Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid bad situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

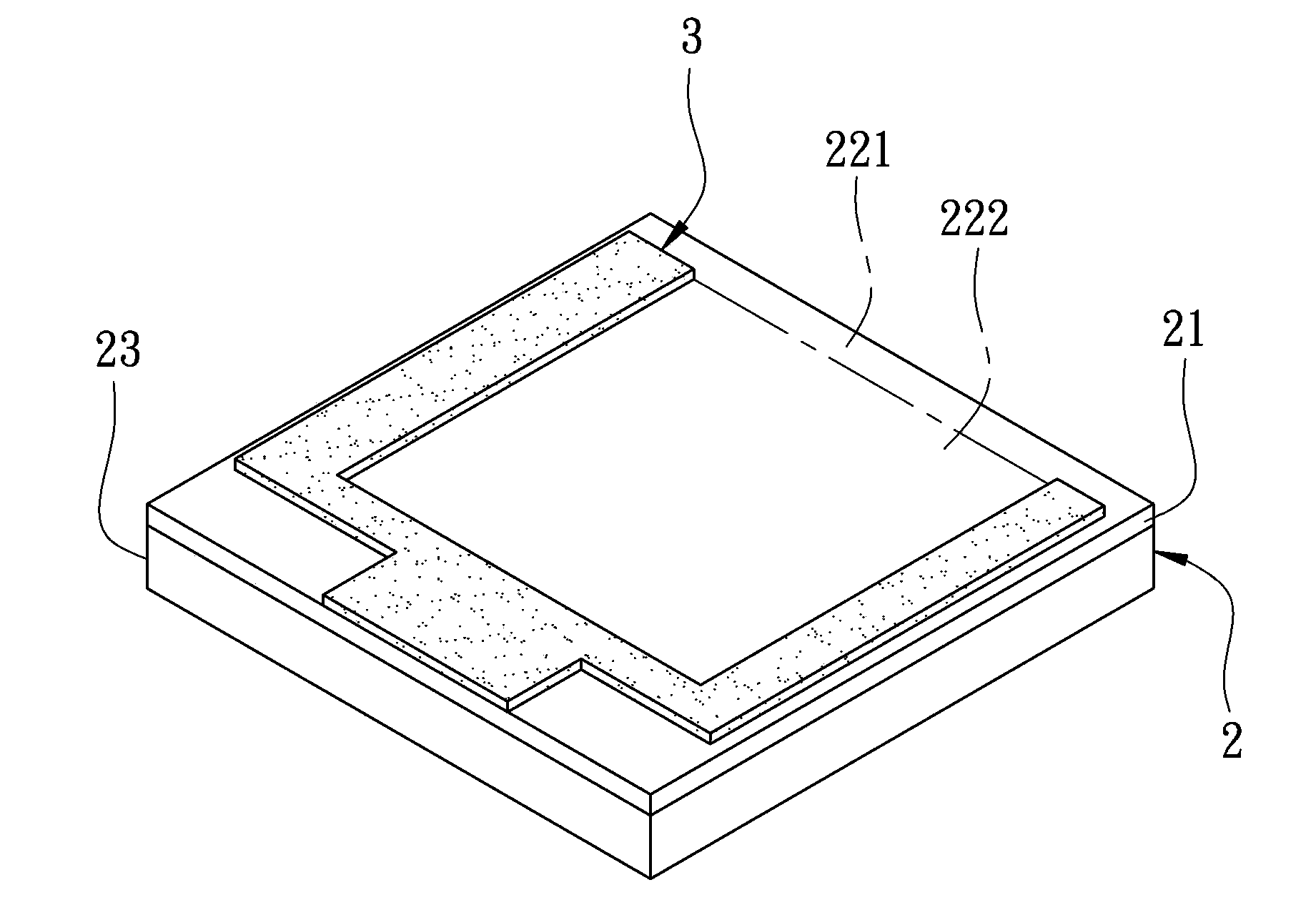

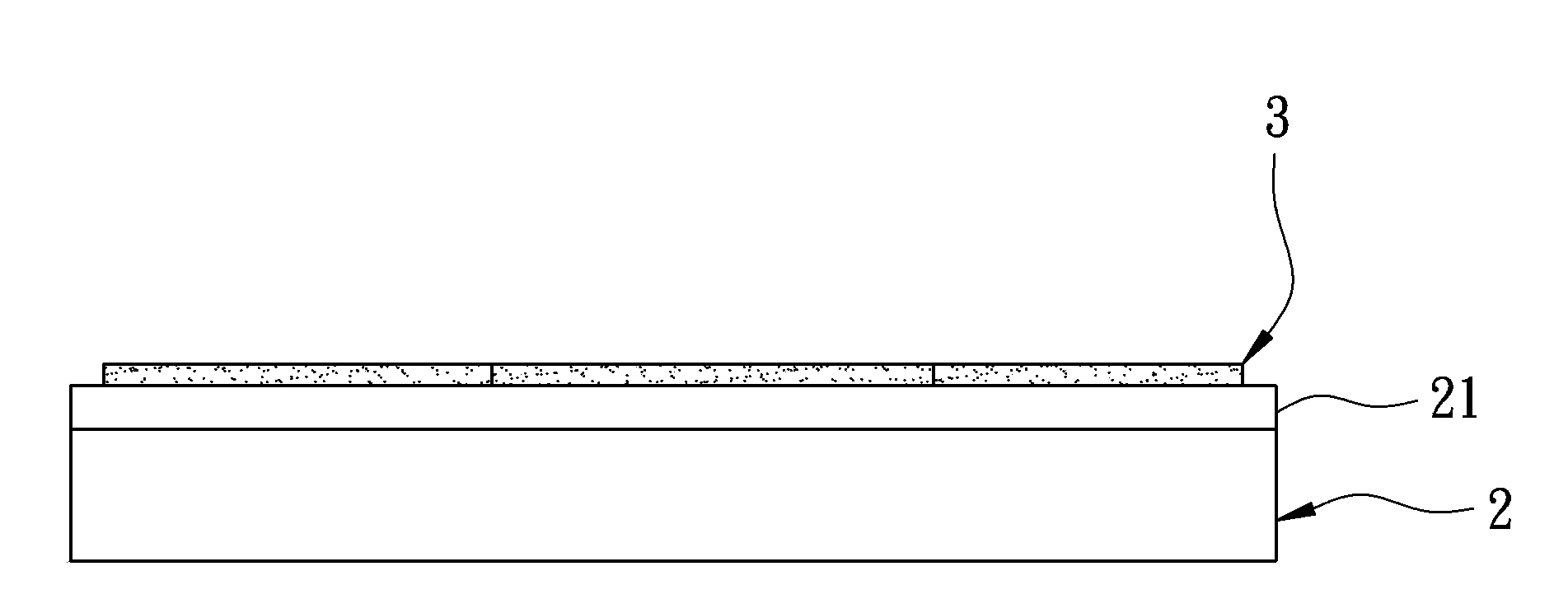

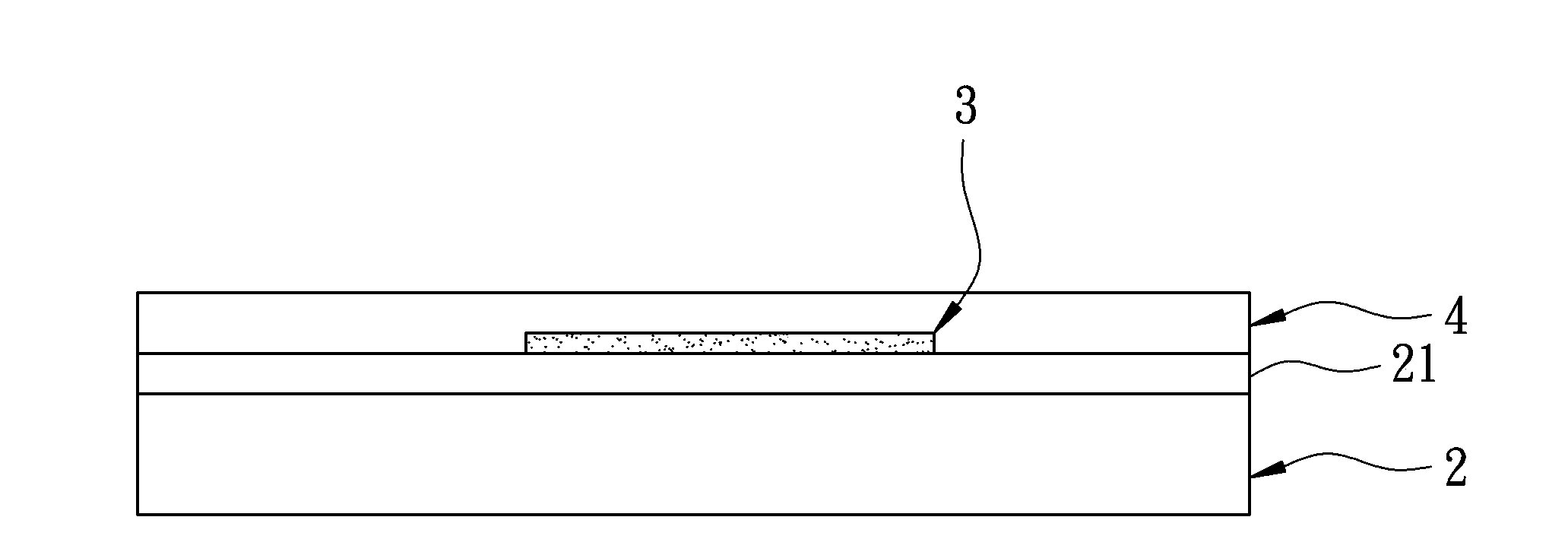

Manufacturing method for touch panel edge wire routing, touch panel and touch display device

InactiveCN103384451AAvoid bad situationsBad or error signal goodConductive material chemical/electrolytical removalInput/output processes for data processingTouch panelSurface smoothness

The invention provides a manufacturing method for touch panel edge wire routing, a control panel with the edge wire routing and a touch display device. The manufacturing method comprises the following steps of (a) forming a photosensitive conductive paste layer on an edge area of a substrate with a transparent conductive layer, enabling the photosensitive conductive paste layer to be at least in partial overlapping with the transparent conductive layer, (b) exposing the photosensitive conductive paste layer by using a mask, and (c) carrying out developing on the exposed photosensitive conductive paste layer to form a patterning edge wire routing unit on the edge area of the substrate. The manufacturing method is beneficial to improving the precision of a wire route under the situation that the wire width of the edge wire routing is narrowed, and can enable the wire route to have good surface smoothness.

