to the Li+ / Li pair.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

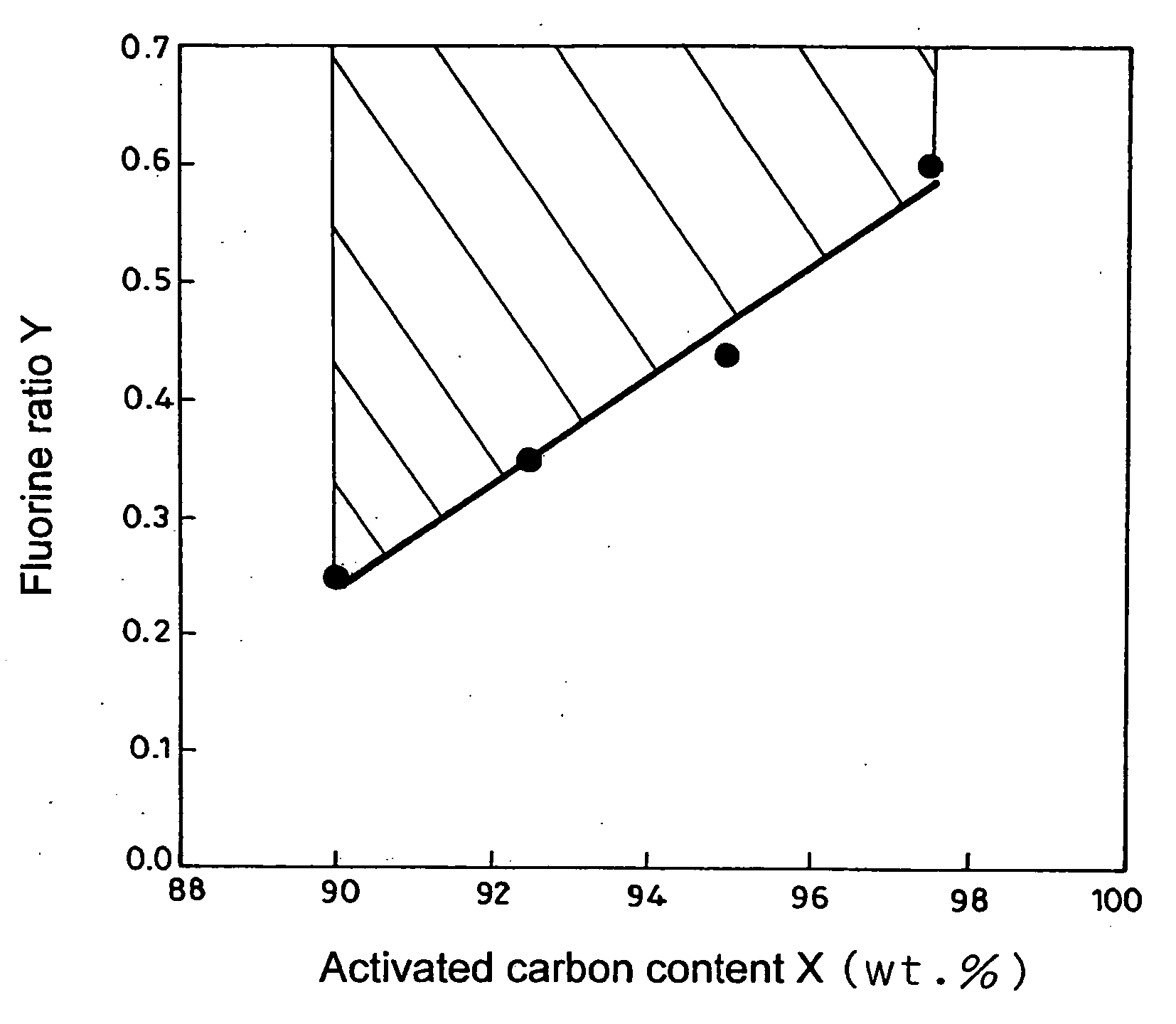

Electrode and electrochemical device using the same

InactiveUS20060166094A1Good effectIncrease packing densityHybrid capacitor electrodesDouble layer capacitorsEngineeringElectrochemistry

