Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Reduced labor requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

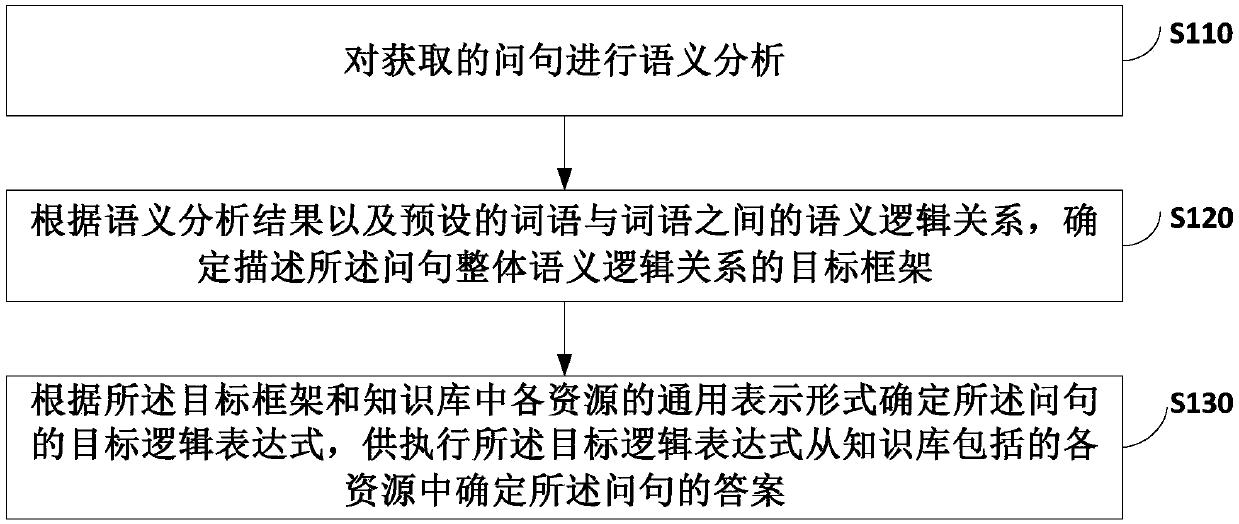

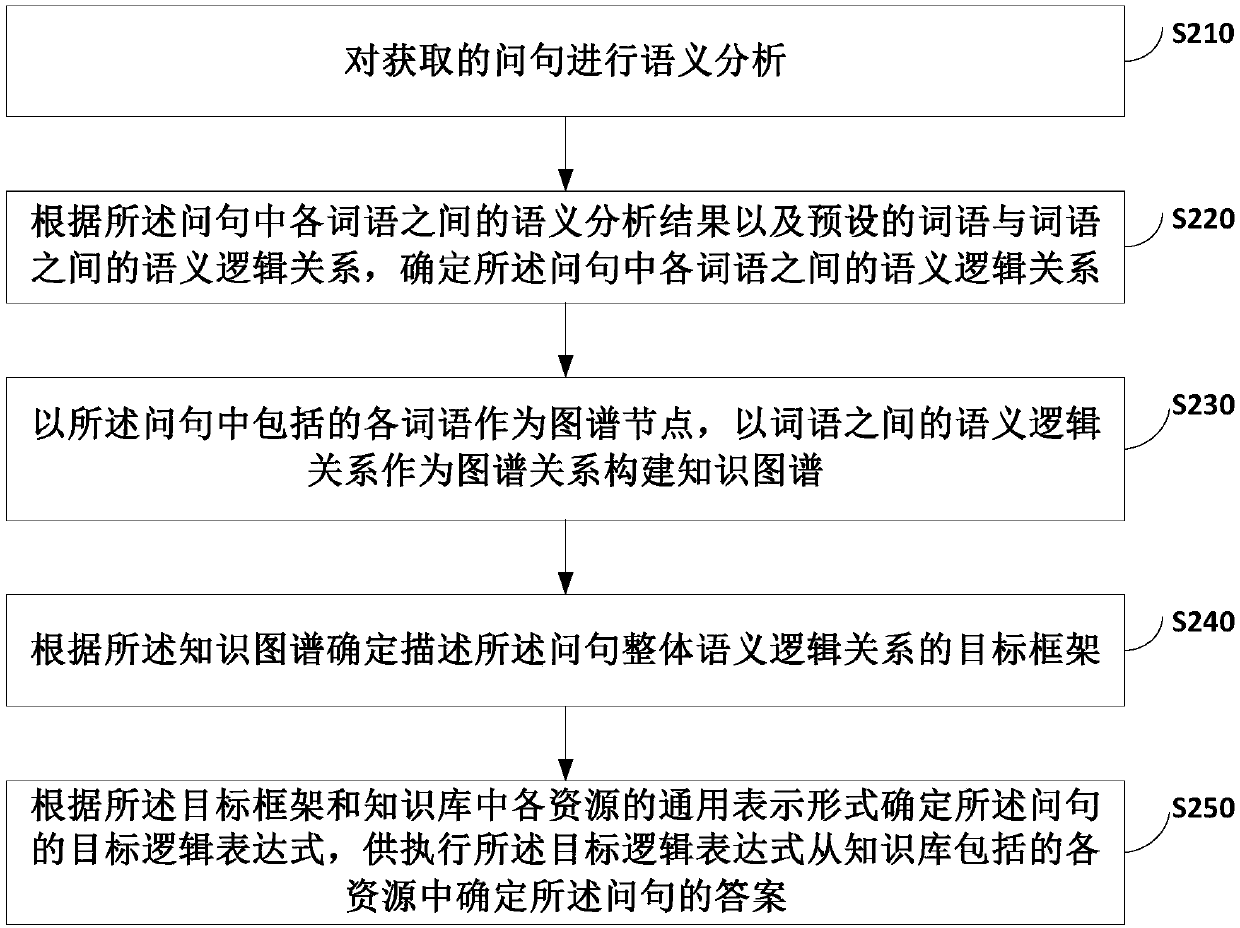

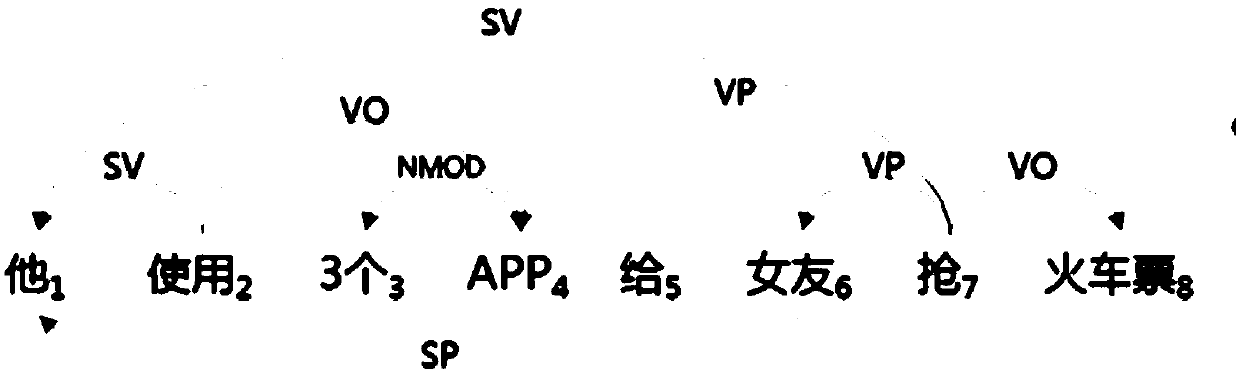

Logic expression determination method, device and equipment and medium

ActiveCN109670024AImplement automatic mappingReduced labor requirementsSemantic analysisSpecial data processing applicationsQuestions and answersComputer science

The embodiment of the invention discloses a logic expression determination method, device and equipment and a medium, and relates to the technical field of intelligent questions and answers. The method comprises the following steps of carrying out semantic analysis on an obtained question; according to a semantic analysis result and a preset semantic logic relationship between words, determining atarget framework for describing the overall semantic logic relationship of the question; and determining a target logic expression of the question according to the target framework and the universalrepresentation form of each resource in the knowledge base, so as to execute the target logic expression to determine the answer of the question from each resource included in the knowledge base. Theembodiment of the invention provides the logic expression determination method, device and equipment and a medium, and aims to determine a logic expression of a question without manually writing the logic expression.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Measurement method for excavation of special-shaped tunnel

ActiveCN107131828AAt the same time understand the shield posture deviationAt the same time understand the attitude deviationUsing optical meansPoint cloudShield tunneling

The invention provides a measurement method for the excavation of a special-shaped tunnel. The method includes the steps of performing a full-angle scanning by arranging a three-dimensional laser scanner behind the tail of a shield tunneling machine in a special-shaped tunnel and a cutter of the shield tunneling machine, to obtain a point cloud map of the inner surface of the special-shaped tunnel and the shell of the shield tunneling machine; according to the point cloud map of the inner surface of the special-shaped tunnel and the shell of the shield tunneling machine, obtaining a special-shaped tunnel inner surface model and a shield tunneling machine head-tail contour model of the special-shaped tunnel through tunnel cross-section extraction and shield tunneling machine outline cutting; determining a central axis of the special-shaped tunnel according to the special-shaped tunnel inner surface model and the shield tunneling machine head-tail contour model; and calculating posture data of the shield tunneling machine and central axis coordinate data of the special-shaped tunnel based on the central axis and a datum point. According to the invention, the limitation that the traditional measurement technology is only applicable to circular tunnels is overcome, through the measurement technology, the posture deviation of the shield tunneling, the deviation of the central axis in the excavation and the construction back break can be known at the same time, and the method of the invention is high in monitoring precision, low in manual requirement and suitable for tunnels of all shapes.