Owner:INNOCOM TECH SHENZHEN +1

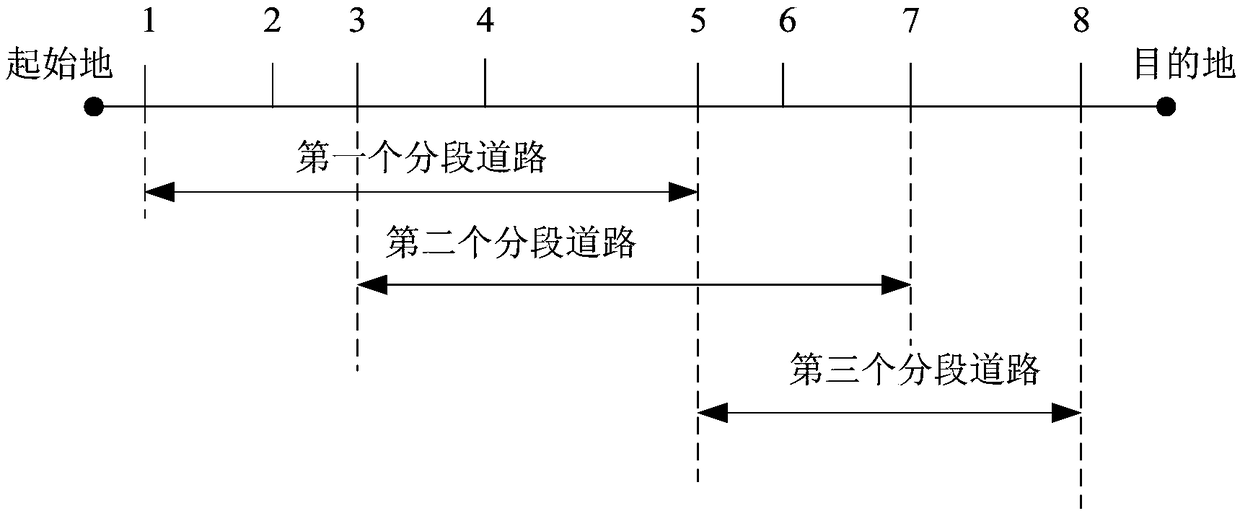

Method and device for determining route

ActiveCN109084788AAvoid bad situationsInstruments for road network navigationTerminal equipmentReal-time computing

The invention provides a method and a device for determining a route. The method comprises the steps of: determining a plurality of candidate routes by a terminal device according to an origination and a destination; segmenting each candidate route according to the number of maneuver points on each candidate route, and acquiring historical user trajectory information of each segment road on each candidate route from the server; and selecting a target route from a plurality of candidate routes according to a historical user trajectory of each segment road on each candidate route, wherein each segment road on the target route is consistent with the corresponding historical user trajectory information. According to the route determining method, since the historical user trajectory is the route actually used by the user, the bad case in the selected target route is avoided.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Grinding device for bearing

InactiveCN106625262AGood effectPlay the role of automatic collection and processingGrinding carriagesGrinding bedsSlagEngineering

The invention discloses a grinding device for a bearing. The grinding device comprises a bearing plate, a connecting rod is arranged on the left side of the top of the bearing plate, a controller is arranged at the bottom of the surface of the connecting rod, the top of the right side of the connecting rod is movably connected with a fixed block through a pulley, a fixed plate is arranged on the right side of the fixed block, a motor is arranged in an inner cavity of the fixed plate in a sleeved manner, a rotating shaft is arranged at the bottom of the motor, a grinding wheel is arranged at the bottom of the rotating shaft, a dust suction cover is arranged on the right side of the top of the bearing plate, dust suction holes are formed in the dust suction cover, a containing ring is arranged in the dust suction cover, and the surface of the containing ring is fixedly connected with a work table. Through cooperation of the dust suction cover, the dust suction holes, through holes, the work table, leakage holes, a dust suction machine and a dust outlet pipe, when the grinding device grinds the bearing, slag or powder can be automatically collected and treated, and therefore when the slag or powder is collected and treated, the effect is better.

Owner:浙江豪科精工技术有限公司

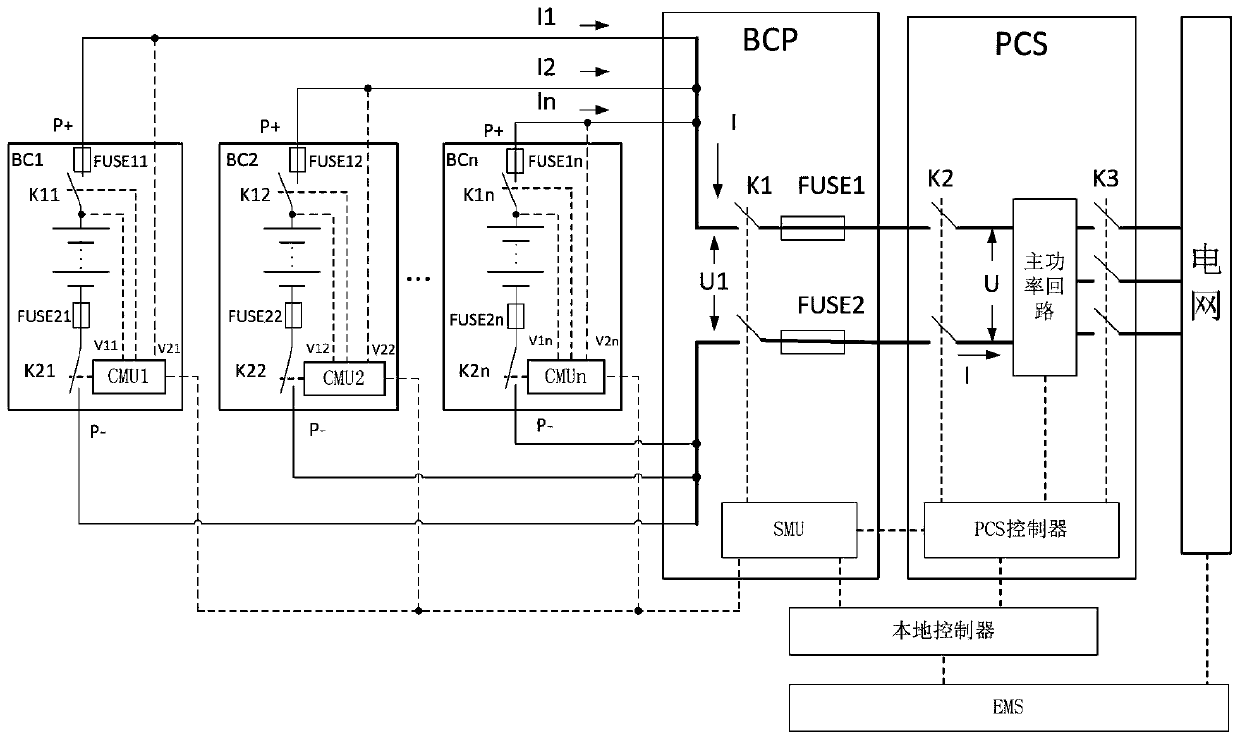

Start-up self-detection method of energy storage system and application device and system thereof

ActiveCN110690721ARealize self-testAvoid bad situationsEarth resistance measurementsElectrical testingTerminal voltageControl engineering

The invention provides a start-up self-detection method of an energy storage system and an application device and system thereof.The PCS controller controls the soft start of the main power loop in the PCS under the condition that the positive relay and / or the negative relay in each battery cluster in the energy storage system is disconnected so that the DC side of the PCS establishes DC voltage and receives the detection value of the DC voltage. Then the positive and negative relays in the BCP are controlled to be closed. Then the detection value of the output terminal voltage of each batterycluster is received through the CMU in each battery cluster. If the output terminal voltage of each battery cluster and the DC voltage meet the corresponding relationship, it is determined that the positive and negative connection of the output terminal of each battery cluster is normal; if the output terminal voltage of the battery cluster and the DC voltage do not meet the corresponding relationship, it is determined that the positive and negative connection of the output terminal of the corresponding battery cluster is abnormal so that the self-detection of the connection condition betweenthe battery cluster and the BCP of the energy storage system before starting up is realized and the occurrence of bad conditions caused by connection errors is avoided.