An electrode and an electrochemical device using the same are provided in which excellent effects can be obtained that the filling density of the active material can be increased and the energy density can be improved. The electrode includes at least an active material, a conductive auxiliary agent, and a fluorine containing binder for binding the active material to the conductive auxiliary agent. In this electrode, a fluorine ratio Y and a filling content X of the active material in the electrode (90 wt. %≦X≦97.5 wt. %) satisfy the relationship of Y≧0.046 X−3.905. The fluorine ratio Y is a ratio of a fluorine content B on a minimum strength surface inside the electrode to a fluorine content A on the surface of the electrode (Y=B / A).

Owner:TDK CORPARATION

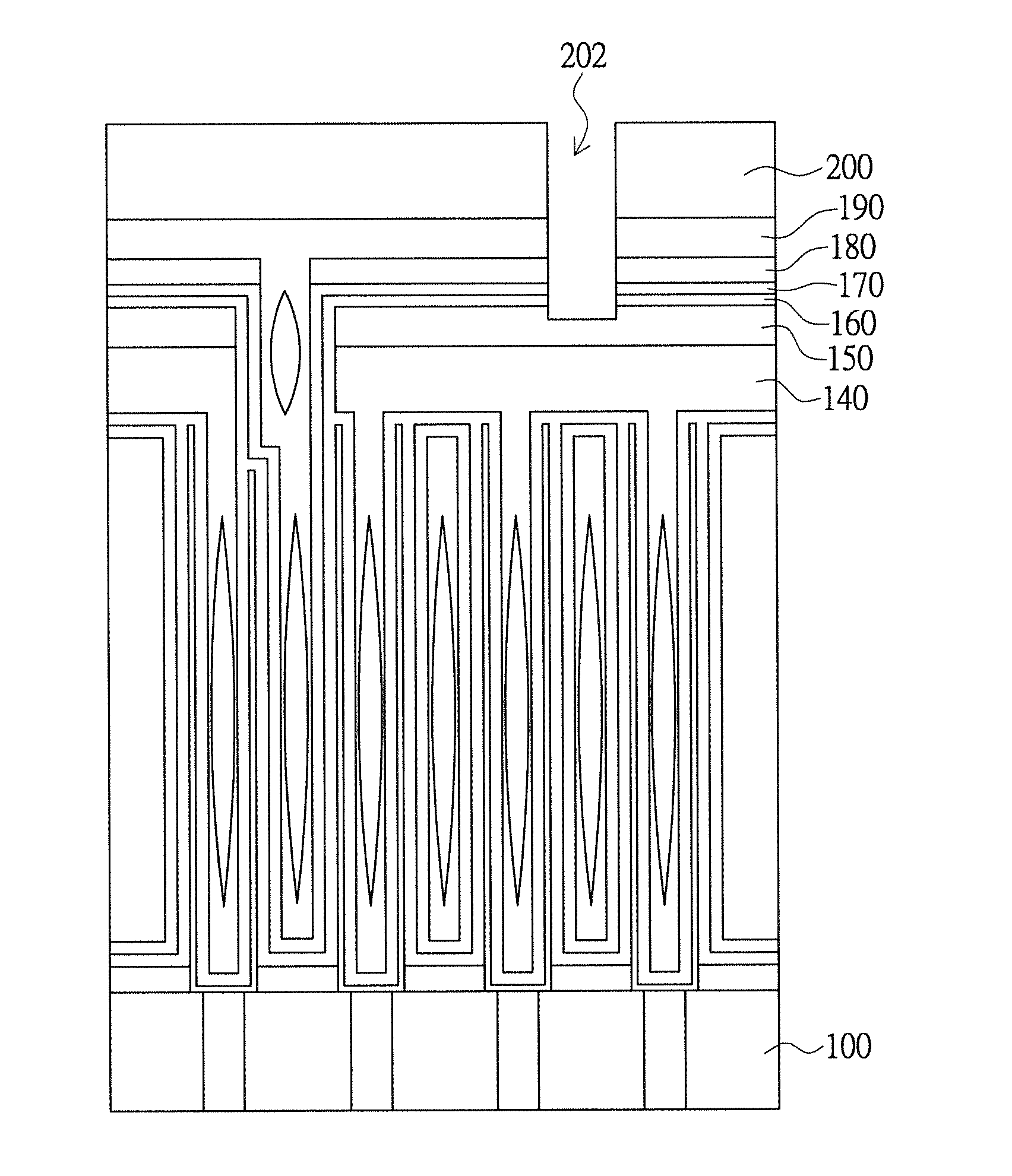

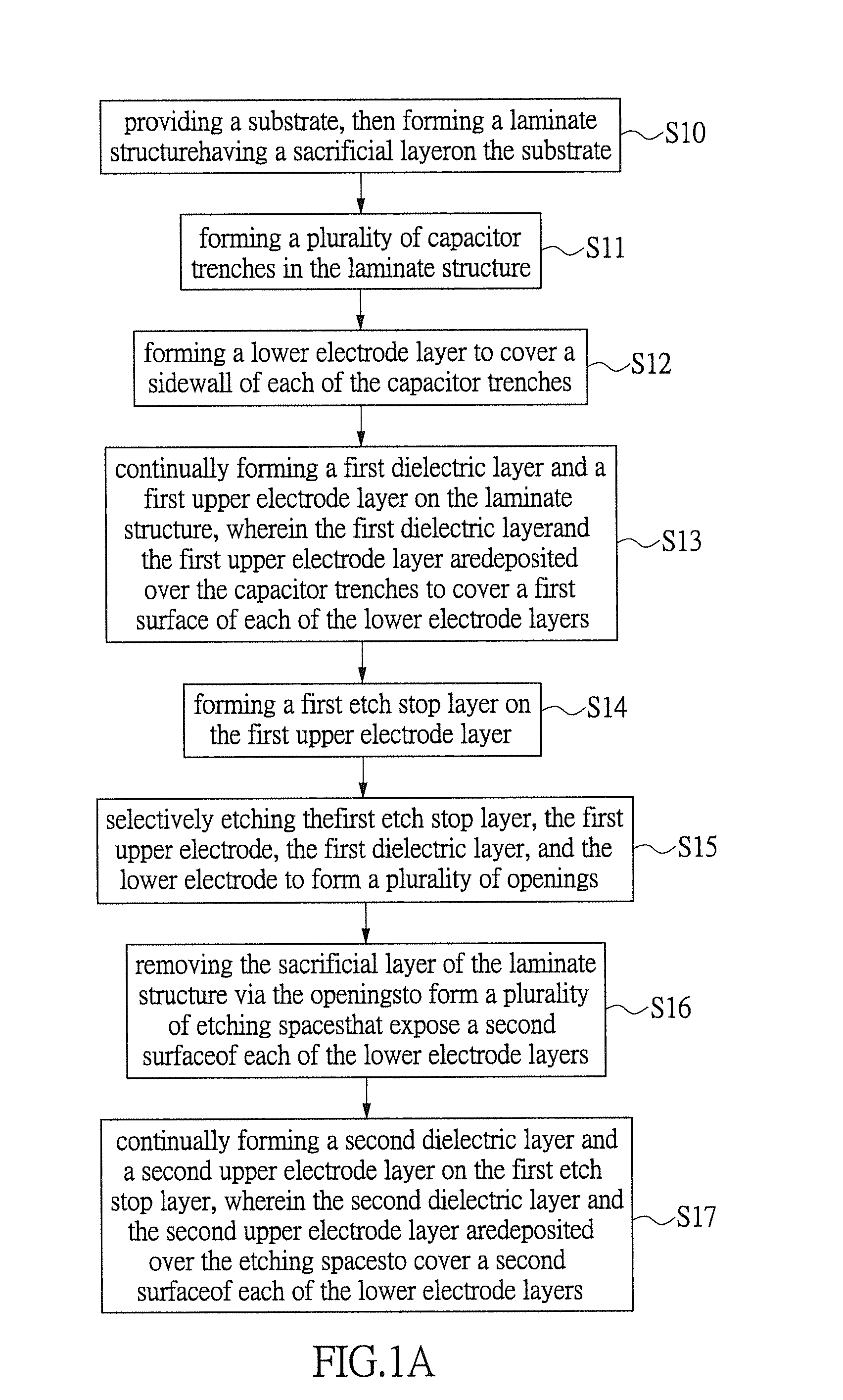

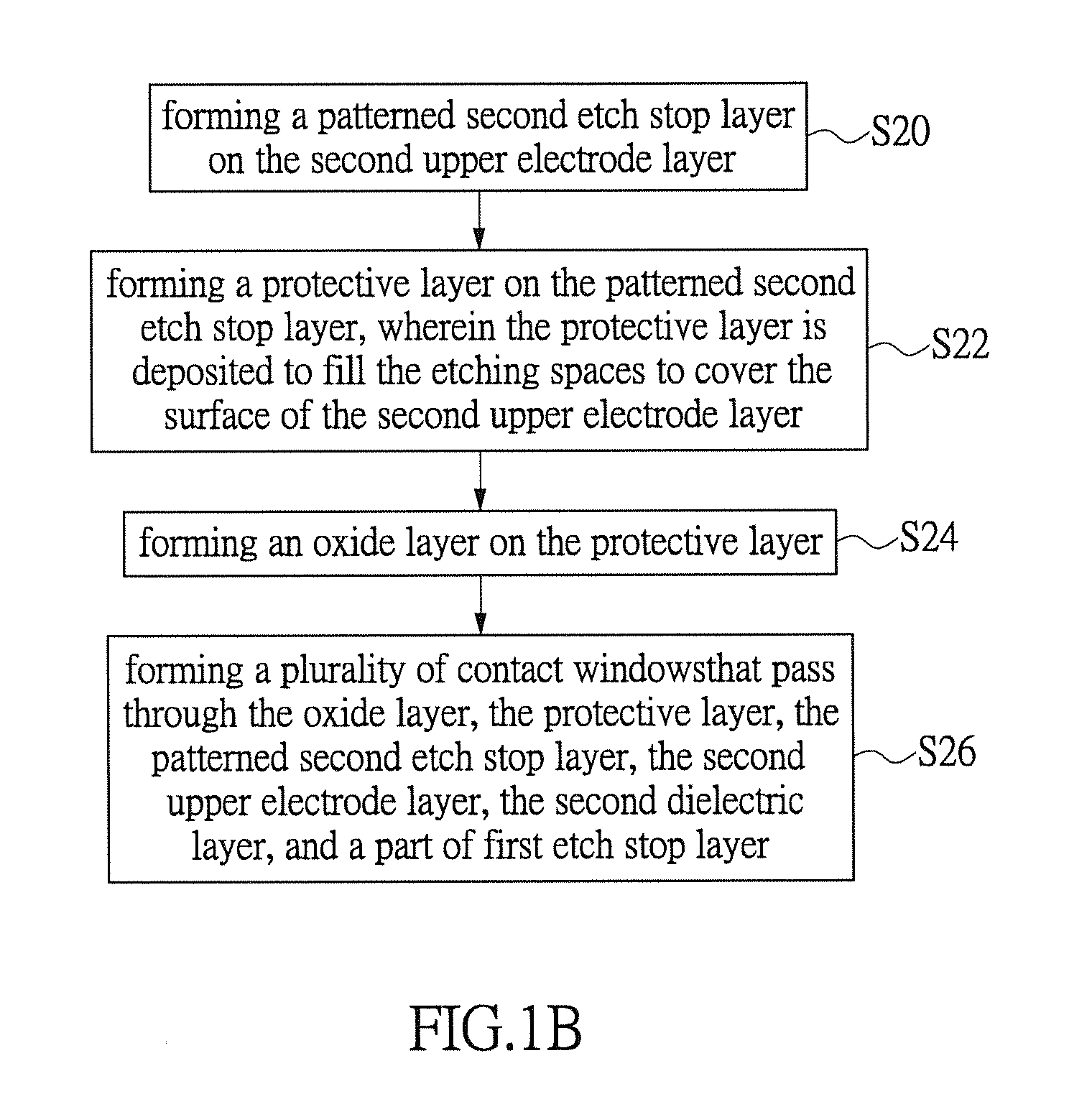

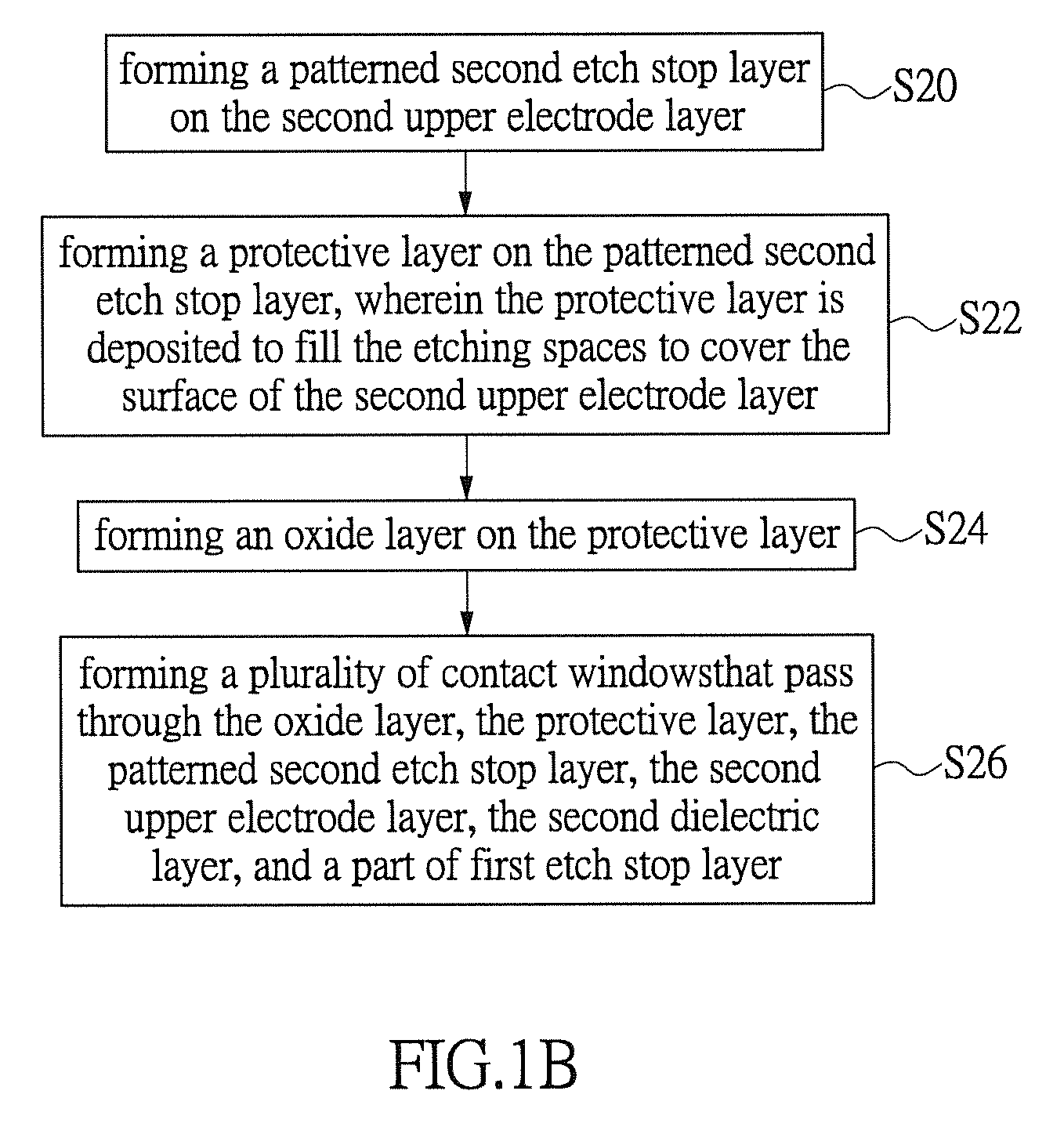