Owner:SHANGHAI CONSTRUCTION GROUP

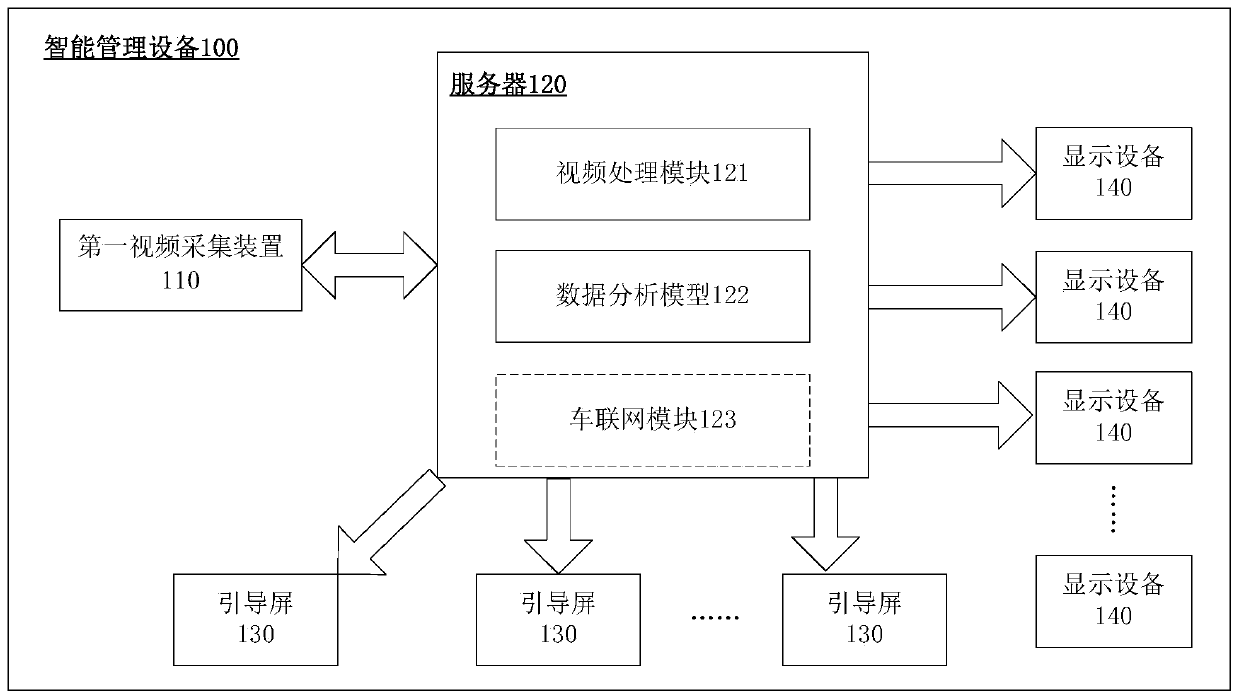

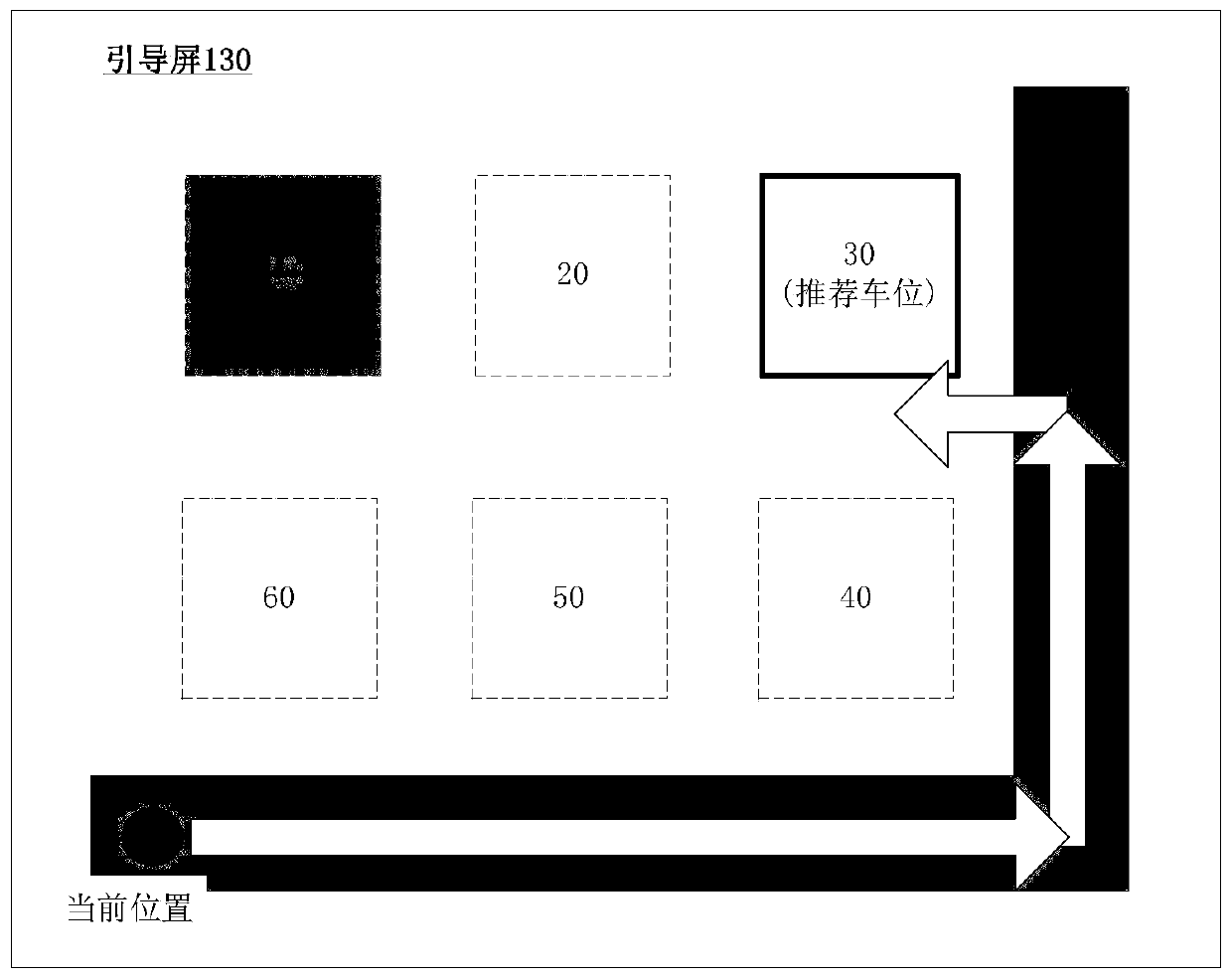

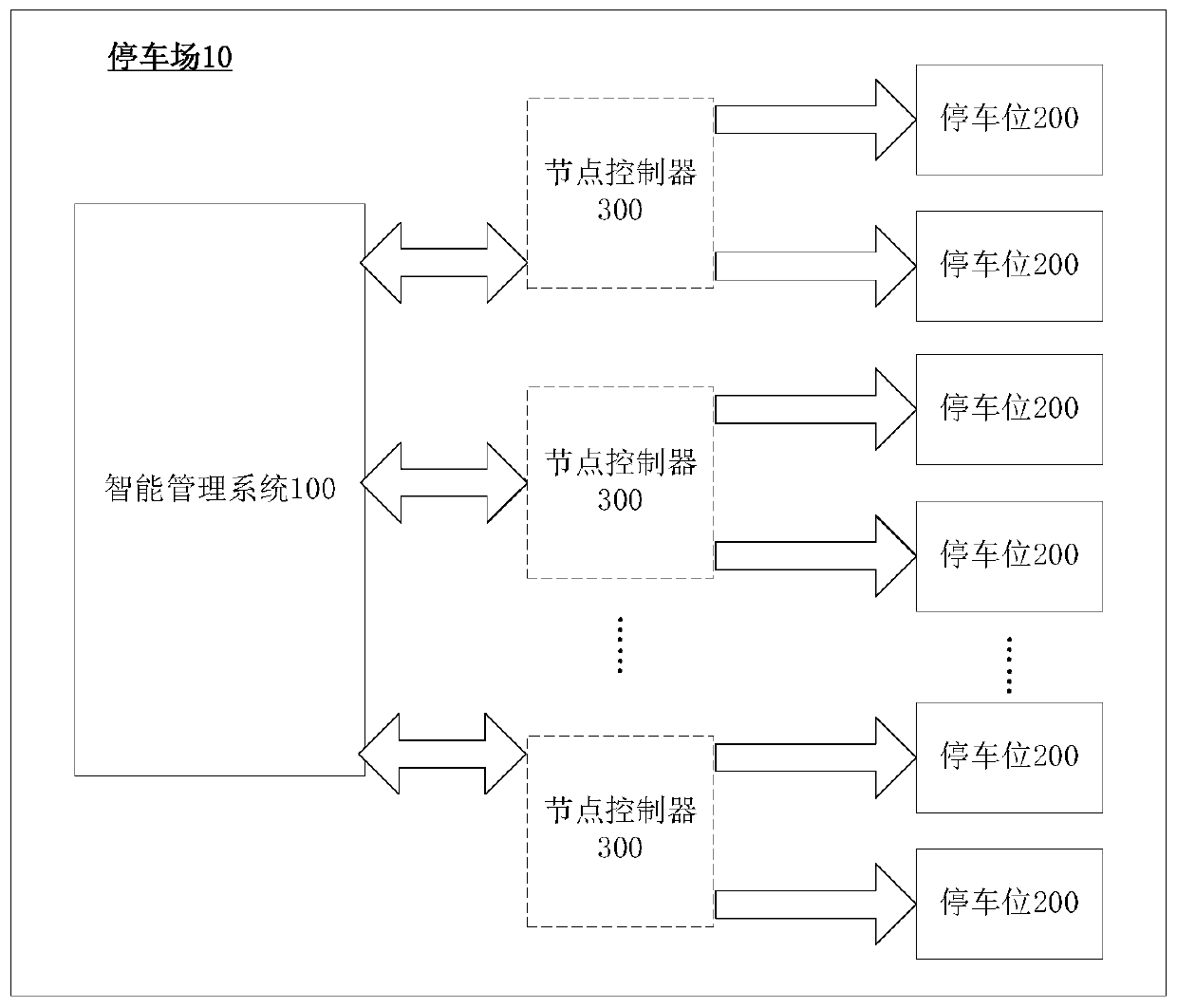

Intelligent management system of parking lot, parking lot, parking method and device

InactiveCN111553994AFast parkingImprove the parking experienceTicket-issuing apparatusIndication of parksing free spacesElectronic identificationDisplay device

The embodiment of the invention discloses an intelligent management system of a parking lot, the parking lot and a parking method and device. The intelligent management system comprises a first videoacquisition device, a server, a guide screen and a display device, wherein the parking lot can obtain related information of a vehicle based on a video, quickly and accurately recommend an appropriateparking space for a user, and directly indicate a path for the vehicle to drive into the parking space through a guide screen near the vehicle, so a reliable data basis is provided for quick parkingof the user; moreover, the intelligent management system can also dynamically generate the dynamic electronic identifier of the vehicle in the parking lot, and provides a reliable certificate for theuser to confirm the parking space, intelligently find the vehicle, intelligently pay the fee and the like. Thus, the requirement of the parking lot for manpower can be reduced, the cost is saved, theparking speed of the user is high, parking payment is not needed, the requirement of people for parking in fast-paced life is met, and the parking experience brought to the user by the parking lot isimproved.

