Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Threshing clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

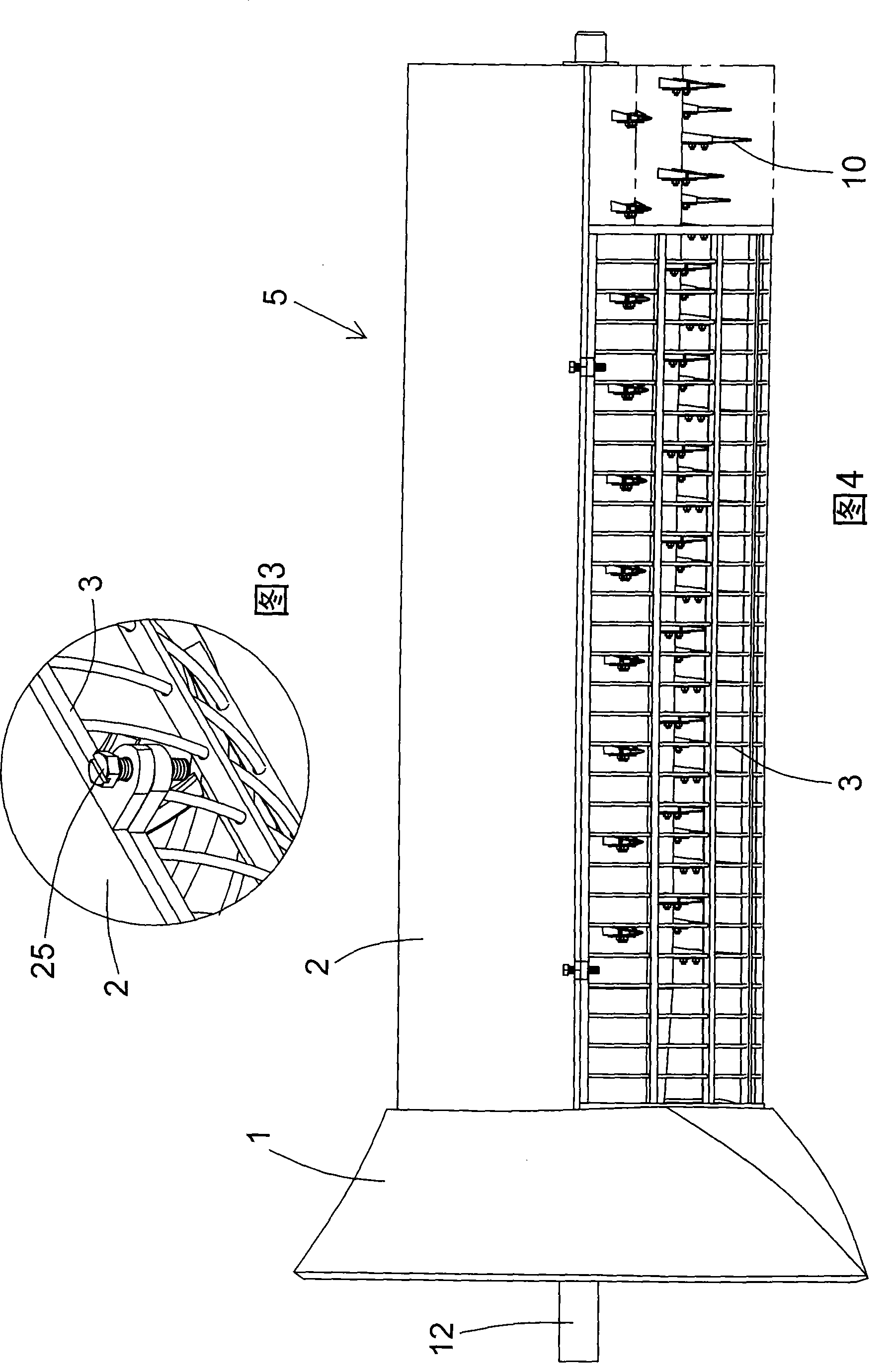

Grain threshing separation device

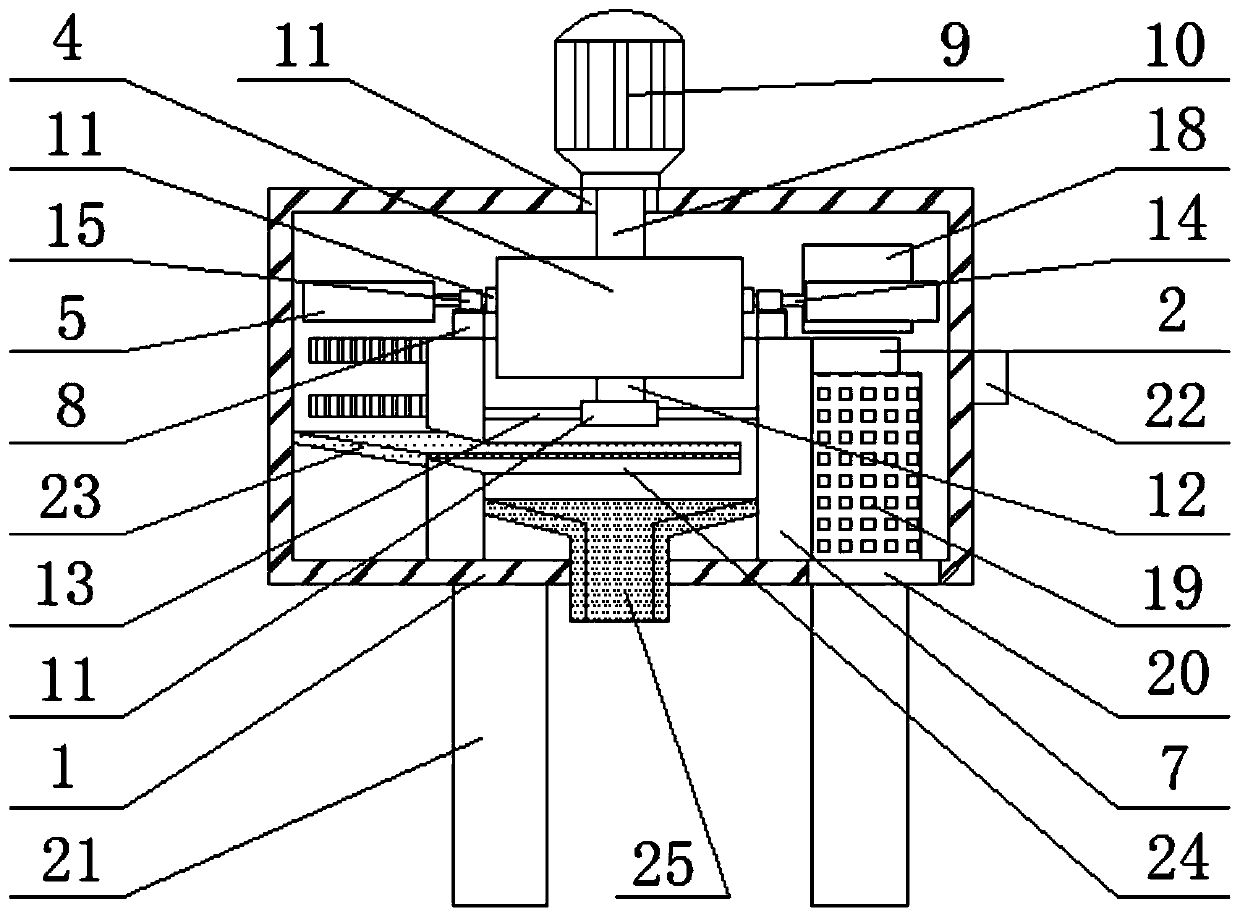

A grain threshing and separating device consists of a feed inlet, an upper cover, a concave grid and a roller; a plurality of arc stock guide plates are arranged on the inner wall of the shell of the feed inlet, each arc stock guide plate is arranged at a deflection angle in relation to the radial direction of the feed inlet; the roller consists of a front section and a rear section, the front section roller takes a conical shape, the rear section roller takes a cylindrical shape, a blade for feeding is welded on the external surface of the front section roller, a plurality of groups of threshing toothholders are welded on the external surface of the rear section roller, each group of the toothholders is arranged along spiral line direction, each toothholder is fixedly connected with a threshing tooth, the toothholder is connected with the threshing tooth in a dismountable way by a bolt fastener; the two ends of the roller are respectively provided with a front spindle nose and a rear spindle nose, and a plurality of arc flow deflectors are obliquely arranged on the top of the inner wall of the upper cover. The grain threshing and separating device has the advantages of fast feeding, thorough threshing, low entrapment loss, is not likely to be blocked by twisting grass, and can thresh a plurality of grains and harvest various grains in fields.