Owner:SUNGROW POWER SUPPLY CO LTD

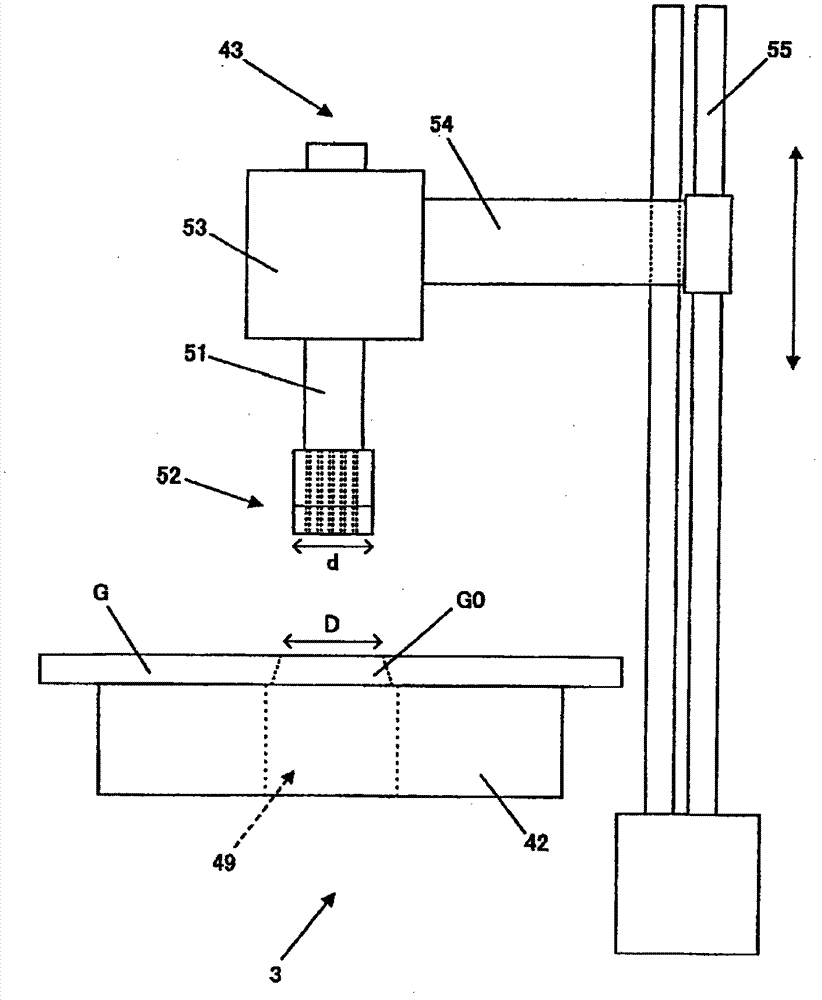

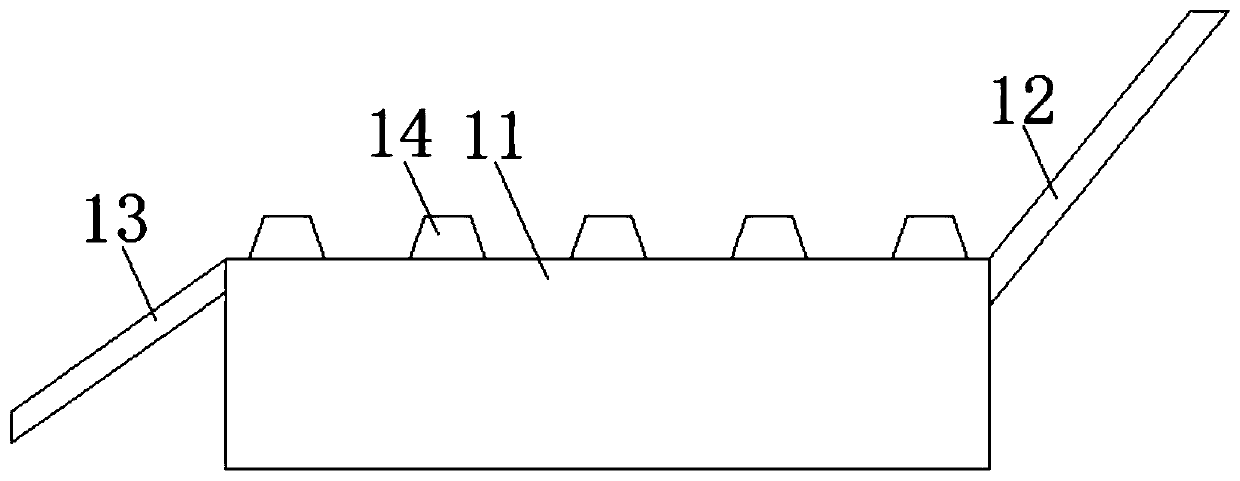

Internal circumference processing method of fragile material substrate

InactiveCN102729345AAvoid bad situationsImprove processing qualityWorking accessoriesFine working devicesEngineeringMechanical engineering

The invention relates to an internal circumference processing method of a fragile material substrate. In the internal circumference processing, a central area in an inner contour line is cut and can be definitely separated, and a separating face can not generates a gap. The method includes a line marking step (a), i.e. forming a marking line C1 as the inner contour line of the internal circumference on a first face of the fragile material substrate G via a scribing wheel 22, wherein a cutting edge chine line of the scribing wheel is periodically formed with a groove 22 which tilts to the axial direction of the scribing wheel; a pressure adding step (b), i.e. using a plate 42 which does not contact with the central area G0 in the inner contour line C1 and is provided with a hole 49 to support the substrate G and to exert the pressure W on the central area G0; and a center cutting step (c), i.e. under the pressure adding condition, separating the central area G0 through cooling and contracting the central area G0.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Method for producing fibers having a low surface energy, and fibers, yarns and textiles having a low surface energy

InactiveCN104790054AImprove antifouling performanceAvoids undesirable conditions caused by heated coking scalesMelt spinning methodsMonocomponent polyolefin artificial filamentYarnPolymer science

The present invention relates to a method for producing a low surface energy fiber having a long-term liquid repellency and anti-stain effect. The present invention relates to an addition of a specific ratio of low surface energy additives to a thermoplastic polymer used as a spinning raw material, which is subjected to spinning processing procedure, such as melting spinning, to produce fibers with a surface tension of between 25˜72 dyne / cm.

Owner:SHINKONG SYNTHETIC FIBERS

Protection device used for oscillation water column type ware energy system air chamber

InactiveCN1556322AFully protectedAvoid bad situationsMachines/enginesEngine componentsEngineeringTurbine

In present system of using wave energy, structure of air chamber is an important point. In general protection method, a flush flow unit is setup in structure of air chamber, but this arrangement has obvious disadvantages. Disclosed protection unit as a flush flow orifice is arranged on top of air chamber. Under operating state, the flush flow orifice is closed by a cover board. Compressed air inside the air chamber through aeration conduit impacts turbine to drive power set to generate energy. In case of abnormal circumstance happening, pressure is increased inside air chamber. The protection unit is opened automatically. Pressure is discharged from top of the air chamber so as to protect safety of structure of air chamber, turbine and power set.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

