Upper threshing warehouse and lower threshing warehouse height adjusting device used for corn thresher

A technology of height adjustment device and threshing bin, which is applied in threshing equipment, application, agricultural machinery and implements, etc., to achieve the effect of simple principle, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

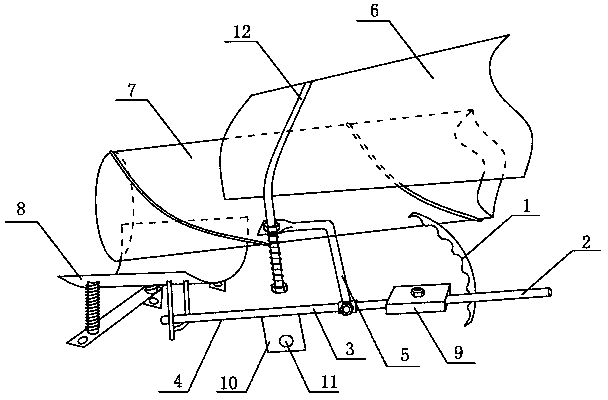

[0022] Such as figure 1 As shown, the height adjustment device for the upper and lower threshing bins of the corn thresher includes a shift gear 1, an adjustment handle 2, and an adjustment arm. The adjustment handle 2 is snapped into the gear slot of the shift gear 1. The adjustment arm is connected; the adjustment arm is divided into the adjustment rear arm 3 and the adjustment forearm 4. The section closer to the adjustment handle 2 is the adjustment rear arm 3, and the farther section from the adjustment handle 2 is the adjustment forearm 4. The adjustment rear arm 3 and the adjustment forearm 4 There is a rotating support point between them, and the adjusting rear arm 3 and the adjusting forearm 4 can rotate around the rotating supporting point. The adjusting rear arm 3 is connected with the upper threshing bin adjusting arm 5, and the upper threshing bin adjusting arm 5 is connected with the bin shell on the corn thresher. 6 connection; the adjustment forearm 4 is connec...

Embodiment 2

[0027] According to the height adjustment device for the upper and lower threshing bins of the corn thresher described in Embodiment 1, a shifting reset device 9 can be arranged between the adjusting handle 2 and the adjusting rear arm 3, and the shifting reset device 9 includes a shifting box, The gear adjustment rotating shaft and the reset tension spring, the adjusting rear arm 3 is connected with the gear shifting box, the gear adjusting rotating shaft is connected with the adjustment handle 2, one end of the reset tension spring is connected with the gear adjustment clip, and the other end of the reset tension spring is connected with the adjustment handle 2 connect. The adjustment handle 2 is pulled back by the return spring, so that the adjustment handle 2 can be quickly clamped in the gear slot, and will not loosen and disengage from the gear teeth, which improves the adjustment stability of the entire adjustment device.

[0028] After the device is installed on the co...

Embodiment 3

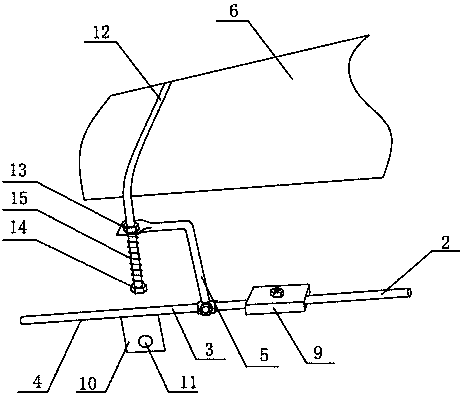

[0030] Such as figure 2 As shown, according to the height adjustment device for the upper and lower threshing bins of the corn thresher described in Example 1, the rotating support point can be realized by using the rotating support hole 11 in cooperation with the screw rod, and the specific structure is as follows:

[0031]A positioning piece 10 is arranged between the adjusting front arm 4 and the adjusting rear arm 3, and a rotating support hole 11 is arranged on the positioning piece 10, and the positioning piece 10 is fixed on the corn thresher by a screw. A supporting piece is arranged on the corn thresher, and the positioning piece 10 is located between the thresher and the supporting piece, and the screw passes through the supporting piece, and the positioning piece 10 is fixed on the corn thresher. The screw rod cooperates with the rotation support hole 11 as a rotation support point. The horizontal displacement of the positioning piece 10 is limited by the limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com