Owner:BANK OF CHINA

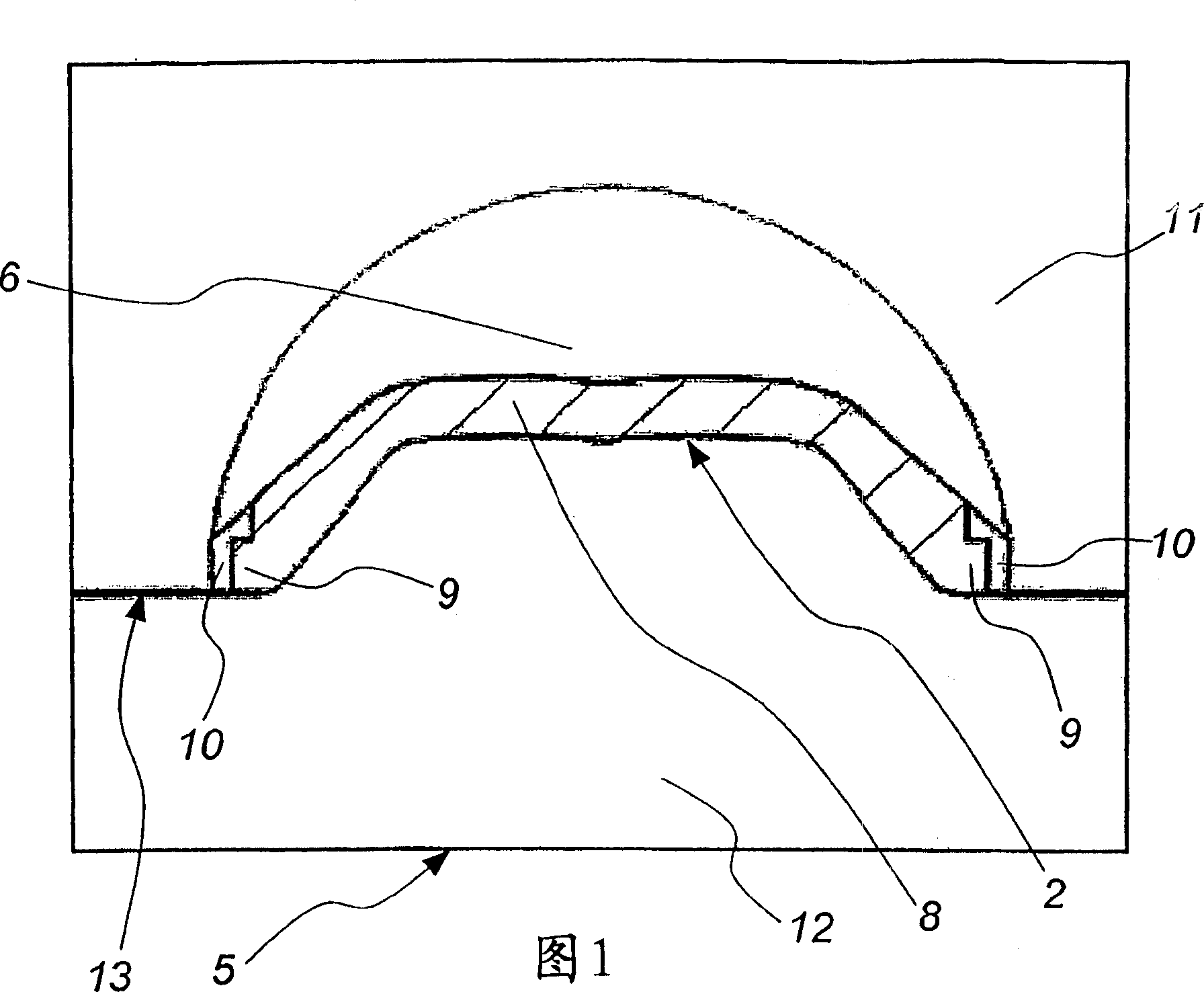

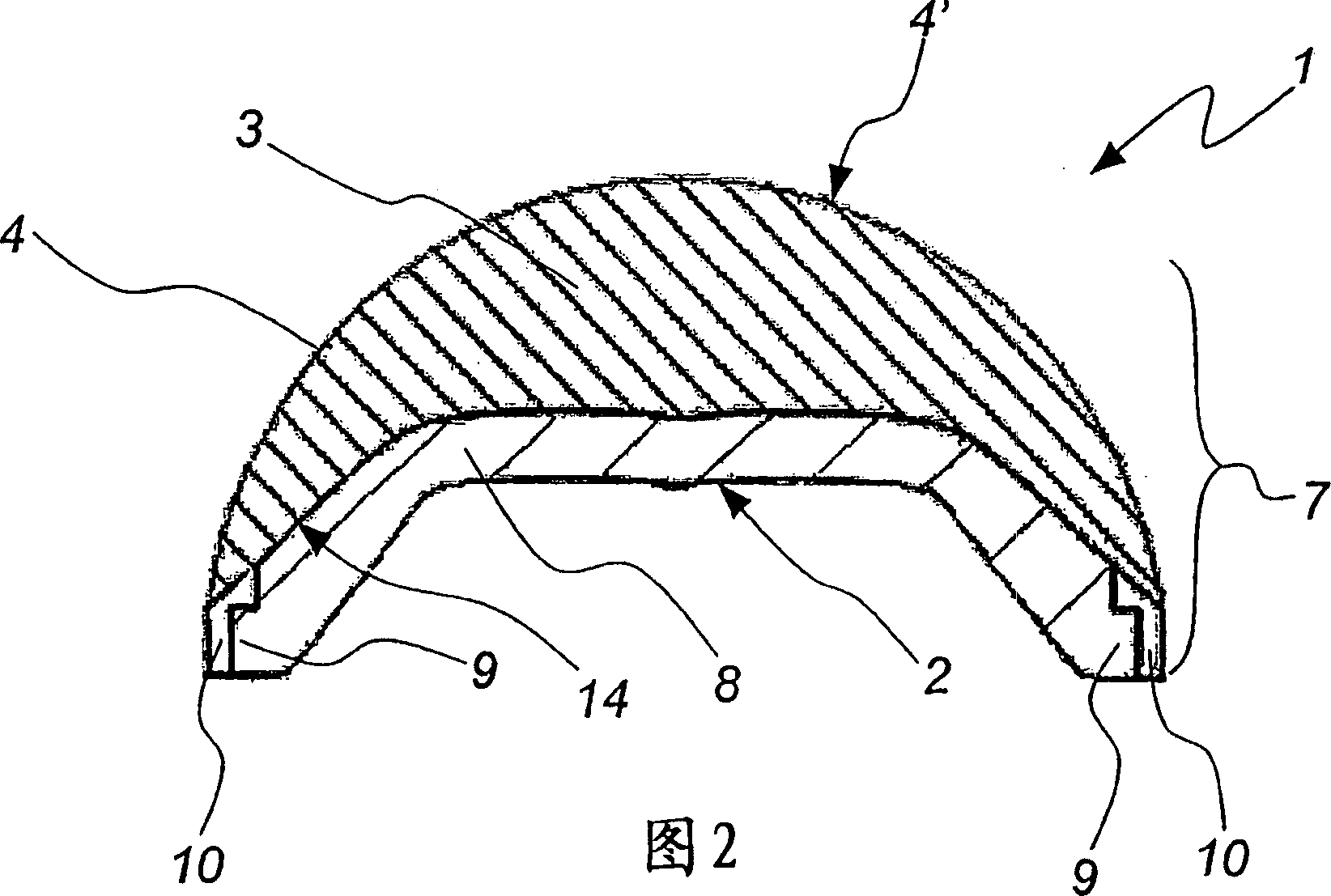

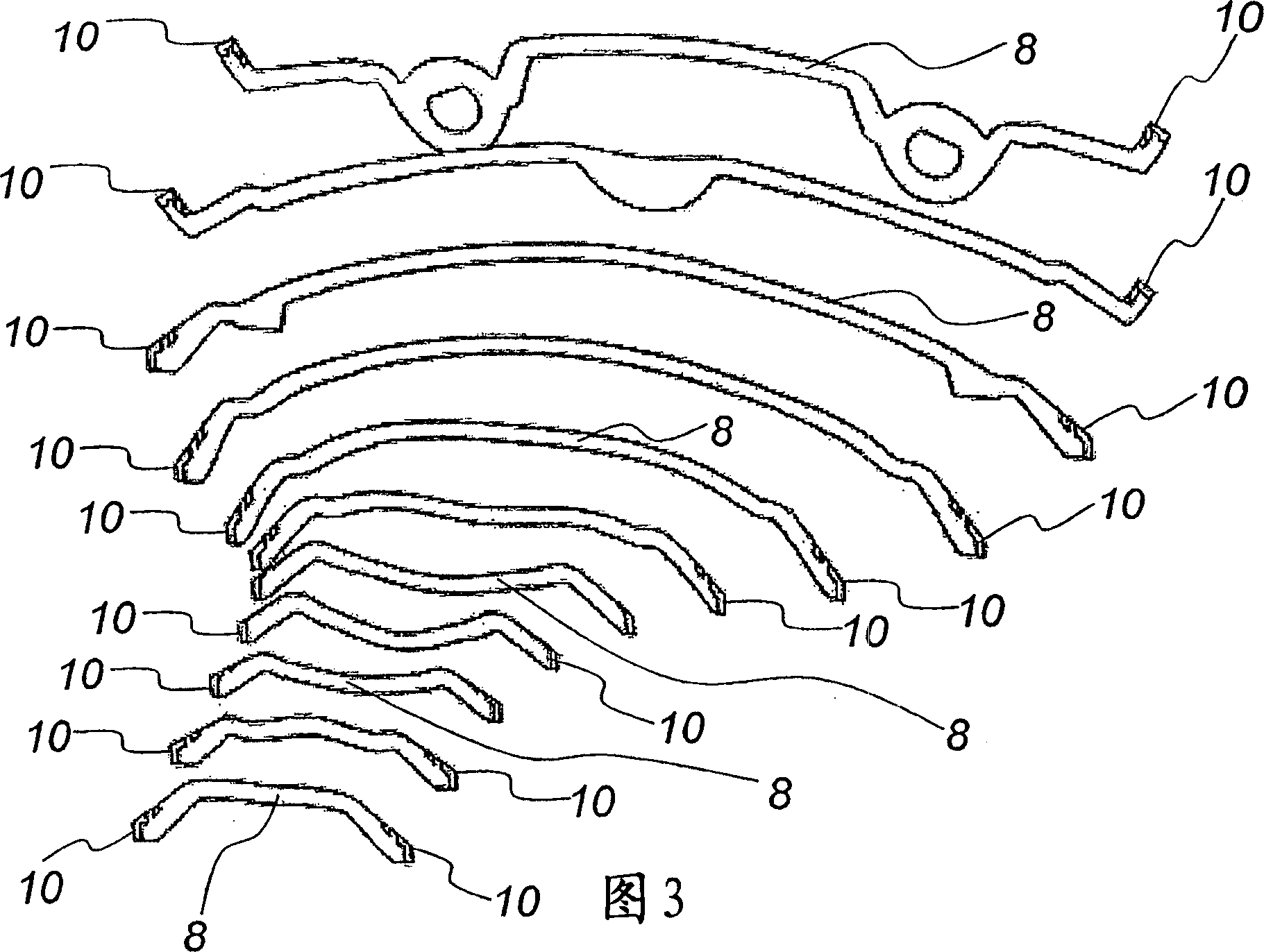

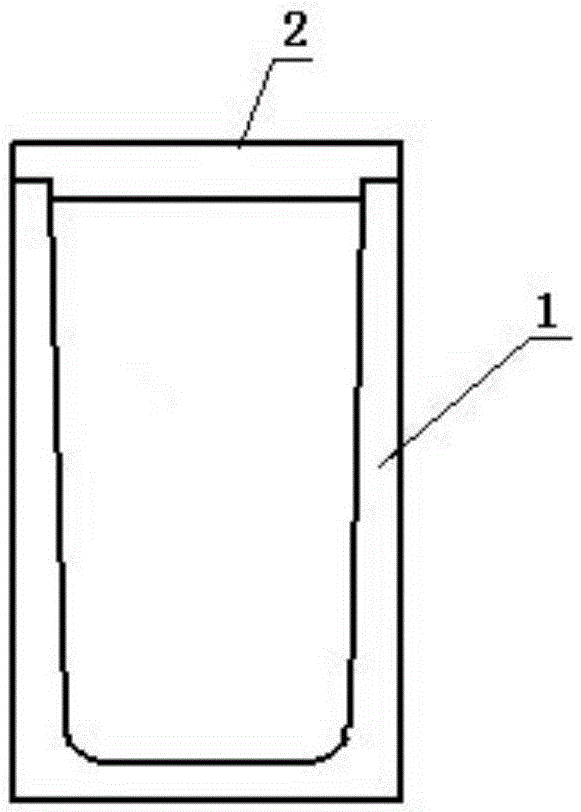

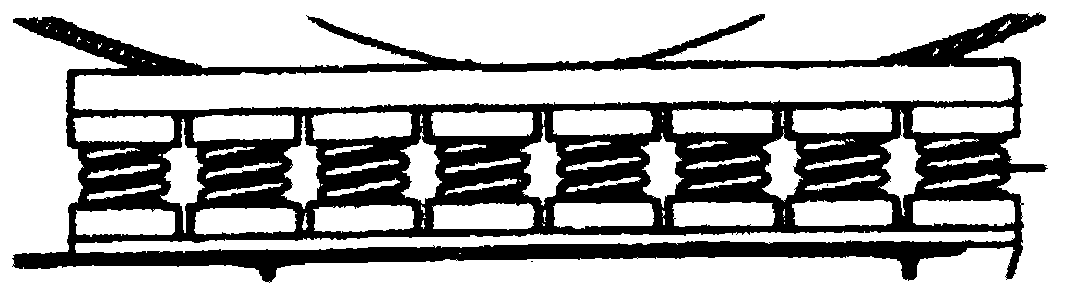

Process for making integral elastic supports and support obtainable by said process

ActiveCN1886244AQuality improvementReduce manual operationsThin material handlingMechanical engineering

A process for making integral elastic supports, such as chair seats, seat backs, arm rests, bicycle saddles and vehicle seats and the like, including the following steps: a) making a shell (2) with a predetermined shape and structure; b) setting up a mold (5) with at least one inner cavity (6) and capable of being moved from an open condition to a closed condition; c) introducing at least one foamable resin and the shell (2) into the inner cavity (6) of the mold (5); d) foaming the resin to form a filler layer (3) to be joined to the shell (2) into a single assembly (7); e) removing the assembly (7) from the mold (5). In greater detail, the shell (2) is manufactured in a first step a1) for making a main body (8) having a peripheral edge (9) and a second step a2) for making a sealing member (10) in the proximity of the peripheral edge (9), to essentially close any gap between the shell (2) and the inner cavity (6) in the proximity of the peripheral edge (9) and prevent the formation of burrs as the foamable resin is foamed.

Owner:SELLE ROYAL SPA

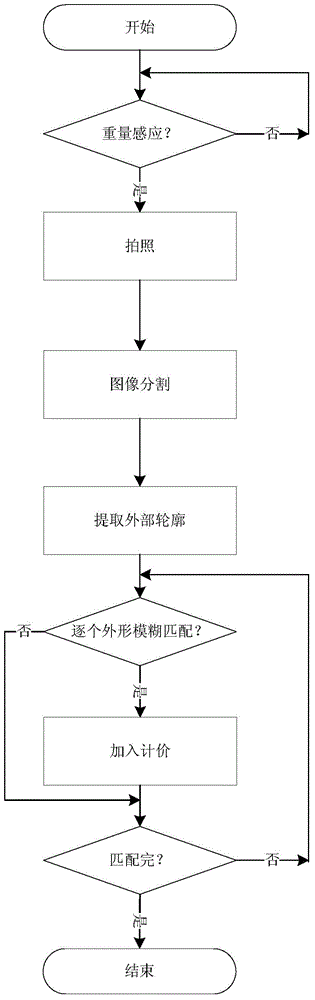

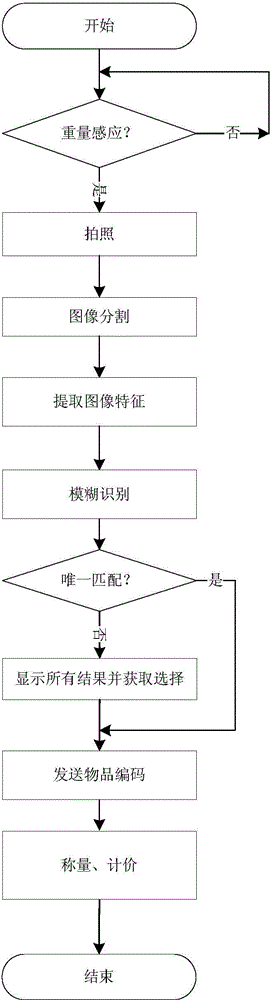

Automatic pricing method

InactiveCN104978585AReduced labor requirementsImprove efficiencyCharacter and pattern recognitionBuying/selling/leasing transactionsPattern recognitionImaging Feature

The present invention relates to an automatic pricing method. The method comprises: 101) acquiring a picture of a priced commodity; 102) extracting an image of the priced commodity from the picture by image division; 103) extracting image features from the image of the commodity, and the image features are the contour, the color, the texture or a combination thereof; 104) identifying the priced commodity by fuzzy matching; and 105) calculating a price according to an identification result or obtaining the calculation price by searching a unit price reference and combining the weight of the priced commodity. The automatic pricing method applies an intelligent image identification technology, thus greatly reducing labour requirements and labour, and improving the pricing correction rate and the pricing efficiency.

Owner:陈建波

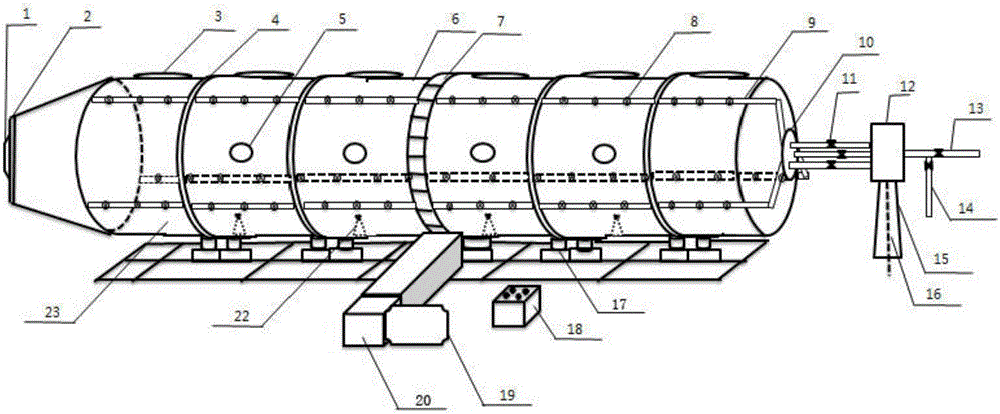

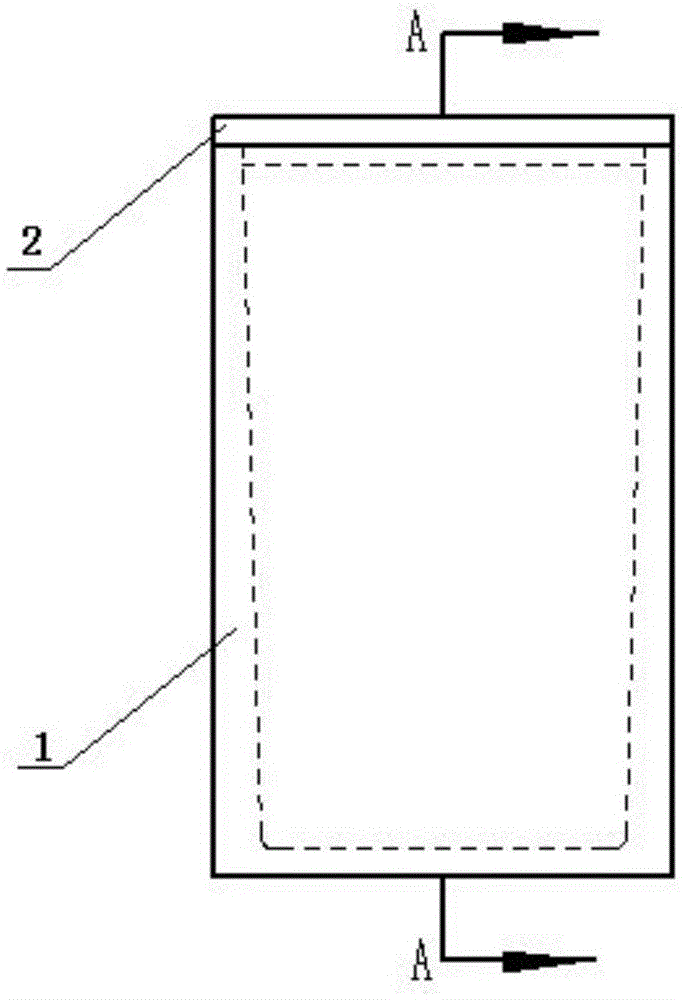

Full-automatic Liupao-tea-leaf fermenting jar and fermenting technology thereof

InactiveCN105724632ATo achieve the stacking effectTurn over evenlyPre-extraction tea treatmentAutomatic controlSpray nozzle

The invention discloses a full-automatic Liupao-tea-leaf fermenting jar and a fermenting technology thereof.The full-automatic Liupao-tea-leaf fermenting jar comprises a jar body, a driving device and a control device.A plurality of feeding openings and a transparent window are formed in the lateral side of the jar body, steam pipes are axially arranged on the inner side of the jar body and provided with high-pressure steam spraying nozzles, a discharging opening with a sealing cover is formed in one end of the jar body, and a plurality of ventilation holes are formed in the sealing cover of the discharging opening.The control device comprises a temperature-humidity monitor, a control center and an electric control valve.The fermenting technology of the fermenting jar includes the steps that the temperature and the humidity in the jar body are monitored, rotation of the jar body is automatically controlled, water or steam is sprayed into the jar body through the electric control valve, and pile fermentation and pile overturning are repeated till raw tea is completely fermented.The full-automatic Liupao-tea-leaf fermenting jar and the fermenting technology are reasonable in design, convenient to operate and high in automation degree, and water adding, ventilation, pile overturning and the like of the fermenting jar can be effectively achieved.