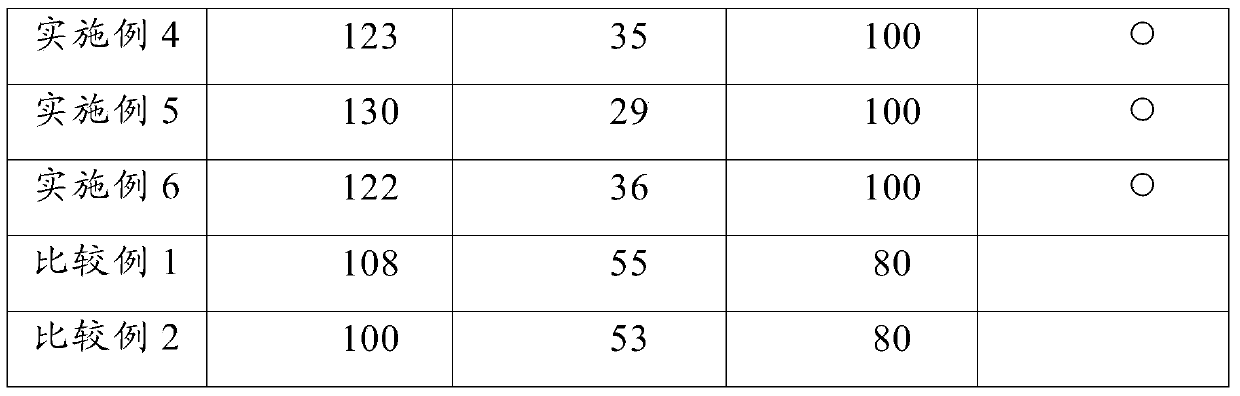

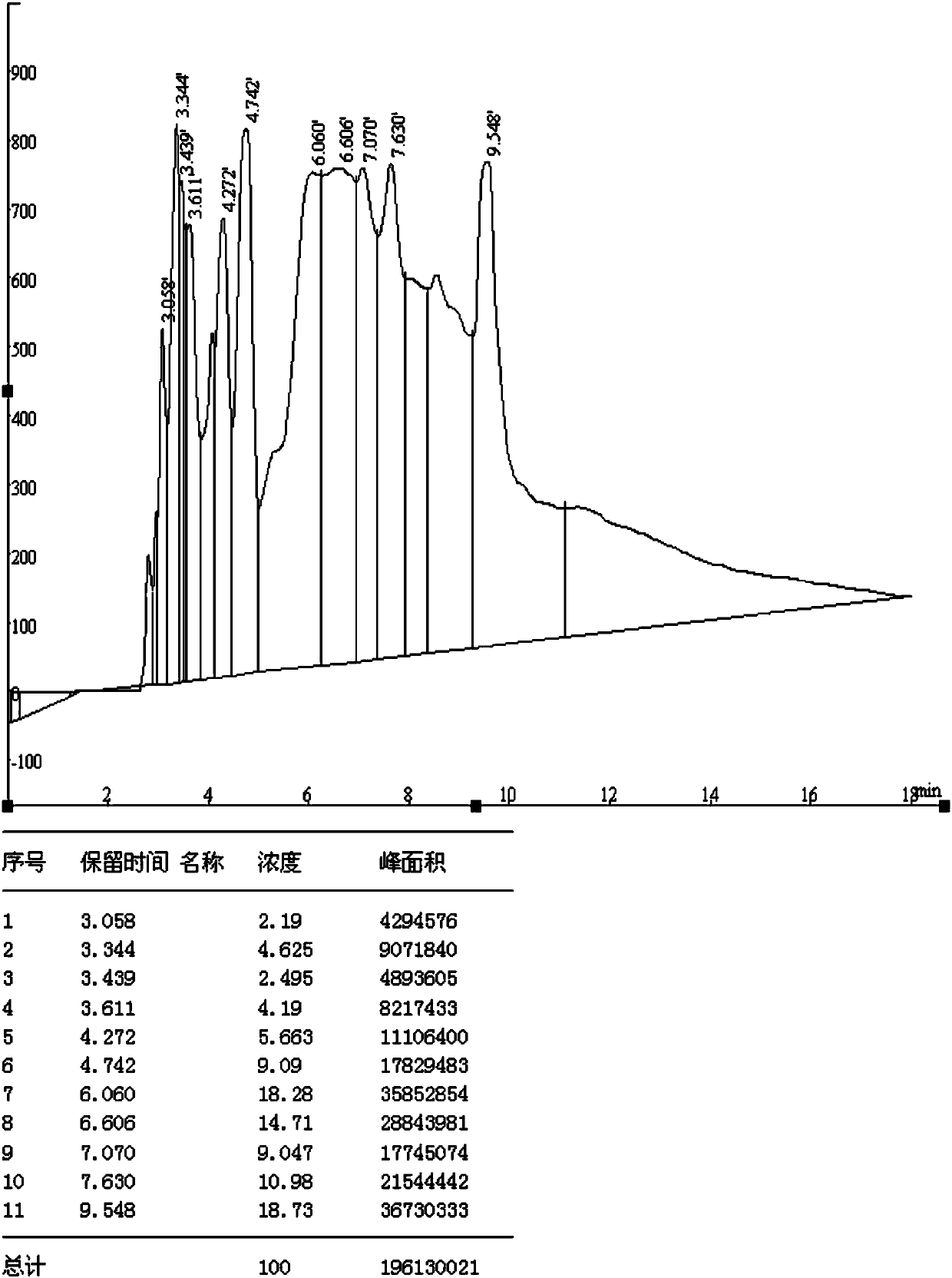

Purification method of hydrophobic polypeptide raw material

InactiveCN107698656AReduce spreadReduce energy costsPeptide preparation methodsOrganic solventPurification methods

The invention discloses a purification method of a hydrophobic polypeptide raw material. The purification method comprises steps of (1) polypeptide raw material dissolution, (2) normal-phase chromatographic analysis, and (3) chromatographic column preparation, adsorption, elution and collection. In step (1), a polypeptide raw material is dissolved into an organic solvent to obtain a solution of the polypeptide raw material. In step (2), the solution of the polypeptide raw material is connected to a normal-phase chromatographic column to carry out gradient detection to obtain analysis atlases.In step (3), according to the analysis atlases, the preparation gradient of chromatographic column is set, the solution of the polypeptide raw material is connected to the prepared chromatographic column to carry out adsorption, then the chromatographic column is eluted, and the eluent is collected to obtain purified hydrophobic polypeptide raw material. The purification method solves the problemsthat a large amount of a strongly hydrophobic raw material is hard to dissolve, the sample is not easy to elute in reverse phase preparation, and the recovery rate is low.

Owner:苏州强耀生物科技有限公司

Wet etching device

InactiveCN103526205AAvoid enteringReduce exceptionSemiconductor/solid-state device manufacturingDevice materialEngineering

The invention discloses a wet etching device. The wet etching device comprises a machine table and a connecting pipeline, wherein liquid medicine is contained in the machine table for etching a semiconductor device placed in the machine table; the connecting pipeline is connected to the bottom of the machine table and used for conveying the liquid medicine to the machine table; the connecting pipeline comprises a liquid getting pipeline, a liquid level slot and a liquid level sensor, wherein the liquid getting pipeline is communicated with the bottom of the machine table; the liquid level slot is connected on the liquid getting pipeline and used for dividing the liquid getting pipeline into a first pipeline and a second pipeline which are communicated from top to bottom; the first pipeline is arranged above the second pipeline; the liquid level slot is mutually communicated with the first pipeline and the second pipeline, and the liquid medicine is distributed from the second pipeline to flow to the first pipeline and the liquid level slot; the liquid level sensor is connected outside the liquid level slot; the wet etching device is characterized in that the wet etching device further comprises a filter device which is connected in the connecting pipeline.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Sewing machine for long-striped ribbon

ActiveCN107653580AAvoid bad situationsEnsure safetyWorkpiece carriersWork-feeding meansSewing machine

The present invention provides a sewing machine for sewing a tape, which has a fabric blocking device, a fabric blocking device that sequentially transports and feeds a plurality of fabrics while theside sequentially transports a plurality of fabrics, and the fabric is continuously fed and fed by the sewing portion on the side edges of the plurality of fabrics. In the case where the sewing fabricterminating end portion of the preceding fabric reaches the predetermined tape cutting position, the fabric portion that protrudes toward the downstream side in the sewing proceeding direction of thetape sewn portion in the sewing start end portion of the succeeding fabric can be partially avoided. With the tape cutting position of the tape cutting device or the position on the upstream side ofthe tape advancing direction from the tape cutting position, it is possible to avoid a disadvantageous situation in which the portion of the succeeding fabric is unnecessarily cut, and so that the tape is not worn. The waste is generated automatically and accurately.

Owner:YAMATO SEWING MASCH MFG CO LTD

Intelligent classification garbage can used for intelligent city construction

InactiveCN111591623AAvoid throwing inImprove recycling efficiencyRefuse receptaclesSmart cityGarbage collection

The invention discloses an intelligent classification garbage can used for intelligent city construction. The intelligent classification garbage can comprises a garbage can. A ventilation pipeline isarranged in the garbage can. A ring-shaped garbage groove is formed in the outer end wall of the ventilation pipeline. A camera used for analyzing the garbage kinds is arranged on the end wall of theside, close to the ventilation pipeline, of the ring-shaped garbage groove. The intelligent classification garbage can is simple in structure, convenient to operate and convenient to maintain. The device can be used for automatically classifying garbage, the phenomenon that people with low quality directly throw unclassified garbage into the garbage can is avoided, meanwhile, the workload of workers in a garbage recycling station is reduced, the garbage recycling efficiency is improved, in addition, the device is used for purifying air in the garbage can and around the garbage can, and therefore the phenomenon that garbage in the garbage can is fermented in the normal-temperature environment, and the air around the garbage can is degraded is avoided, the air quality around the garbage canis improved, and the device has high use and popularization value.

Owner:黄家顺

Flexible damping bearing bush

ActiveCN111089117AReduce the amplitudeAvoid bad situationsBearing componentsVibration suppression adjustmentsReciprocating motionPiston

The invention belongs to the application field of rotating machinery and particularly relates to a flexible damping bearing bush which is composed of a bush outer ring, a bush inner ring, a bush mainbody, a damping piston and a sealing ring, wherein an annular hydraulic oil cavity is formed in the bush outer ring; a plurality of piston cavities are uniformly distributed in the bush main body in the circumferential direction; the piston cavities communicate with the annular hydraulic oil cavity through damping holes formed in the bush main body; the damping piston is mounted in the piston cavities uniformly formed in the circumferential direction; the root part of the damping spring is fixedly connected with the bush inner ring and does reciprocating motion in the piston cavities to extrude or absorb hydraulic oil; the sealing ring is arranged between the damping piston and the piston cavities and is mounted in a sealing ring mounting groove at the upper section of the damping piston;the bush outer ring, the bush main body and the bush inner ring are sequentially and concentrically stacked; and a damping device is further arranged between the bush main body and the bush inner ring.

Owner:中国航发贵阳发动机设计研究所

A corn threshing device

ActiveCN108966850BGuarantee threshing qualityThreshing cleanThreshersGear wheelAgricultural engineering

The invention discloses a corn threshing device and relates to the technical field of corn threshing. The progressive corn threshing device based on the geometric relationship of the space coordinate axis includes a body, the left side of the top of the body is provided with a material inlet, and the right side of the inner wall of the body is fixedly installed with a guide slide plate, and the bottom of the guide slide plate is provided with a A support plate, and the front and rear sides of the support plate are respectively fixedly connected with the front and rear sides of the inner wall of the body, the middle part of the top of the support plate is provided with a first rotating motor, and the output shaft of the first rotating motor is sleeved with a driving gear. The corn threshing device based on the progressive geometric relationship of the spatial coordinate axis effectively solves the problem of It solves the problem that the traditional corn thresher cannot perform relatively complete threshing of the corn kernels at both ends of the corn.