Owner:黄宝玉

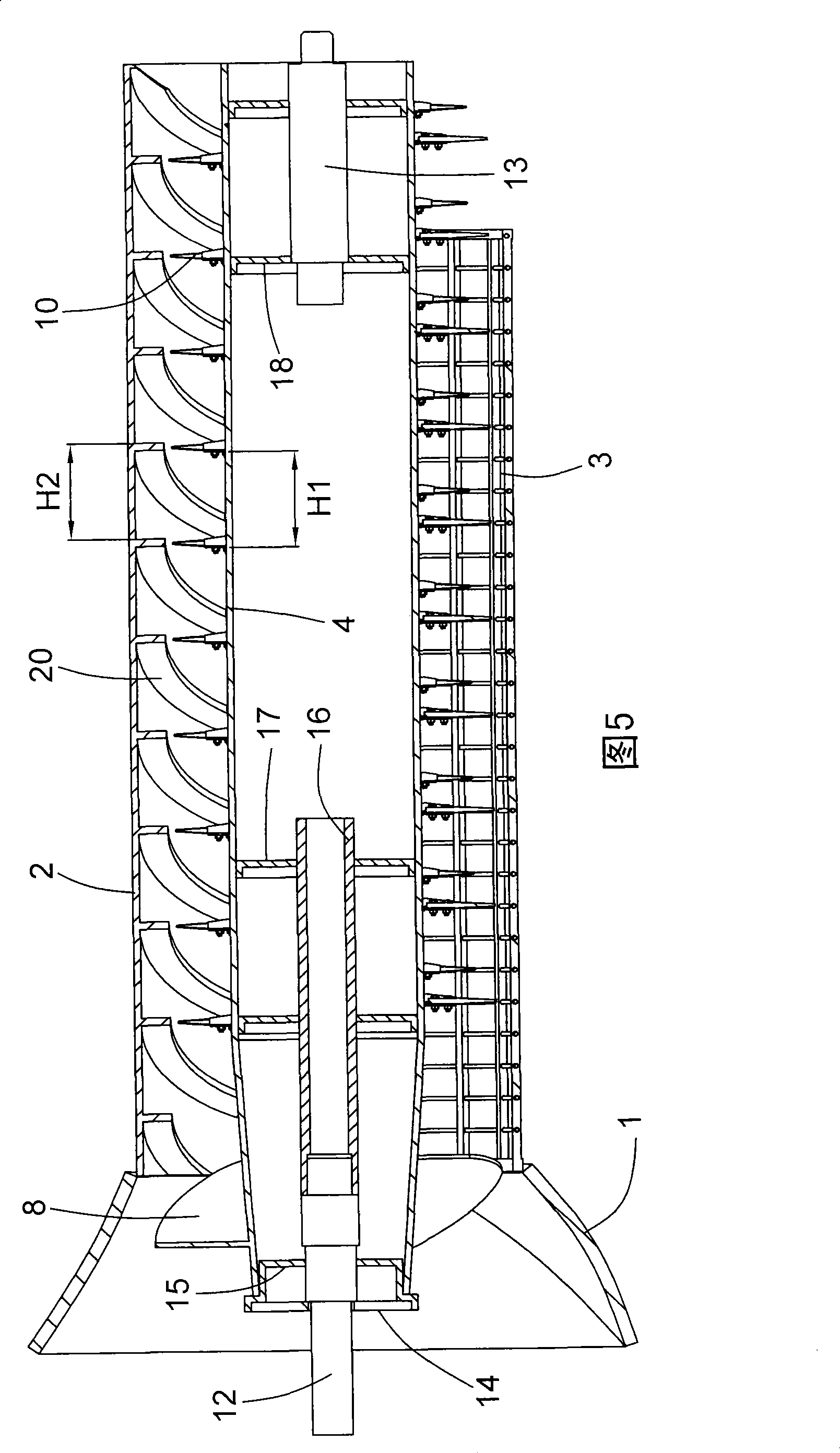

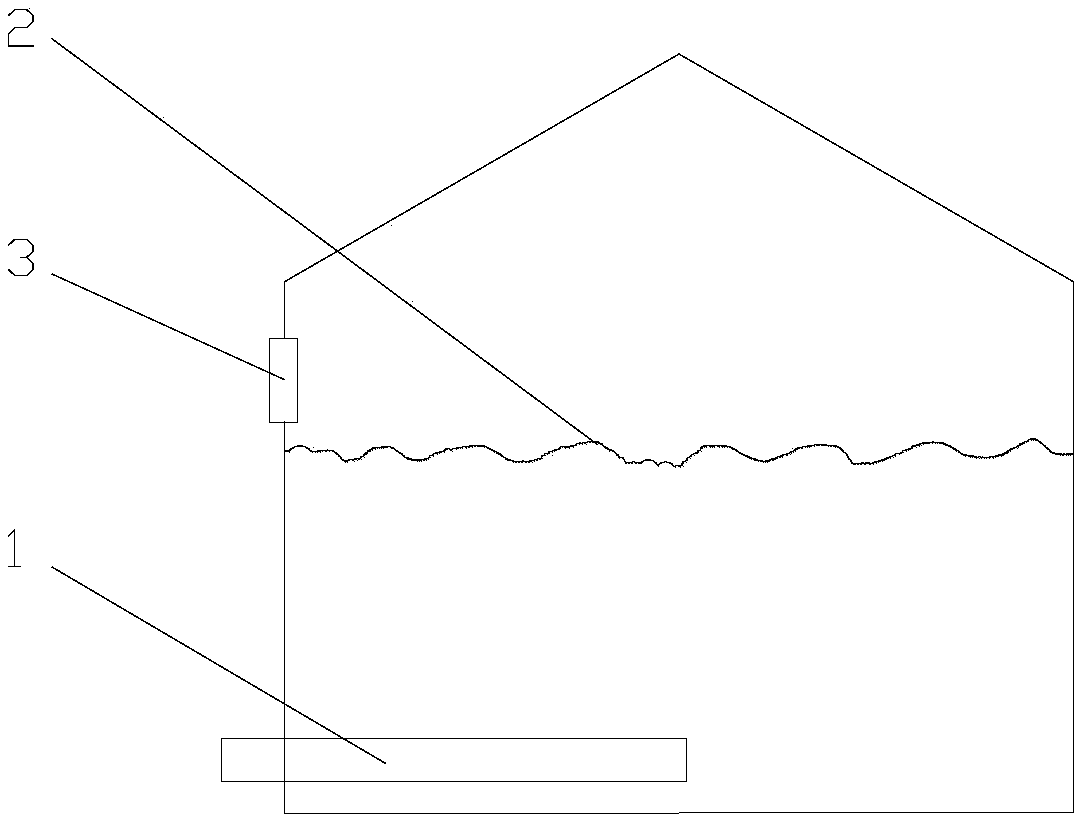

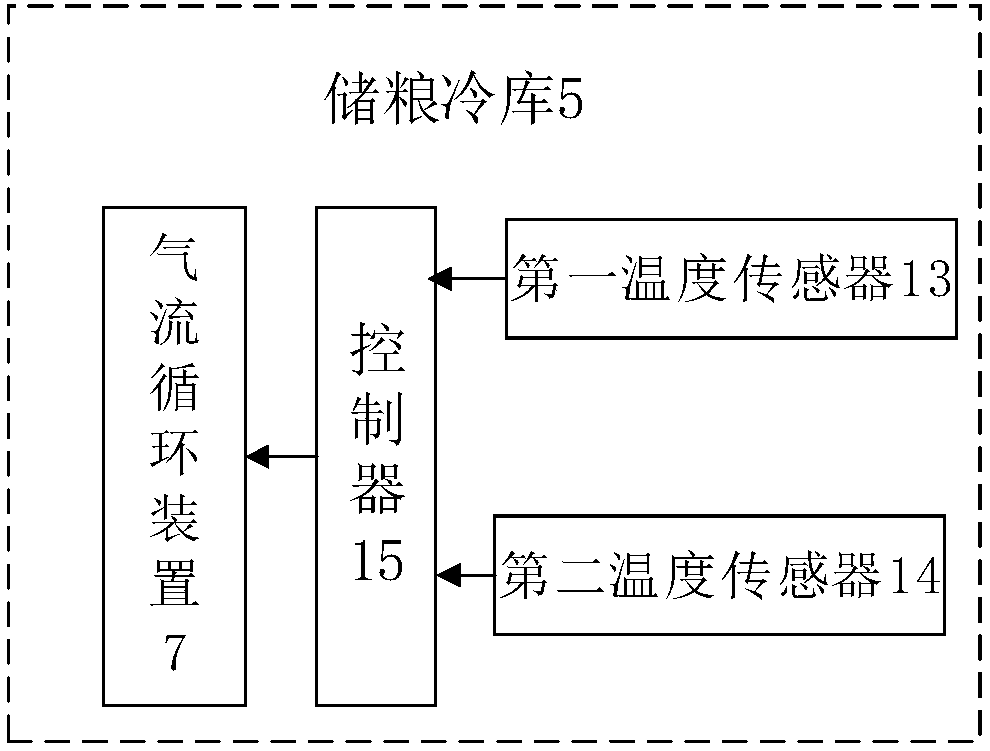

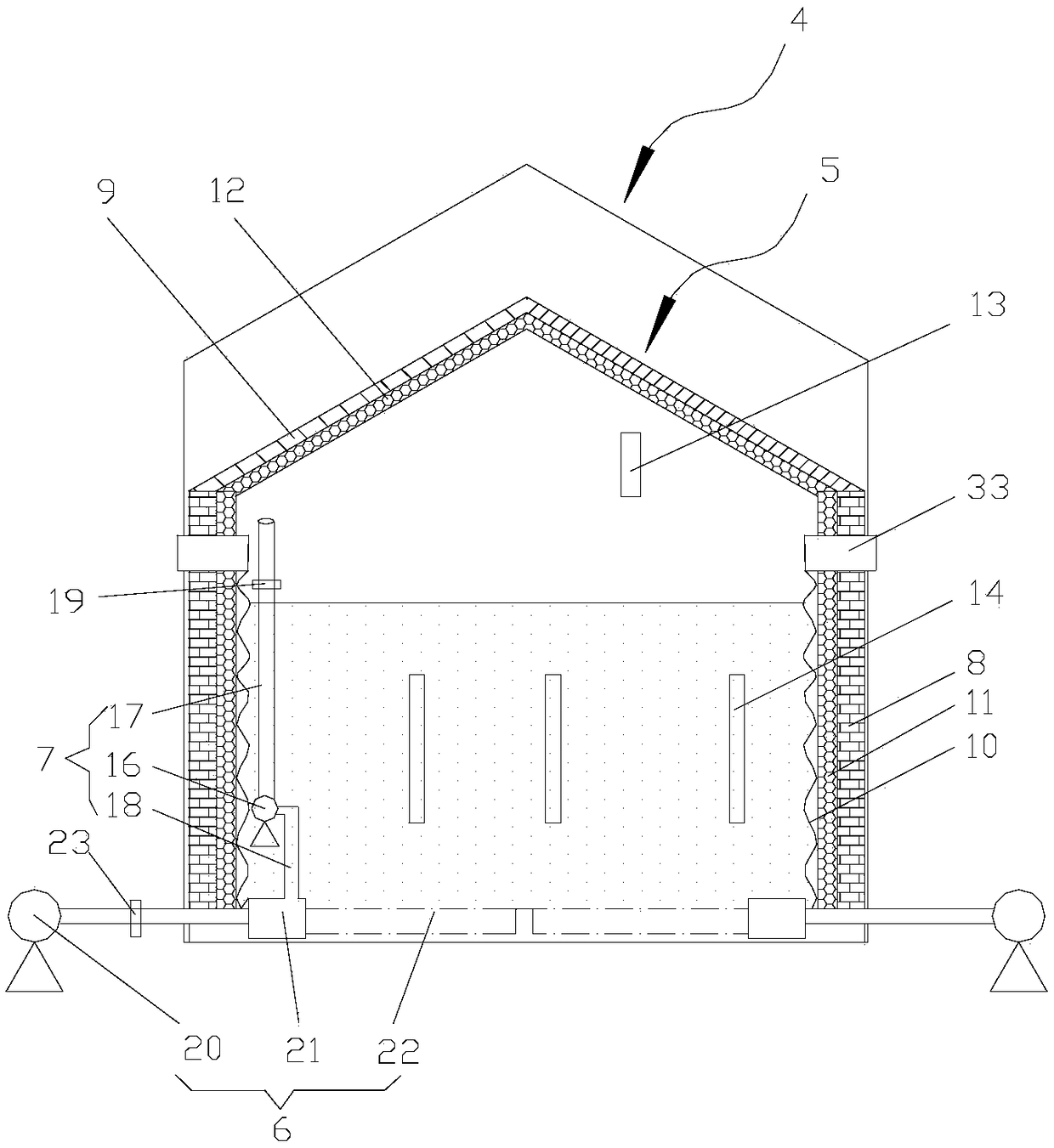

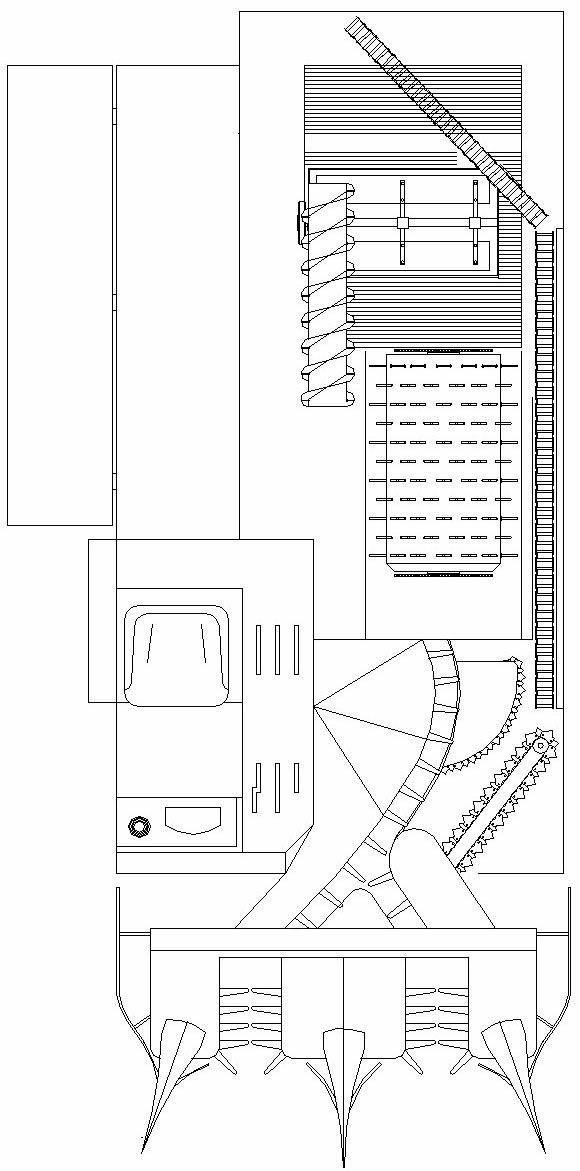

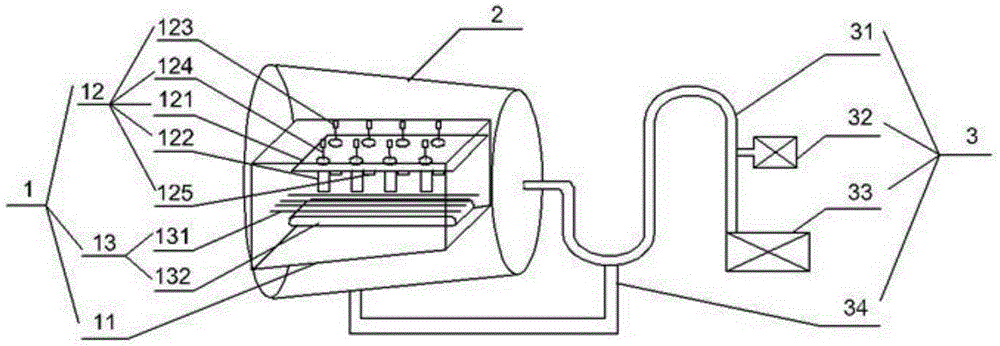

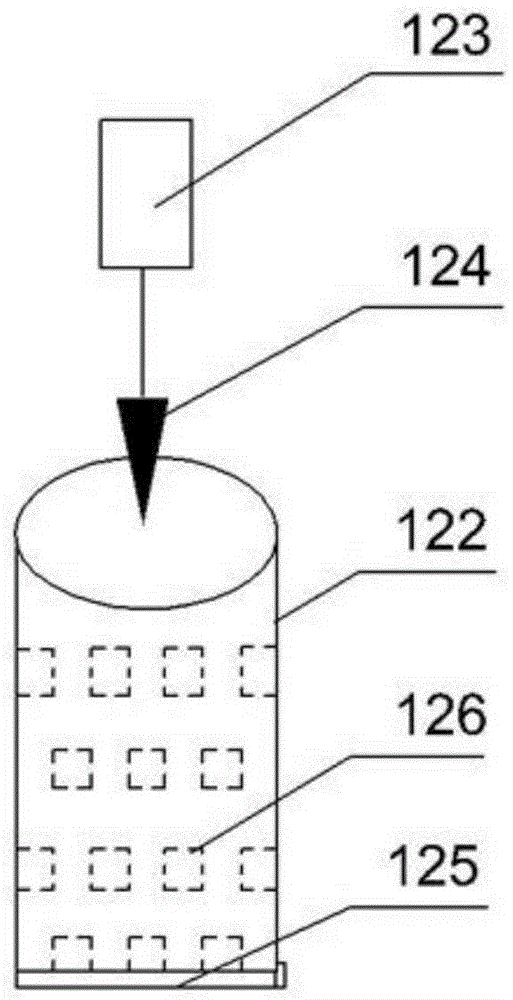

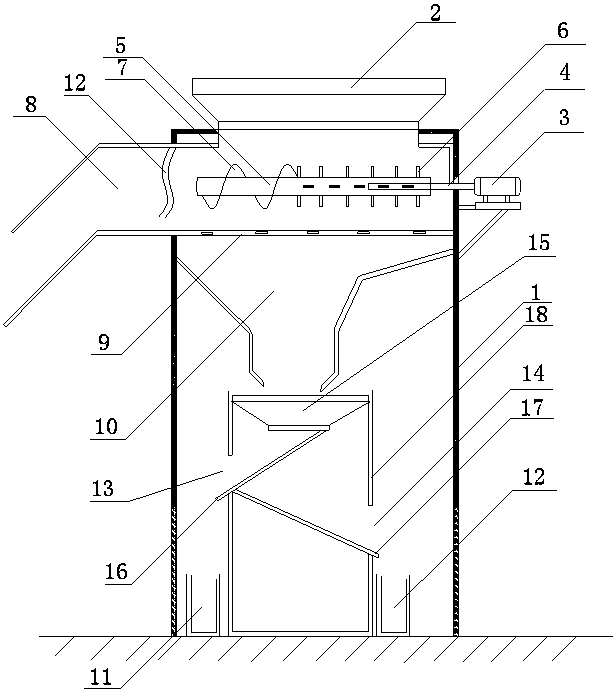

Grain storage refrigeration house and grain storage method

ActiveCN107896650AIncrease moistureImprove qualityAgriculture tools and machinesHarvested fruit hanging devicesTemperature controlMoisture condensation

The invention relates to a grain storage refrigeration house and a grain storage method, the grain storage refrigeration house comprises a grain storage bin body, a sealed grain storage refrigerationhouse is arranged in the grain storage bin body, grain is stored in the grain storage refrigeration house, and at least one set of air supply mechanism 6 is arranged at the bottom of the grain storagerefrigeration house; at least one set of air circulation device is arranged in the grain storage refrigeration house and used for pumping the air above the grain surface in the grain storage refrigeration house to the grain bottom for internal circulation; a controller controls operation of the air circulation device according to the received temperature of the a first temperature sensor; or thecontroller controls operation of the air circulation device according to the temperature difference of the first temperature sensor and a second temperature sensor. According to the grain storage method, air is conveyed in winter and used for internal circulation in next summer, the temperature difference of the grain surface and the inside of a grain heap is reduced, moisture condensation cannotoccur to the grain heap, the condition of grain mildewing is avoided accordingly, ageing is not easy to occur to the grain and the good moisture can be kept, and the stored grain quality is improved.

Owner:谷晓辰

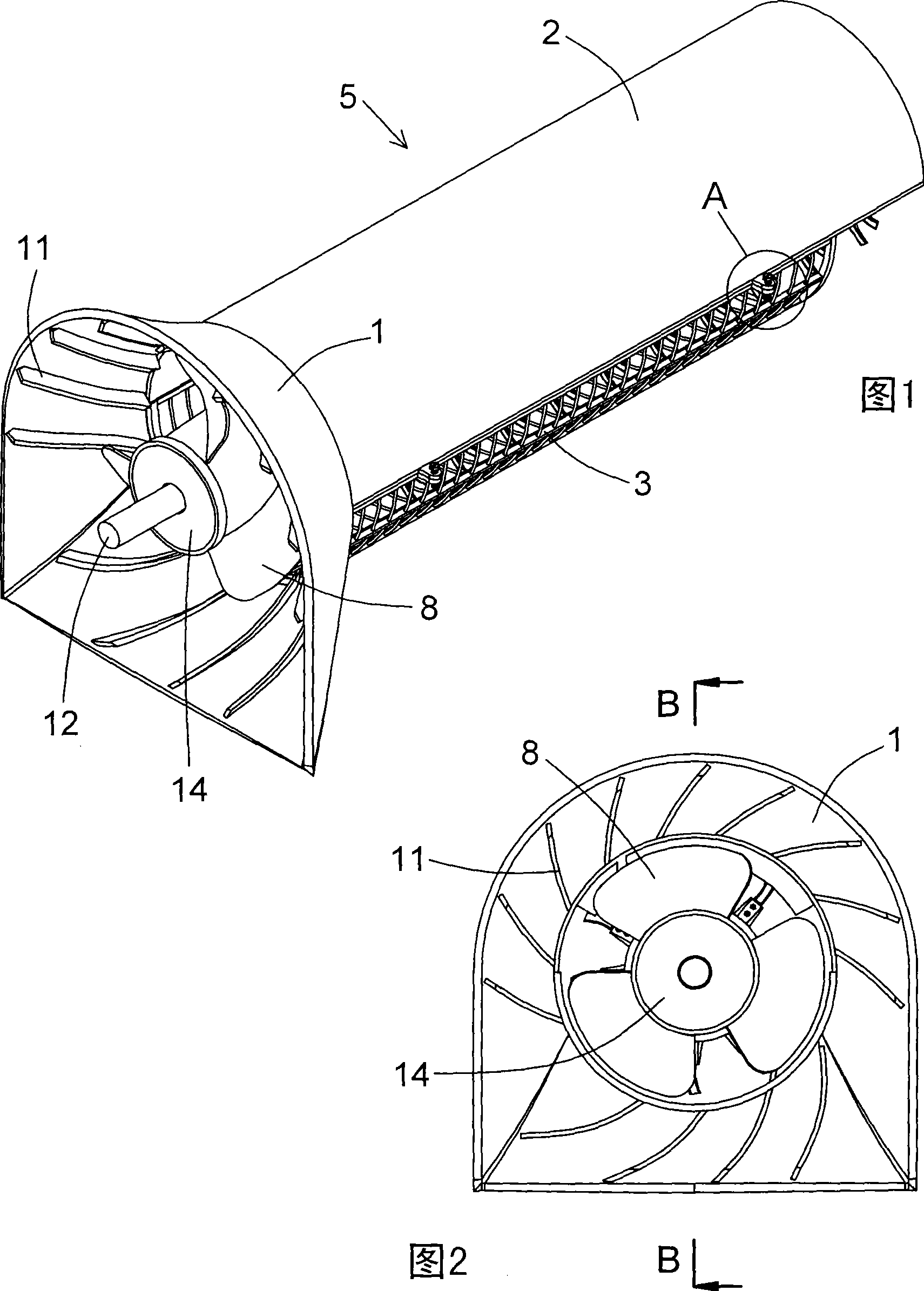

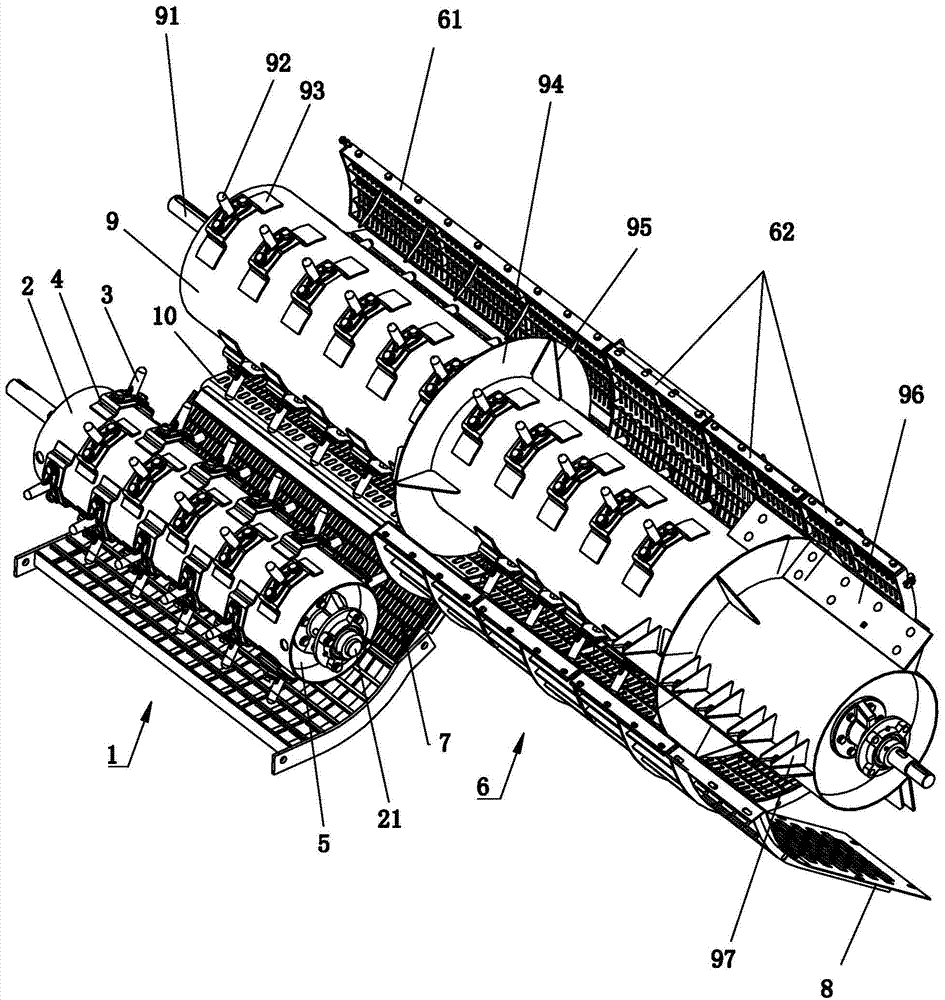

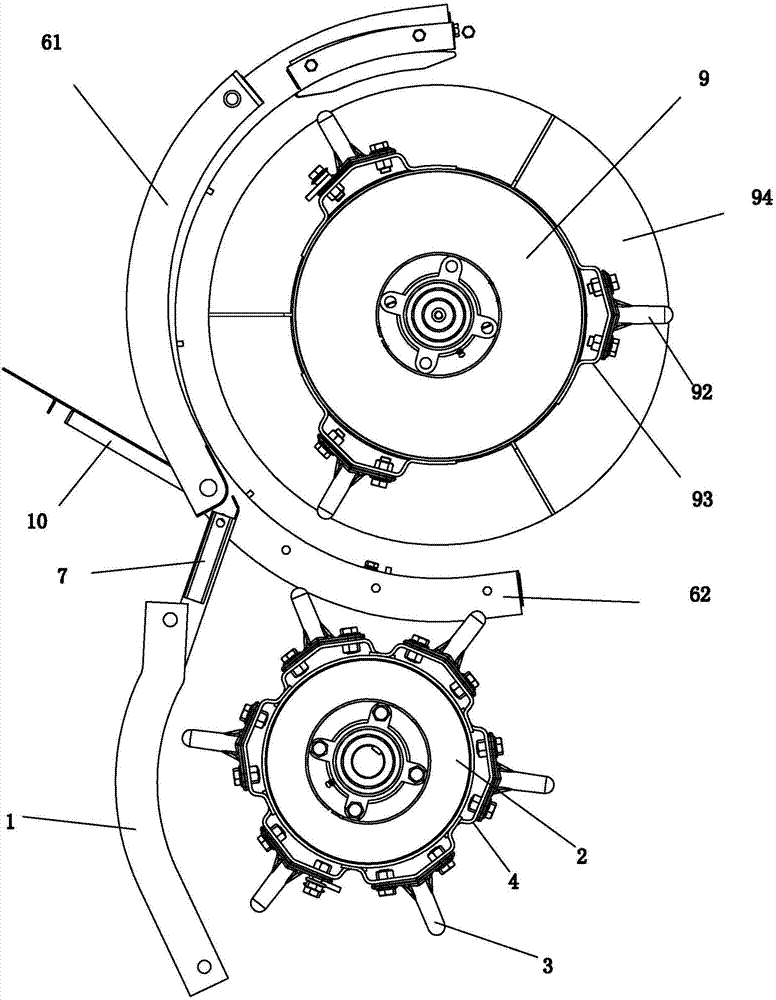

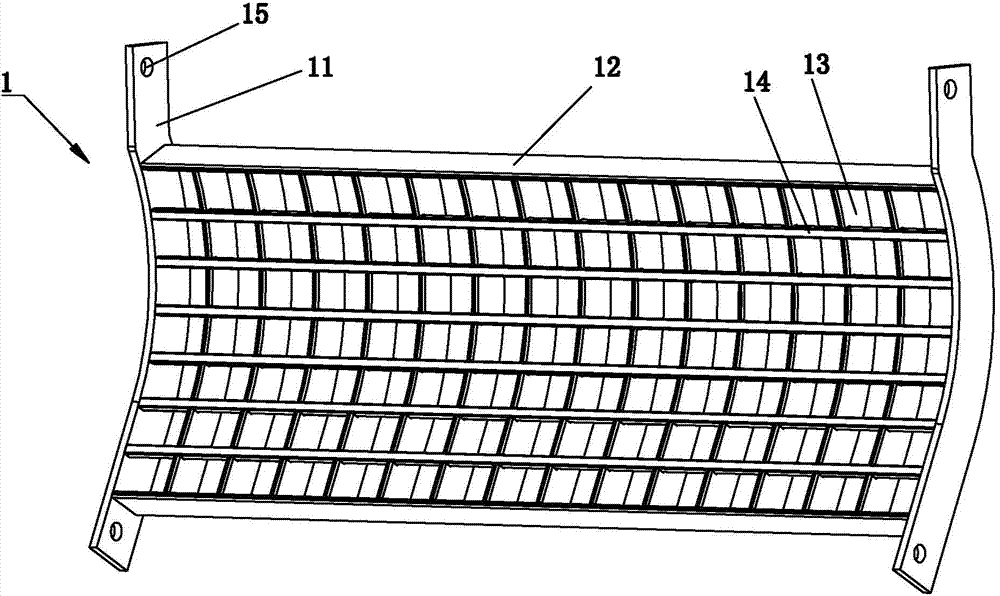

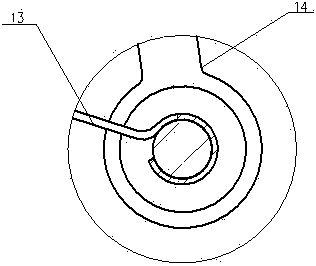

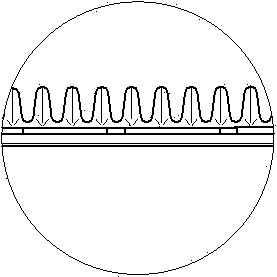

Corn kernel threshing and separating device

The invention discloses a corn kernel threshing and separating device which comprises a threshing roller with threshing teeth. Each threshing tooth comprises a tooth rod with a spherical top end, a threshing concave plate is arranged below the threshing roller and comprises a concave plate body, the concave plate body comprises two side plates, supporting plates are arranged between the two side plates, a longitudinal separation plate is arranged between the two supporting plates, separation bars are arranged on the longitudinal separation plate, and the separation bars and the longitudinal separation plate are flush with the side plates. A separation roller is arranged on one side of the flowing direction of crops, and separation teeth and separation plates are arranged on the separation roller in a staggered mode. A separation concave plate communicated with the threshing concave plate is arranged below the separation plate. Through rubbing between the threshing teeth and the threshing concave plate, threshing is achieved, power consumption is little, and cost is low. Through the threshing concave plate, while passing ability and screening efficiency are guaranteed, strength and use reliability are improved, and the crushing rate is lowered; meanwhile, through replacement of the corn kernel threshing and separating device, the effect of harvesting corn crops at the same time is achieved, and the use rate of a rice and wheat harvester is improved.

