Method for preparing high-tungsten-content tungsten-zirconium alloy

A technology of tungsten-zirconium content, which is applied in the field of preparation of high-tungsten-content tungsten-zirconium alloys. It can solve the problems of demanding alloy properties, tungsten component settlement, and less element diffusion, so as to improve the density, strength and toughness, and improve the distribution state. , The effect of high electrode strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

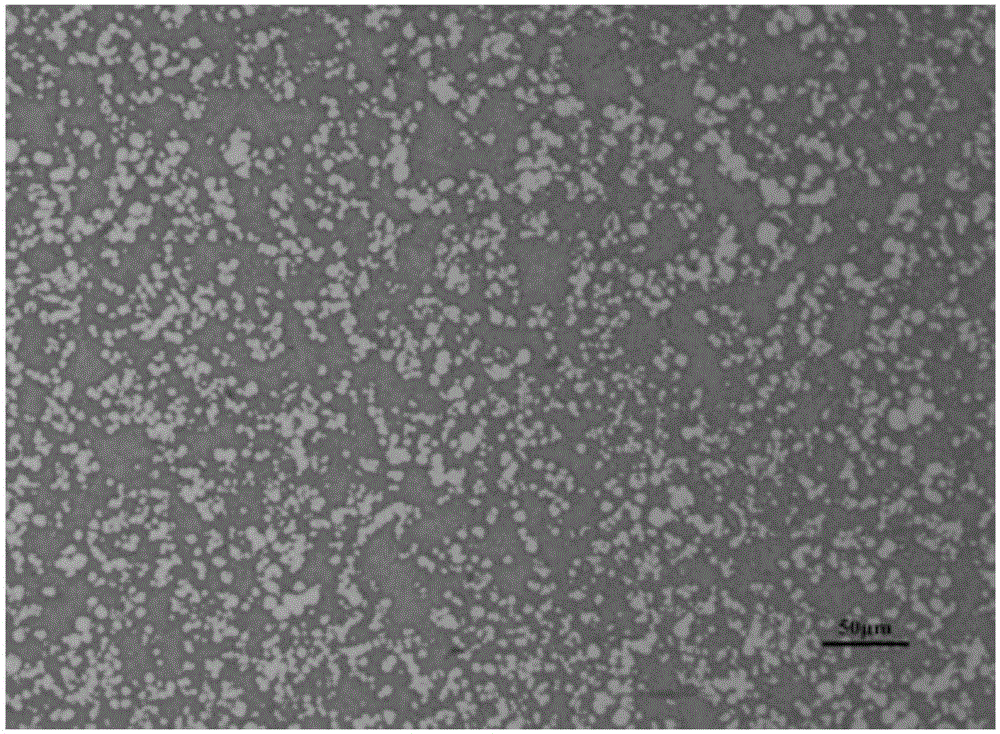

[0025] Embodiment 1: the preparation of ZrTi-50W alloy

[0026] (1) mix powder, mix powder

[0027] Mix ZrTi powder (zirconium titanium powder) and W powder (tungsten powder) with 50% (mass percentage) each, mix evenly with a mixing tank, and mix the powder for 2 hours. After mixing the powder, add 5% SBP glue and granulate .

[0028] In this example, ZrTi powder is produced by gas atomization of zirconium-titanium alloy rods. The zirconium content in the zirconium-titanium alloy is 40-60%, the particle size of ZrTi powder is 100-150 μm, and the particle size of W powder is 3-5 μm. Example 2 It is the same as that of Embodiment 3, and will not be repeated here.

[0029] (2) Pressing and sintering

[0030] Pressing with a cold isostatic press at 220MPa, keeping the pressure for 2 minutes, and releasing the pressure in stages, the green compact was obtained; the green compact was degreased at 600°C for 2 hours, sintered at 1300°C, and kept for 1.5 hours; Cylindrical electro...