Method for manufacturing high-strength structural stacked caacitor

ActiveUS20150171088A1Large electrodeIncrease capacitanceTransistorSolid-state devicesHigh intensityUltimate tensile strength

The instant disclosure relates to a method for manufacturing high-strength structural stacked capacitor. The novel feature of the instant disclosure is forming a part of upper electrode layer to cover the first / outer surface of each of the lower electrode layers before removing the sacrificial layer, and forming another part of upper electrode layer to cover the second / inner surface of each of the lower electrode layers after removing the sacrificial layer. Hence, the structure strength of the lower electrode layer in all process steps has been improved.

Owner:MICRON TECH INC

Negative Electrode Active Material For Nonaqueous Electrolyte Secondary Batteries

InactiveUS20170352872A1Increase capacityHigh reactivityNegative electrodesLi-accumulatorsElectrical batteryPhysical chemistry

Provided is a novel method of preparing a negative electrode for nonaqueous electrolyte secondary batteries, which contains silicon and is capable of improving cycle characteristics and is also capable of suppressing aggregation of active material particles in a slurry. After formation of a molten liquid by any one of methods (i) to described in the specification, the molten liquid is micronized by atomization or liquid quenching, thereby forming a micronized active material in the form of powder, and the micronized active material is pulverized and classified in a nitrogen atmosphere in which air is present in an amount of less than 1%, and the balance is composed of nitrogen, to thereby adjust the particle size of the micronized active material.

Owner:MITSUI MINING & SMELTING CO LTD

Method of producing an electrode for a lithium secondary battery, and method of producing a lithium secondary battery