Owner:LOVOL HEAVY IND CO LTD

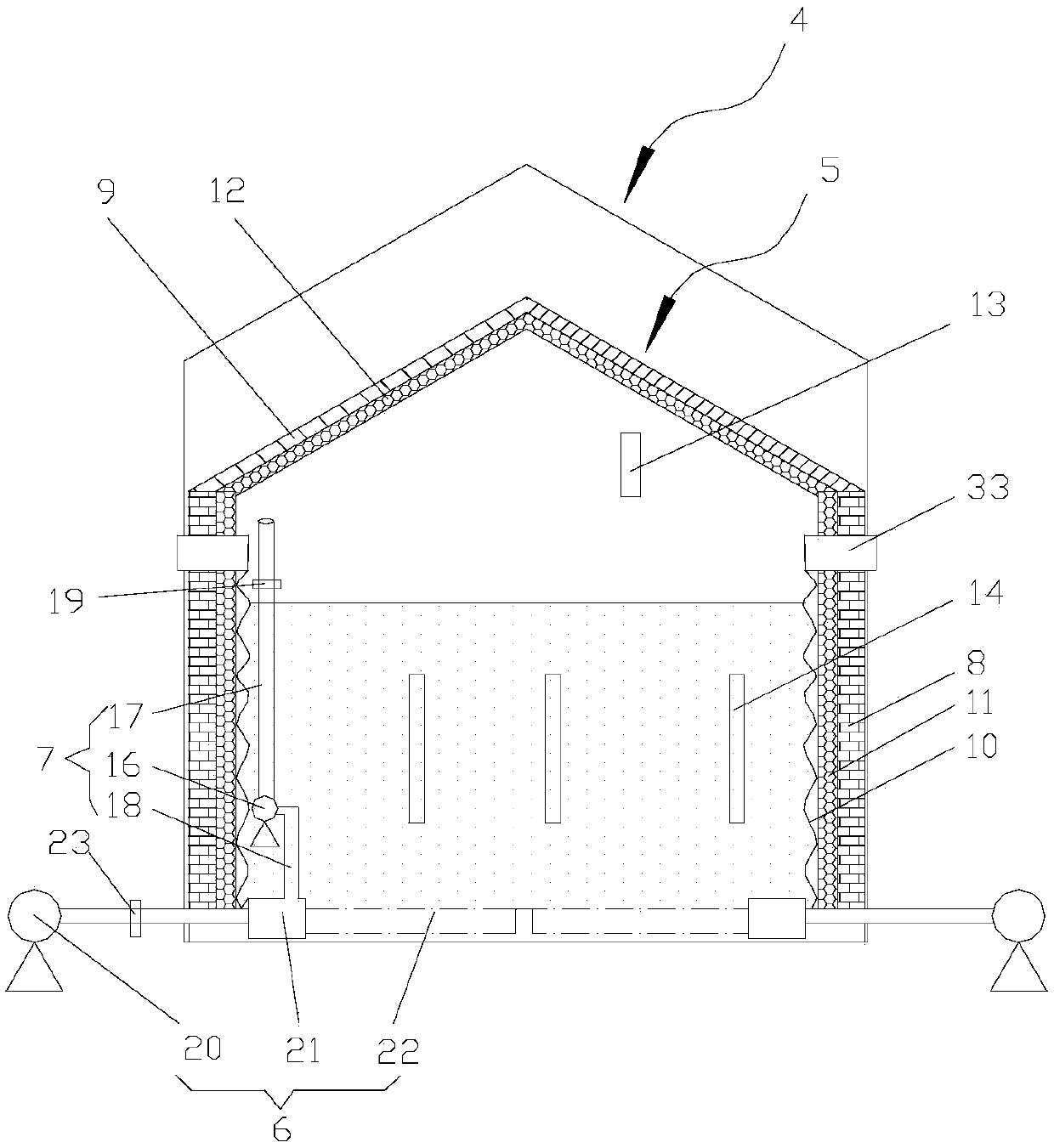

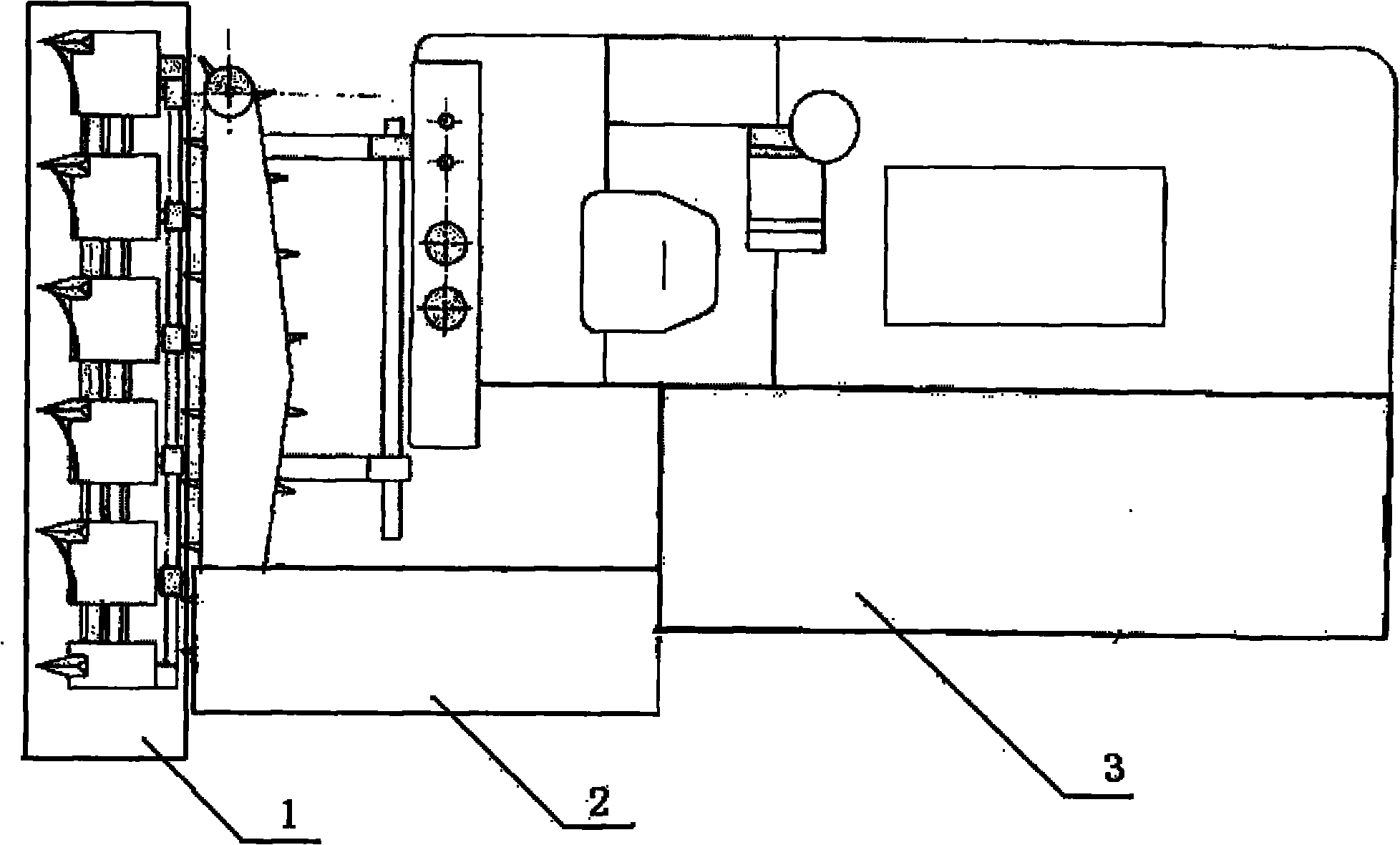

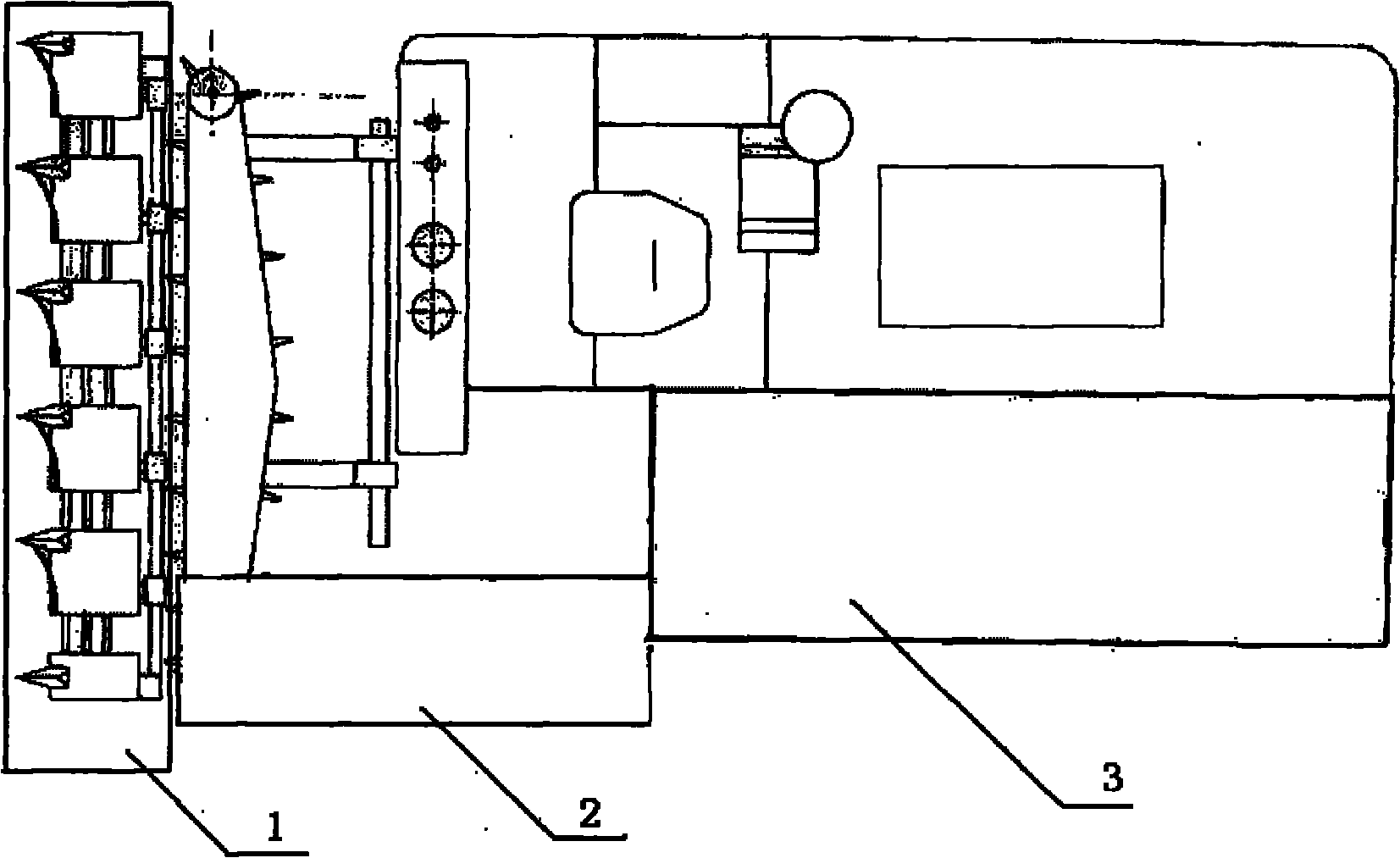

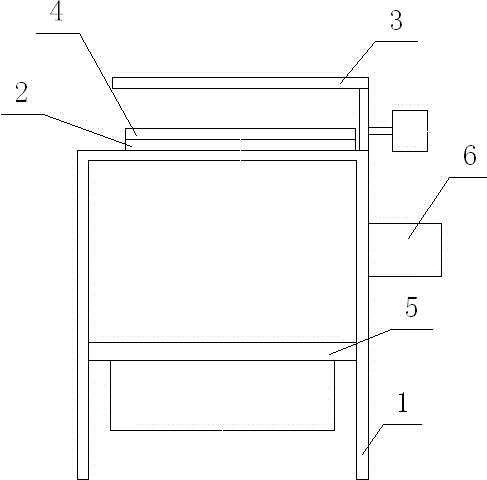

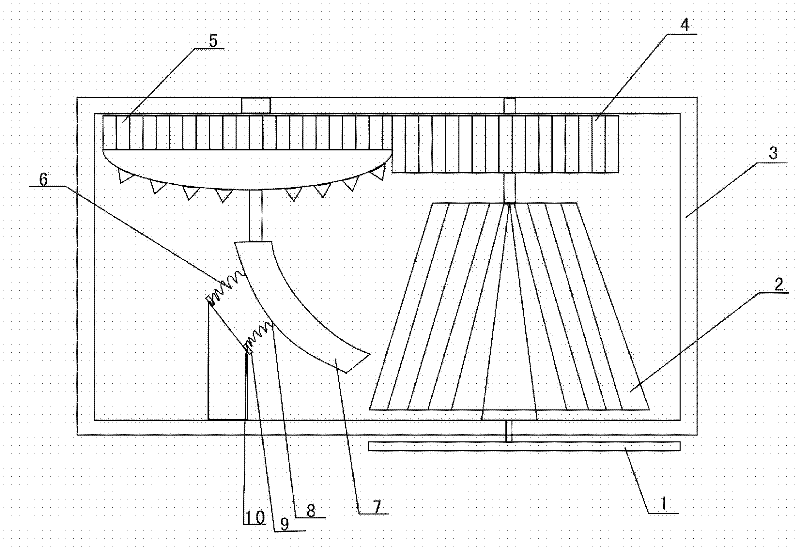

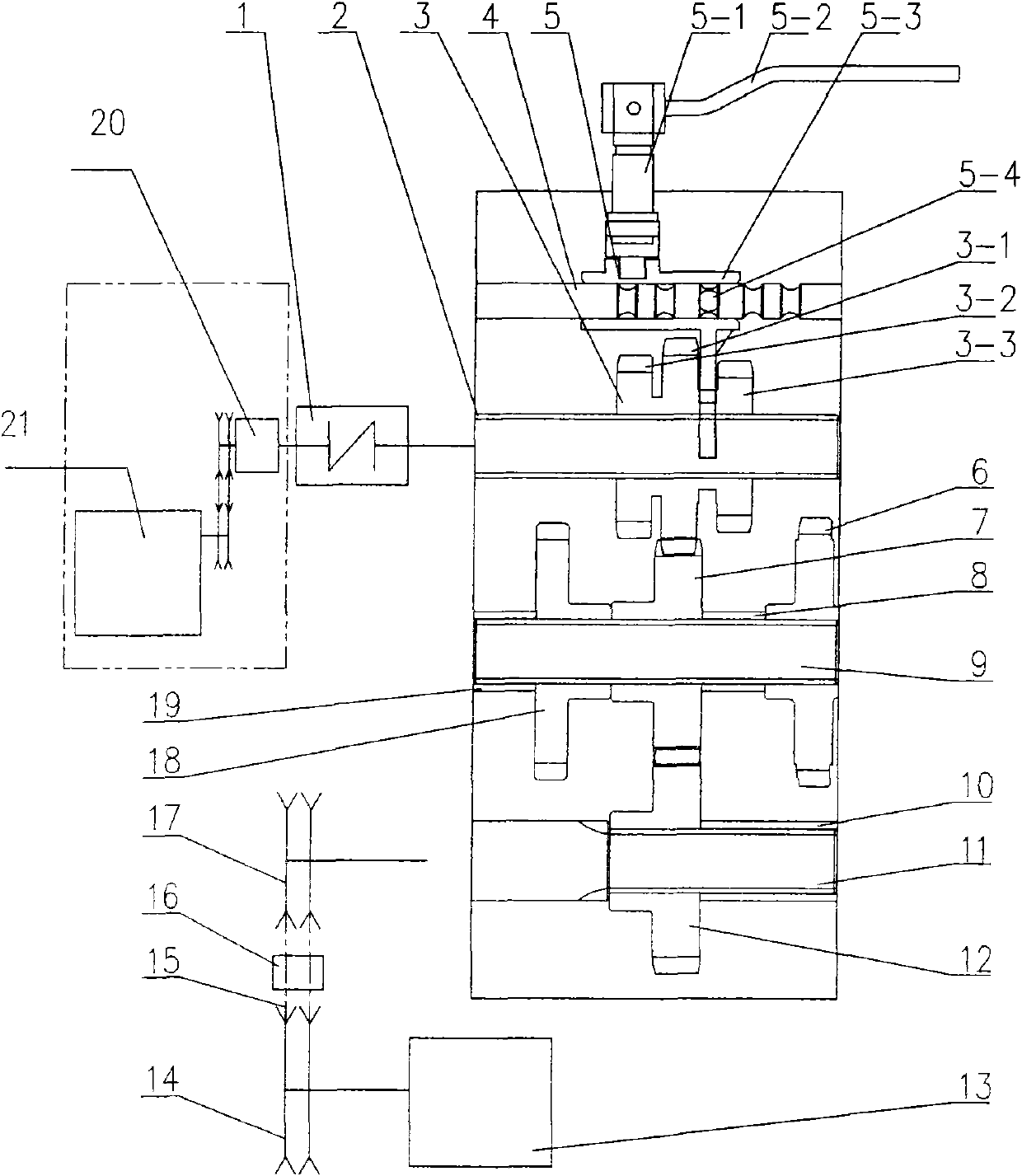

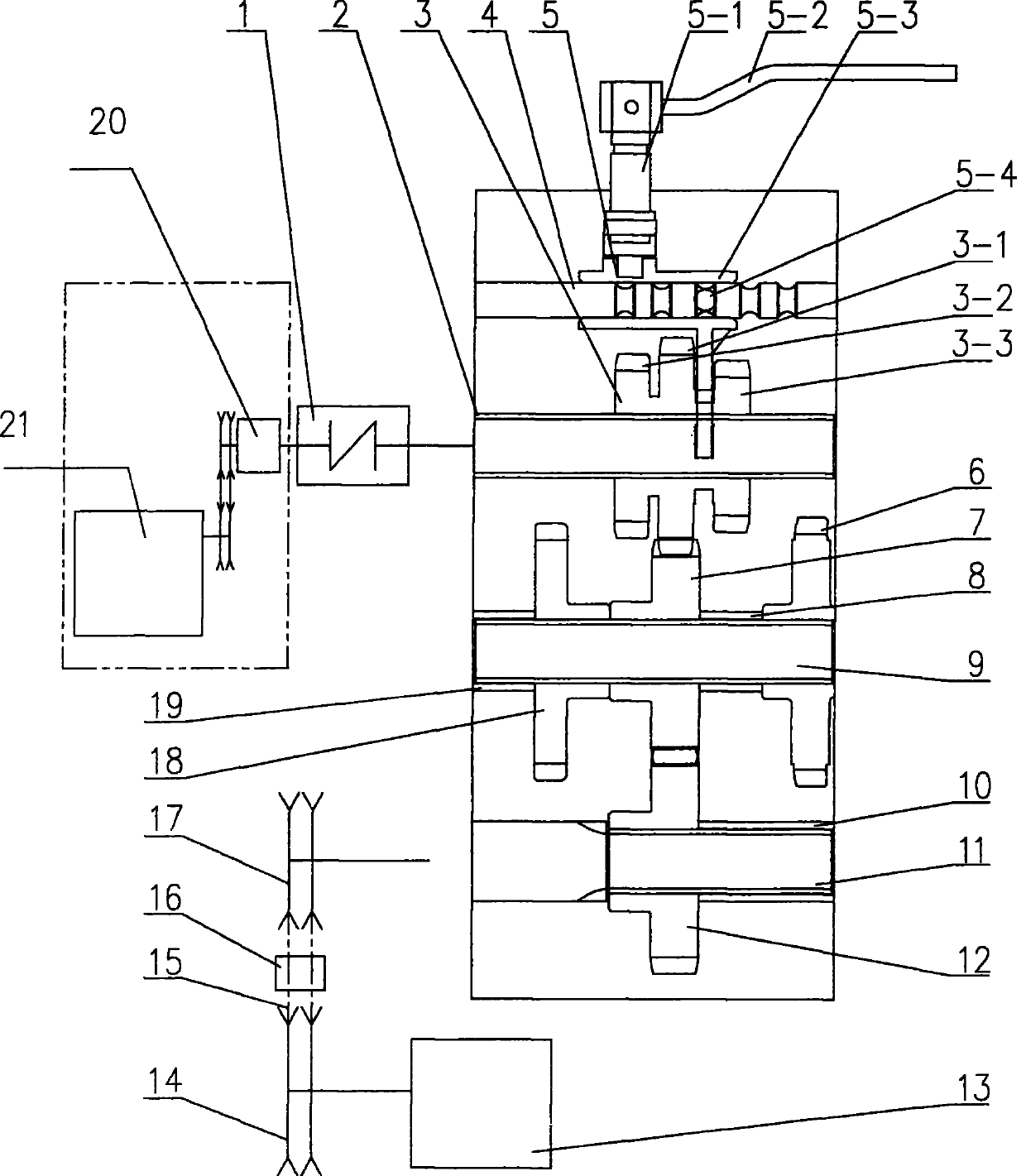

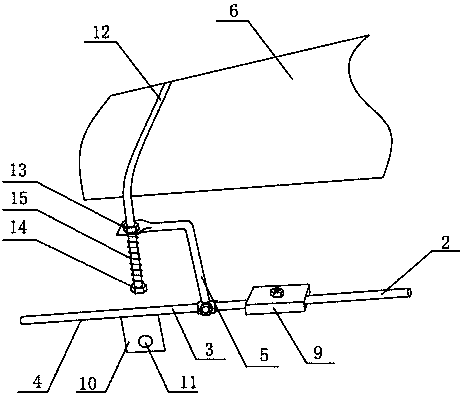

Rape threshing machine

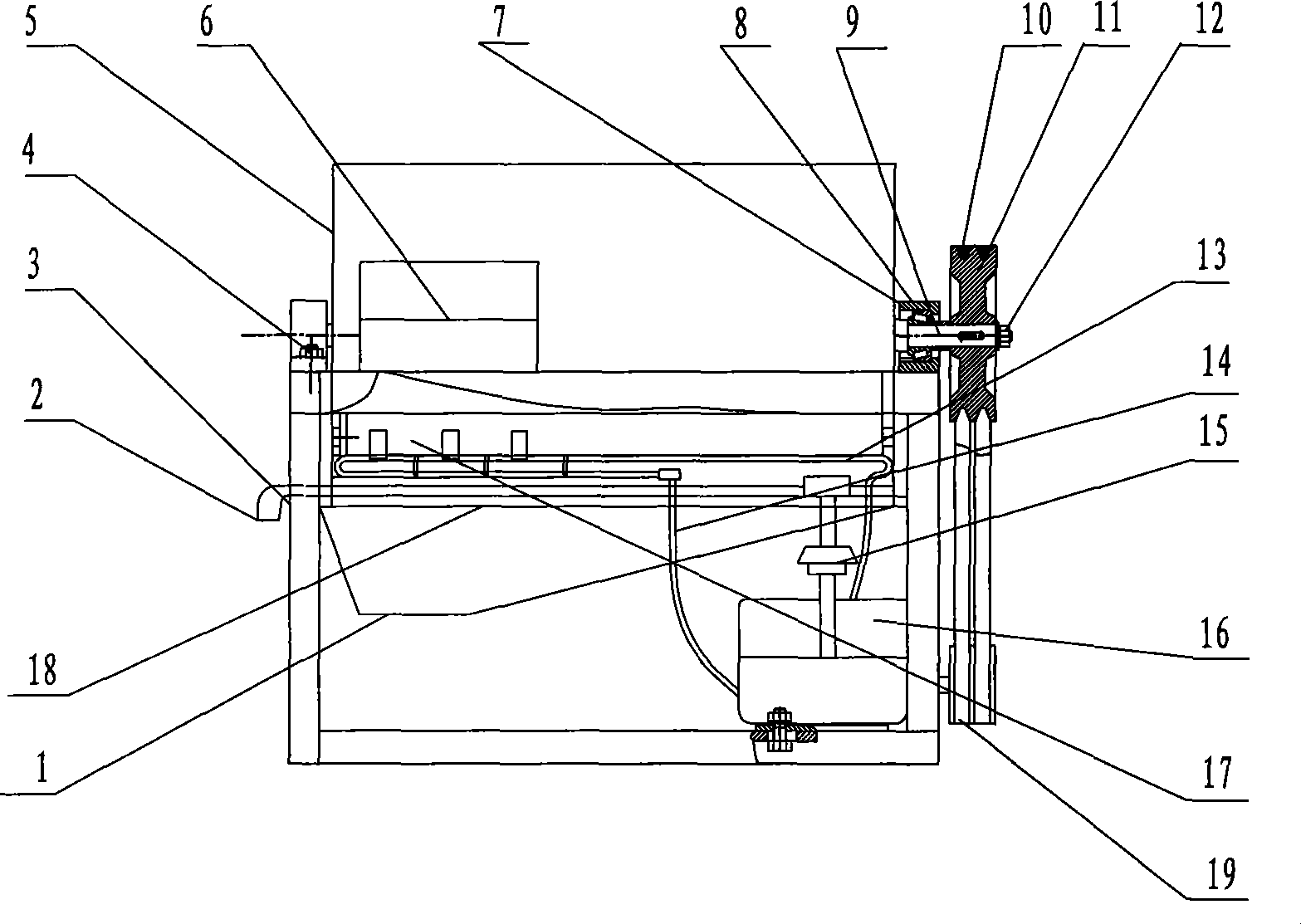

The invention discloses a rape threshing machine which comprises a machine frame, a driving system, as well as a threshing system and a cleaning and selecting system which are arranged inside the machine frame, wherein the cleaning and selecting system is arranged below the threshing system; the threshing system comprises a main shaft and a threshing roller, the main shaft is mounted on the machine frame, the main shaft drives the threshing roller to rotate, the cleaning and selecting system comprises a shake slide plate, a slide plate hoisting rod, a vibration sieve box, a sieve box hoisting rod, a crank shaft, a grain receiving plate and a blower, the slide plate hoisting rod and the sieve box hoisting rod are both hinged to the interior of the machine frame, one end of the shake slide plate is connected onto the machine frame in a hanging manner through the slide plate hoisting rod, and the other end of the shake slide plate is hinged to the sieve box hoisting rod through a hinge; one end of the vibration sieve box is connected onto the machine frame in the hanging manner through the slide plate hoisting rod, and the end meanwhile is hinged to the shake slide plate, and other end of the vibration sieve box is connected with the crank shaft installed on the machine frame; the grain receiving plate is arranged below the vibration sieve box, and fixed on the machine frame. According to the invention, a whole-feed axial-flow type threshing system is adopted, so that the threshing time is prolonged, the threshing is more thorough and the threshing loss is reduced.