Owner:徐州全盛电机有限公司

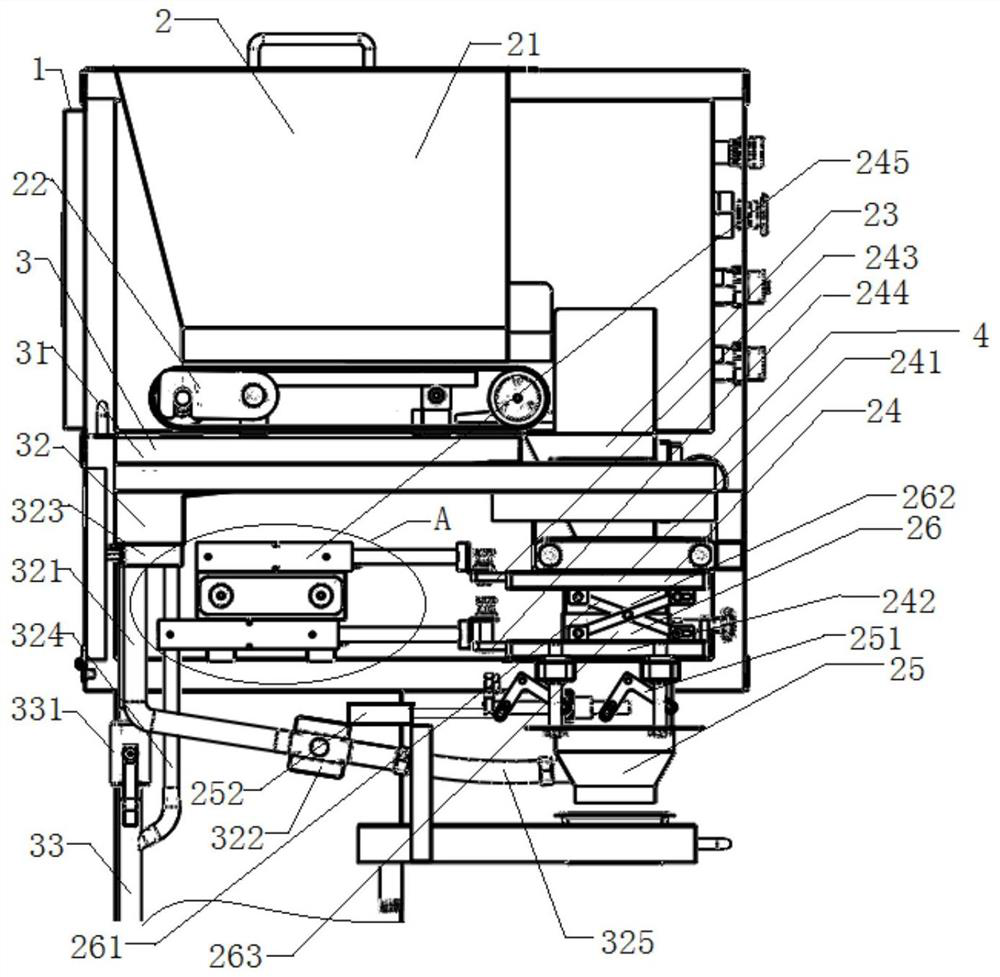

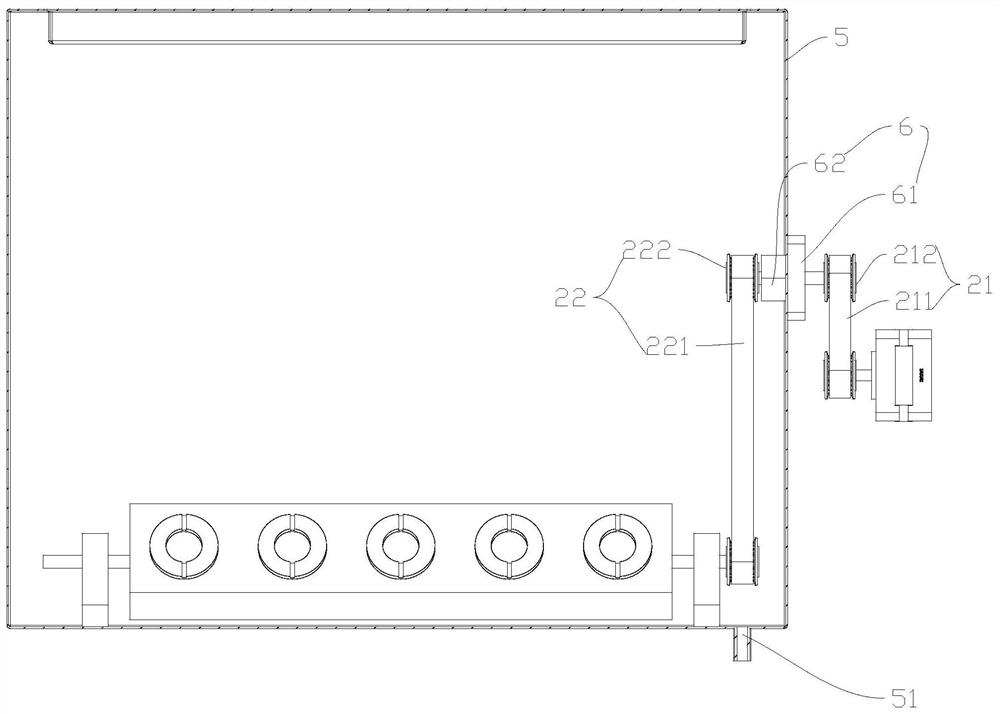

Novel quantitative dish distribution machine

PendingCN113892825APlay a role in heat preservationImprove the efficiency of cookingCooking vesselsMechanical engineering

The invention relates to a novel quantitative dish distribution machine, and belongs to the field of catering equipment. The machine comprises a shell, a dish distributing device and a soup receiving device; the dish distributing device comprises a dish pouring funnel, a dish-soup separating device, a dish discharging funnel, a quantitative dish distributing container, a cutting device and a dish distributing funnel, the dish pouring funnel is arranged on the shell, the dish-soup separating device is arranged below the dish pouring funnel, the dish discharging funnel is arranged below the dish-soup separating device, the cutting device is arranged on the dish discharging funnel, the quantitative dish distributing container is installed on the cutting device, and the dish distributing funnel is arranged below the cutting device; and the soup receiving device comprises a soup receiving plate, a soup storage funnel and a soup discharging pipe, the soup receiving plate is arranged below the dish-soup separating device, the soup receiving plate is provided with the soup storage funnel, and the soup storage funnel is provided with the soup discharging pipe. The problems of high manual dish serving cost and low dish serving efficiency are solved, the dish distribution speed of a canteen is increased, the canteen operation cost is reduced, an important link of automatic dish distribution is provided for modernized construction of a central kitchen, and the modernized catering service is more efficient and sanitary.

Owner:安徽川上中央厨房设备有限公司

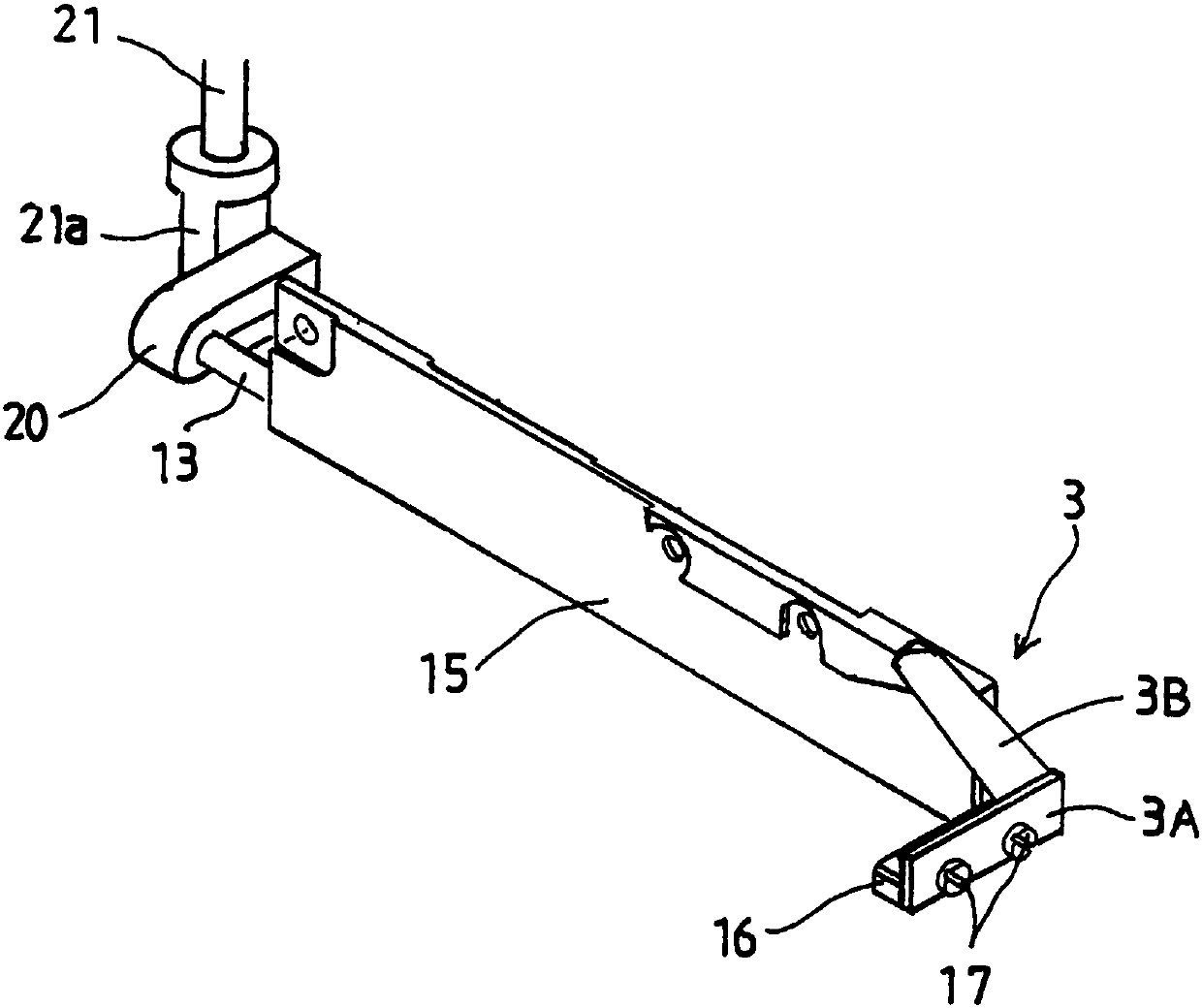

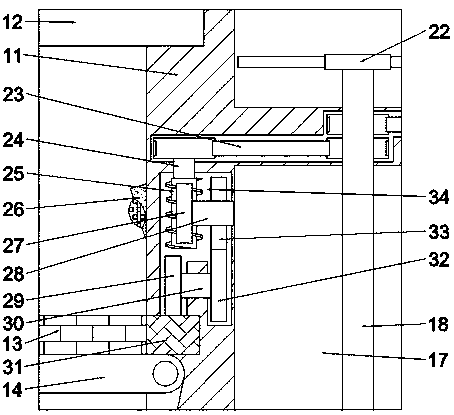

Holding structure of safety belt

InactiveCN102529877AImprove the environmentReduce forming costBelt anchoring devicesEngineeringBelt safety

The present invention provides a holding structure of a safety belt, which has the following functions: reducing forming cost, improving appearance quality and improving environment in the carriage. An inner decoration component (2) has a vertical two-part structure which is composed of an upper inner decoration component (10) and a lower inner decoration component (20). An appearance surface (20M) side of the inner decoration component is provided with a safety belt holding member (30) which is used for snapping and holding the safety belt (3). The safety belt holding member is integrally formed at a random one selected from a lower end of the upper inner decoration component in mutual connection, and furthermore projects from a sub-molding-surface of the random one. The safety belt holding member furthermore opposes a holding surface (17) of the appearance surface side of the other member in the lower end of the upper inner decoration component and the upper end of the lower inner decoration component. The safety belt is inserted between the safety belt holding member and the holding surface and is jointed with the safety belt holding component.