InactiveUS20120079712A1Increase energy densitySuppression voltageElectrode manufacturing processesFinal product manufactureLithiumOxyanion

Owner:YU DENIS YAU WAI +5

Method for manufacturing high-strength structural stacked capacitor

ActiveUS9349736B2Large electrodeIncrease capacitanceTransistorSolid-state devicesHigh intensityUltimate tensile strength

The instant disclosure relates to a method for manufacturing high-strength structural stacked capacitor. The novel feature of the instant disclosure is forming a part of upper electrode layer to cover the first / outer surface of each of the lower electrode layers before removing the sacrificial layer, and forming another part of upper electrode layer to cover the second / inner surface of each of the lower electrode layers after removing the sacrificial layer. Hence, the structure strength of the lower electrode layer in all process steps has been improved.

Owner:MICRON TECH INC

Joint strengthening ring for graphite electrodes

InactiveUS20060291524A1Improves high column bending strengthHigh strengthElectric discharge heatingRod connectionsGraphite electrodeGraphite

Owner:GRAFTECH INT HLDG INC

Silk screen aided laser soldering method for heterogeneous multi-layer structure

InactiveCN1159130CGuaranteed requirements for fatigue strengthEnsure proper heatingSoldering apparatusLaser beam welding apparatusMetallic materialsOptoelectronics

A wire screen aided laser soldering technology for making multi-layer heterogeneous composite side electrode of element includes coating soldering material on the side of element, putting metallic wire screen in the soldering material, heating by laser beams to fuse them, and cooling to form the side electrode of element. Its advantages include good connection between layers, local heating, no damage to element, high electrode strength, and high machining efficiency.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com