Owner:HUNAN AGRICULTURAL UNIV

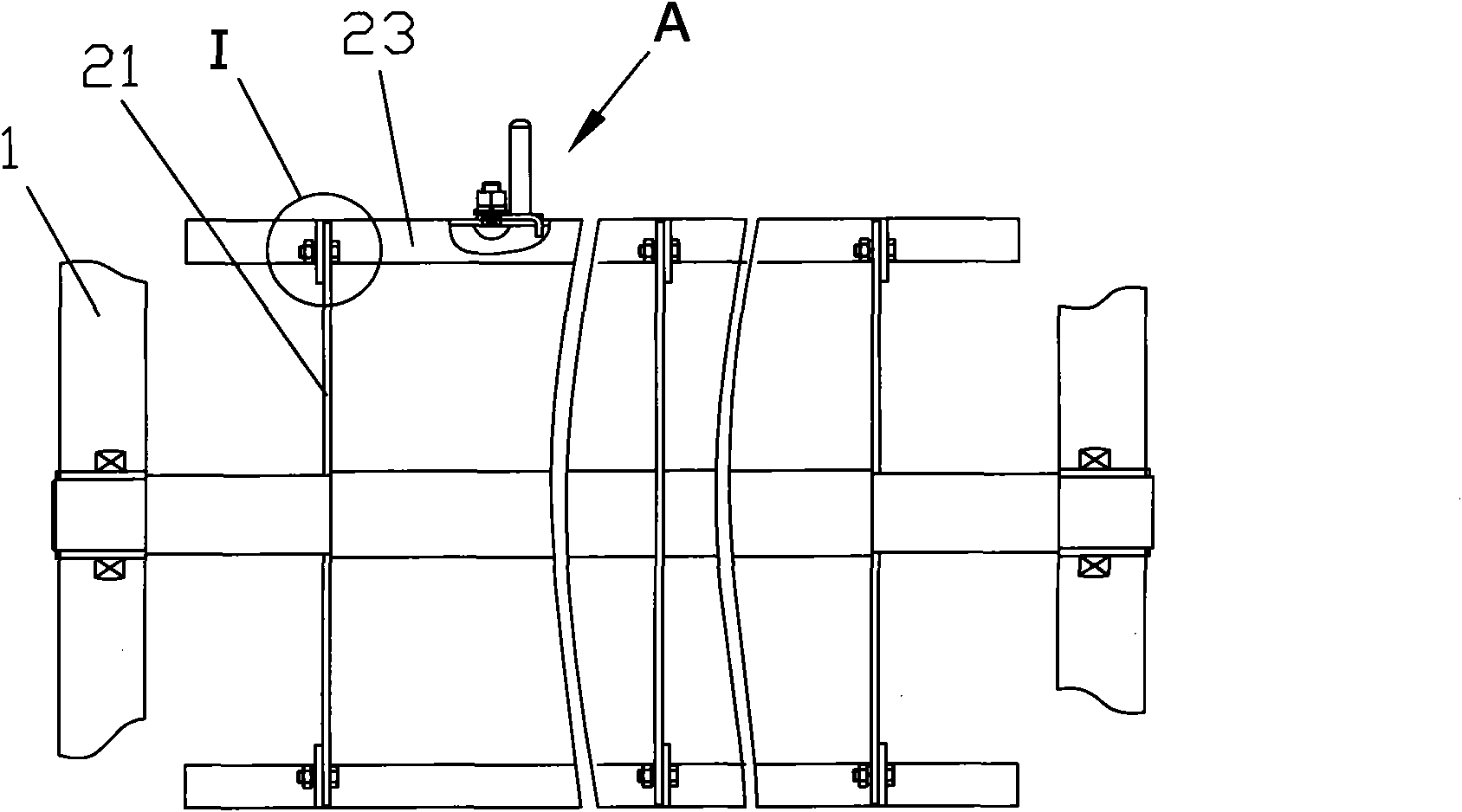

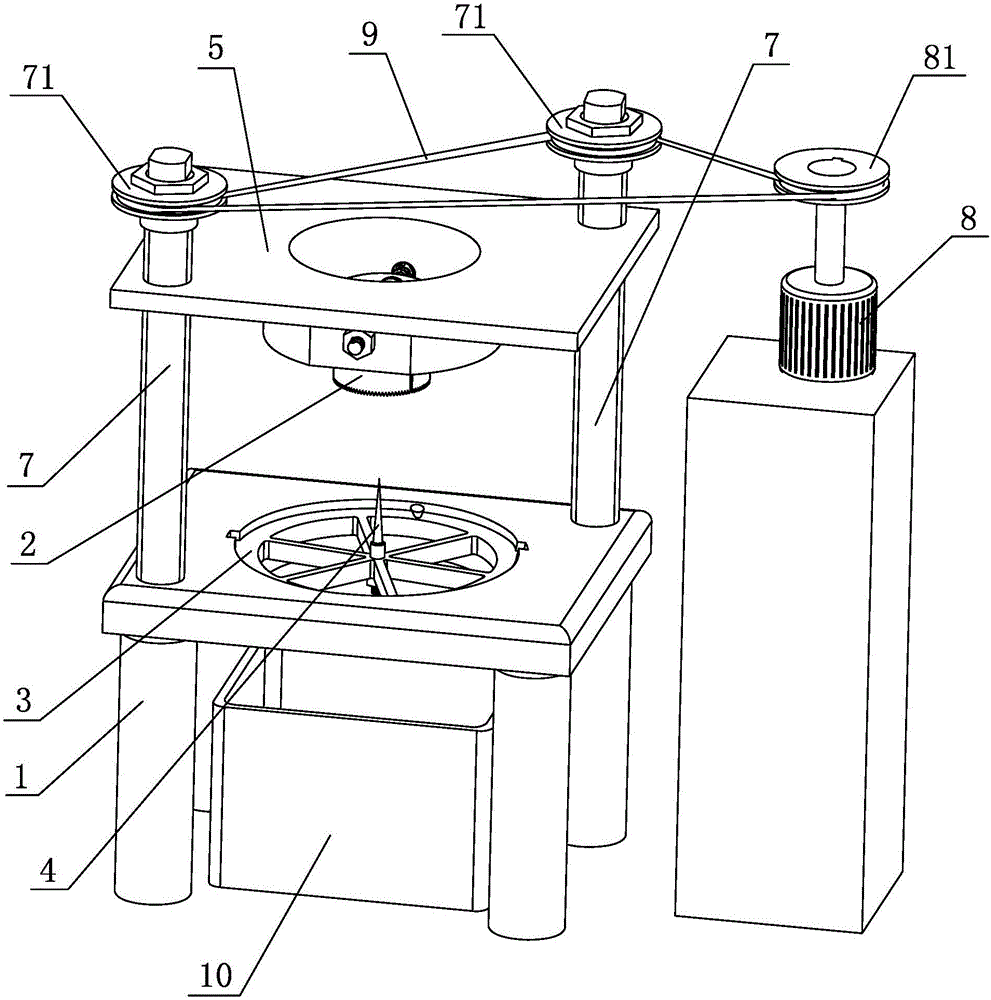

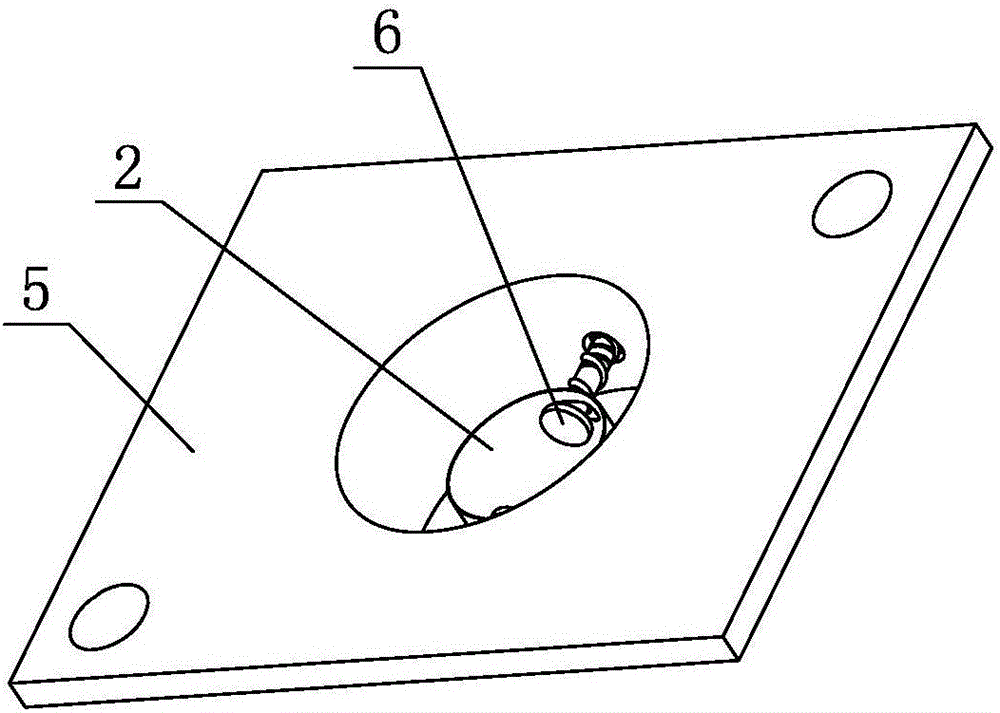

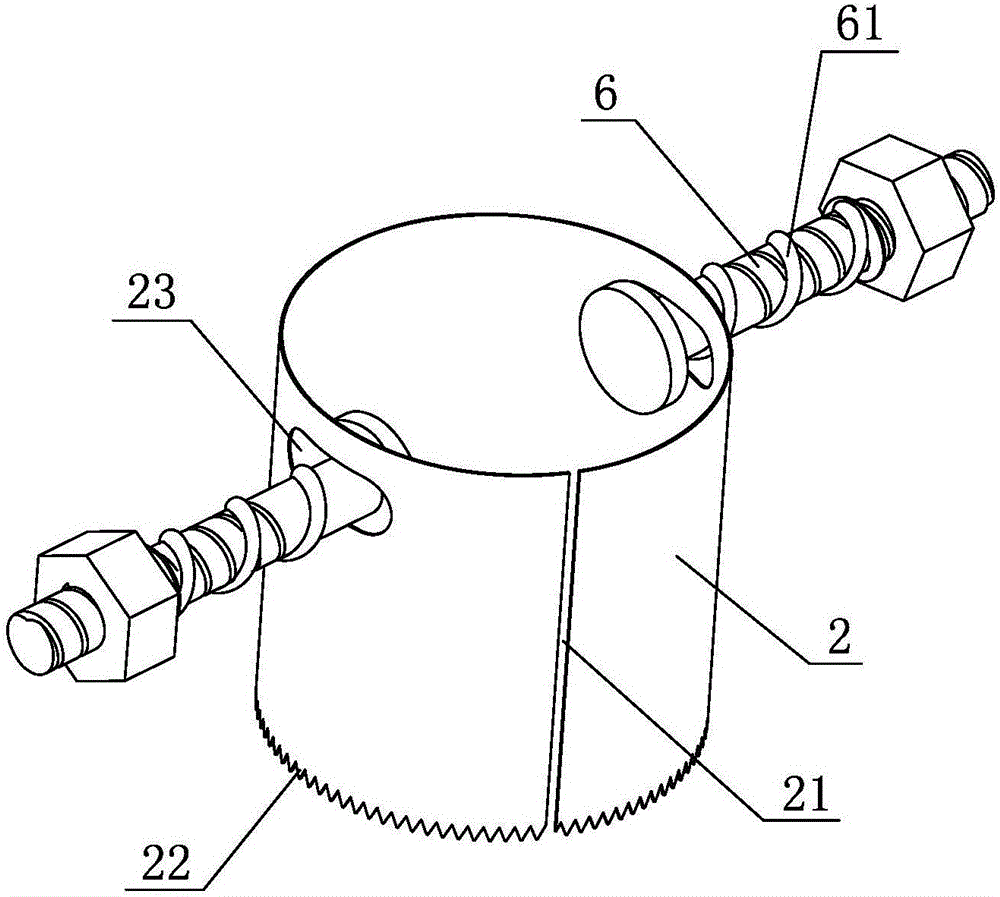

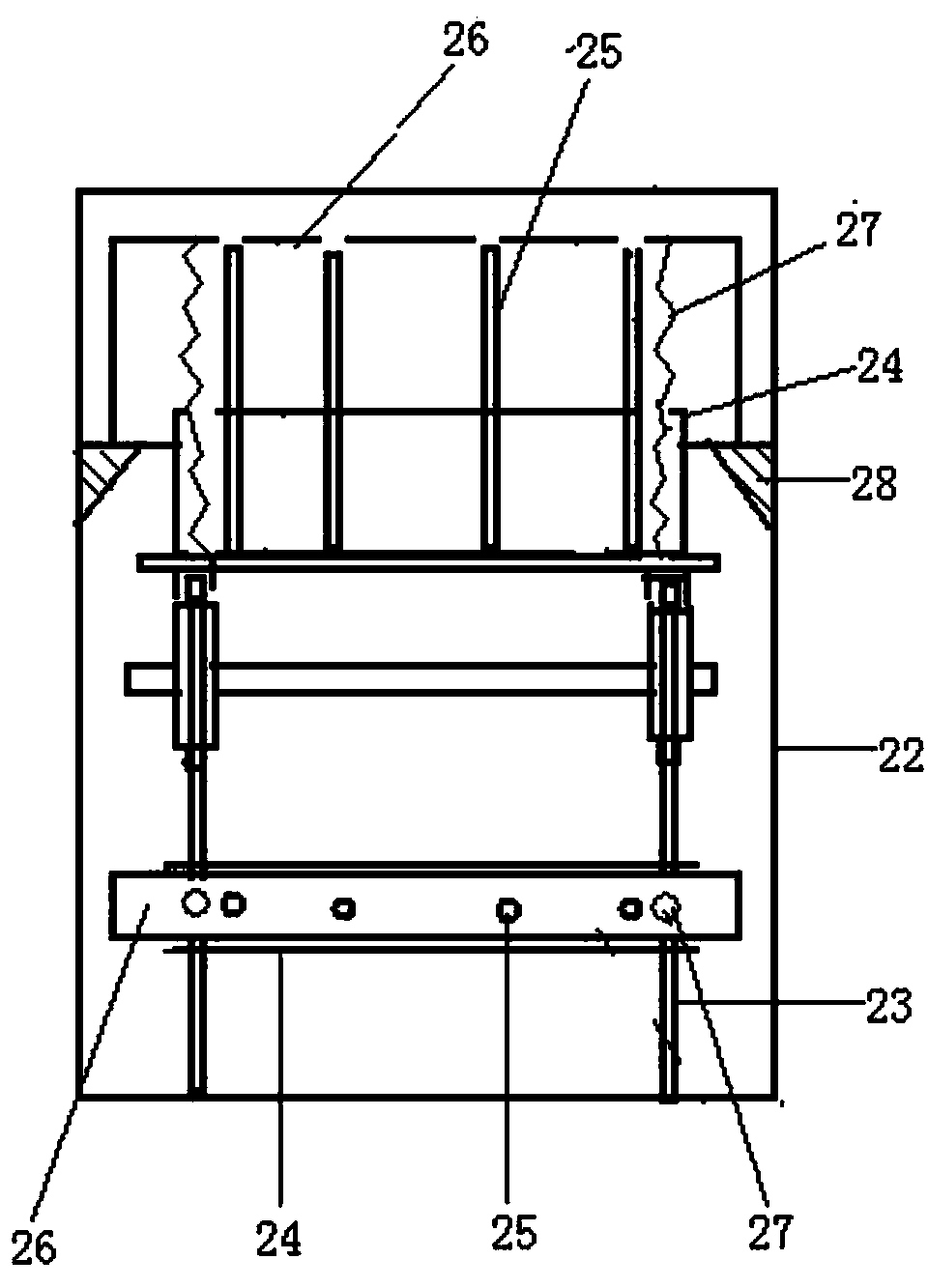

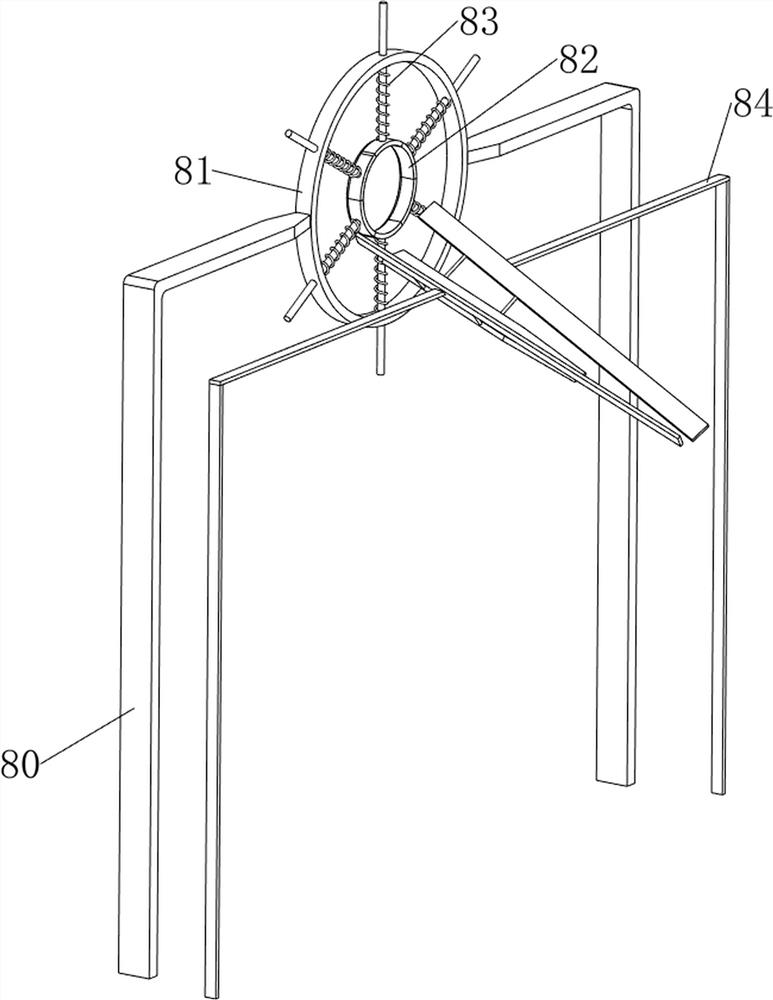

Thresher based on differential inversion principle of corn ear grains

A thresher based on the differential inversion principle of corn ear grains comprises a rack and a motor, wherein two vertical plates which are oppositely arranged on the rack are respectively provided with a corn ear clamping device and a threshing device, each threshing device comprises a roller and a belt wheel connected with one end of the roller and driven by the motor, one end of each roller is hung in the air, the end, hung in the air, of each roller is provided with at least two threshing components, and each threshing component is composed of a bolt arranged on the circumferential face of the corresponding roller in a penetrating mode, a fixing block connected to the bolt and threshing blades arranged on the fixing block; the other end of each roller is arranged on the center shaft of the corresponding belt wheel in a sleeved mode, a bearing in rolling fit with each center shaft is arranged in the corresponding roller, a hollow sleeve and a bearing end cover are arranged on each center shaft, and the two ends of each center shaft are respectively provided with a shaft end baffle. According to the thresher based on the differential inversion principle of corn ear grains comprises, through the threshing blades capable of being located in the line gaps of the corn ear grains, rows of grains are removed from corncobs, the grains in different positions of one core ear can be threshed at differential speeds through the same threshing blade, and it is guaranteed that the grains are totally separated from the corncobs.

Owner:HENAN UNIV OF SCI & TECH

A grain storage cold storage and grain storage method

ActiveCN107896650BIncrease moistureImprove qualityAgriculture tools and machinesHarvested fruit hanging devicesTemperature controlMoisture condensation

Owner:谷晓辰

Sesame threshing machine

The invention relates to a sesame threshing machine, which mainly consists of a drive roll, a driven roll, an adjusting rail, a motor, a screen, a rack and a transverse air pipe, wherein the drive roll and the driven roll are adjacently arranged side by side to form a spore grinding and crushing mechanism; moving adjustment is performed on spacing between the driven roll and the drive roll by the adjusting rail; the upper part of the spore grinding and crushing mechanism is provided with a feed hopper, and the lower part of the spore grinding and crushing mechanism is provided with the screen; all components are connected into a whole by the rack. According to the sesame threshing machine, the drive roll and the driven roll form the sesame spore crushing mechanism, and moreover, surfaces of the two rolls are respectively made of an elastic material; the spacing between the two rolls can also be adjusted; sesame can be rapidly threshed clean, and sesame grains can be kept complete; the sesame threshing machine is the best special threshing machine for the sesame.