Owner:SUZUKI MOTOR CORP

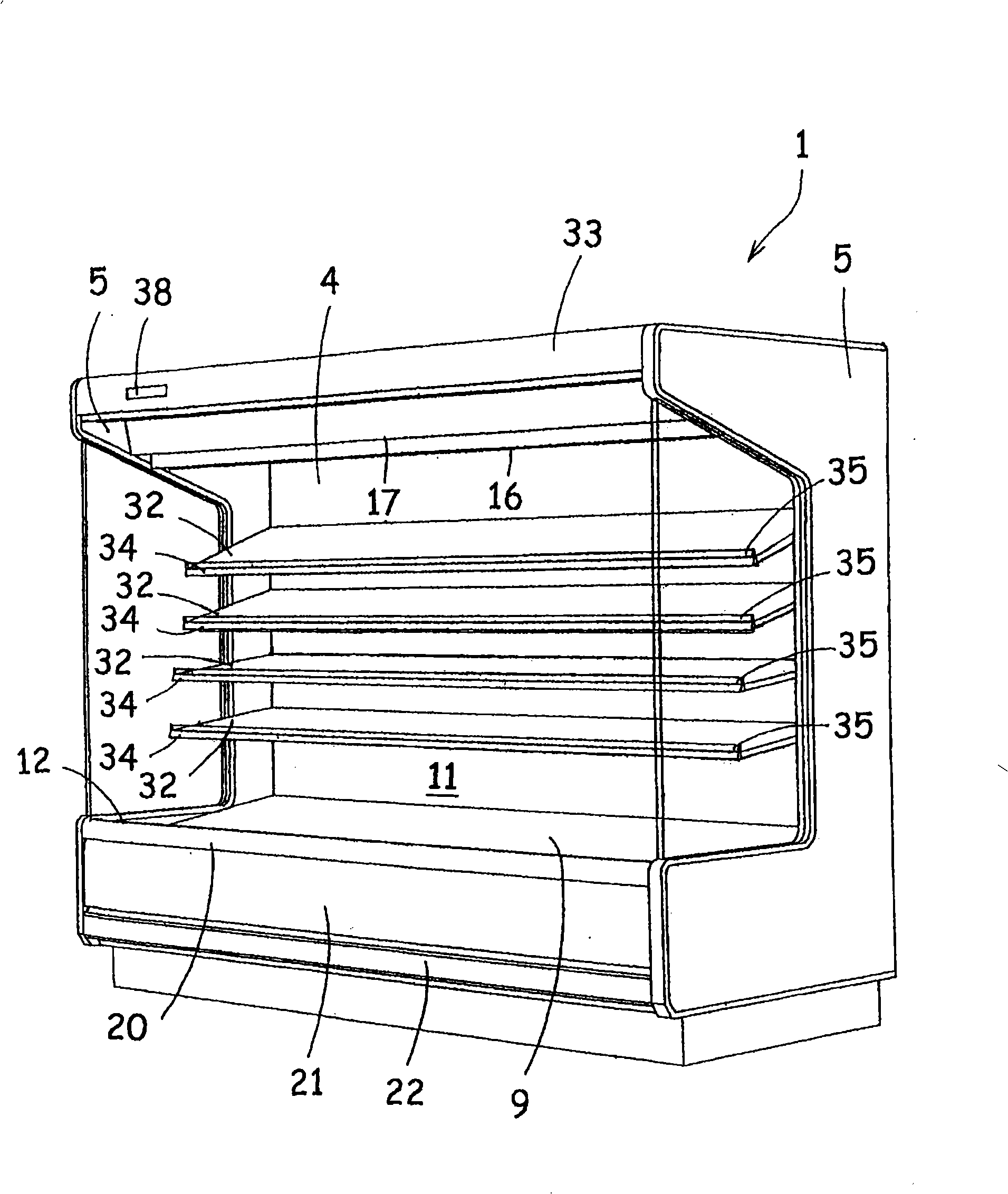

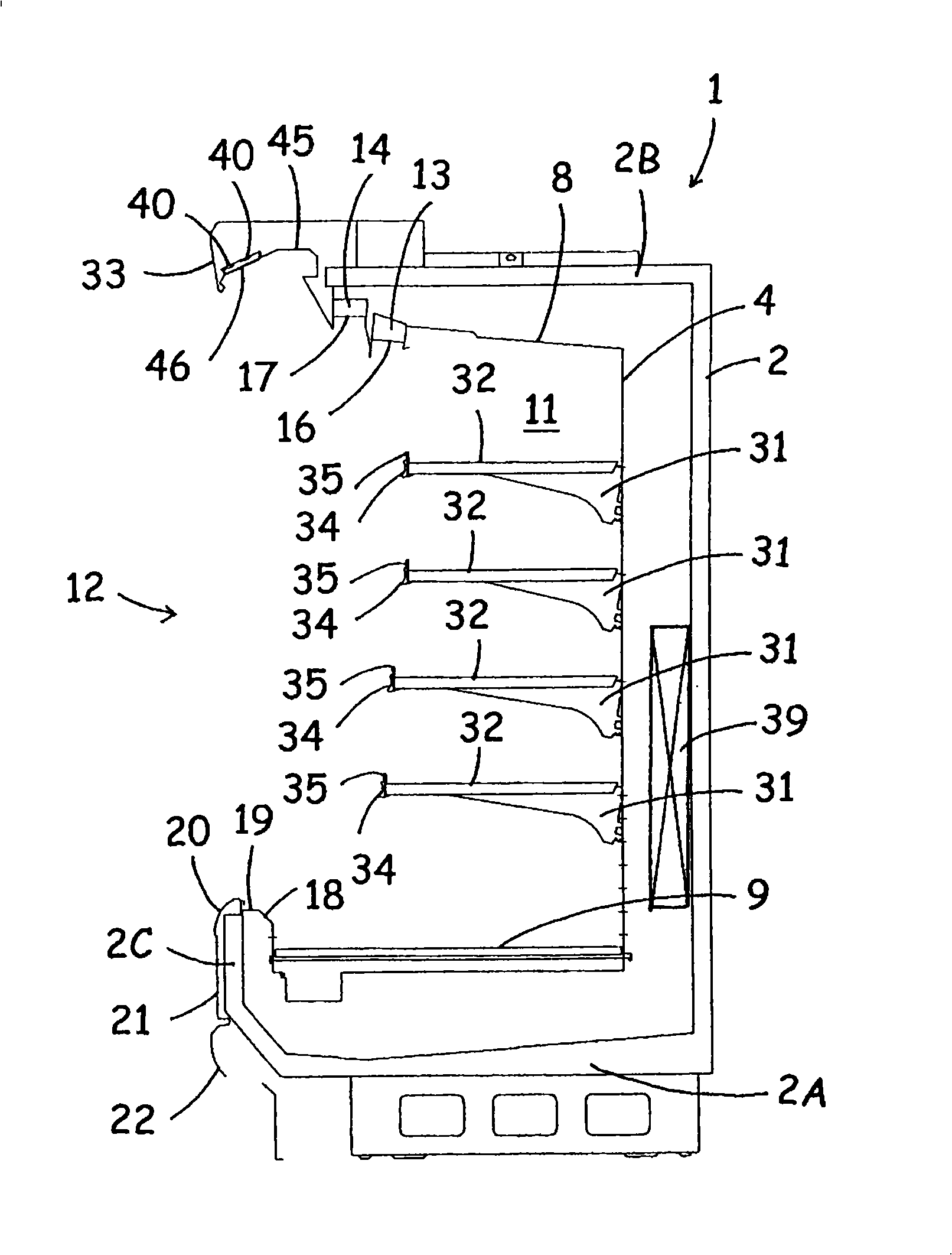

Open showcase

InactiveCN101256047AEffective lightingSimple structureShow cabinetsMechanical apparatusCold airEngineering

Owner:SANYO ELECTRIC CO LTD

Progressive corn threshing device based on spatial coordinate axis geometric relationship

ActiveCN108966850AGuarantee threshing qualityThreshing cleanThreshersGeometric relationsTransmission belt

The invention discloses a progressive corn threshing device based on a spatial coordinate axis geometric relationship, and relates to the technical field of corn threshing. The progressive corn threshing device based on the spatial coordinate axis geometric relationship comprises a machine body, wherein the left side of the top of the machine body is provided with a feeding port, the right side ofthe inner wall of the machine body is fixedly provided with a guiding sliding plate, a supporting plate is arranged under the guiding sliding plate, the front and rear sides of the supporting plate are fixedly connected to the front and rear sides of the inner wall of the machine body respectively, the middle of the top of the supporting plate is provided with a first rotating motor, an output shaft of the first rotating motor is in sleeved connection with a driving gear. The progressive corn threshing device based on the spatial coordinate axis geometric relationship has the advantages thatthrough the cooperative arrangement of an air cylinder, a beam, a third rotating motor, a rotating wheel, a transmission belt, a connecting rod, a moving plate, a rotating shaft and a concave cutter wheel, the problem is effectively solved that a traditional corn thresher cannot more completely thresh corn kernels at the two ends of corn.