Owner:CHINATEA WUZHOU

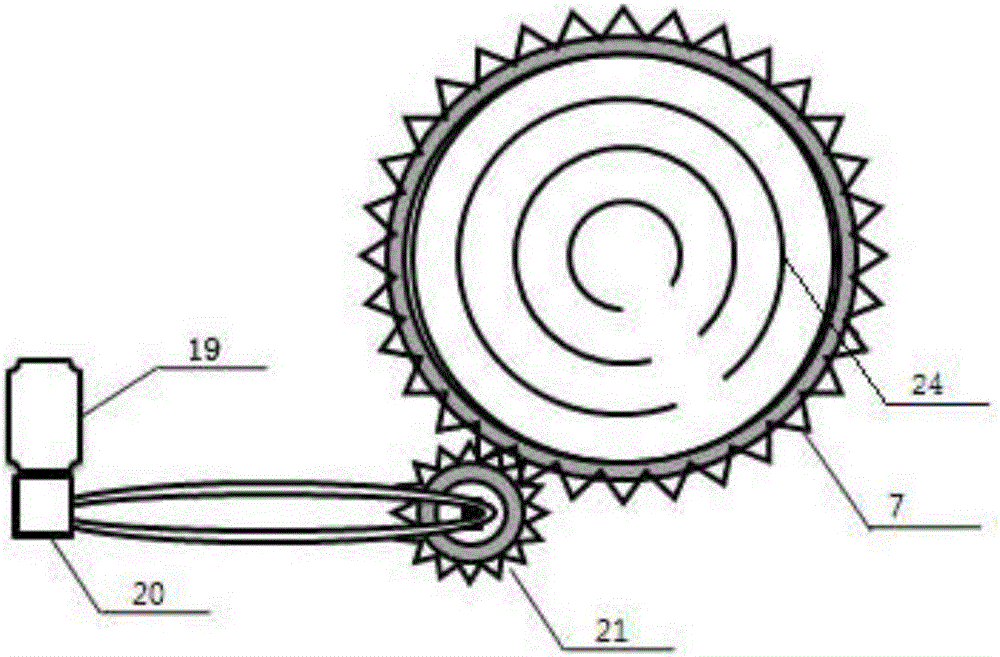

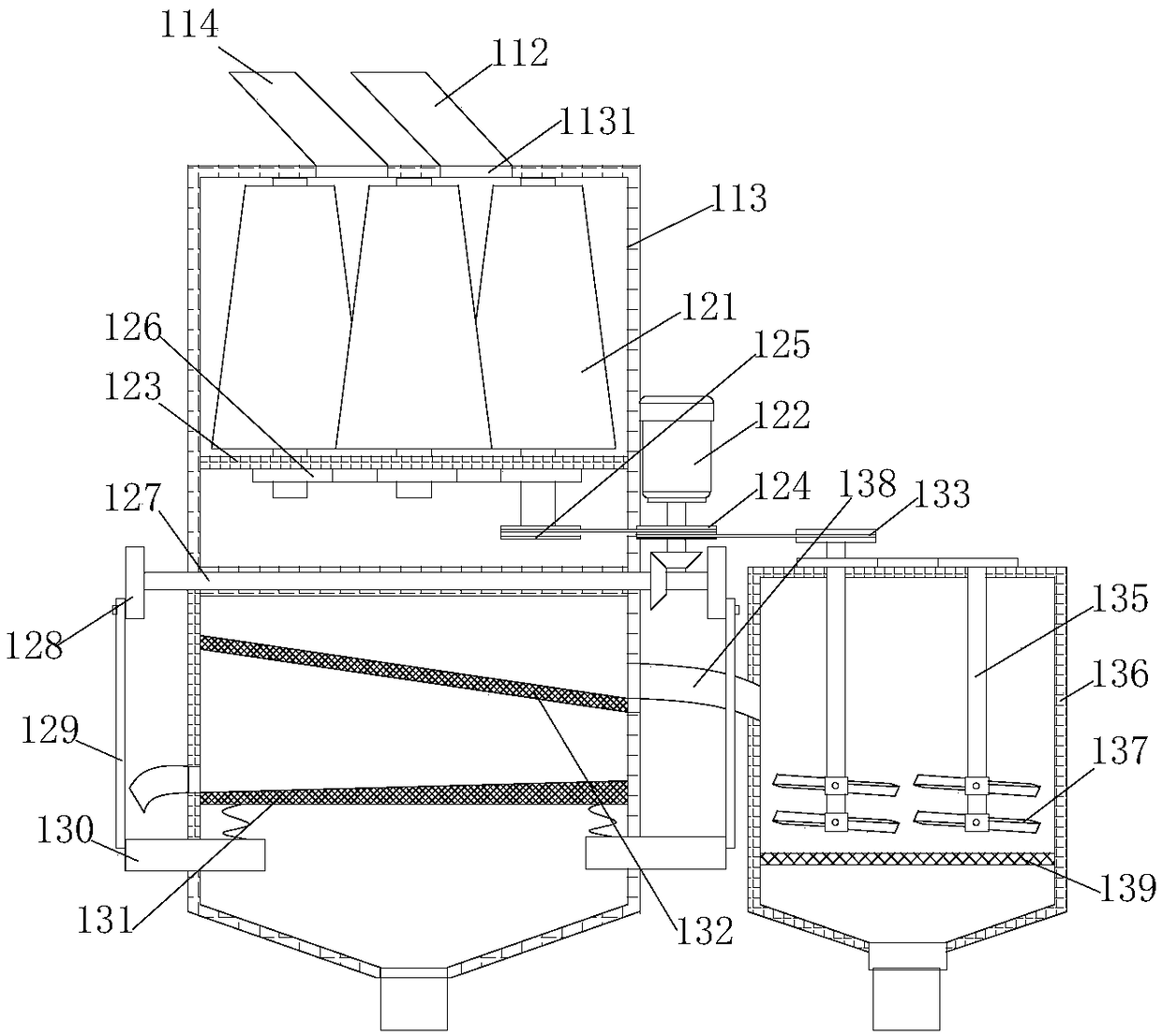

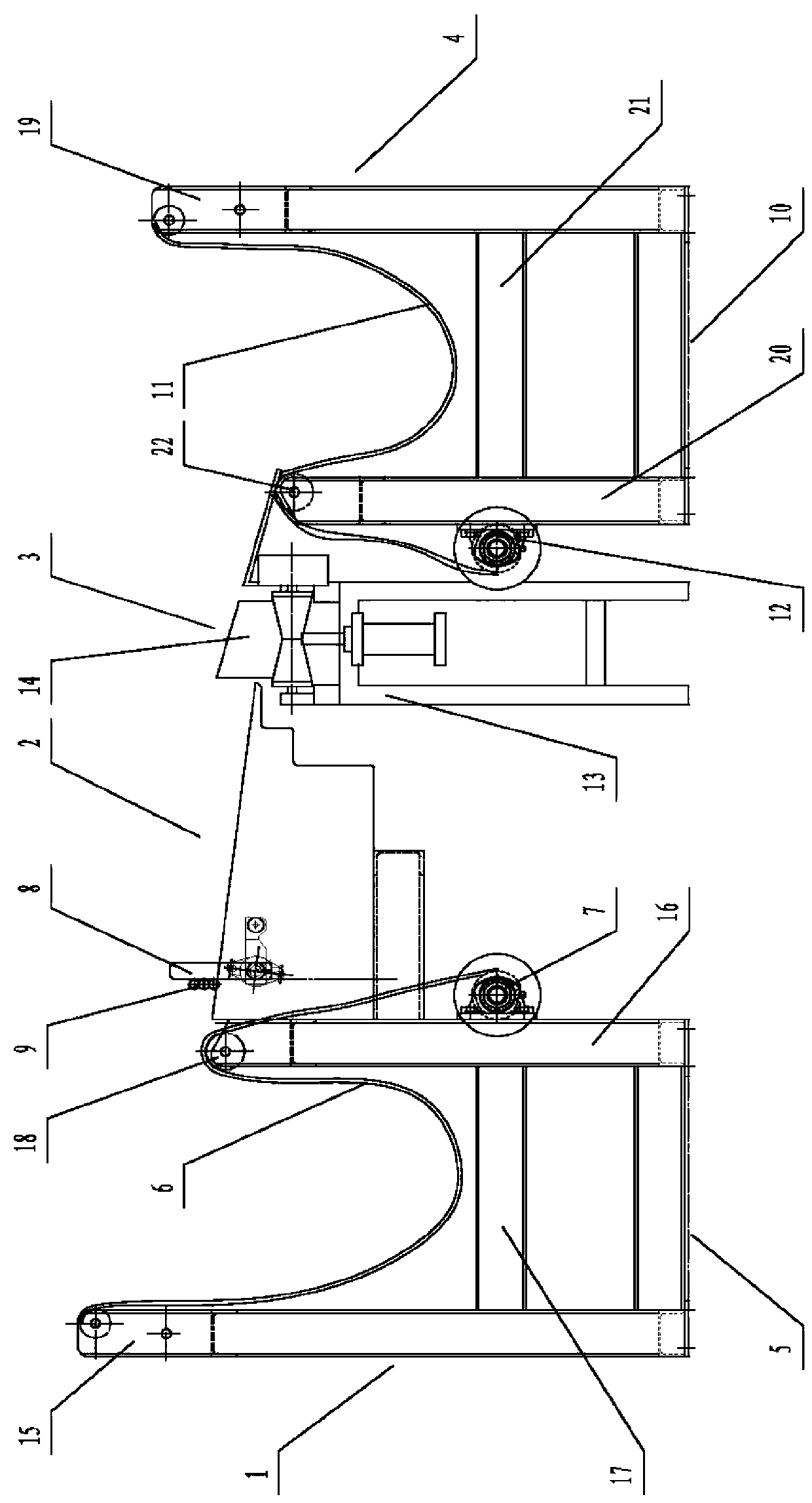

Agricultural machine for producing edible powder

InactiveCN108617277AReduced labor requirementsFree handsTransportation and packagingMixersAgricultural engineeringCorn flour

The invention discloses an agricultural machine for producing edible powder. The agricultural machine sequentially comprises a corn cob processing device, a corn grain crushing device, a powder mixingdevice and a powder operation device according to a process flow. The corn cob processing device comprises a feeding unit and a processing unit. The powder mixing device comprises a material mixing tank body and a material mixing upper cover which covers the material mixing tank body. A first material mixing and sieving plate, a first mixing chamber, a second material mixing and sieving plate, and a crushing / mixing integrated chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. The powder operation device comprises an operation conveying belt, a turnoverdischarging device, an operation baffle, a conveying hopper, an operation elastic device and an operation lifting base table. The agricultural machine provided by the invention has the advantages that the processing efficiency of corn cobs is improved, the quality of the produced corn flour is ensured, the mixing effect of the corn flour and the flour is good, the corn flour and the flour do notcake easily, blocking does not occur easily, the working continuity is strong, the feeding amount of a single time is accurate, and the working efficiency is high.

Owner:芜湖拓云农业技术有限公司

Preparation method of ethyl 4-chloro-3-hydroxybutanoate

The invention relates to a preparation method of ethyl 4-chloro-3-hydroxybutanoate.In a reaction kettle, ethyl acetate is added to purified water, so as to be used as a solvent, hydrophosphate is used as a solution pH buffering agent, ethyl 4-chloroacetoacetate is used as a reaction substrate, the reaction time is 6 to 10 h, the reaction temperature is 28 to 33 DEG C, and after reaction, the steps of filtration, extraction and concentration under reduced pressure are performed, so as to obtain a crude product of the ethyl 4-chloro-3-hydroxybutanoate; wherein biocatalysts include keto reductase, glucose dehydrogenase and NADPH (Nicotinamide Adenine Dinucleotide Phosphate), and a hydrogen donor is glucose; the molar concentration of the hydrophosphate is 0.04 mol / L to 0.08 mol / L, the mass-to-volume ratio concentration of the substrate of the ethyl 4-chloroacetoacetate is 8 g / mL to 15 g / mL, the used mass of the keto reductase and the glucose dehydrogenase is 3% to 8% of that of the ethyl 4-chloroacetoacetate, wherein the use ratio of the keto reductase to the glucose dehydrogenase is 2:3, and the mass of the NADPH is 0.1% to 0.3% of that of the ethyl 4-chloroacetoacetate. According to the preparation method, the operation steps and the reaction steps are simplified, and the yield of the ethyl 4-chloro-3-hydroxybutanoate can be increased.