Owner:王庆忠

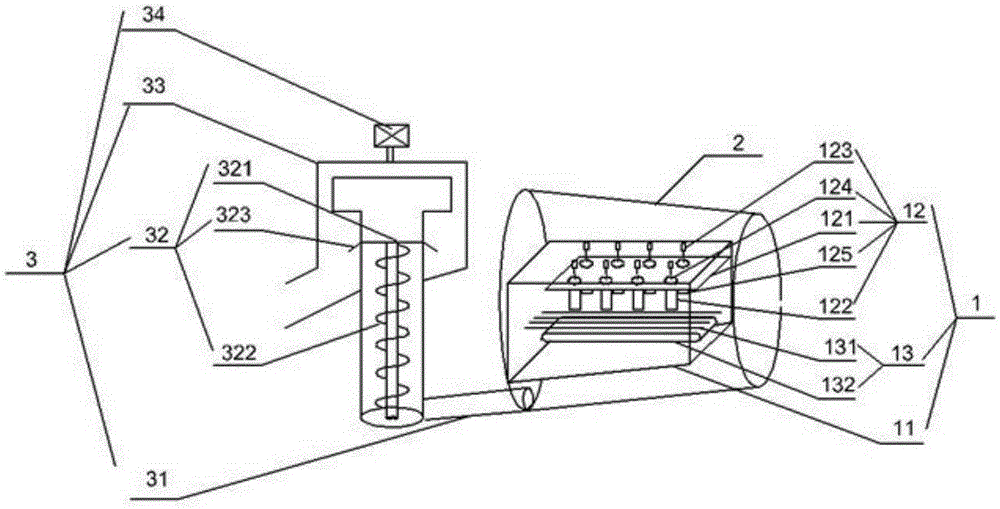

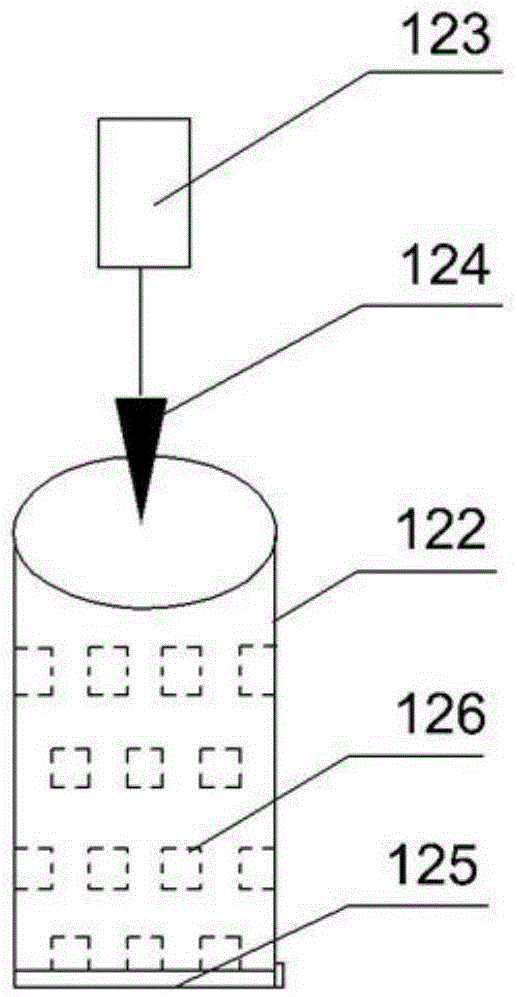

Whole-feed type combine harvester with vertical reaper

The invention provides a whole-feed type combine harvester with a vertical reaper. The invention is characterized in that the vertical reaper is wider than the reaper of a half feeding type combine harvester; a compulsory clamp turning conveyor is arranged on an ear feeding device which is formed by respectively adding a double teeth clamp chain between the two rows of conveying chains and at a turning; press steel wires are arranged between the upper and lower tooth of the double teeth clamp chain, and the height thereof is lower than the prong height of the double teeth clamp chain; a driving wheel for driving the double teeth clamp chain and a driven wheel of the conveying chains are coaxial. A threshing device uses a design of a longitudinal axial-flow type threshing cylinder, the threshing tooth of the threshing cylinder are in a spiral belt shape revolving a shaft and are fixed on the surface of the cylinder; and the angle of the threshing tooth and the cylinder shaft can be regulated. The invention derives advantages of the whole-feed type harvester and the half feeding type harvester, thereby solving the problem that the traditional whole-feed type combine harvester is hard to harvest lodging rice, has more threshing constraints and the threshing is unclean; and the invention has the advantages of clean threshing, complete separation, low broken rate and less trash content.

Owner:GUANGXI GUIGANG COMBINE HARVESTER

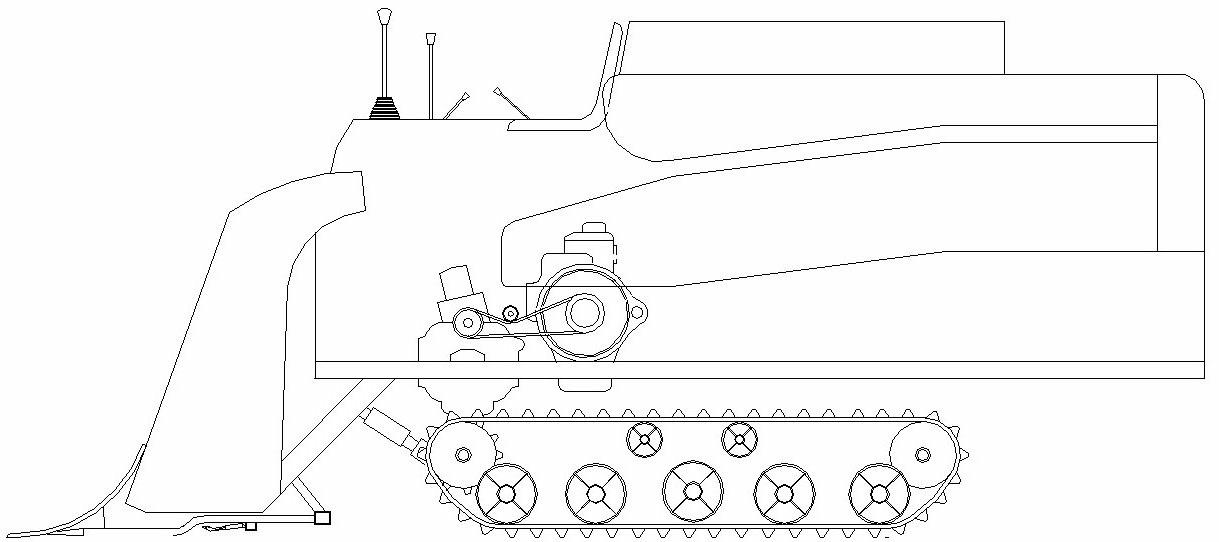

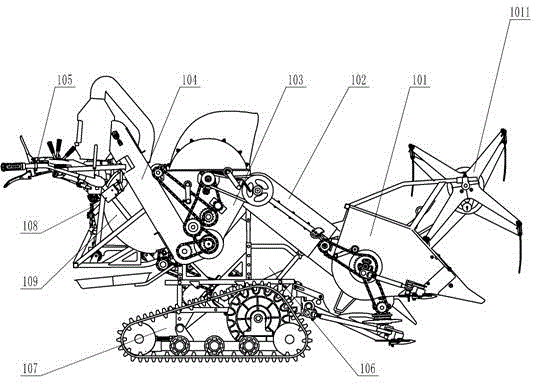

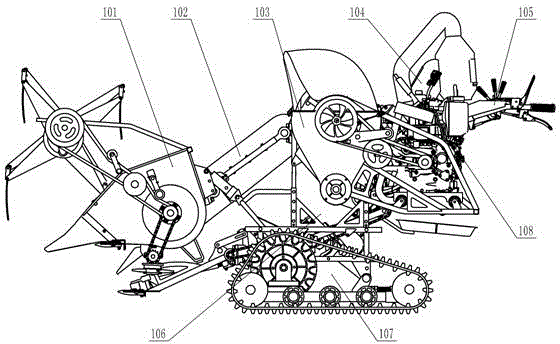

Combine harvester

InactiveCN102150503AGreat tractionShorten the lengthMowersThreshersDrive wheelAgricultural engineering

The invention relates to an agricultural machine, in particular to a combine harvester. The combine harvester comprises a harvesting table, an operating table, a threshing system, a gear box, an engine, a stalks transmitting chain, a stander, a travelling mechanism and a second cleaning system; the stander is fixedly arranged on the travelling mechanism; the travelling mechanism comprises a front guide wheel, a back driving wheel, a thrust wheel and two crawler belts; the harvesting table, the operating table, the threshing system, the gear box and the engine are fixedly arranged on the stander, the engine is arranged behind a complete machine and connected with a back driving wheel shaft in the travelling mechanism by the gear box; and the threshing system is arranged between the two crawler belts of the travelling mechanism, and the second cleaning system is arranged under the threshing system. The combine harvester changes the structure of the traditional harvester, the structure is simpler and more reasonable, and the work efficiency can be greatly improved.

Owner:夏发明

Beating type oilseed rape thresher

Owner:SICHUAN LINGGUAN TECH

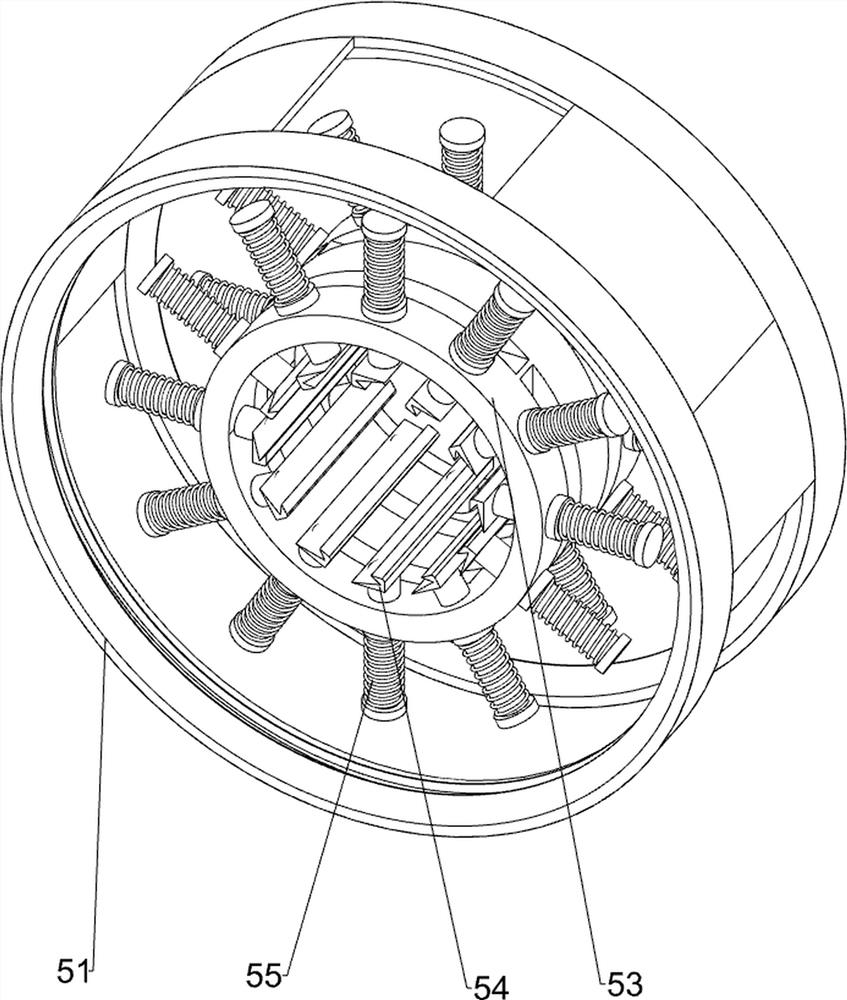

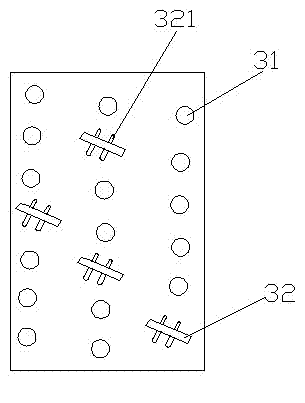

Multifunctional threshing device of combine harvester

InactiveCN101595789AImprove threshing and separation abilityReduce in quantityThreshersLoss rateEngineering

The invention discloses a multifunctional threshing device of combine harvester, comprising a threshing roller shelf, wherein, the threshing roller shelf is provided with a threshing roller and a top cover of the threshing roller; and a concave grid is arranged at the bottom of the threshing roller; a radialis disc is arranged axially on the threshing roller, rectangular toothed bars are evenly arranged on the circumference of the radialis disc by a fixing plate; threshing components are arranged on the rectangular toothed bars, threshing components are fixedly connected onto the rectangular toothed bars by a fixing device; the fixing device comprises long slots arranged on the rectangular toothed bars along the extending directions of the rectangular toothed bars; the fixing device also comprises a bolt I and a screw nut I, wherein, the bolt I passes through the long slot and then is connected with the threshing components, and the screw nut I is screwed into the bolt I and the threshing components are fixedly connected onto the rectangular toothed bars. The invention has the advantages of low threshing loss rate, low broken rate, and good threshing effect, meanwhile, users can arbitrarily combine the types and numbers of the threshing components according to actual situations, thereby the threshing is cleaner, and the power consumption is smaller.

Owner:ZHONGJI SOUTHERN MACHINERY

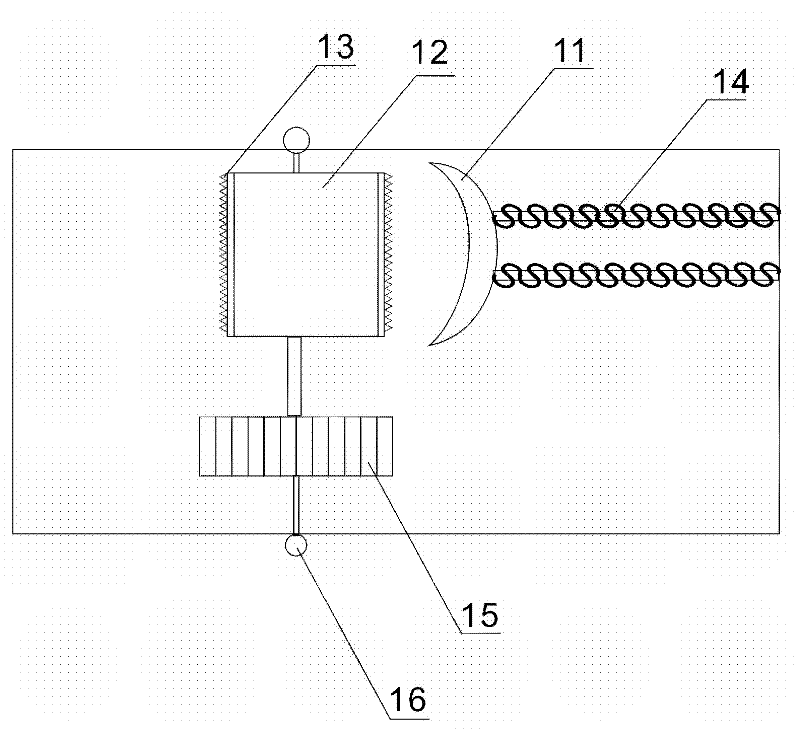

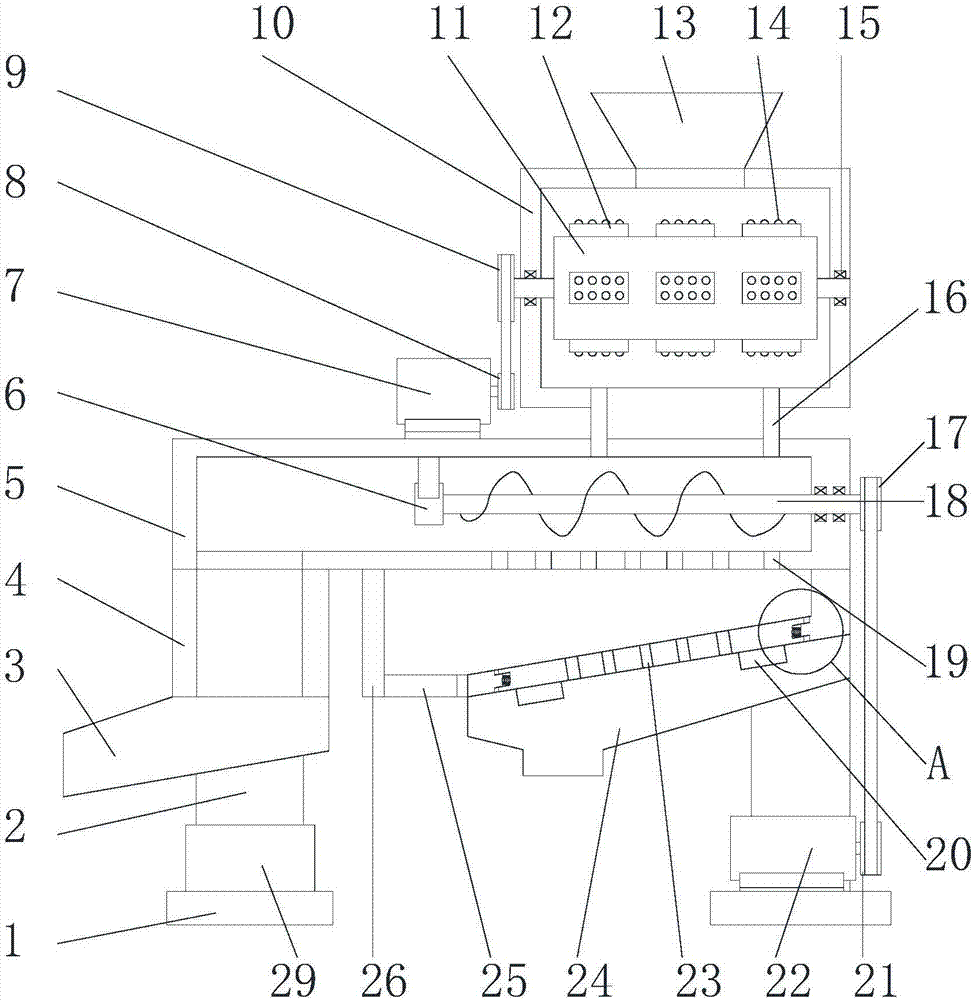

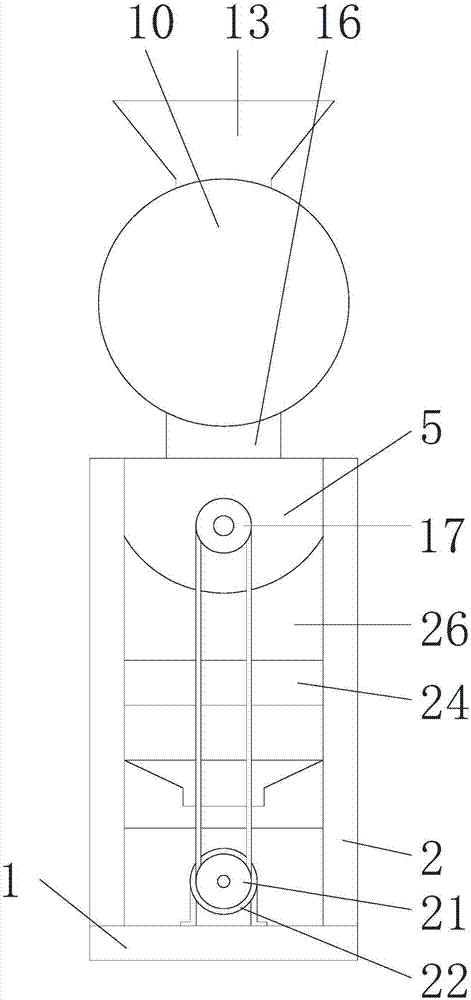

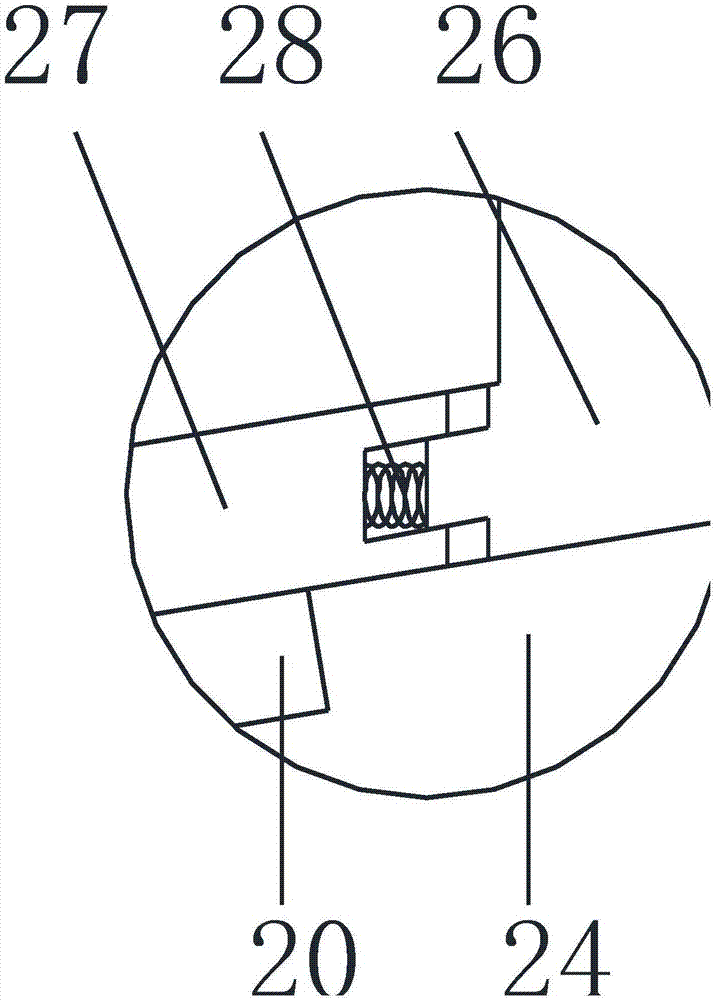

Combined corn thresher and threshing method thereof

The invention provides a combined corn thresher which consists of a transverse threshing device and a longitudinal threshing device. The transverse threshing device and the longitudinal threshing device are in occlusion connection through a gear and a gear with a nail disk, wherein the transverse threshing device consists of a motor, a belt pulley, a cone gear, a rack, a transmission gear, the gear with the nail disk, a regulator bracket, a baffle, a spring, a regulating nut and a screw; and the longitudinal threshing device consists of a concave thresher, a threshing roller with spike teeth, roller threshing teeth, a regulating device, a transmission gear and a bearing support. In a threshing method disclosed by the invention, a transverse and longitudinal alternate threshing technology is adopted. The threshing method has good threshing effect and high efficiency. Corncobs are not crushed. The threshing method is suitable for vast rural market.