Owner:徐州全盛电机有限公司

Power-on self-test method of energy storage system and its application device and system

ActiveCN110690721BRealize self-testAvoid bad situationsEarth resistance measurementsElectrical testingElectrical batteryTerminal voltage

Owner:SUNGROW POWER SUPPLY CO LTD

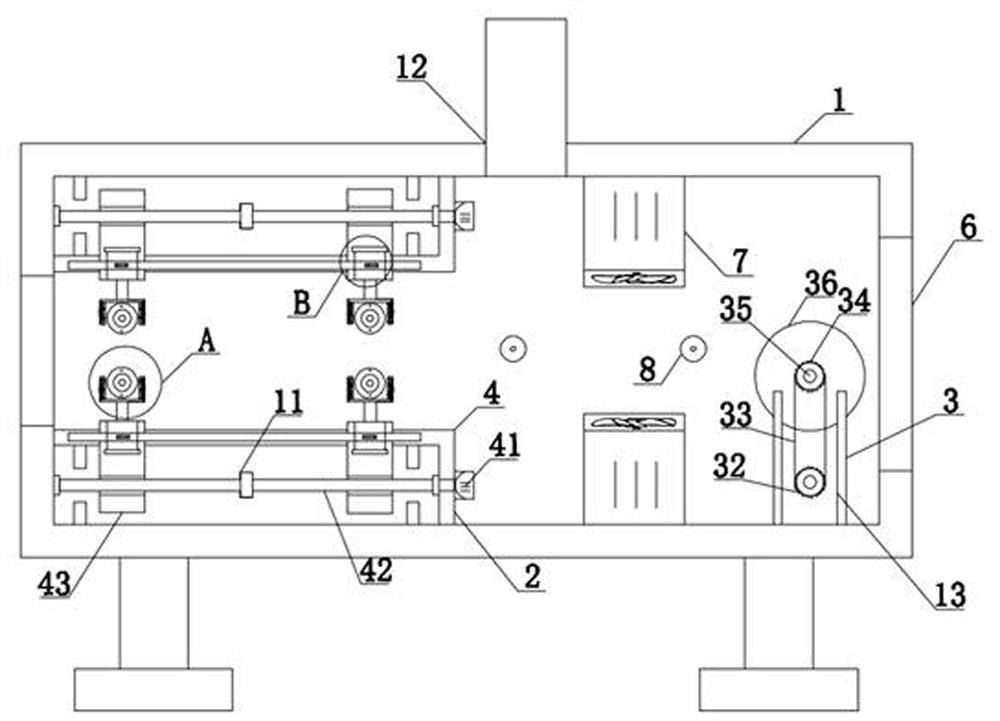

Production equipment of macromolecular electrothermal film electrode

PendingCN114193680ACircumstances that shorten the service lifeImprove cooling effectOhmic-resistance electrodesFlat articlesElectric machineEngineering

The production equipment comprises a processing box and is characterized in that through holes are formed in the left side and the right side of the processing box correspondingly, fixing frames are fixedly connected to one sides of the interiors of the upper end and the lower end of the processing box correspondingly, and guiding mechanisms are arranged in the fixing frames; a fixing seat is arranged on one side of the guide mechanism, a first motor in the driving mechanism drives the winding roller to rotate, a formed electrothermal film sequentially passes through the cooling roller and the guide roller to be wound in the winding roller, a cooling mechanism is arranged in the cooling roller, a cooling pipe in the cooling mechanism enables the temperature of the cooling roller to be reduced, and therefore the electrothermal film can be cooled. And two groups of first fans are matched, so that the conditions that the electrothermal film is too high in temperature and too slow in cooling, the quality of finished products is influenced and the service life of the electrothermal film is shortened can be avoided, heat dissipation after the electrothermal film is formed is facilitated, the working efficiency of the cooling mechanism can be improved through the guide mechanism, and cooling processing of the electrothermal film is facilitated.

Owner:浙江波仕科技有限公司

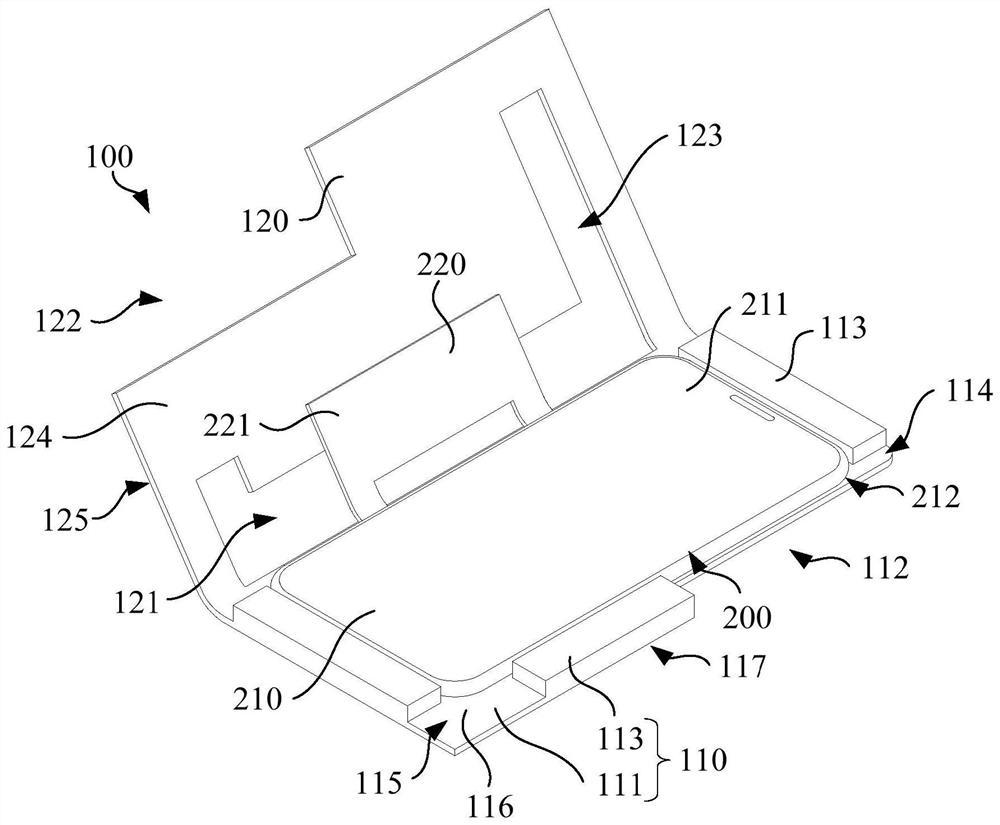

Detection jig and detection method

PendingCN112730250AImprove the detection effectAvoid damageOptically investigating flaws/contaminationEngineeringStructural engineering

The invention relates to a detection jig and a detection method. The detection jig comprises a first jig plate used for limiting a workpiece, wherein the first jig plate comprises a first inner side face and a second inner side face which are arranged oppositely; and a second jig plate which is connected with the first jig plate, wherein the second jig plate comprises a second inner side face and a second outer side face which are arranged back to back, the detection jig has an open state and a closed state, and when the detection jig is in the open state, the first inner side face and the second inner side face are located on the same side of the workpiece, when the detection jig is in the closed state, the first inner side surface is opposite to the second inner side surface; an avoiding groove is formed in the second jig plate and used for being opposite to a flexible element of the workpiece. When the detection jig is used for detecting the workpiece, the hands of the human body can complete detection of all surfaces of the workpiece without contacting with the workpiece, and the detection effect is good.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Cleaning arm for atomizer and using method of cleaning arm

InactiveCN113117949AExtended service lifeAvoid adverse conditions that affect the atomization effectLiquid spraying apparatusElectric machineEngineering

The invention provides a cleaning arm for an atomizer and a using method of the cleaning arm, and belongs to the field of household appliance accessories. The cleaning arm comprises a stepping motor, a belt rotating assembly and atomizing arms. The output end of the stepping motor is connected with the input end of the belt rotating assembly. The output end of the belt rotating assembly is connected with one end of each atomizing arm. A plurality of atomizing sheets are screwed on the upper surface of each atomizing arm; and the atomizing pieces are distributed on the upper surface of each atomizing arm at equal intervals. The output shaft of the stepping motor rotates clockwise, then a second drive belt rotating assembly works, overturning of the atomizing arms is changed, and the atomizing pieces fixed to the atomizing arms at equal intervals are also overturned. Liquid left after atomization slides off from the surfaces of the atomizing pieces under the action of gravity, so that the surfaces of the atomizing pieces are kept dry, and the adverse situation that the atomizing effect is affected due to scale or impurities generated by accumulation and precipitation of the liquid left for a long time is avoided.

Owner:广东鑫隆崟丰智能设备有限公司

A method of capture, early warning and avoidance of power grid "flash"

ActiveCN106532632BHigh precisionLow costElectrical testingEmergency protective arrangements for automatic disconnectionCapacitanceProduction line