Embodiment 2

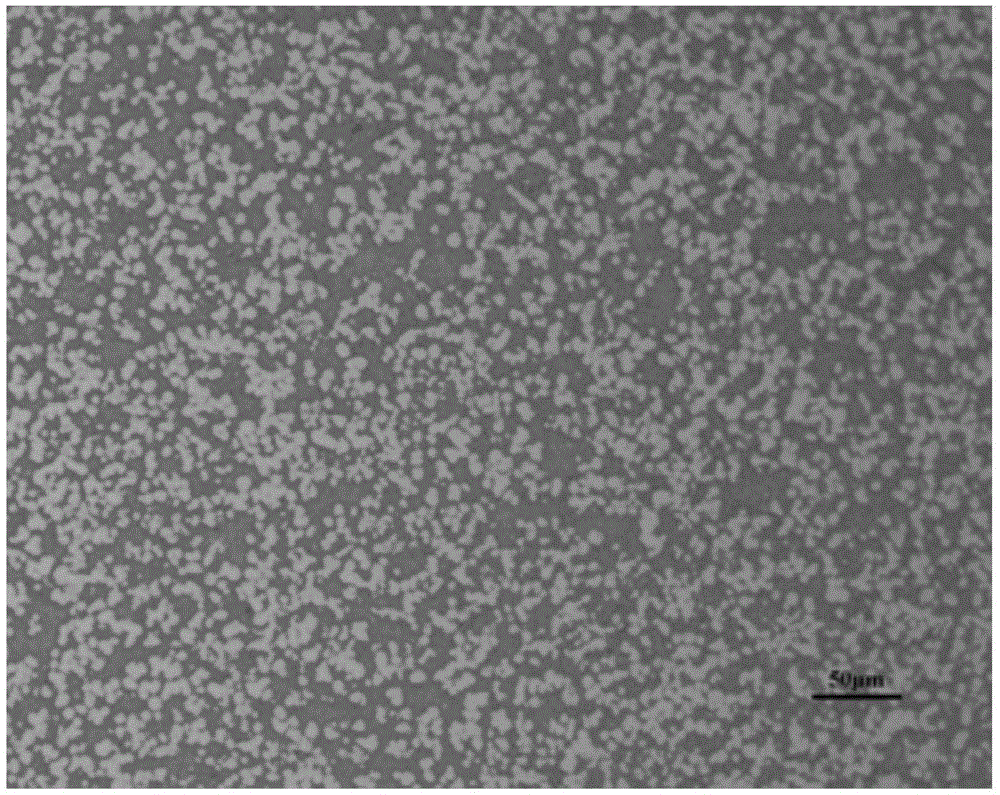

[0039] Embodiment 2: the preparation of ZrTi-60W alloy

[0040] (1) mix powder, mix powder

[0041] Mix 40% ZrTi powder and 60% W powder (mass percentage), mix evenly with a mixing tank, and the mixing time is 2 hours. After mixing, add 5% SBP glue and granulate.

[0042] (2) Pressing and sintering

[0043] Pressed with a cold isostatic press at 220MPa, kept the pressure for 2 minutes, and released the pressure in stages to obtain a compact; degrease the compact at 600°C for 2h, sinter at 1300°C, and keep it warm for 1.5h; Cylindrical electrode, using the electrode as a consumable electrode for consumable arc melting.

[0044] (3) Consumable arc melting

[0045] The vacuum degree of consumable arc melting is 10 -1 Above Pa, the melting voltage is 26V, after a consumable arc melting: the melting current is 1-1.25KA, the arc-stabilizing current is 1.8-2.5A, the melting time is 2-3min, cooled to below 150°C and released from the furnace. Obtain the high tungsten content tun...

Embodiment 3

[0047] Embodiment 3: the preparation of ZrTi-70W alloy

[0048] (1) mix powder, mix powder

[0049] Mix 30% ZrTi powder and 70% W powder (mass percentage), mix evenly with a mixing tank for 2.5 hours, add 5% SBP glue and granulate.

[0050] (2) Pressing and sintering

[0051] Use a cold isostatic press at 200MPa to press, keep the pressure for 3 minutes, and release the pressure in stages to obtain a compact; degrease the compact at 600°C for 2h, sinter at 1300°C, and keep it warm for 1.5h; Cylindrical electrode, using the electrode as a consumable electrode for consumable arc melting.

[0052] (3) Consumable arc melting

[0053] The vacuum degree of consumable arc melting is 10 -1 Above Pa, the melting voltage is 24V, after a consumable arc melting: melting current 1-1.25KA, arc-stabilizing current 1.8-2.5A, melting time 2-3min, cool to below 150°C and take out the furnace. Obtain the high tungsten content tungsten-zirconium alloy (being ZrTi-70W primary ingot) that the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com