Owner:FENGGANG FENGMING AGRI MACHINERY MFG

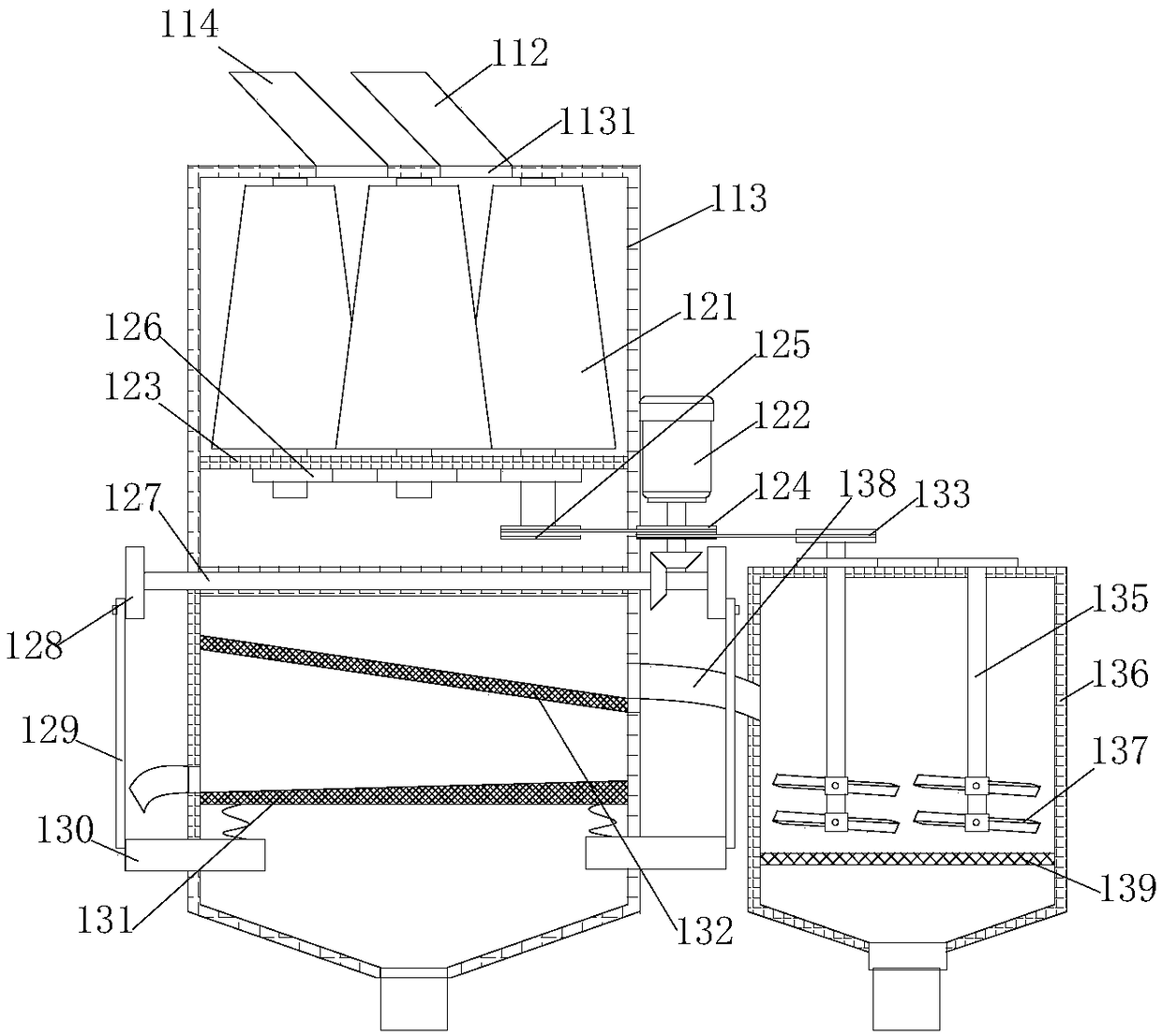

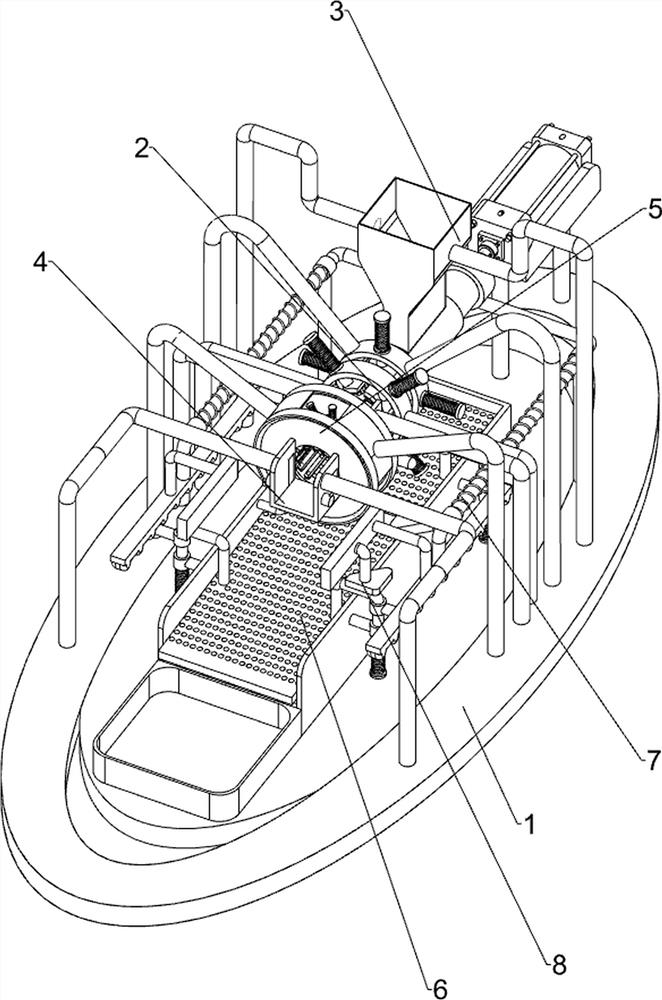

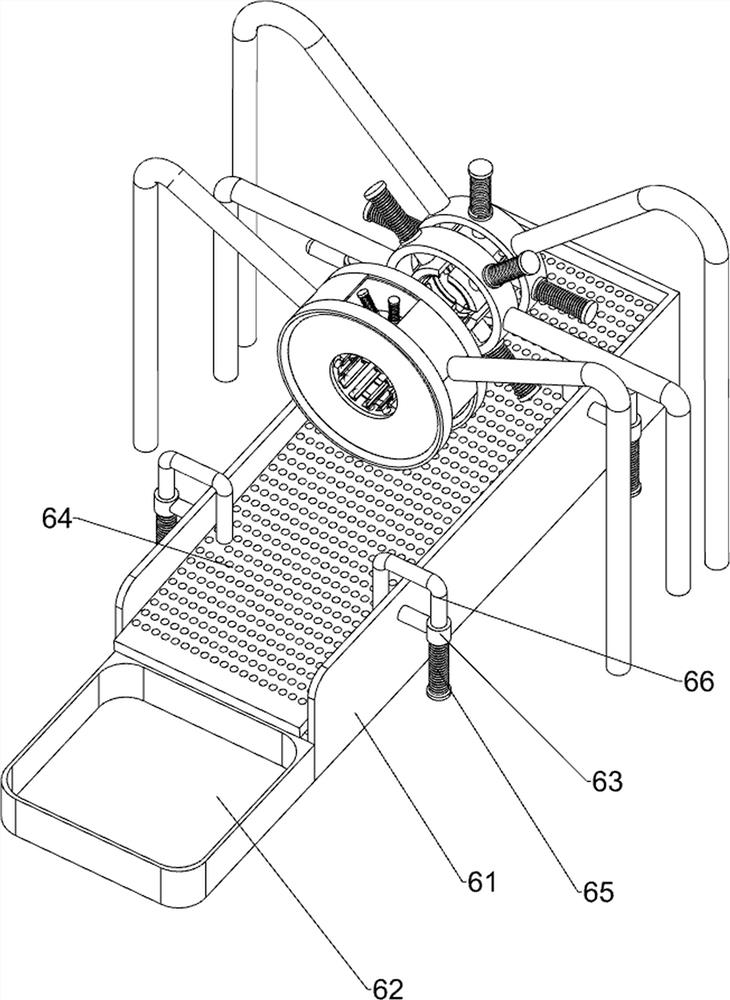

Agricultural machine for producing edible powder

InactiveCN108617277AReduced labor requirementsFree handsTransportation and packagingMixersAgricultural engineeringCorn flour

The invention discloses an agricultural machine for producing edible powder. The agricultural machine sequentially comprises a corn cob processing device, a corn grain crushing device, a powder mixingdevice and a powder operation device according to a process flow. The corn cob processing device comprises a feeding unit and a processing unit. The powder mixing device comprises a material mixing tank body and a material mixing upper cover which covers the material mixing tank body. A first material mixing and sieving plate, a first mixing chamber, a second material mixing and sieving plate, and a crushing / mixing integrated chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. The powder operation device comprises an operation conveying belt, a turnoverdischarging device, an operation baffle, a conveying hopper, an operation elastic device and an operation lifting base table. The agricultural machine provided by the invention has the advantages that the processing efficiency of corn cobs is improved, the quality of the produced corn flour is ensured, the mixing effect of the corn flour and the flour is good, the corn flour and the flour do notcake easily, blocking does not occur easily, the working continuity is strong, the feeding amount of a single time is accurate, and the working efficiency is high.

Owner:芜湖拓云农业技术有限公司

Fresh corn threshing machine

The invention discloses a fresh corn threshing machine which is characterized by comprising a framework and an annular blade. The annular blade is used for cutting corn kernels, an axial slit is formed in the annular blade so that the annular blade can be opened, the inner diameter of the annular blade in a natural state is equal to or slightly smaller than the diameter of the head of each corn cob, a corn cob fixing mechanism and a blade downward movement driving mechanism are arranged on the framework, and the annular blade is mounted on the blade downward movement driving mechanism. The fresh corn threshing machine has the advantages that the fresh corn threshing machine is integrally small and is simple in structure, low in cost, wide in application area and suitable for household use; the axial slit is formed in the annular blade, the inner diameter of the annular blade in the natural state is equal to or slightly smaller than the diameter of the head of each corn cob, accordingly, the annular blade can assuredly always cling to the surfaces of the corn cobs when the fresh corn cobs are about to be threshed, and fresh corns can be completely threshed.

Owner:NINGBO UNIV

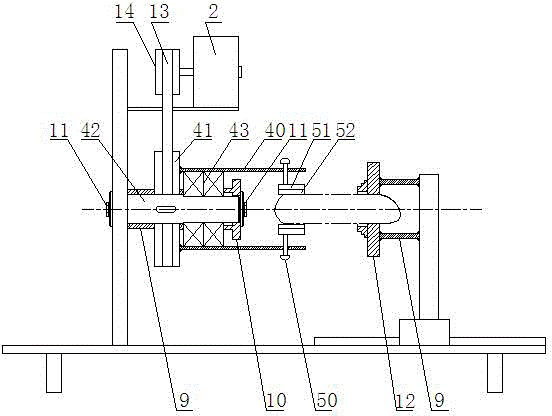

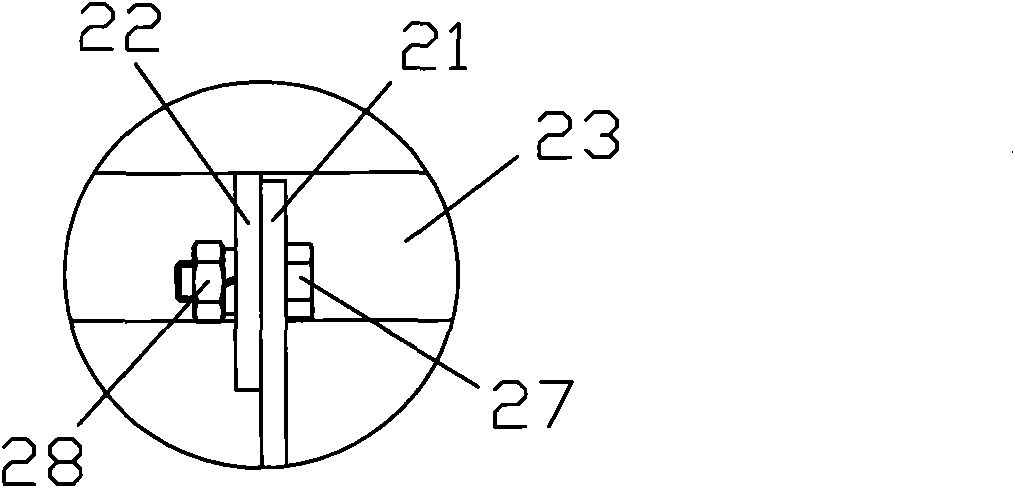

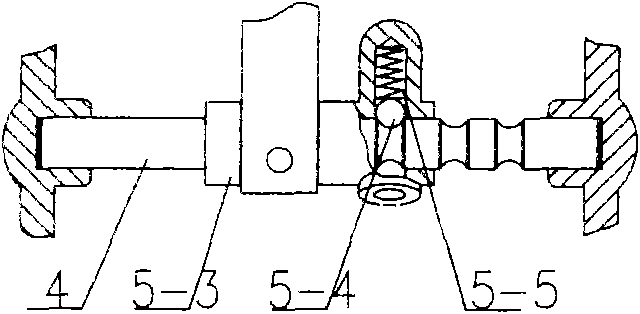

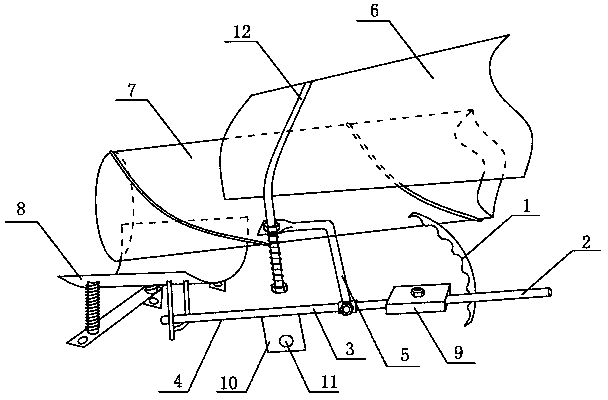

Three-speed variable transmission device for threshing cylinder of semi-feeding rice and wheat combine harvester

InactiveCN102084766AExtended service lifeImprove adaptabilityThreshersGear wheelAgricultural engineering

The invention relates to a three-speed variable transmission device for a threshing cylinder of a semi-feeding rice and wheat combine harvester capable of adjusting the threshing speed, which is transmitted through an input shaft, a transition gear spline shaft and an output shaft, wherein power is transmitted to the input shaft through a coupler, then a change gear is regulated by using a gear shift fork to realize three-gear speed change, and then the power is transferred at equal speed through I-level gears on the transition gear spline shaft and the output shaft, output by the output shaft and transmitted to the threshing cylinder through a belt. Through regulating the speed of the threshing cylinder, the defect of the single speed of the original threshing cylinder is improved to ensure that the machine body can select a proper threshing speed when working according to the difference of rice varieties and the yield of crops so that unnecessary power consumption loss is reduced, crops are threshed more cleanly, the loss rate of grains is reduced, and the adaptability of the machine body is greatly improved.

Owner:TAIZHOU CHANGFA AGRI EQUIP

Threshing and deslagging integrated device for corn

ActiveCN105409463AGuaranteed smoothnessImprove threshing efficiencySaving energy measuresThreshersEngineeringConveyor belt

The invention discloses a threshing and deslagging integrated device for corn. The device comprises a threshing part, a separating part and an impurity removing part, wherein the threshing part comprises a horizontally arranged box body and a first threshing mechanism and a second threshing mechanism; the first threshing mechanism comprises a plurality of pressing assemblies, a supporting plate and a plurality of rotor drums; each of the pressing assemblies comprises an air cylinder and a needle head; a bottom plate is hinged to the bottoms of the rotor drums; a sensor is arranged on the bottom plate; the air cylinder, the rotor drums, the bottom plate and the sensor are connected with a controller; the second threshing mechanism comprises a roll shaft assembly and a conveyor belt; the separating part comprises a barrel body, wherein a space where corn kernel roll is formed between the barrel body and the box body; the impurity removing part comprises a conveying pipeline, a T-shaped impurity removing tower, a collecting tower and an exhaust fan. By threshing the cobs in two sections, corn kernels and cobs are separated; impurities of the cobs are removed in two sections, so that the corn kernels are separated from small particle slag body impurities and cob impurities; the device has the advantages of being sanitary, energy-saving, convenient, high in threshing efficiency, good in corn kernel quality and the like.

Owner:界首市金龙机械设备有限公司

Corn threshing and sorting integrated device

The invention discloses a corn threshing and sorting integrated device which is structurally composed of a base plate, a supporting plate, a discharging port, a discharging pipe, a secondary threshingtank, a rotating seat, a second motor, a second driving wheel, a second driven wheel, a primary threshing tank, a threshing roller, a threshing grinding block, a hopper, abrasive particles, a bearing, a guide tube, a first driven wheel, a threshing worm, a filter hole, a vibrator, a first driving wheel, a first motor, a sorting hole, a discharging hood, a material outlet, a sorting tank, a sorting sieve plate and a spring. The primary threshing tank and the secondary threshing tank which are arranged in the corn threshing and sorting integrated device thresh corn twice, it is ensured that thecorn threshing is performed more thoroughly, and the corn threshing quality is improved. The sorting tank disposed on the lower side of the secondary threshing tank can sort defective products in corn kernels, extra sorting processing is not required, and the corn threshing and sorting integrated device reduces cost and saves time and labor. The device is high in working efficiency and rich in function and can well meet the use requirements.

Owner:李晓丹

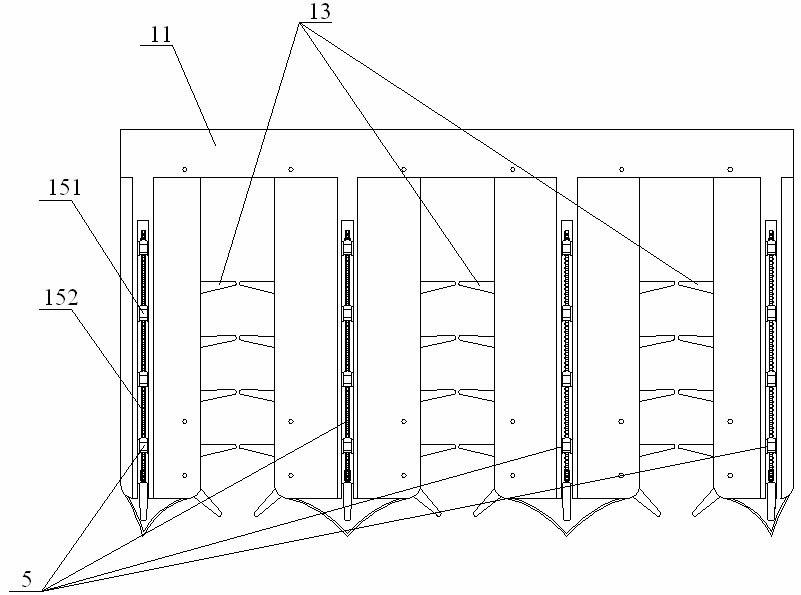

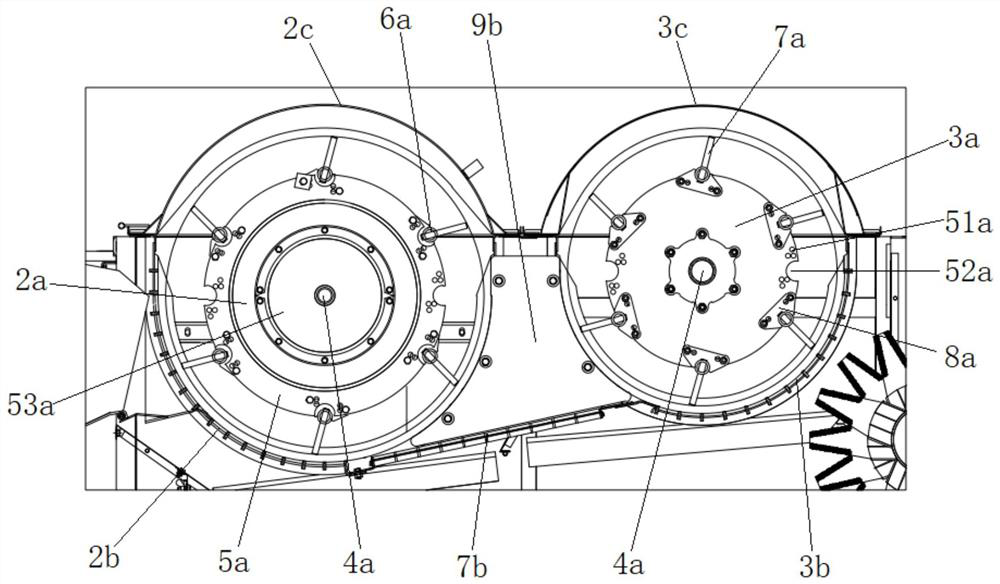

Double-helix threshing and conveying system and combine harvester

PendingCN112690111AGuaranteed mobilityThreshing cleanMowersThreshersAgricultural engineeringStructural engineering

The invention provides a double-helix threshing and conveying system and a combine harvester. The double-helix threshing and conveying system comprises two threshing spaces which are horizontally arranged in the advancing direction of the harvester at intervals front and back, each threshing space is a hollow cylindrical mounting cavity defined by a concave plate screen and a cylinder cover, and a roller is mounted in each mounting cavity. Guiding pieces are arranged on the inner wall faces of the cylinder covers at intervals and used for guiding crops entering the threshing spaces to move directionally around the axis, the rollers drive the crops to move when rotating and enters the second threshing space from the first threshing space through guiding of the guiding pieces, and therefore the lengths of working areas of the two threshing spaces are the same. Therefore, a crop threshing path passes through the length of two rollers and can fully thresh crops. The two threshing spaces are horizontally arranged in a spaced manner, so that the structure on the rack is more compact, the lengths of the two threshing working areas are the same, the threshing path long enough can be guaranteed, and the threshing effect is fully guaranteed while the overall maneuverability of the harvester is guaranteed.

Owner:JIANGSU WORLD AGRI MACHINERY

Threshing and deslagging integrated device for corn

ActiveCN105409462AGuaranteed smoothnessImprove threshing efficiencyThreshersEngineeringConveyor belt

The invention discloses a threshing and deslagging integrated device for corn. The device comprises a threshing part, a separating part and a deslagging part, wherein the threshing part comprises a horizontally arranged box body and a first threshing mechanism and a second threshing mechanism; the first threshing mechanism comprises a plurality of pressing assemblies, a supporting plate and a plurality of rotor drums; each of the pressing assemblies comprises an air cylinder and a needle head; a bottom plate is hinged to the bottoms of the rotor drums; a sensor is arranged on the bottom plate; the air cylinder, the rotor drums, the bottom plate and the sensor are connected with a controller; the second threshing mechanism comprises a roll shaft assembly and a conveyor belt; the separating part comprises a barrel body, wherein a space where corn kernel roll is formed between the barrel body and the box body; the deslagging part comprises a serpentine pipeline, an exhaust fan and a dust box. By threshing the cobs in two sections, corn kernels and cobs are separated; the cobs are deslagged in two sections, so that the corn kernels are separated from small particle slag body impurities and cob impurities; the device has the advantages of being sanitary, energy-saving, convenient, high in threshing efficiency, good in corn kernel quality and the like.