Owner:SHIJIAZHUANG XUXIN OPTOELECTRONIC TECH CO LTD

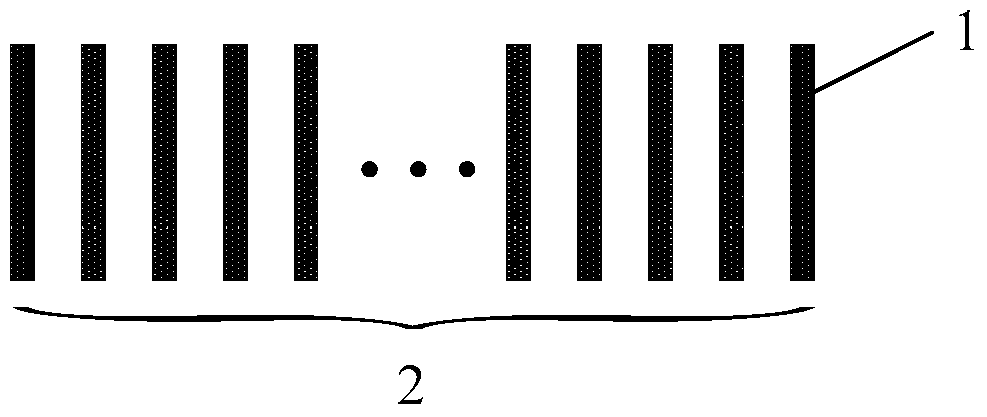

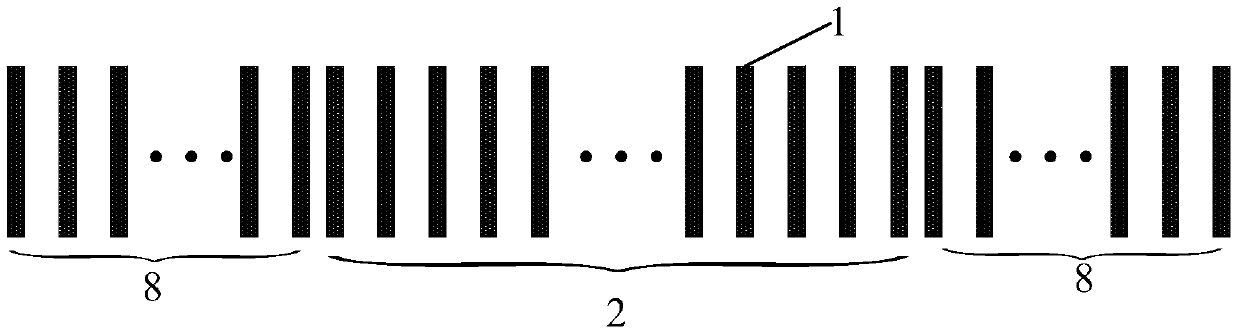

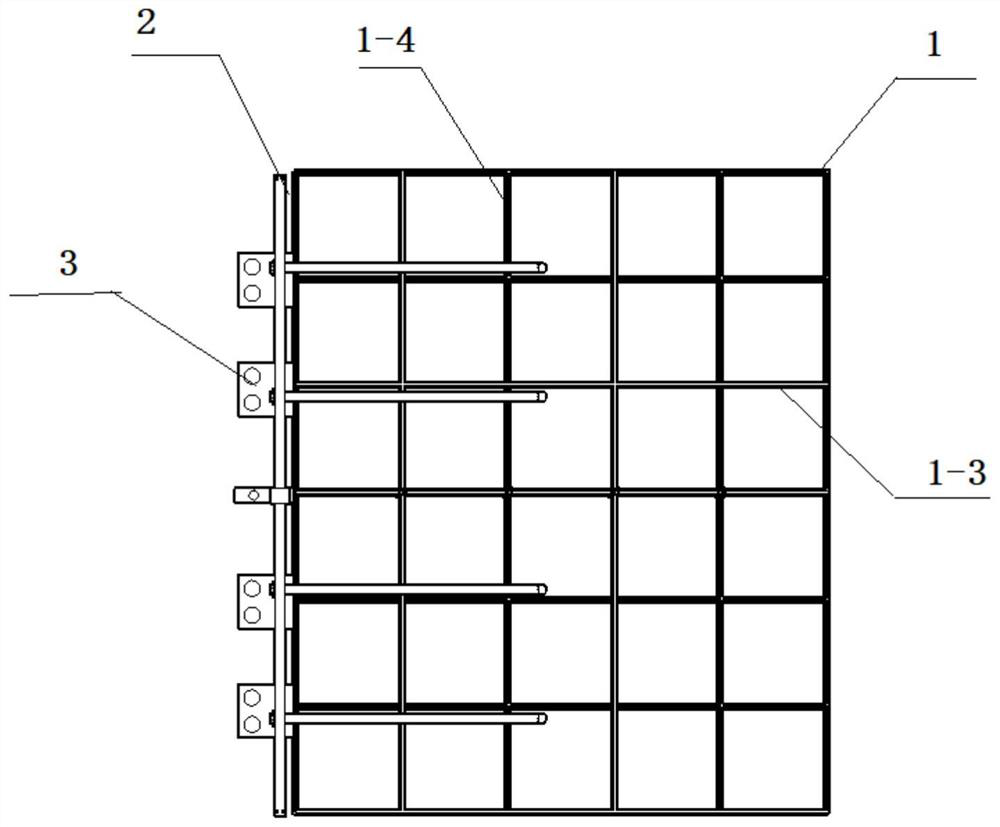

Probe block for detection and detection device thereof

ActiveCN104360510BSolve the problem of short circuitImprove bad detection rateStatic indicating devicesElectrical measurement instrument detailsImaging qualityImage quality

Embodiments of the present invention provide a probe block for detection and a detection device thereof, which relate to the field of display technology and solve the problem of short circuit between probes when the existing probe block is used to detect a display panel, avoiding failure The defect detection of the display panel occurs, which improves the defect detection rate of the display panel, ensures the display quality of the display panel images, and further avoids the waste of production materials and reduces the production cost. The probe block includes: applied to the detection of the display panel, the probe block includes probes, and the probe block has a first probe area corresponding to the lead wires in the display panel, wherein: in the first probe area The probe is set at the position corresponding to the first lead in the connected leads in the display panel, and no probe is set at the position corresponding to the lead adjacent to the first lead; wherein, the first lead is any of the connected leads a lead. The invention is applied in the detection of the display panel.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Fabricated light high-strength lattice frame flexible retaining wall and mounting method thereof

PendingCN113089718AIncrease weightLow costArtificial islandsRoadwaysCantileverMechanical engineering

The invention provides a fabricated light high-strength lattice frame flexible retaining wall and a mounting method thereof. According to the fabricated light high-strength lattice frame flexible retaining wall and the mounting method thereof, concrete retaining wall forms such as a balance weight type, a cantilever type or a counterfort type are replaced, and the purposes of beautifying the environment and reducing the construction cost are achieved. The fabricated light high-strength lattice frame flexible retaining wall is a novel supporting and retaining structure which is formed by stacking lattice frame layers composed of injection molding lattice frame prefabricated parts and wall body filling materials according to a certain gradient and interlayer spacing and filling and compacting the lattice frame layers with the filling materials. According to the fabricated light high-strength lattice frame flexible retaining wall, a high-strength lattice can be mainly applied to retaining protection of a road slope, and the action character of the high-strength lattice is mixed with interaction of four influence factors including a wall body, a reinforced layer, filling behind the wall and a foundation.

Owner:CHANGAN UNIV +1

Light-emitting diode (LED) temperature and humidity sensor

The invention discloses a light-emitting diode (LED) temperature and humidity sensor. The LED temperature and humidity sensor includes a sensor main body, a probe rod and a power source, an LED display screen is arranged on one face of the sensor main body, and the face of the sensor main body is fixed to one end of the probe rod, the power source is installed on one side of the sensor main body,the sensor main body includes a temperature sensor and a humidity sensor inside, and sensing elements of the temperature sensor and the humidity sensor are installed on the other end of the probe rod,and the sensing elements can detect the temperature and the humidity of an air tube, so as to avoid the shortcoming that it is usually necessary to connect a wire or a cable from another part becausea temperature and humidity sensor cannot be used due to the absence of a power source on site, and technical improvement is made in the field.

Owner:TAIZHOU JIABO INSTR TECH CO LTD

Route determination method and device

ActiveCN109084788BAvoid bad situationsInstruments for road network navigationSimulationTerminal equipment

The invention provides a method and a device for determining a route. The method comprises the steps of: determining a plurality of candidate routes by a terminal device according to an origination and a destination; segmenting each candidate route according to the number of maneuver points on each candidate route, and acquiring historical user trajectory information of each segment road on each candidate route from the server; and selecting a target route from a plurality of candidate routes according to a historical user trajectory of each segment road on each candidate route, wherein each segment road on the target route is consistent with the corresponding historical user trajectory information. According to the route determining method, since the historical user trajectory is the route actually used by the user, the bad case in the selected target route is avoided.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Protection device used for oscillation water column type ware energy system air chamber

InactiveCN1274958CFully protectedAvoid bad situationsMachines/enginesEngine componentsEngineeringTurbine

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Dual mosaic structure, interconnect structure and methods for fabricating the same

ActiveCN100403517CMediate stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsLow-k dielectric

The present invention relates to interconnects with harmonized stress and methods for fabricating the same. An interconnect comprises a substrate having a conductive member. A composite low-k dielectric layer interposed with at least one stress-harmonizing layer therein overlies the substrate. A conductive feature in the composite low-k dielectric layer passes through the at least one stress-harmonizing layer to electrically connect the conductive member.

Owner:TAIWAN SEMICON MFG CO LTD

Gas integrated unit

ActiveCN101210317BLess quantityAvoid bad situationsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingFluid controlProcess engineering

The present invention provides a gas integration unit capable of reducing base space. In the gas integration unit, setting first gas units (72A, 72B, 72C), for controlling the supply of a first gas; a second gas unit (73), connecting with the first gas units (72A, 72B, 72C) and controlling cleaning gas converging to the first gas units (72A, 72B, 72C) by means of a plurality of fluid control components (31 to 34, 38A to 43a, 38B to 43B, 38C to 43C); and stackup blocks (61A, 61B, 61C), stacking on the first gas units (72A, 72B, 72C) and stacking parts (38A 38B, 38C) of the fluid control components on the stackup blocks (61A, 61B, 61C).

Owner:CKD

Idle trial heading adjusting device of cold header

InactiveCN106799450AAvoid bad situationsForging/hammering/pressing machinesInduced gravityEngineering

The invention discloses an idle trial heading adjusting device of a cold header. The device comprises a machine body (1); the machine body (1) is provided with a gravity induction module (2), an operation induction module (3), a remote communication module (4) and a management module (5); during operating, the gravity induction module (2) induces the material condition on the machine body (1); the operation induction module (3) induces the operation state of the machine body; the remote communication module (4) transmits the induced condition to the management module (5) for processing; the operation induction module (3) is connected with a timing module (6); under the condition of zero gravity, the operation time of the machine body (1) is recorded; a display module (7) is arranged on the management module (5) for displaying the induced gravity and operation states and the timing condition in real time; the management module (5) is connected with a reminding module (8); and the idling of the cold header before formal operation is guaranteed to remove faults so as to prevent bad conditions generated in the operation.

Owner:董幼兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com