Owner:LIANYUNGANG HONGYE CHEM

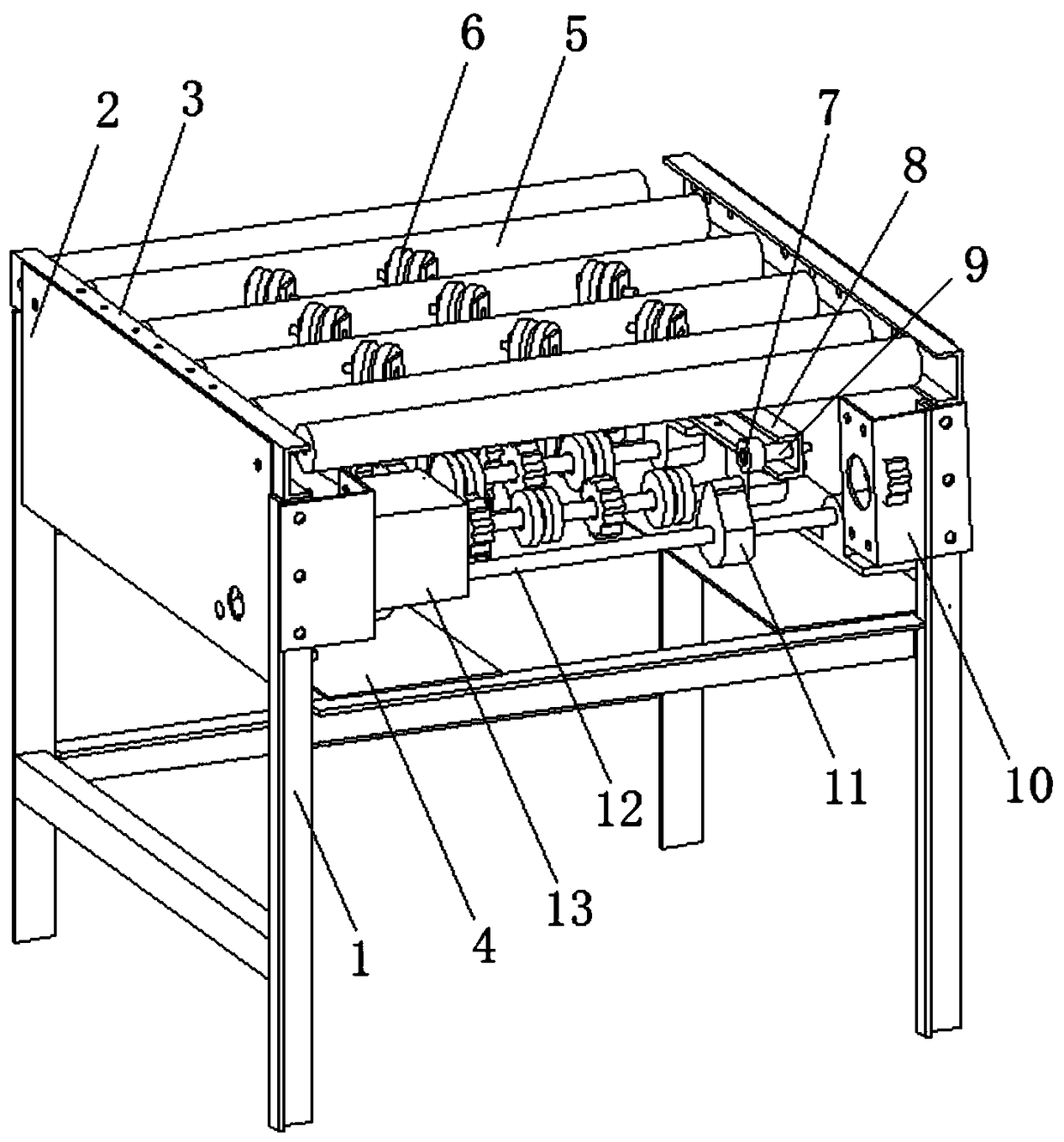

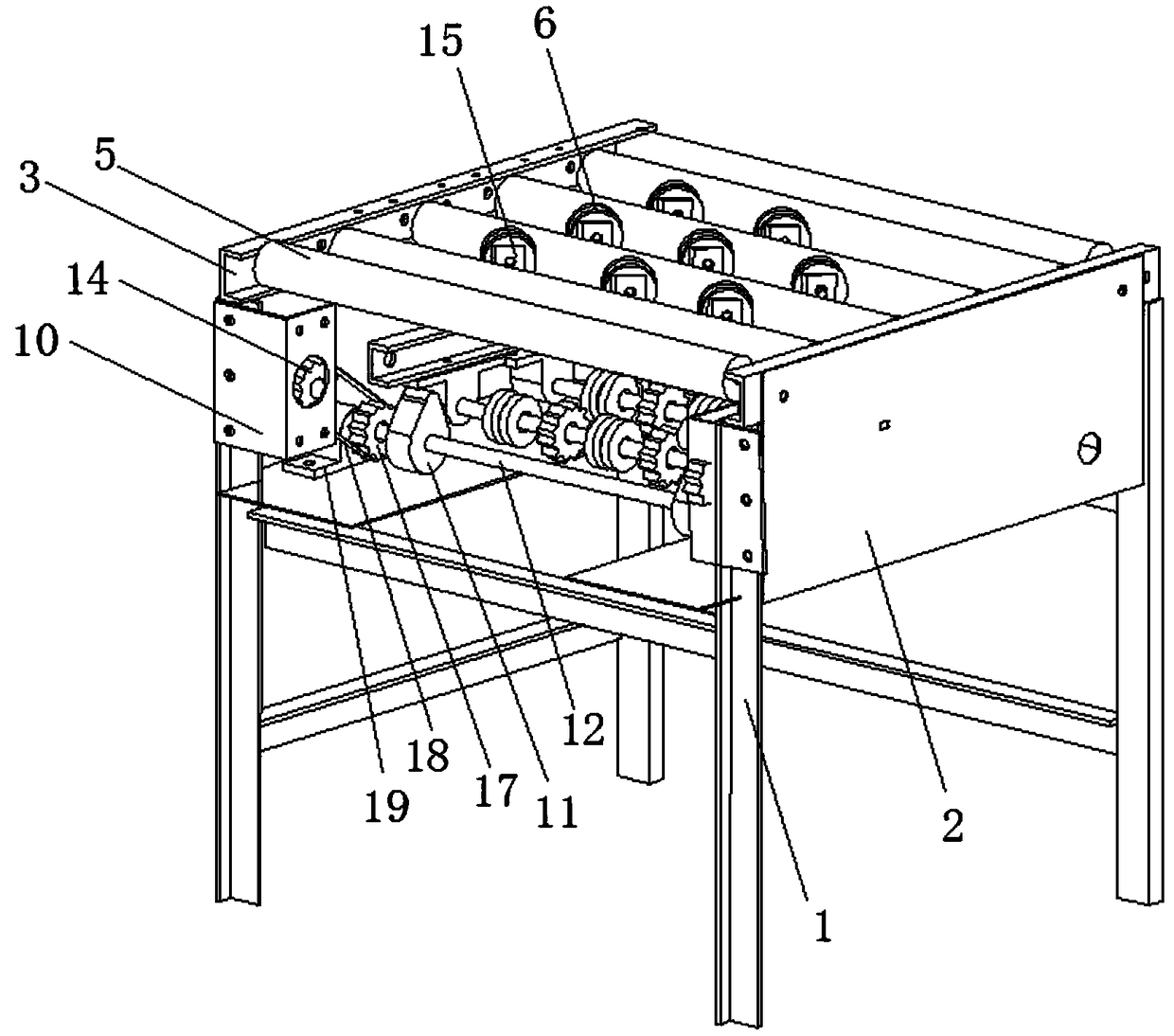

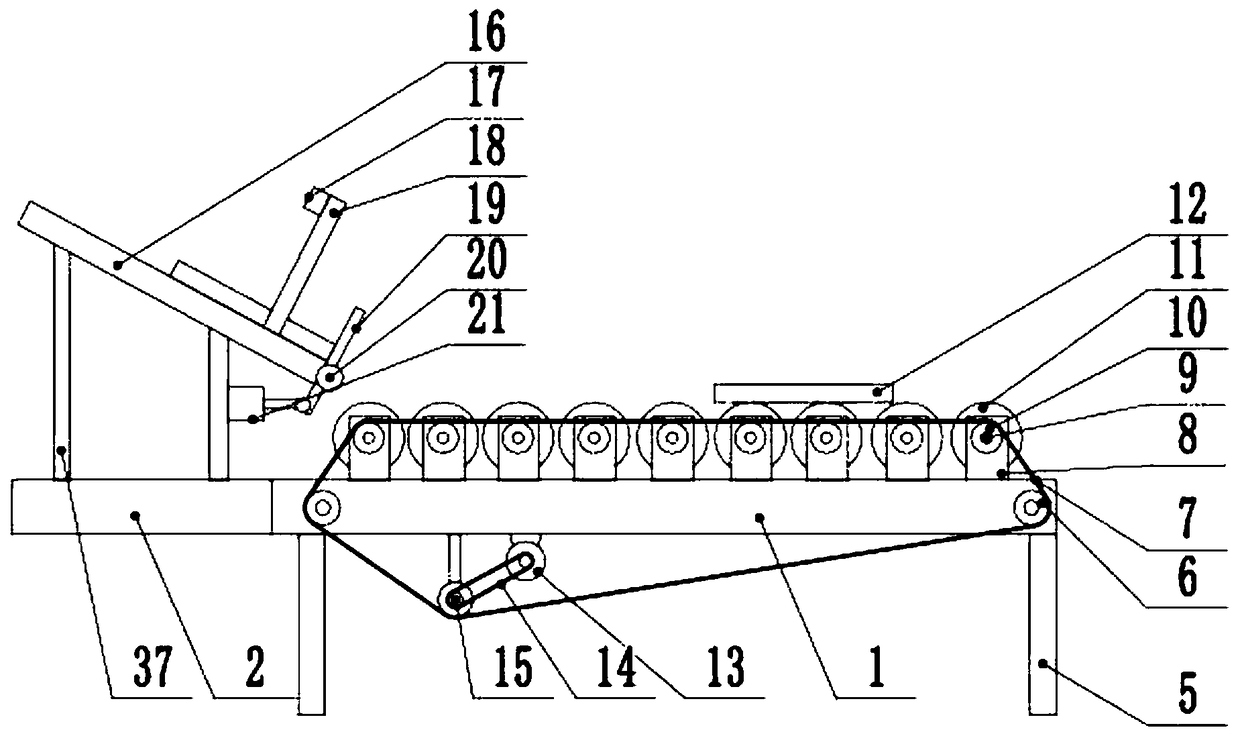

Automatic pinching rack

ActiveCN103302098AReduced labor requirementsImprove efficiencyMetal rolling arrangementsWinding machineElectrical and Electronics engineering

The invention relates to an automatic pinching rack which comprises a charging mechanism, a connecting mechanism, a feeding mechanism and a collecting mechanism, wherein the charging mechanism comprises a charging frame, a charging belt arranged on the charging frame, and a first winding machine matched with the charging belt; the connecting mechanism is connected with the charging frame; connecting parts of the connecting mechanism are mutually matched; a movable baffle is movably arranged on the connecting mechanism; the collecting mechanism comprises a collecting frame, a collecting belt arranged on the collecting frame, and a second winding machine matched with the collecting belt; and the feeding mechanism is matched with the connecting mechanism, and connected with the collecting frame. The automatic pinching rack is suitable for production of cold-rolled seamless steel pipes.

Owner:JIANGSU FENGLI PRECISION TUBE MFG

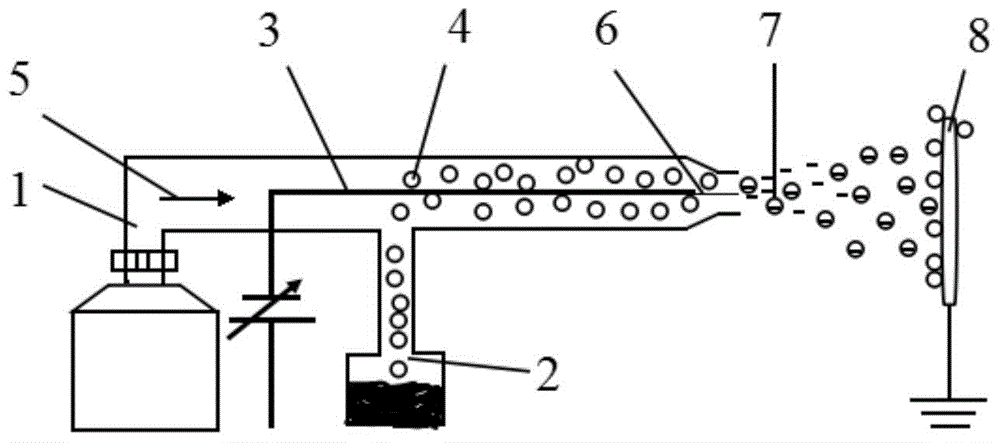

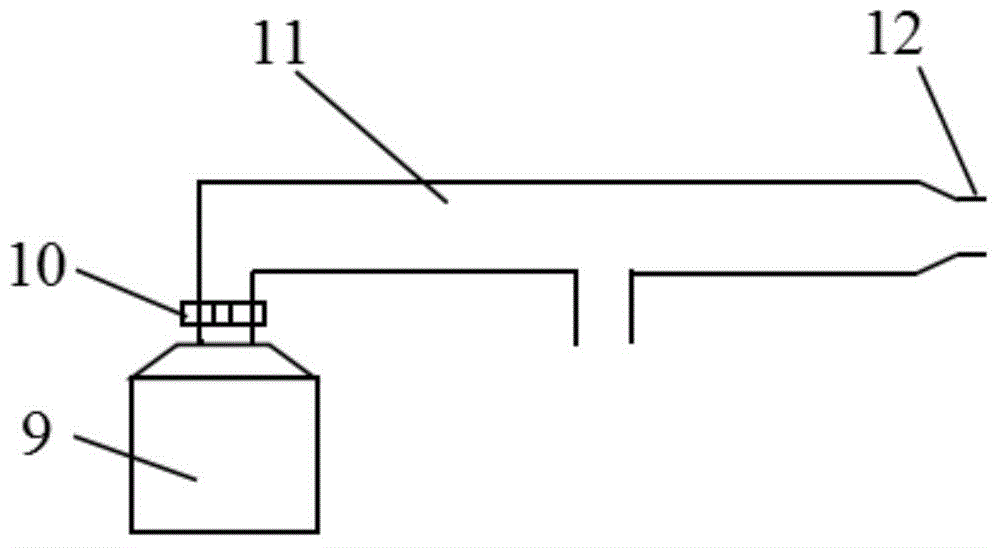

Electrostatic aquatic product flour coating device and method thereof

InactiveCN105054265AFood safety is guaranteedSimple device structureFood shapingFood preparationElectric fieldCorona discharge

The invention discloses an electrostatic aquatic product flour coating device and a method thereof. The electrostatic aquatic product flour coating device comprises an air jetting system, a flour supply device and an electrostatic generation device. The electrostatic aquatic product flour coating device adopts an air jetting technology which is combined with the flour supply device to spray flour, a high-voltage electrostatic field is built between a sprayer and an aquatic product which is grounded simultaneously, and the flour has charges in a corona discharge manner; under the combined action of airflow acting force, electric field force and gravity, all flour particles with or without charges in air flow move towards the aquatic product, and as the charges of the flour particles are the same in character and have repulsive interaction, the flour particles can disperse from one another uniformly in the movement process and thus form a uniform flour coating layer on the surface of the aquatic product. The electrostatic aquatic product flour coating device has the characteristics of simple structure, convenience in operation, uniformity, high efficiency and saving of flour, and serves as a new technical device for coating aquatic products with flour.

Owner:ZHEJIANG UNIV

Mail automatic sorting device

InactiveCN109174659AImprove sorting efficiencyReduced labor requirementsSortingEngineeringMechanical engineering

Owner:XIAN UNIV OF POSTS & TELECOMM

School library book automatic identifying and sorting device

The invention relates to the field of book management and discloses a school library book automatic identifying and sorting device. The school library book automatic identifying and sorting device comprises a conveying table. A recognition table is fixedly connected to the left side of the conveying table. Stacking tables and sorting tables are arranged on the upper and lower sides of the conveying table correspondingly. The upper portion of the recognition table is fixedly connected with supporting rods. The tops of the supporting rods are fixedly connected with an inclined plate. The right side of the inclined plate is connected with a rotary seat. The rotary seat is fixedly connected with a baffle. The lower portion of the baffle is hinged to a first cylinder piston rod. The inclined plate is fixedly connected with a probe stand column. The probe stand column is fixedly connected with a recognition probe. The school library book automatic identifying and sorting device can be used for classifying returned library books, can automatically judge the type of the books under the combined action of sensors and cylinders and place the different types of books onto the different stacking tables, greatly reduces manual operation and is higher in efficiency, more accurate in sorting and suitable for application and popularization in various large libraries.

Owner:LUOHE MEDICAL COLLEGE

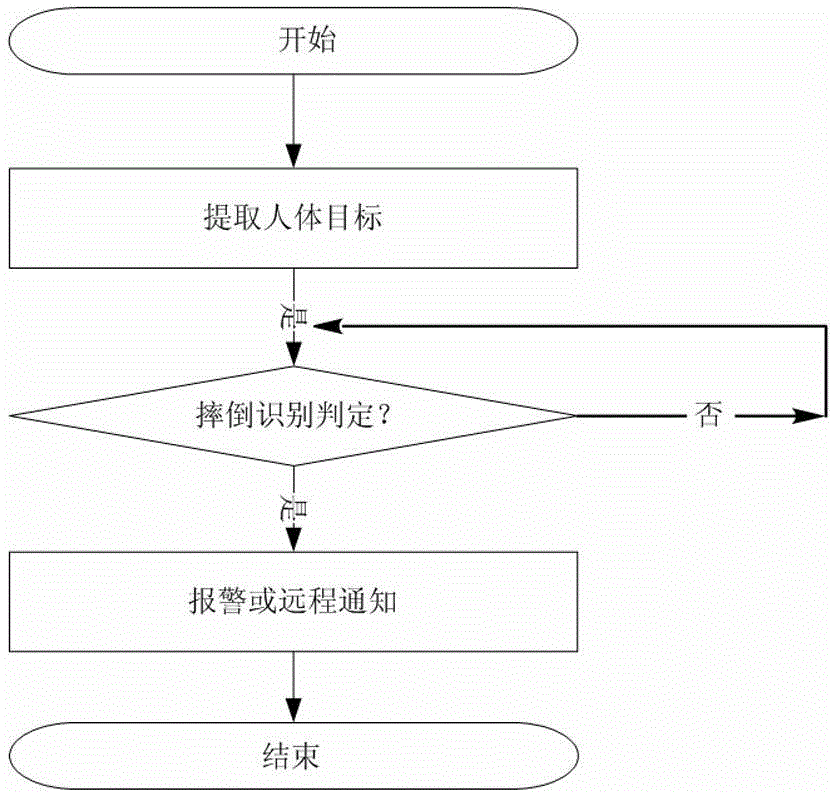

Intelligent and safe nursing method

InactiveCN104954761AReduce labor requirements and laborImprove efficiencyCharacter and pattern recognitionClosed circuit television systemsComputer visionMedical physics

The invention relates to an intelligent and safe nursing method. The method is characterized in that an infrared monitoring and video monitoring system is used for monitoring a site in real time when necessary. The method comprises steps as follows: (101) extracting a human body image target from an infrared monitoring image; (102), tracking, recognizing and judging whether the image target falls over, performing the next step if the answer is positive and performing the step again if the answer is negative; (103), performing warning or remote notification. According to the intelligent and safe nursing method, a person can be nursed constantly day and night by means of infrared imaging and intelligent image recognition techniques, sleeping and resting of a caregiver are not influenced, no sensor is required to be worn, and the safety of special crowds is guaranteed.

Owner:满欣然

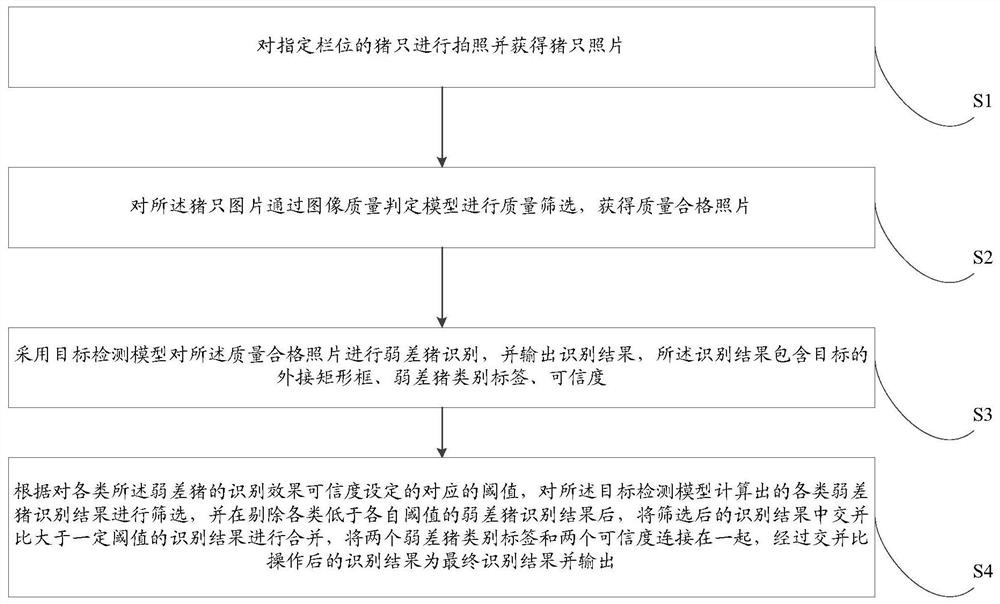

Method and system for automatically detecting and marking weak pigs

InactiveCN113537064AReduced labor requirementsLow experience requirementImage enhancementImage analysisAnimal scienceAlgorithm

The invention discloses a method and system for automatically detecting and marking weak pigs. The method comprises the following steps: S1, taking pictures of pigs in a specified field and obtaining pig pictures; S2, performing quality screening on the pig pictures through an image quality judgment model to obtain quality-qualified pictures; S3, adopting the target detection model to carry out weak pig identification on the quality-qualified pictures, and outputting an identification result, wherein the identification result comprises an external rectangular frame of a target, a weak pig category label and credibility; S4, screening identification results of various weak pigs calculated by the target detection model according to corresponding threshold values set for the credibility of the identification effects of the various weak pigs, and after the various weak pig identification results lower than the respective threshold values are removed, combining the identification results of which the intersection-union ratio is greater than a certain threshold value in the screened identification results to obtain a combined result; and connecting the two weak pig category labels and the two credibility levels together, and outputting a final recognition result which is the identification result after intersection-parallel comparison operation.

Owner:河南牧原智能科技有限公司

Manufacturing method of civil air defense door frame

PendingCN109664074AStable positionIncrease productivityWar-like protectionWelding processCivil engineering

The invention relates to the technical field of civil air defense doors, in particular to a manufacturing method of a civil air defense door frame. The manufacturing method is used for manufacturing the door frame formed by assembling two longitudinal steel angles, an upper steel angle and a lower steel angle. The manufacturing method includes the following steps that the four steel angles are derusted by a civil air defense equipment derusting device; locking holes and rib penetrating holes are stamped in the two longitudinal steel angles; compression strips are welded to the four steel angles; the four steel angles are straightened one by one through a straightening machine; the whole door frame is assembled by the four steel angles and an upper hinge base and a lower hinge base are welded on a welding platform; and quality inspection and paint brushing treatment are completed. According to the manufacturing method of the civil air defense door frame, by the adoption of the technicalscheme, the technical problems that an existing manufacturing process of the civil air defense door frame is complex, the welding process is high in requirement, and the quality is not stable are solved.

