Threshing method based on waste heat utilization and thresher based on waste heat utilization

A technology of threshing machines and threshing drums, applied in threshing equipment, applications, harvesters, etc., can solve the problems of inability to be popularized and applied on a large scale, high requirements for crop varieties, narrow scope of application, etc., and achieve obvious economic benefits and social significance. The effect of low cost and convenient threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

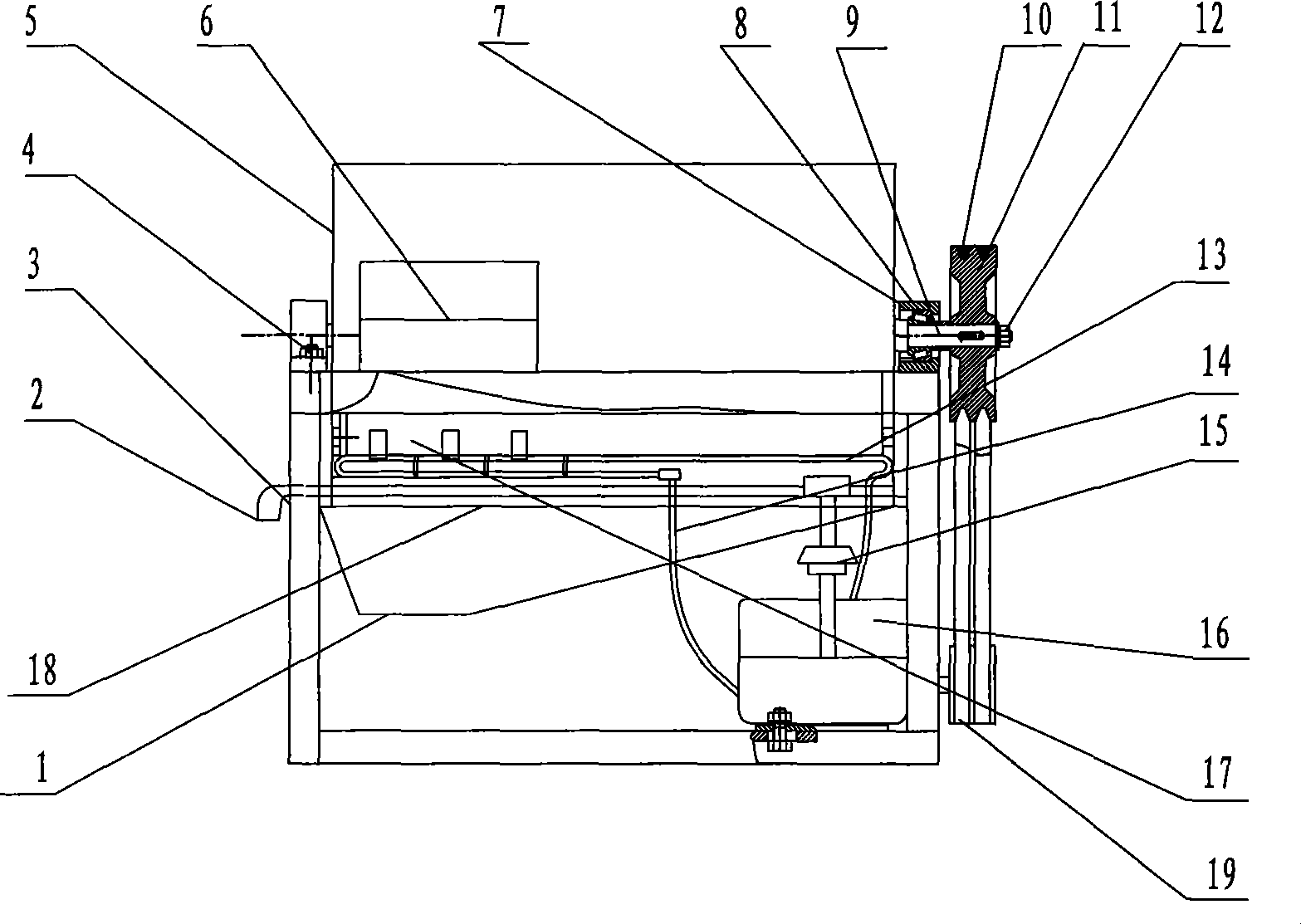

[0030] Such as figure 1 As shown, the temperature control threshing machine support body is a frame 3, a threshing drum 17 is installed on the frame 3, the drum shaft 9 is supported by a bearing 8 installed on the bearing seat 7, and the threshing drum 17 is supported by a top cover 5 and a concave sieve plate 18 Parcel, concave sieve plate is equipped with hot water outlet pipe 13 and waste heat exhaust pipe 15, and motor 16 is installed in frame 3 bottoms, and small V belt pulley 19 is equipped with on motor output shaft. Heating wires are also installed on the concave sieve plate, and the heating size of the heating wires can be adjusted by a voltage regulating switch (such as a thyristor voltage regulating switch).

[0031] Working principle, when the temperature-controlled threshing machine is working, the small pulley 19 of the engine 16 drives the large pulley 11 to rotate through the V-belt, and the large pulley 11 is connected to the drum shaft 9 through a key. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com