Owner:唐山鑫盛源农产品加工有限公司

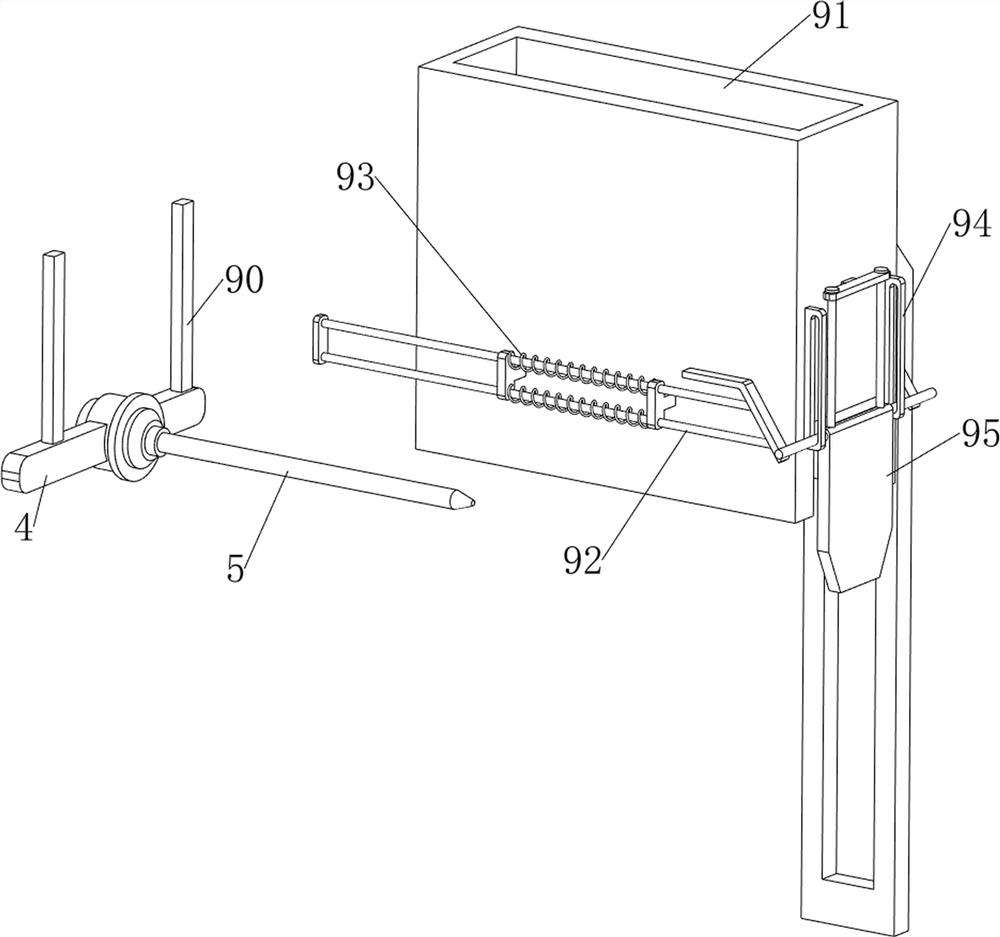

Corn thresher for food processing

PendingCN112314185AEasy threshingConvenient for secondary threshingThreshersAgricultural scienceAgricultural engineering

The invention relates to a threshing device, in particular to a corn thresher for food processing. The corn thresher for food processing is good in threshing effect, and corn cobs are easy to take out. The corn thresher for food processing comprises a bottom plate, a pushing surface scraper mechanism and a discharging pushing scraping mechanism. The pushing surface scraper mechanism is arranged inthe middle of the top of the bottom plate. The discharging pushing scraping mechanism is arranged at the top of the bottom plate. A worker starts an air cylinder to extend to drive corns to move leftwards, so that the corns are threshed by a sliding scraper conveniently and quickly; impurities on corn kernels can be filtered by a mesh screen plate, so that the filtering time of workers is saved;when the air cylinder contracts, the mesh screen plate continuously shakes up and down, the filtering efficiency is improved, and meanwhile, a slope pushing plate is driven to move rightwards, so thata clamping plat clamps the corn cobs; and when the air cylinder contracts, a one-way straight gear is driven to rotate clockwise to thresh the corns, so that the corns are threshed more thoroughly, and waste is reduced.

Owner:陈美凤

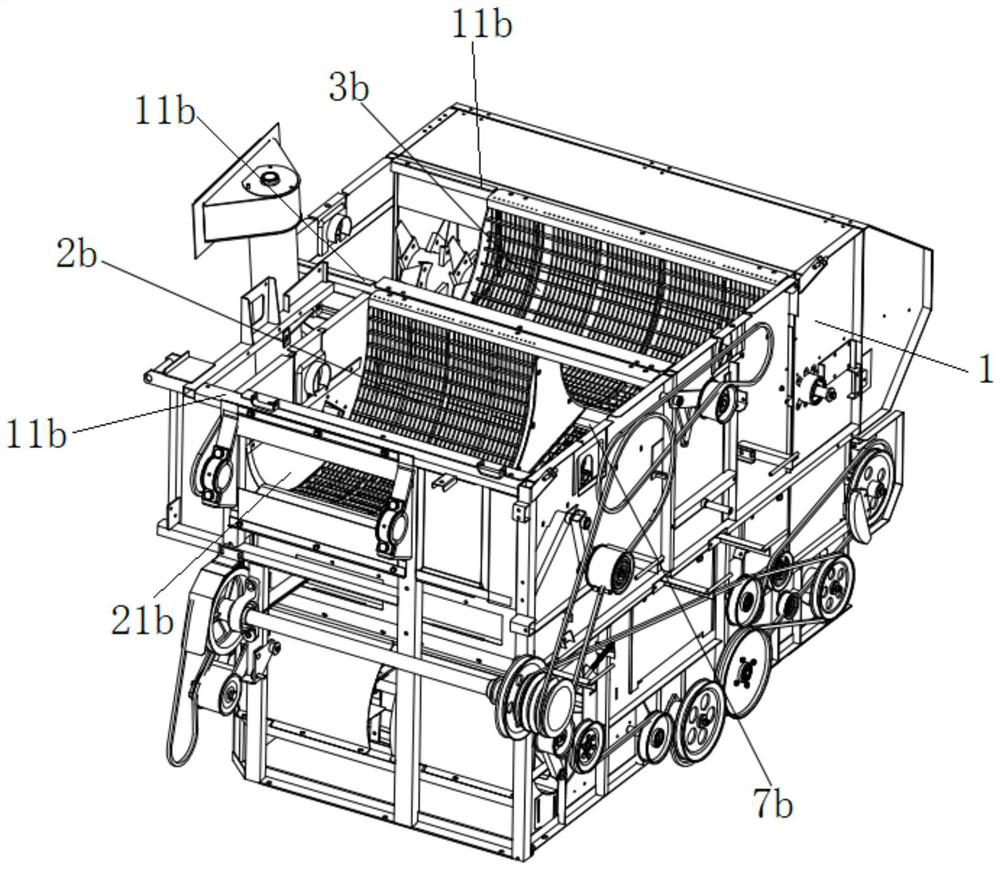

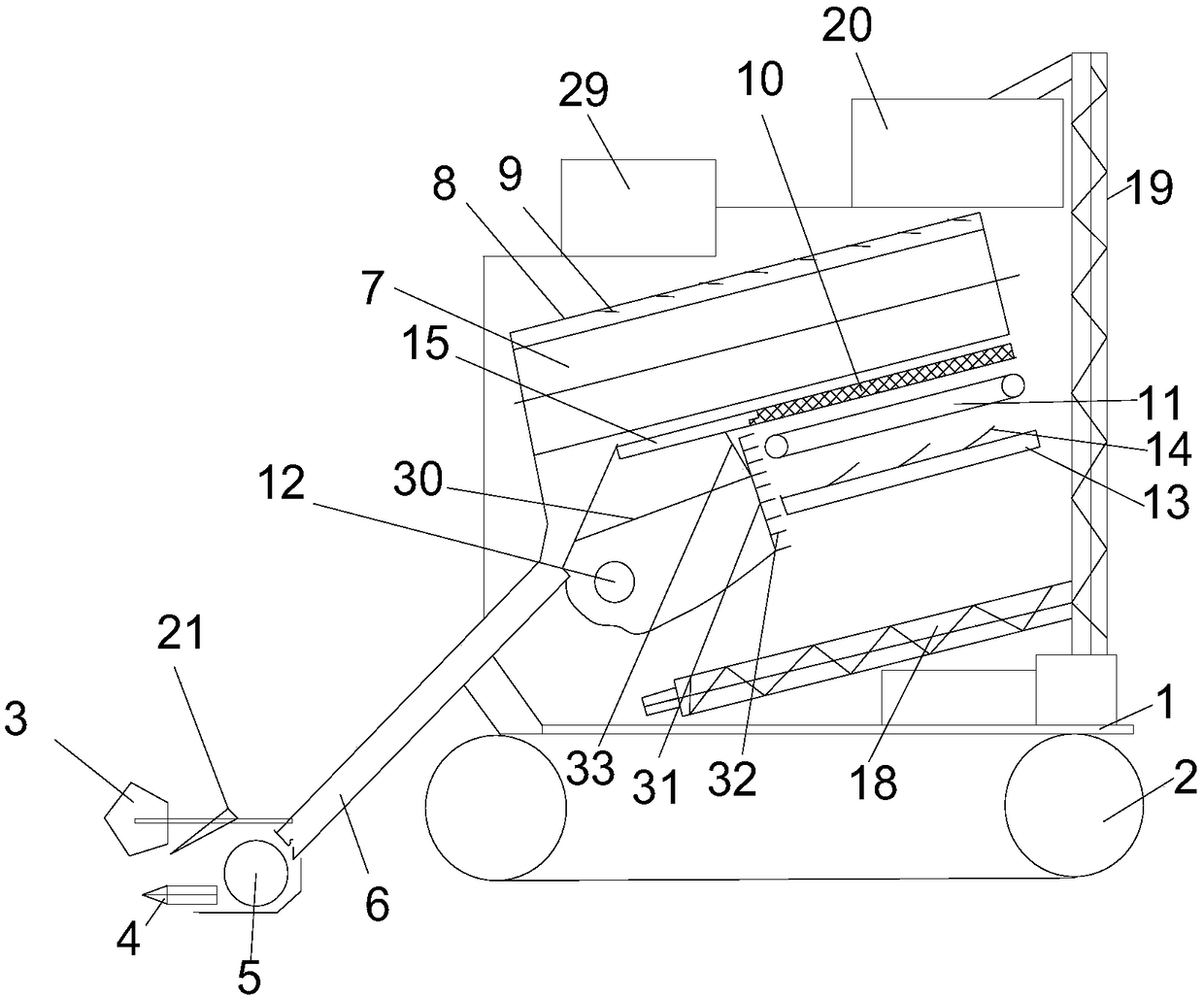

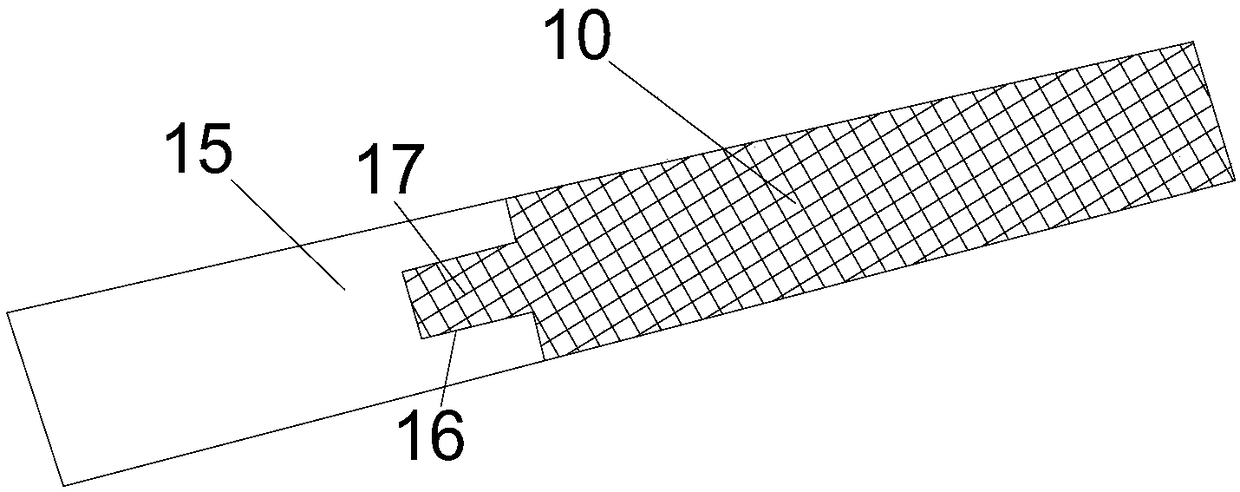

Sufficiently-threshed whole-feed combine harvester

The invention discloses an ear falling prevention whole-feed combine harvester. An upward inclined grass conveying chain is arranged in the rear of a stem poking roller, an upward inclined threshing roller is mounted at the upper end of the grass conveying chain, a screen, a conveying belt, a fan, a vibrating screen and a bottom screw conveyer are arranged on the lower portion of the threshing roller, the screen is fixed with a baffle plate matched with the grass conveying chain, the baffle close to the end middle of the screen is recessed to form a groove, a baffle plate replacement screen isfixed in the groove, a wind retaining plate matched with the fan is fixed below the baffle plate and connected with the mounting plate, a flow comb is fixed on the mounting plate, and a fixing plateis mounted between the mounting plate and the baffle plate. The combine harvester has the advantages that the threshing roller is obliquely arranged, grains are threshed, kernels and shells can be rapidly separated, a double-box four-gear structure in the grass conveying chain cannot be locked, and the combine harvester is provided with the baffle plate, so that rapeseed stems, long ears and wheatears cannot fall when the combine harvester harvests crops.

Owner:杨松柏

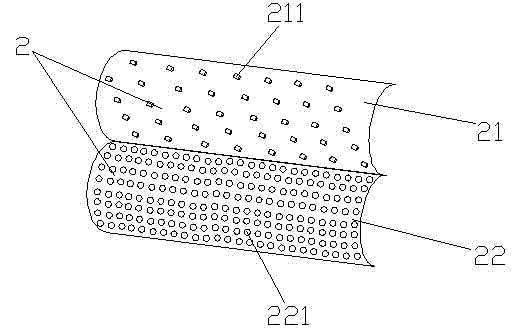

Threshing cylinder of corn thresher

InactiveCN103918416AImprove threshing efficiencyThreshing thoroughlyThreshersAgricultural engineeringStructural engineering

A threshing cylinder of a corn thresher comprises a roller and a screen. The roller is provided with threshing teeth which are distributed from the first to the last in a single helical line manner. The threshing teeth include cylinder teeth and blade teeth, wherein the blade teeth are obliquely arranged along the helical line. The screen is a transversely disposed cylinder, and the upper portion of the screen is a solid plate and the lower portion of the screen is a screening plate. A plurality of first projections are arranged on the inner side of the solid plate. The first projections are arranged on the inner side of the solid plate on the upper portion of the cylindrical screen, threshing efficiency of corn cobs is greatly improved, and threshing of the corn cobs is more thorough. The threshing teeth include blade teeth, and pushing the corn cobs forward is improved, so that the problem that the corn cobs are stuck between the roller and the screen is solved, and threshing capacity is more improved due to the fact that second projections are arranged on the side of the blade teeth.