Owner:惠州市人防防护设备有限公司

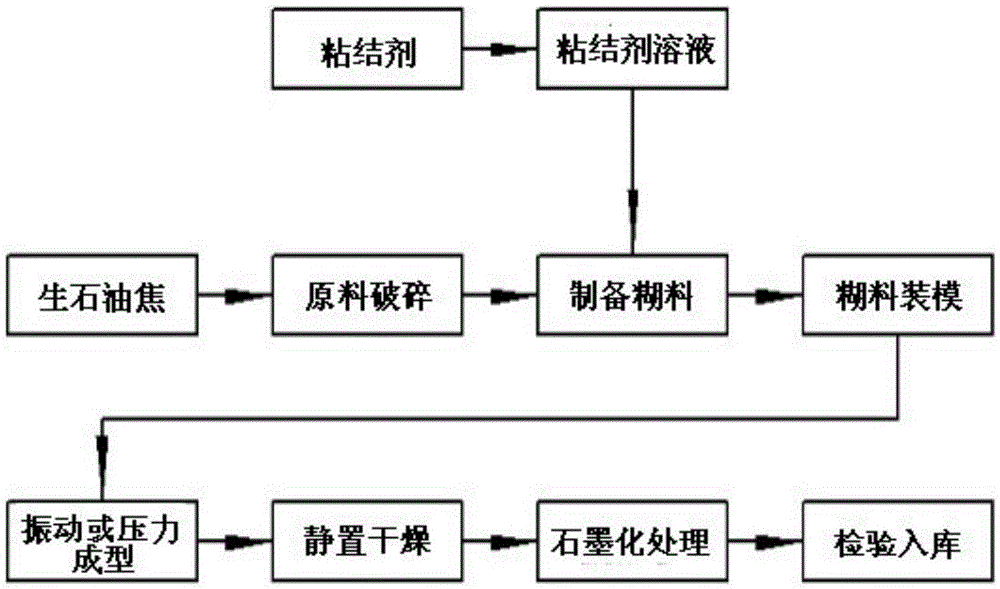

Crucible made from green oil coke and water-soluble adhesive and manufacturing method of crucible

ActiveCN105565308AOmit roastingEliminates the graphitization processChemical industryOrganic solventAdhesive

The invention relates to a crucible made from green oil coke and water-soluble adhesive and a manufacturing method of the crucible. The method includes the steps of smashing green oil coke into particles with granularity smaller than 4 mm, mixing water-soluble organic solvent with diluent to prepare an adhesive solution, mixing and stirring the adhesive solution and smashed green oil coke according to a certain proportion to obtain slurry, putting the slurry in a crucible mold, and forming a crucible wet blank through a mechanical vibration or pressure forming method, taking out the formed crucible wet blank to stand, conducting drying and demolding to obtain a crucible rough blank, and adding a carbon negative electrode material into the crucible rough blank to conduct graphitizing to obtain the qualified crucible. The crucible has the advantages of being capable of saving energy, environmentally friendly, ecological, low in cost, high in production efficiency, low in requirement for plants and devices, low in rejection rate, and the like.

Owner:贵州微蓝新能源材料有限公司

Low-thermal-resistance radiating LED lamp

InactiveCN104110590AGuaranteed lifeEnsure brightnessPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

The invention relates to a low-thermal-resistance radiating LED lamp and belongs to the field of lighting techniques. The low-thermal-resistance radiating LED lamp comprises a plastic radiator, an LED and a ceramic substrate. The low-thermal-resistance radiating LED lamp is characterized in that the LED is arranged on the upper surface of the ceramic substrate by soldering, and the ceramic substrate is embedded in the top of the plastic radiator. The low-thermal-resistance radiating LED lamp is simple in structure and has significant radiating effect, the service life and brightness of the high-power LED lamp are effectively ensured, less heat-conducting silicone is applied, a step of mounting an LED lamp panel on a radiator is omitted, and accordingly, process time is shortened, demanded labor is reduced, and production cost is reduced.

Owner:CHONGQING SANGNAIMEI PHOTOELECTRIC TECH

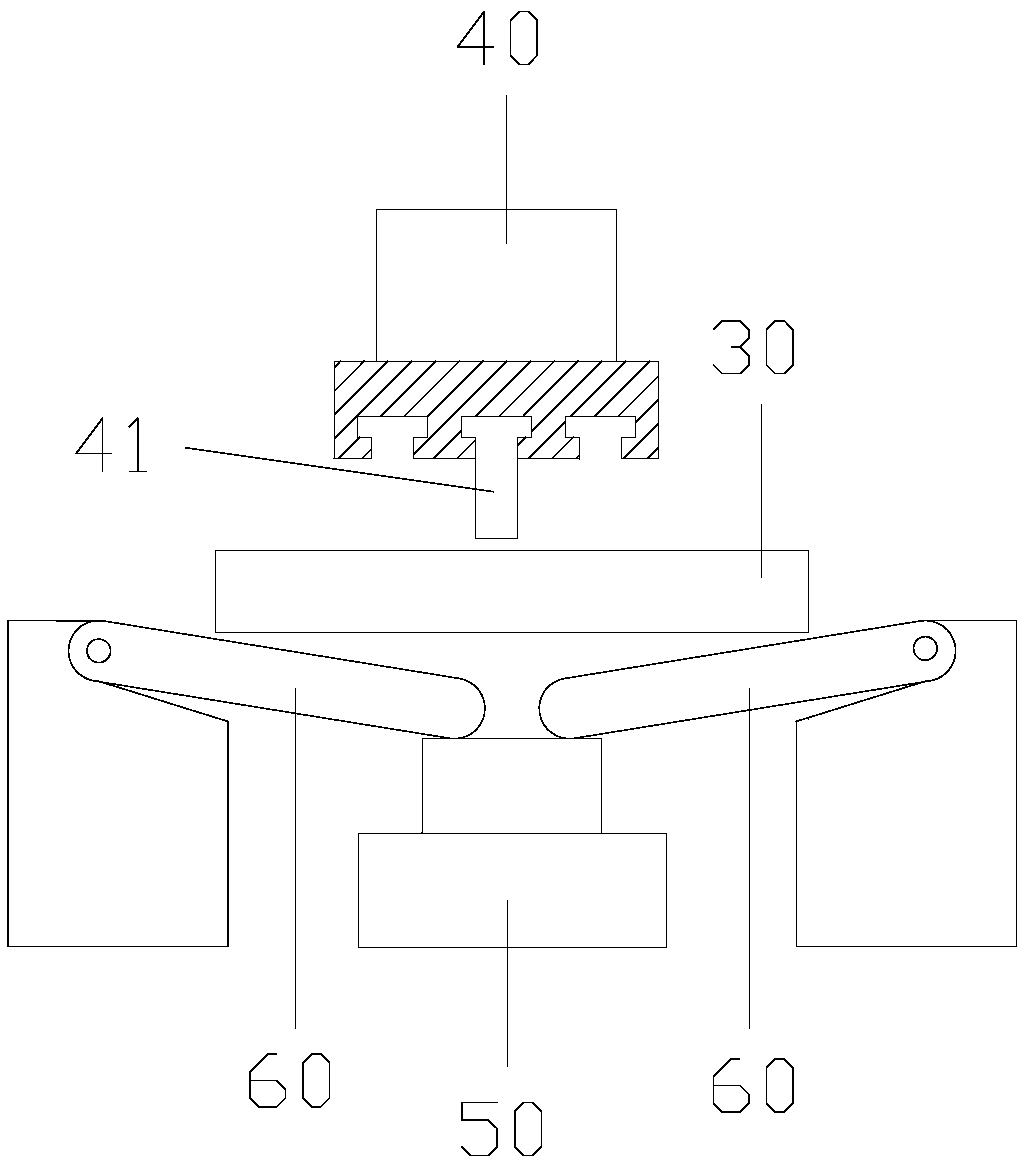

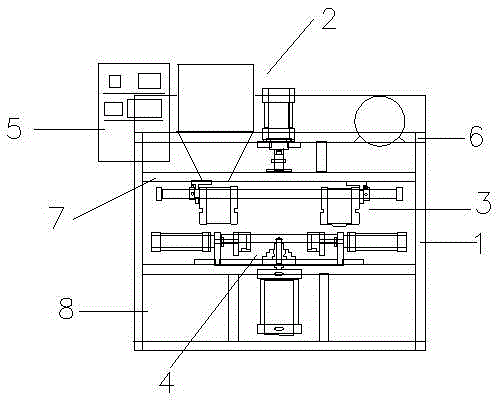

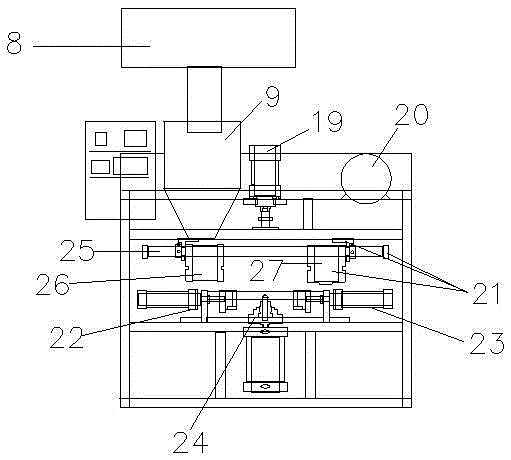

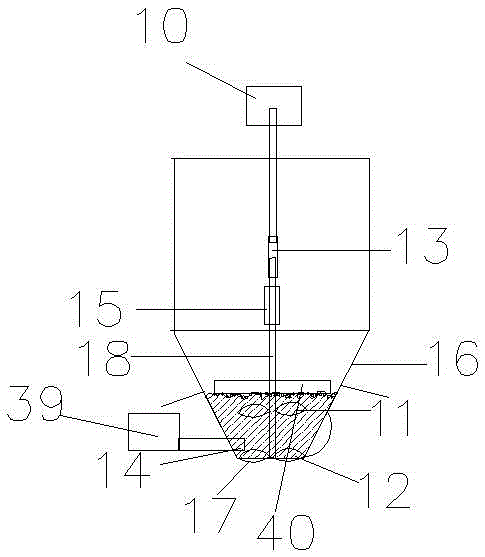

Automatic sand core machine for mocha coffeemaker

ActiveCN105344945ARapid productionQuick collectionMoulding machinesEngineeringMechanical engineering

The invention relates to the technical field of casting modeling, in particular to an automatic sand core machine for a mocha coffeemaker. According to the technical scheme, the automatic sand core machine for the mocha coffeemaker comprises a rack, a sand supply module, a sand filling module, a die combination module and a control module. The sand supply module is composed of a sand feeding device, a sand supply hopper, a sand pressing valve, a stirring paddle and a sand suction device. The die combination module is composed of a sand pressing air cylinder, an air supply cylinder, sand supply devices, a left die locking mechanical arm, a right die locking mechanical arm and a core pulling table. The die combination module is further provided with a sand removal and recycling module. The sand removal and recycling module comprises a sealing hood, a strong-pressure fan, strong-pressure air lead-in pipes and a collection plate. The sealing hood is circular or similar to a circle and composed of a front half hood body and a rear hood body. The front half hood body or the rear half hood body is provided with the strong-pressure air lead-in pipe or both the front half hood body and the rear half hood body are provided with the strong-pressure air lead-in pipes. A unique recycling opening is formed right ahead or right behind the sealing hood.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

Online coliform group detection system

PendingCN112063521ARealize online detectionAvoid affecting test resultsBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidEngineering

Owner:HANGZHOU GREAN WATER SCI & TECH INC

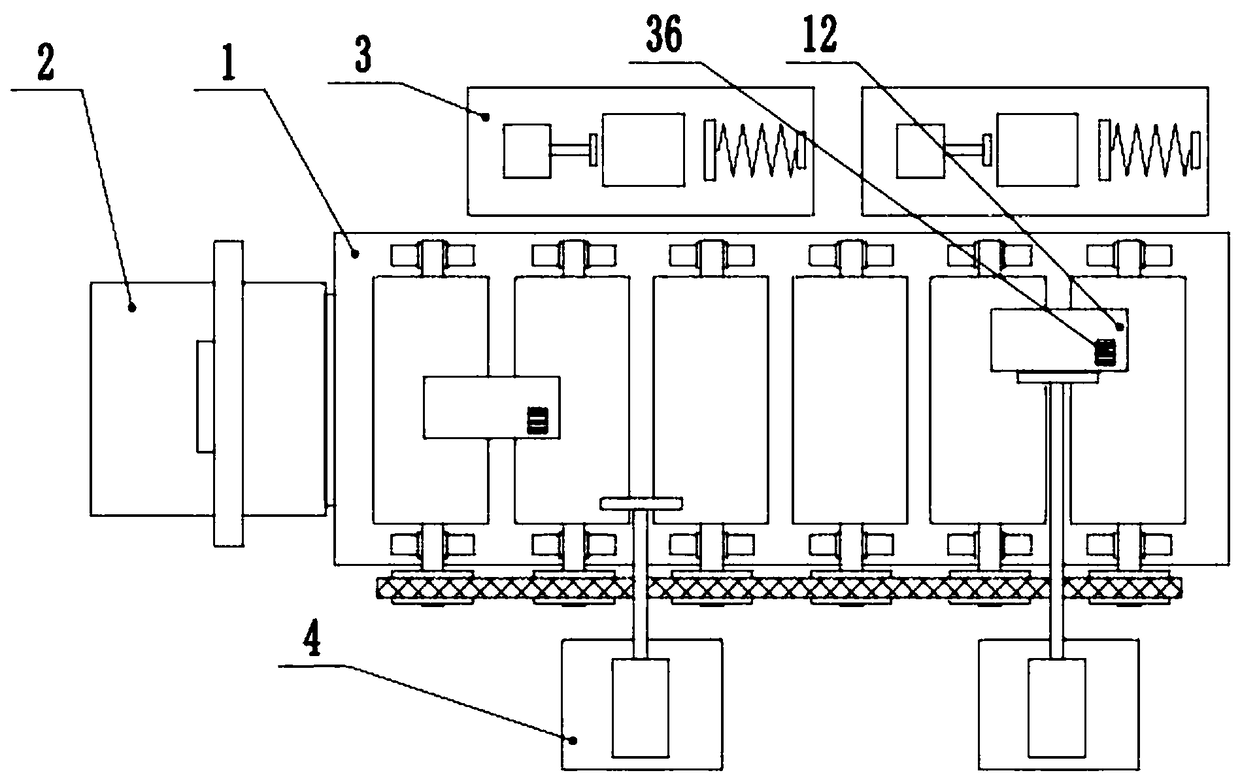

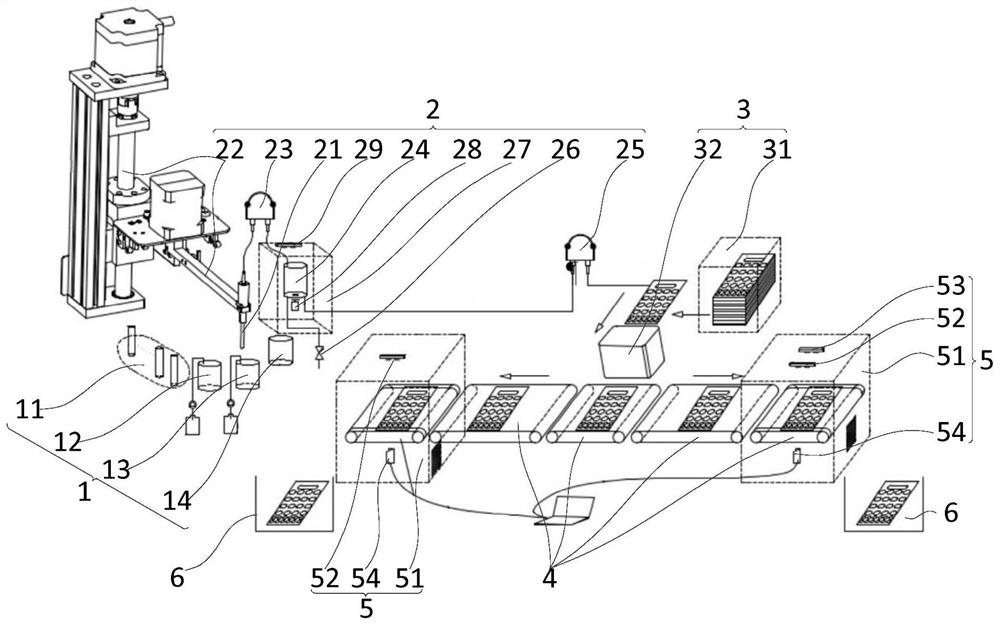

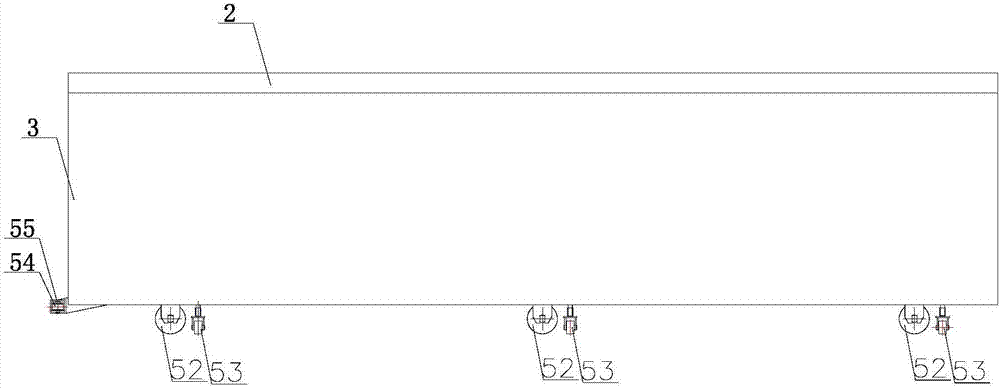

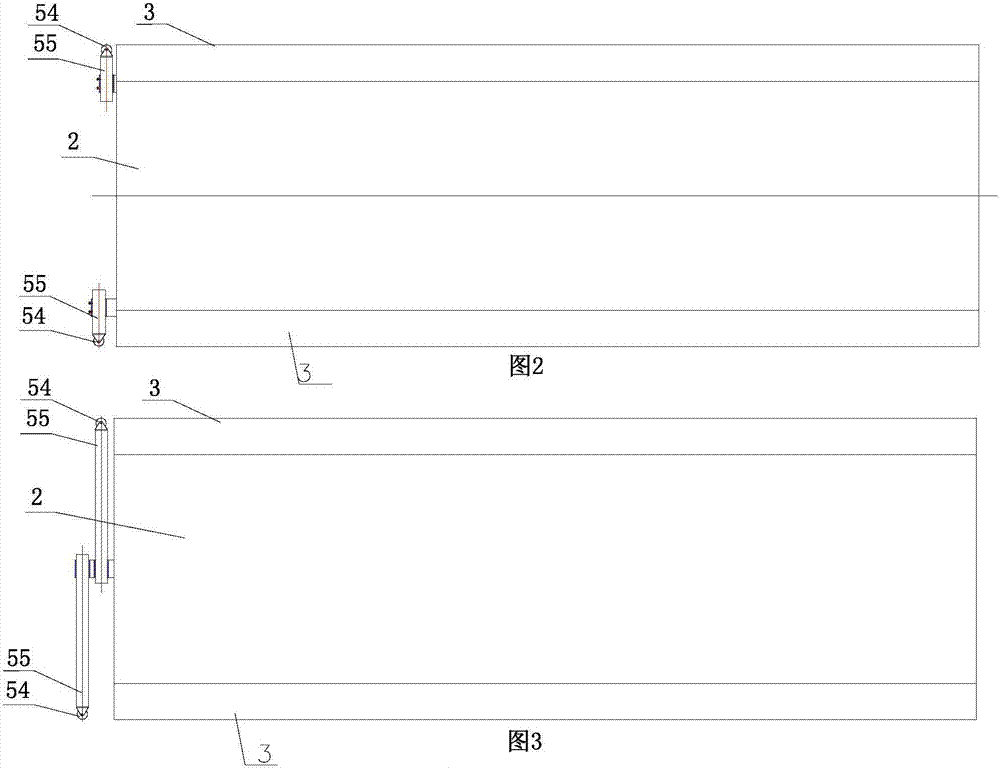

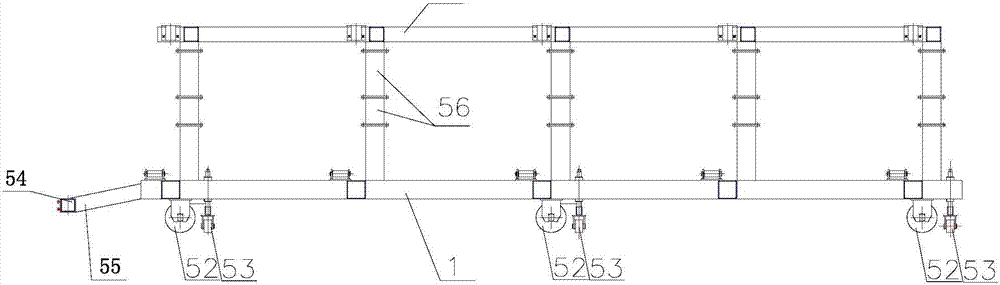

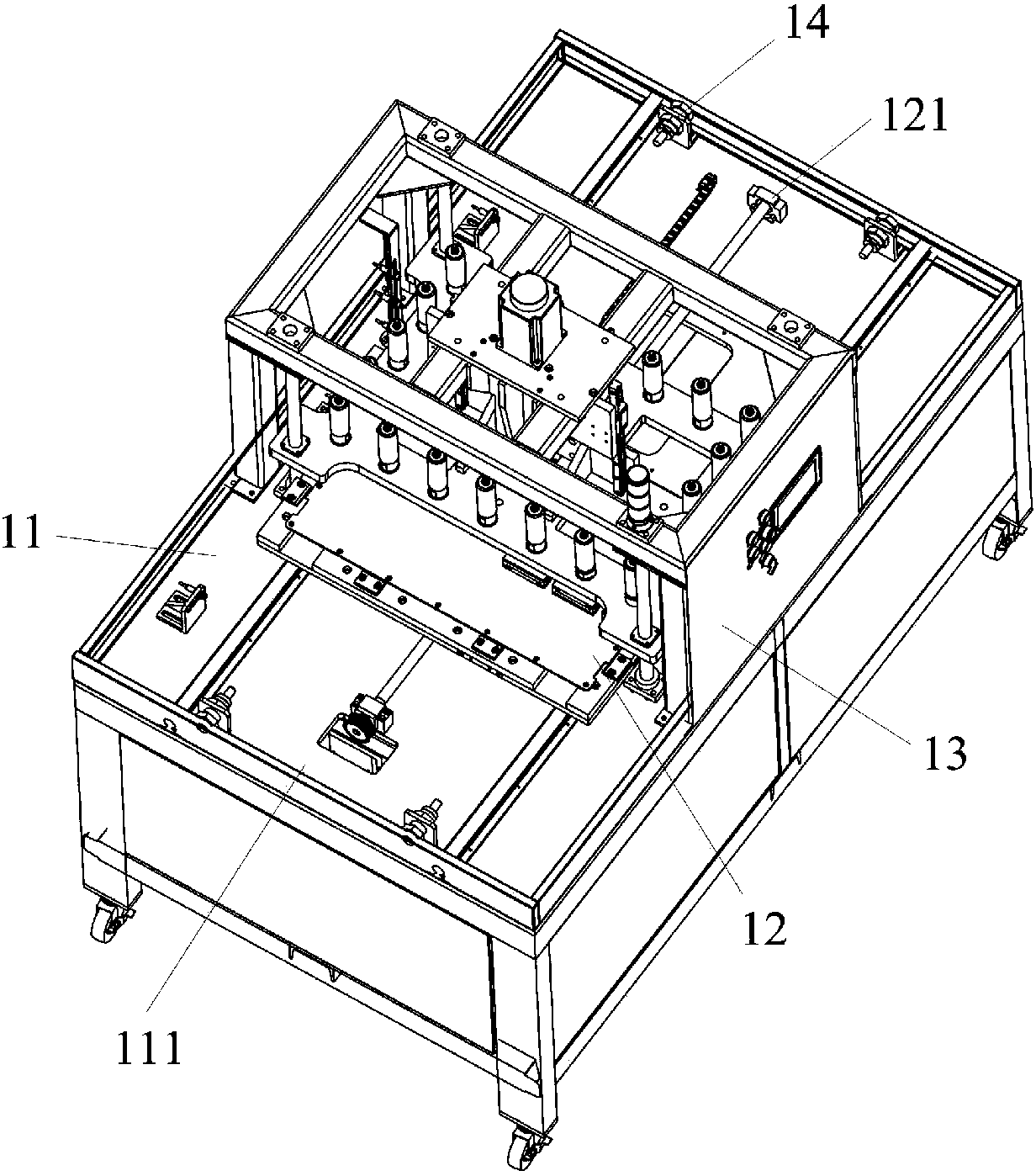

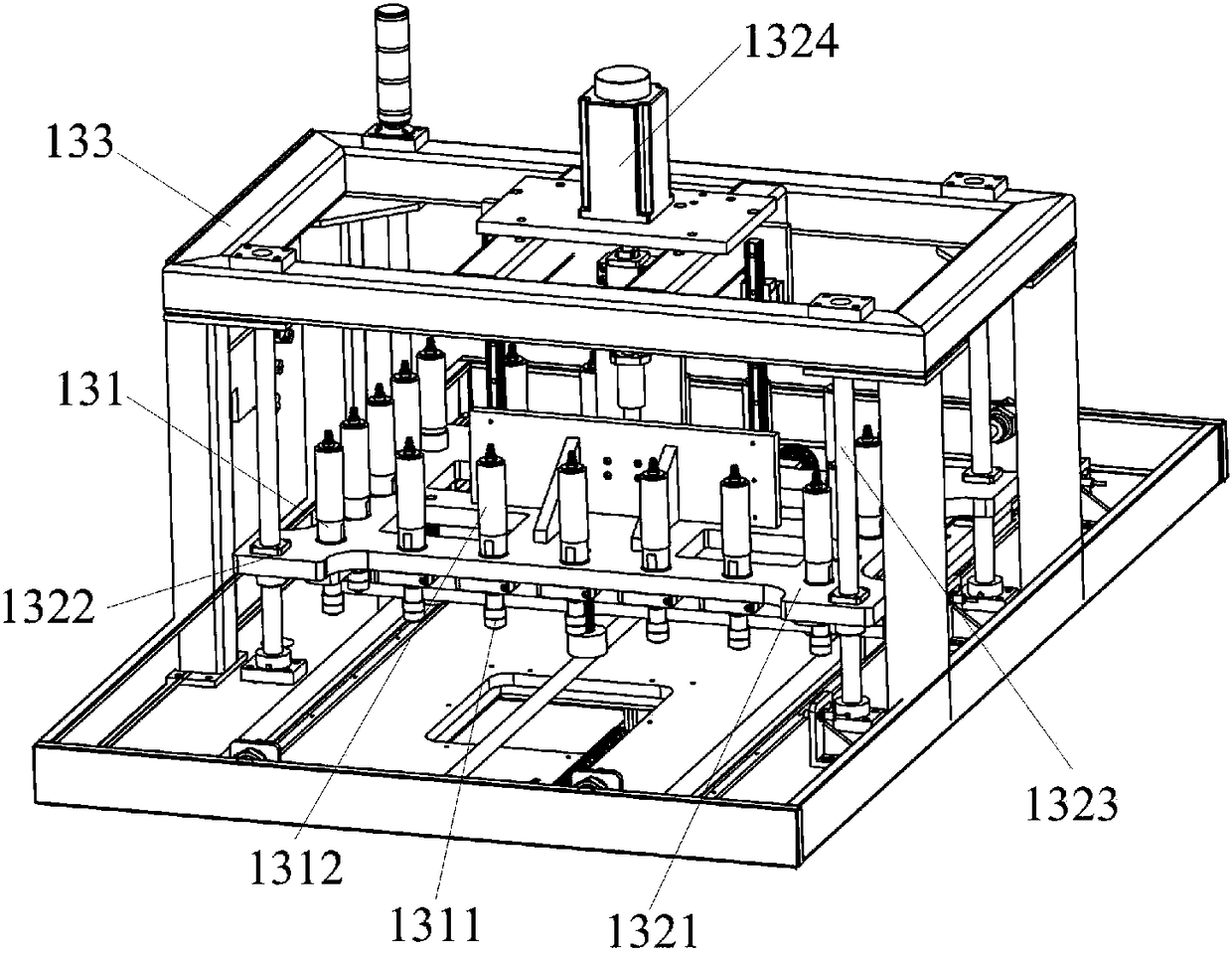

Vehicle model die assembly for comprehensive pipe gallery construction

ActiveCN106854875ADisengage evenlyEasy to demouldArtificial islandsUnderwater structuresVehicle frameEngineering

The invention discloses a vehicle model die assembly for comprehensive pipe gallery construction. The vehicle model die assembly comprises a frame body, a top die assembly and side die assemblies, wherein the top die assembly is movably connected to the frame body through at least two lifting devices, the side die assemblies located on the right side and the right side of the frame body respectively are connected to two sides of the frame body through at least two telescopic devices, a walking mechanism is arranged at the bottom of the frame body, the top die assembly is connected with the side die assemblies, the telescopic devices are fixedly connected with the side die assemblies and are telescopically and movably connected with the left side and the right side of the frame body, the top ends of the lifting devices are connected with the top die assembly, and the lower ends of the lifting devices are connected with the frame body. The vehicle model die assembly for comprehensive pipe gallery construction is simple in structure, makes die assembly and die release more convenient and quicker, has self-walking ability and high repeated utilization rate and is high in die assembly precision, short in construction period, easy to release and low raw material consumption, operation is easy, and the labor cost is low.