Owner:ZHANGQIU CITY YONGSHENG VEHICLE FITTINGS

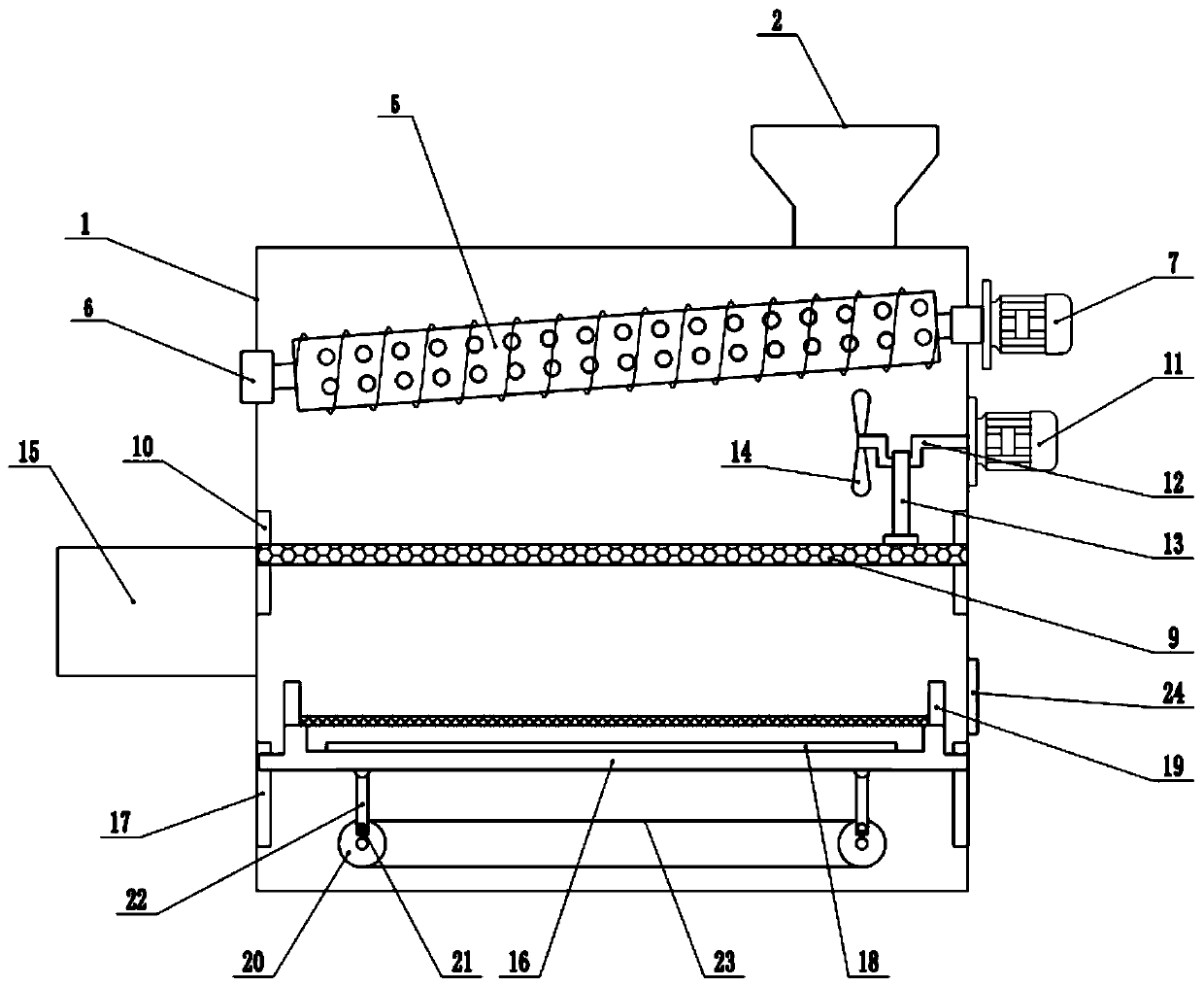

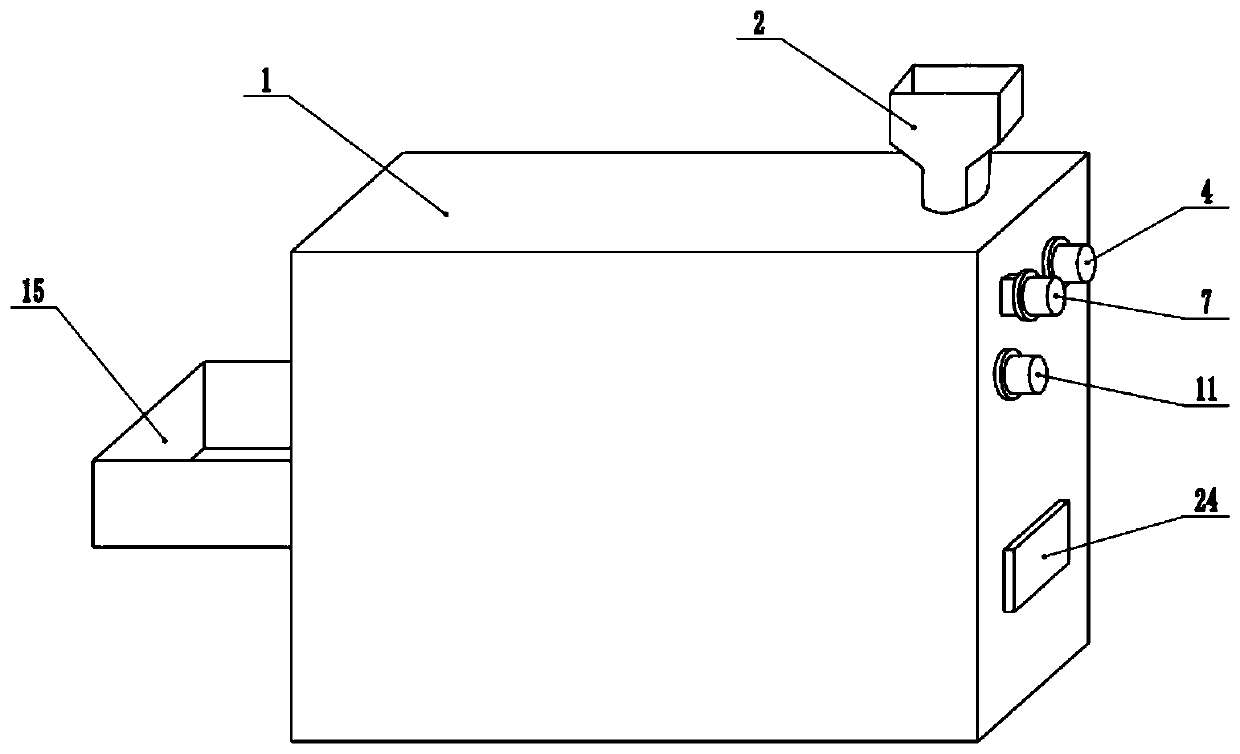

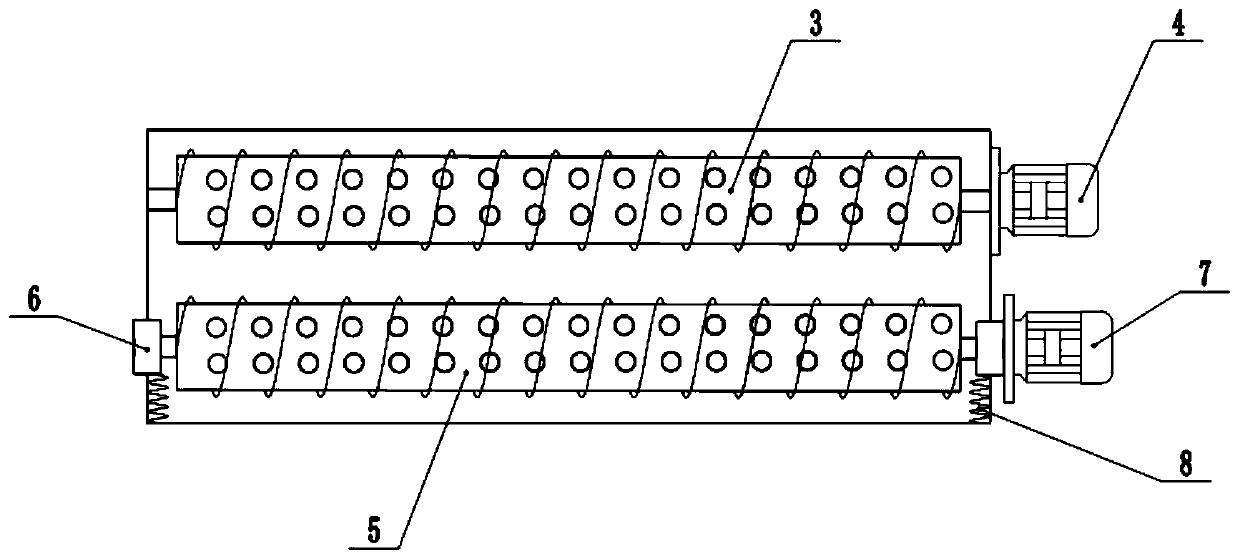

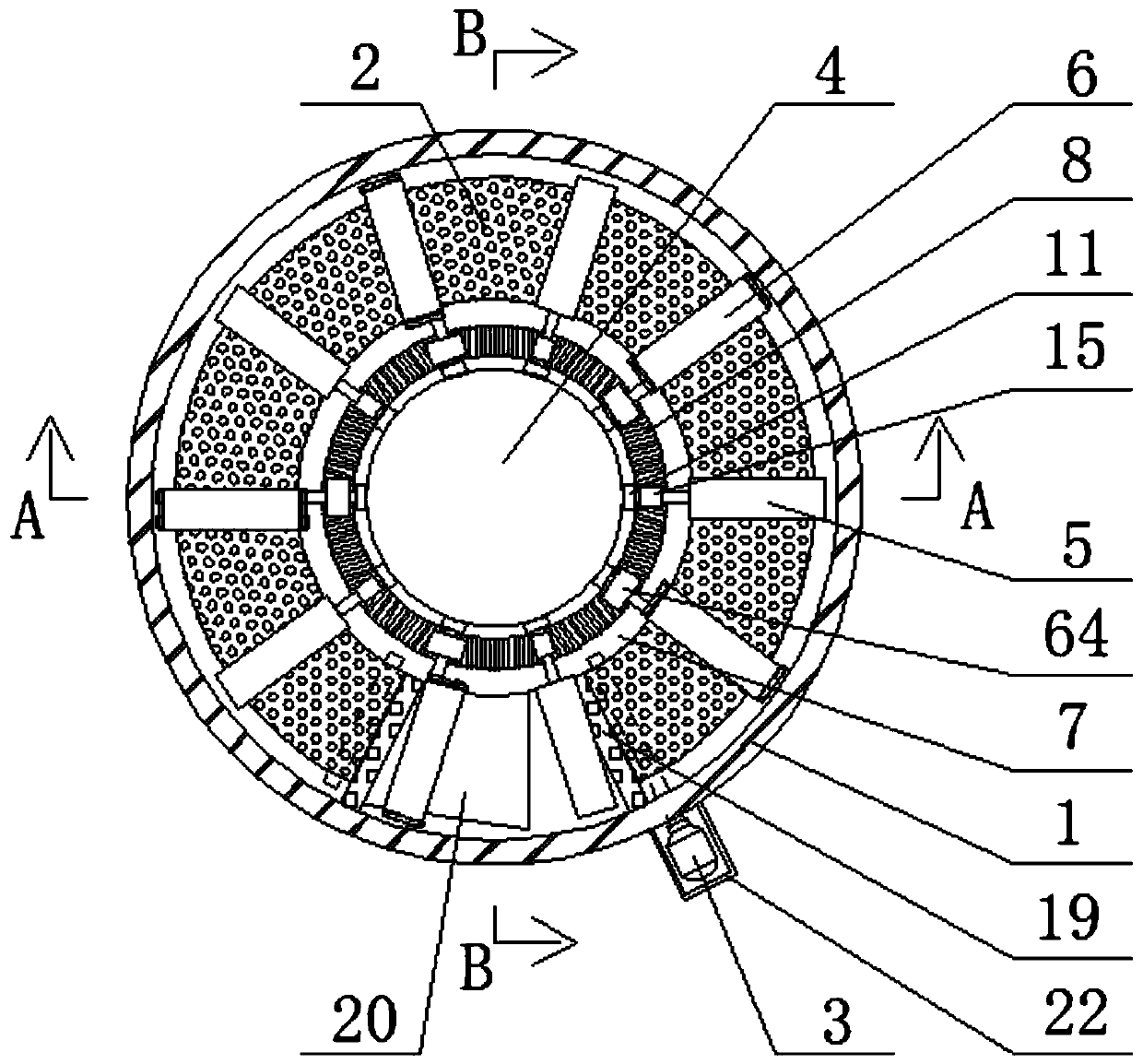

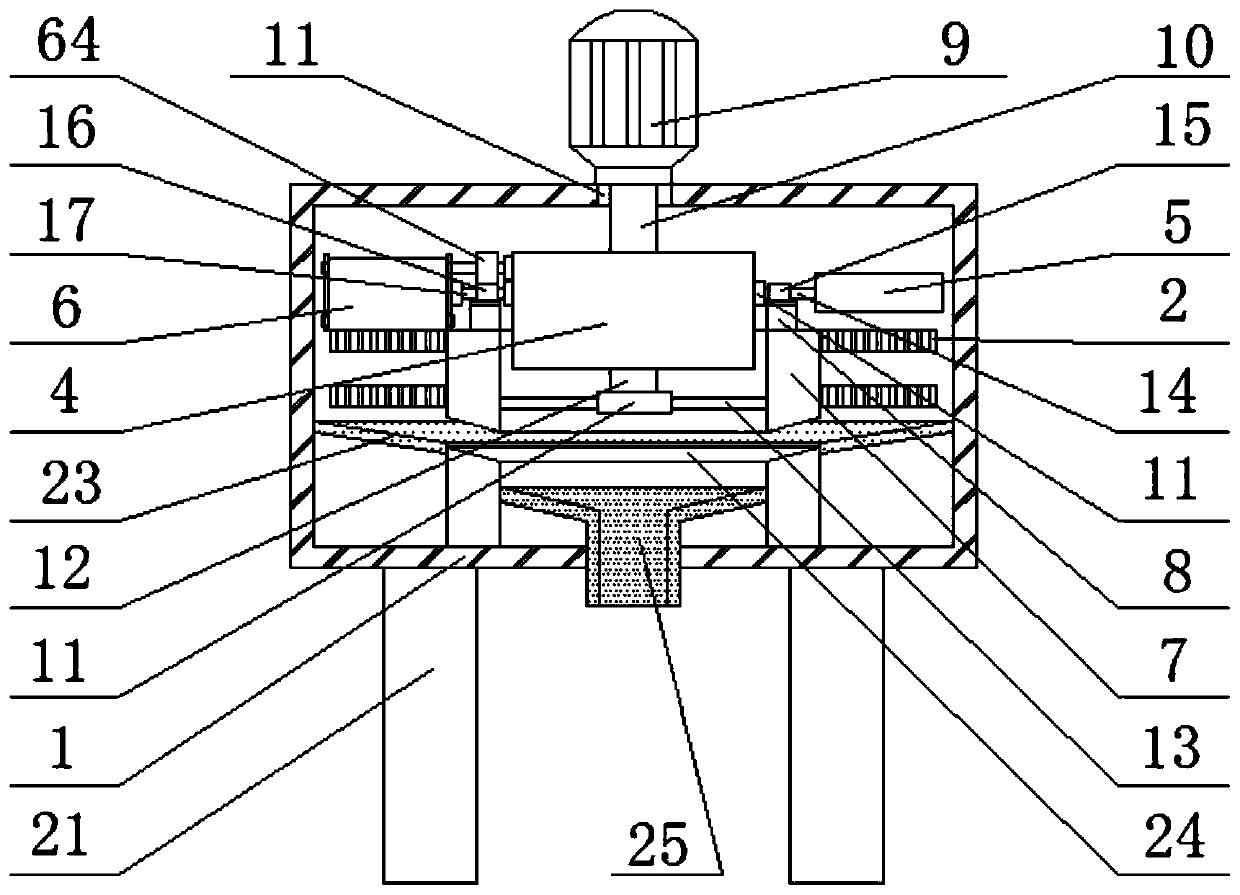

Vibration corn threshing and drying integral machine

InactiveCN110063146AThreshing cleanEvenly heatedThreshersSeed preservation by dryingEngineeringMechanical equipment

The invention relates to the field of agricultural product harvesting and storage treatment mechanical equipment and particularly discloses a vibration corn threshing and drying integral machine whichcomprises a housing, a feeding hole, a first threshing roller and a first threshing motor, wherein the first threshing rollers are mounted inside the housing; the first threshing motor is fixedly connected with the outer side wall of the housing; a second threshing roller is mounted inside the housing; sliding blocks are respectively and rotationally connected with the left end and the right endof the second threshing roller; springs are fixedly connected with the surfaces of the sliding blocks; a second threshing motor is arranged at the right end of the second threshing roller; a screeningplate is arranged below the second threshing roller; and a vibration mechanism is arranged above the screening plate. In the threshing process, corn cobs are kept at a tightly stuck state with the first threshing roller and the second threshing roller, then corn grains can be thoroughly threshed, corn stigma can be blown off from a residue discharge hole by using fan blades, the corn grains are dried by using an electric heating plate, in the drying process, a vibration platform is moved up and down to drive the corn grains to turn over up and down, and the corn grains can be uniformly heated.

Owner:赣州轩义科技有限公司

Agricultural machine used for threshing

InactiveCN111213496AExpand the difference in movement speedIncrease the differenceThreshersAgricultural scienceGear wheel

The invention discloses an agricultural machine used for threshing, and belongs to the field of agricultural threshing devices. The agricultural machine used for threshing comprises an outer box, an arc conveyor belt and a central rotating column, wherein an annular rack is arranged between the central rotating column and the arc conveyor belt, pressure rolls and scarifying assemblies are installed on the circumferential side of the central rotating column at equal intervals, and the sides, facing the central rotating column, of the pressure rolls are connected with first gears meshed with theannular rack; the scarifying assemblies comprise triangular turning conveyor belts and three rotating shafts, one rotating shaft is fixedly sleeved with a second gear, and the bottom of the second gear is meshed with a third gear meshed with the annular rack; and mesh holes through which beans penetrate are distributed in the arc conveyor belt, an isolation cylinder fixed to the bottom surface ofthe outer box is arranged between the arc conveyor belt and the central rotating column, and isolation baffles which are fixedly connected with the isolation cylinder and the bottom of the outer boxare fixed to both ends of the arc conveyor belt. According to the agricultural machine used for threshing, the threshing strength is adjustable, beanpoles can be turned, full threshing is ensured, andthe threshed beanpoles can be discharged fully automatically.

Owner:孙申安

Threshing method based on waste heat utilization and thresher based on waste heat utilization

The invention discloses a threshing method based on waste heat utilization and a thresher based on the waste heat utilization. The thresher comprises a threshing cylinder, a concave sieve plate arranged below the threshing cylinder and an engine for driving the threshing cylinder; and is characterized in that the concave sieve plate is internally provided with a circulating cooling water pipe which is used for performing heat exchange with the inside of the concave sieve plate and cooling the engine; and the concave sieve plate is internally provided with an exhaust pipe which is used for performing heat exchange with the inside of the concave sieve plate and exhausting waste heat of the engine. The threshing method and the thresher make full use of waste heat of the engine, and are applicable to threshing of different crops by preheating and predrying materials in the threshing cylinder.

Owner:HUNAN AGRICULTURAL UNIV

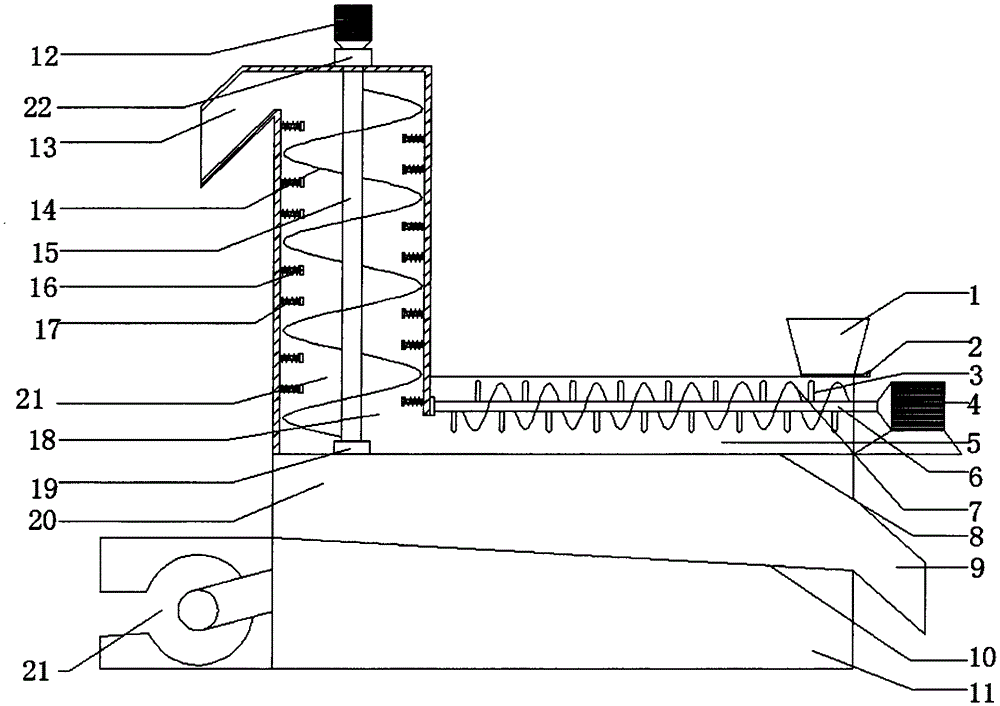

Efficient corn thresher

InactiveCN106717580ATimely processingImprove efficiencyThreshersFixed bearingAgricultural engineering

The invention discloses an efficient corn thresher which comprises a feeding port, a second rotating shaft, a fixed bearing and a second threshing cabin. The efficient corn thresher is characterized in that the feeding port is installed on a first threshing cabin, a first rotating shaft is installed in the middle of the first threshing cabin, a first spiral piece and a first rubber rod are installed on the first rotating shaft, the right end of the first rotating shaft is connected with a first motor, the first motor is in transmission connection with the first rotating shaft, the second rotating shaft is installed on the fixed bearing, a second spiral piece is installed on the second rotating shaft, the upper portion of the second rotating shaft is connected with a second motor, the second motor is in transmission connection with the second rotating shaft, and a discharging cabin is installed below a first screen cloth. Compared with the prior art, the efficient corn thresher has the advantages that the efficient corn thresher is economical, practical, convenient to use, safe and swift, the stripping is fuller, and dust can be timely treated out of the thresher.

Owner:庄坤达

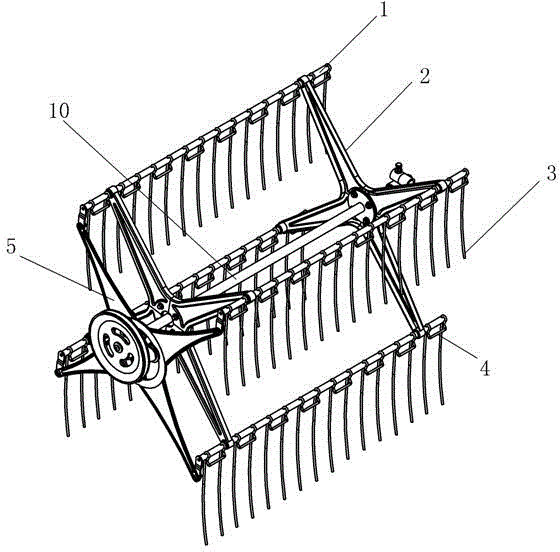

Small size combine harvester

The invention discloses a small size combine harvester which is high in adaptability and threshing rate, convenient to lift, thorough in sorting, simple in structure and convenient to demount and mount. The small size combine harvester comprises a header device, a middle conveying device, a threshing device, a grain conveying device, an operating device, a lifting device, a walking device, a grain sorting device and a power device. According to the small size combine harvester, the angles between elastic claws of reels and crops to be harvested can be adjusted through eccentric wheels, harvesting is more thorough, and waste of grains is reduced; a threshing drum is good in threshing effect, smooth in crop straw discharging and more thorough in threshing; the height adjusting range of the harvester meets the harvesting operation demands of grain in various height states, and meanwhile the harvester is simple in structure and convenient to use; a walking speed changing box is higher in reliability, convenient to assemble, reasonable in gear shifting, light and easy to carry; a fan device capable of sucking in impurities while blowing out the impurities is adopted in a sorting device, losses of the grains in the harvesting process of the harvester can be reduced, and the grains are sorted more thoroughly.

Owner:四川穗通科技有限公司

Multifunctional peanut threshing machine

The invention discloses a multifunctional peanut thresher, which belongs to the technical field of peanut threshing. The shell of the thresher is fixedly equipped with a feeding hopper on the top of the shell of the thresher. The device is fixedly connected with the connecting rod, the end of the connecting rod away from the motor runs through the shell of the thresher and extends to the inside of the shell of the thresher, and the end of the connecting rod extending to the inside of the shell of the thresher is fixedly connected with a threshing shaft; the shell of the thresher is far away from the There is a debris discharge pipe on one side of the motor, and a screen is installed at the bottom of the threshing shaft. The screen is fixedly connected with the inner wall of the shell of the threshing machine. The bottom of the screen is fixedly connected with the inner wall of the shell of the thresher. There is no contact between them, and the first filter net and the second filter net are arranged under the funnel, so that the peanut pods can be filtered in multiple layers, and the invention can classify the quality of the peanut pods.

Owner:广西万里顺机械制造有限公司

Upper threshing warehouse and lower threshing warehouse height adjusting device used for corn thresher

InactiveCN103960001AThreshing cleanSimple structureThreshersAgricultural scienceAgricultural engineering

The invention discloses an upper threshing warehouse and lower threshing warehouse height adjusting device used for a corn thresher. The upper threshing warehouse and lower threshing warehouse height adjusting device used for the corn thresher comprises gear shifting teeth, an adjusting handle and adjusting arms, wherein the adjusting handle is clamped into a gear tooth groove of the gear shifting teeth; the adjusting handle and the adjusting arms are connected; the rear adjusting arm and the front adjusting arm of the adjusting arms rotate with a rotating supporting point as the rotating center; the rear adjusting arm drives an upper threshing warehouse adjusting arm connected with the rear adjusting arm to move; the upper threshing warehouse adjusting arm drives a warehouse shell to move; the front adjusting arm is connected to the lower portion of a bottom pressing board at the lower end of a threshing cylinder in a sleeved mode; the front adjusting arm pulls the bottom pressing board to move; in this way, the height of an upper threshing warehouse and the height of a lower threshing warehouse can be adjusted at the same time, corn can be rapidly threshed not only in the upper threshing warehouse but also in the lower threshing warehouse, the corn is prevented from being clamped or being broken when the diameter of the corn is large, and the corn can be completely threshed even when the diameter of the corn is small.

Owner:巴中市红河农业机械有限公司

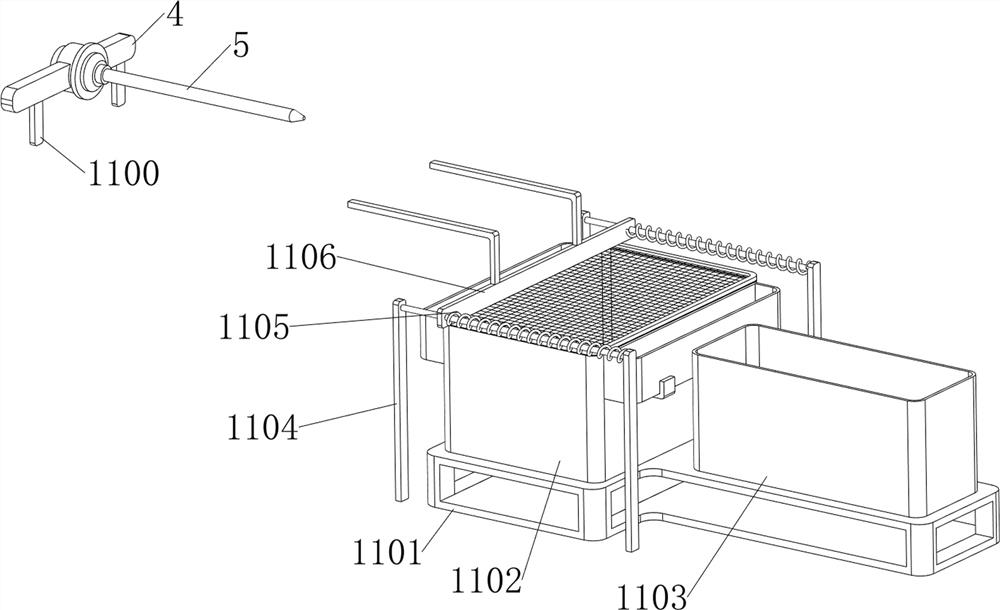

Agricultural corn kernel rapid threshing equipment

ActiveCN113228948AThe speed of threshing is fastSimple and fast operationThreshersAgricultural engineeringEngineering

The invention relates to threshing equipment, in particular to agricultural corn kernel rapid threshing equipment. The technical problem to be solved is to provide the agricultural corn kernel rapid threshing equipment which is high in corn kernel threshing speed and relatively thorough in corn kernel shedding. The agricultural corn kernel rapid threshing equipment comprises a bottom plate, an air cylinder, a first fixing block, an iron needle, a placing frame, a rotating mechanism, and a stripping mechanism; supporting rods are symmetrically arranged on the bottom plate; the air cylinder is arranged between the supporting rods; the first fixing block is arranged on an air cylinder telescopic rod; the iron needle is rotationally arranged on the first fixing block; the placing frame is arranged on the bottom plate; the rotating mechanism is arranged on the bottom plate; and the stripping mechanism is arranged on the bottom plate. According to the agricultural corn kernel rapid threshing equipment, through the cooperation of the iron needle and the rotating mechanism, corn is automatically threshed, the corn threshing speed is high, and operation is easy and convenient.

Owner:重庆重运矿山机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com