Owner:宁夏众力管廊科技有限公司

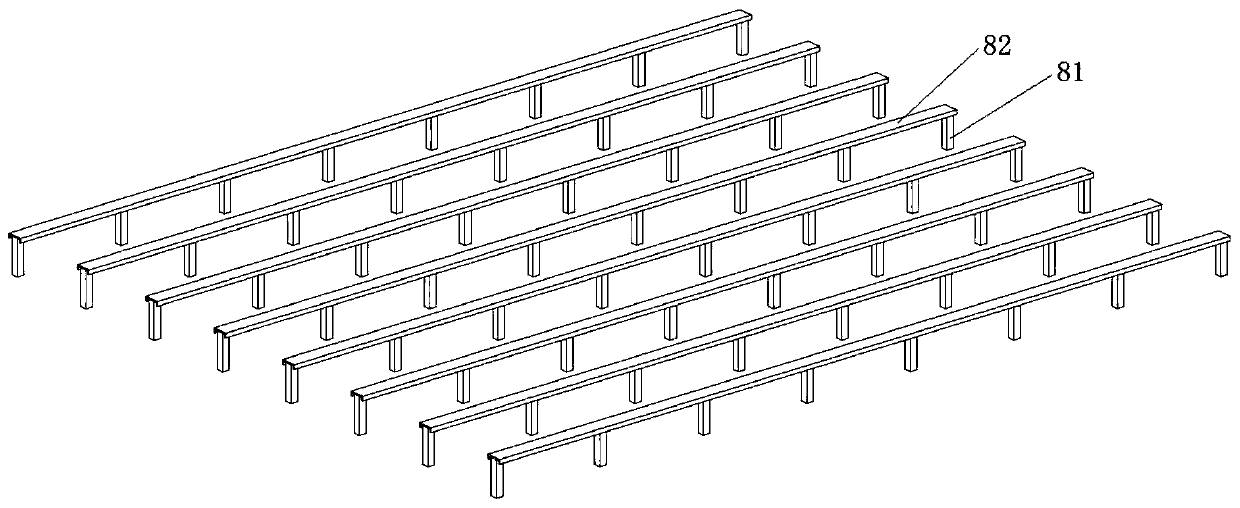

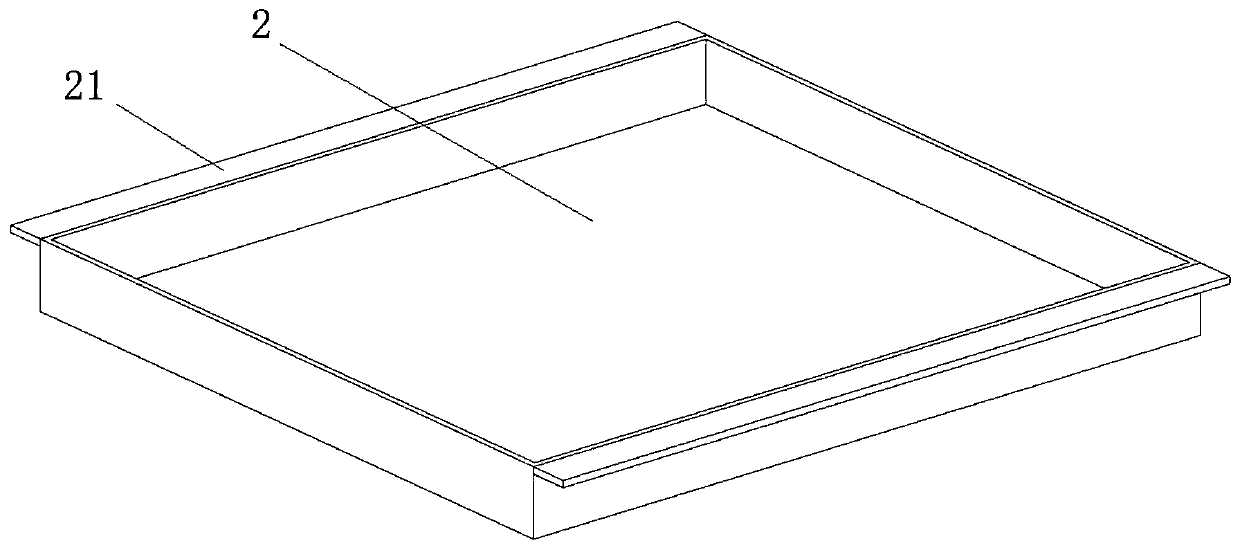

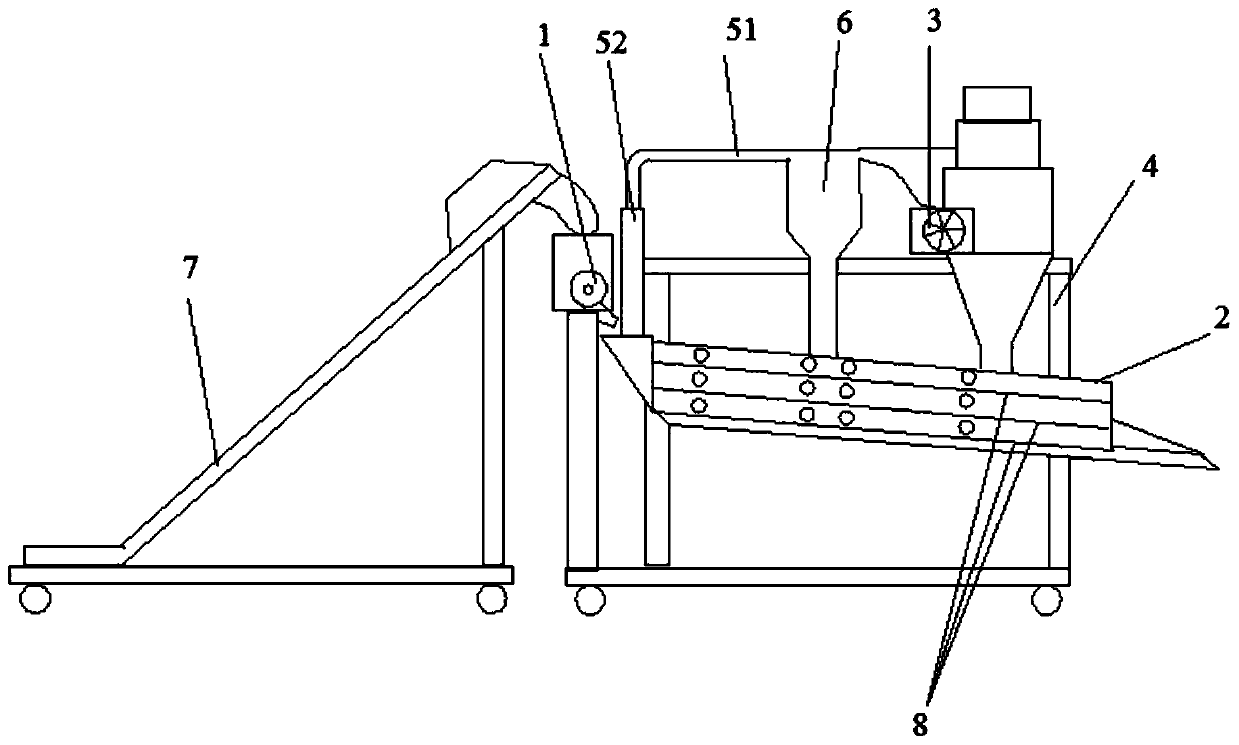

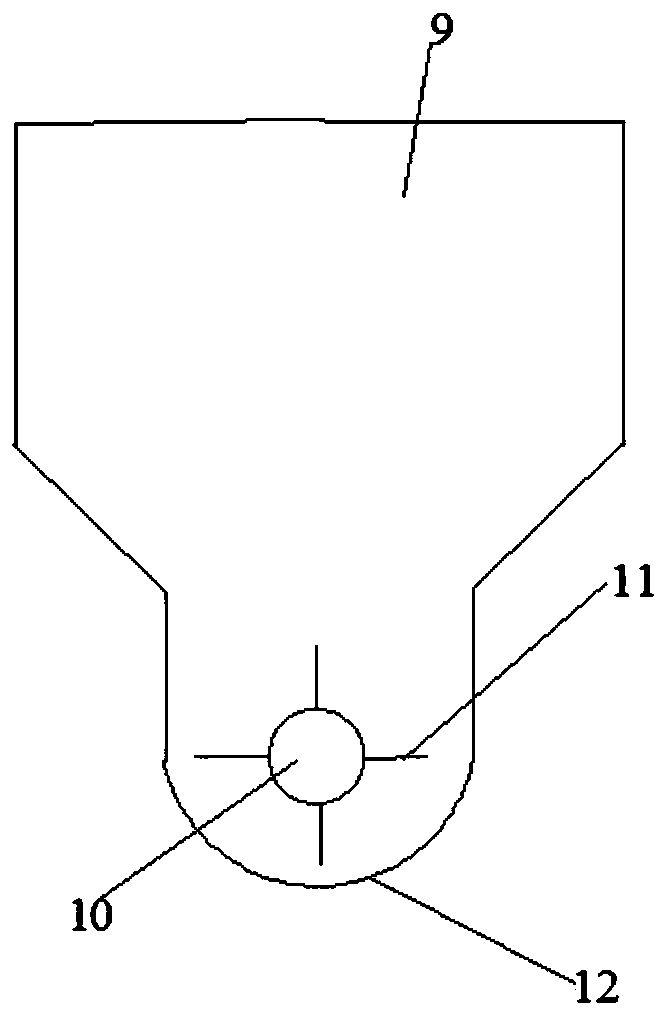

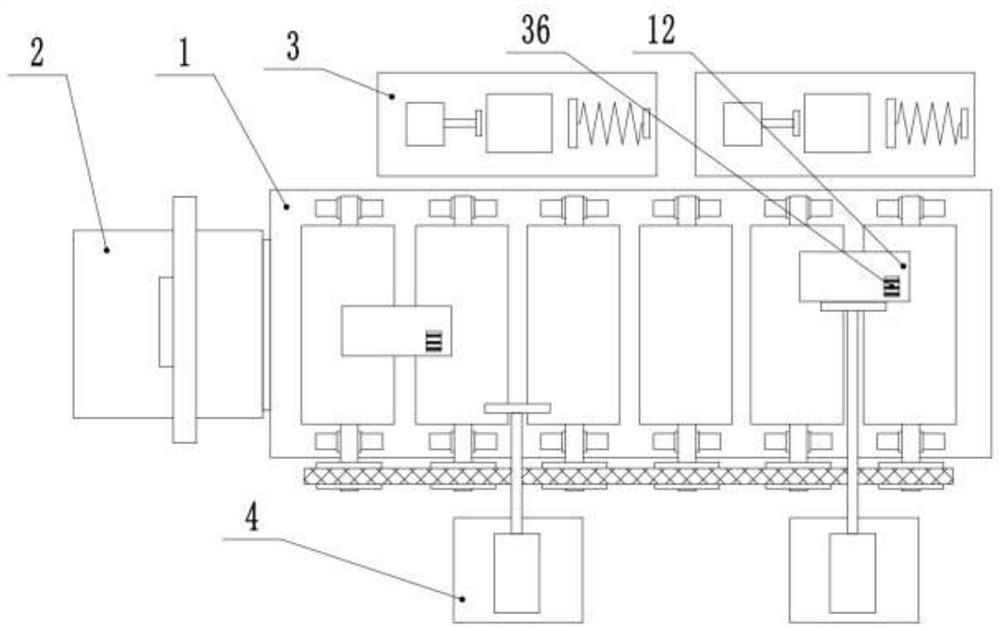

Automatic tea leaf sun-drying system

PendingCN111217157AReduce lossIncrease production capacityConveyorsPre-extraction tea treatmentEngineeringMechanical engineering

The invention discloses an automatic tea leaf sun-drying system, and relates to the technical field of tea making equipment. The automatic tea leaf sun-drying system comprises a sun-drying field for sun-drying tea leaves and trays for containing the tea leaves, and further comprises a carrying device for carrying the trays. The carrying device is provided with wheels for moving one part or the whole of the carrying device, a driving mechanism for driving the wheels to run, and a horizontal component for lifting up the trays. Thus, the automation of the tea leaf sun-drying process is realized,the problem of secondary contamination during manual tea leaf sun-drying is reduced, and the tea leaf sun-drying quality is improved.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

Sichuan pepper screening and impurity removal integrated machine

The invention discloses a Sichuan pepper screening and impurity removal integrated machine. The Sichuan pepper screening and impurity removal integrated machine comprises a rack, a threshing mechanism, a negative pressure device and a screen vibrating mechanism, wherein the threshing mechanism and the negative pressure device are located on the upper portion of the rack, the screen vibrating mechanism is transversely arranged below the threshing mechanism and the negative pressure device, and the outlet of the threshing mechanism is located above the inlet of the screen vibrating mechanism; and a vertical material pipe is vertically arranged above the inlet of the screen vibrating mechanism, the upper end of the vertical material pipe communicates with the negative pressure device througha horizontal material pipe, and the lower end of the vertical material pipe is in a horn mouth shape. According to the Sichuan pepper screening and impurity removal integrated machine, the negative pressure device is arranged to discharge light impurities mixed in Sichuan pepper grains out of the system through the vertical material pipe and the horizontal material pipe in sequence; by arranging areturn pipe, part of small Sichuan pepper grains in the light impurities in the horizontal material pipe fall into the screen vibrating mechanism through the return pipe, a next step of screening continues, and the loss and waste of the small Sichuan pepper grains are avoided; and by arranging three screens, the Sichuan pepper grains are screened in sequence at three grades.

Owner:陕西为康生物科技股份有限公司

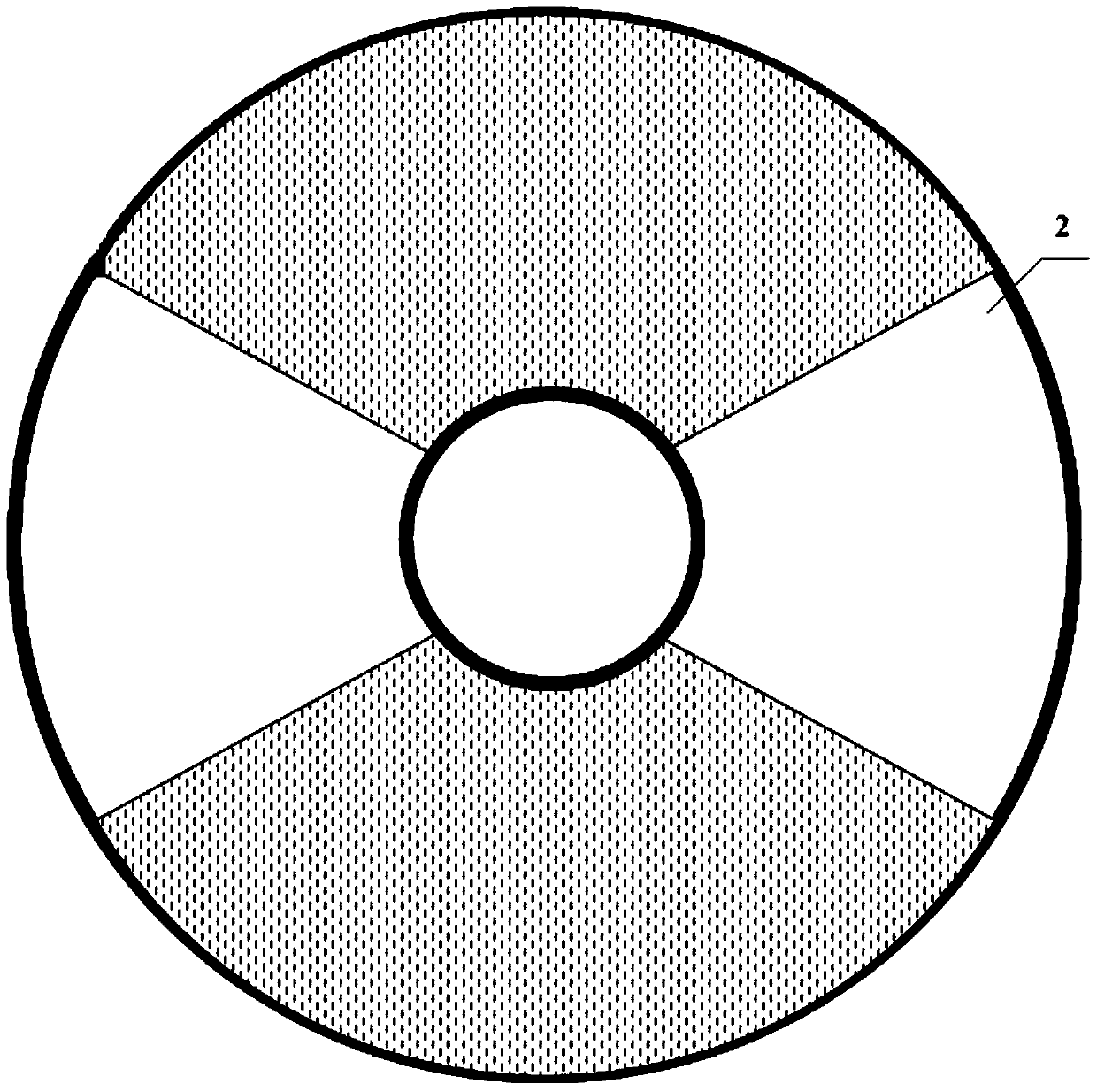

A method of manufacturing a polarization-maintaining optical fiber

ActiveCN104591534BSimple structureSimple processGlass making apparatusPolarization-maintaining optical fiberEngineering

The invention belongs to the technical field of optical fiber manufacturing, and discloses a method for manufacturing a polarization-maintaining optical fiber, comprising the following steps: on the wall of the first layer of casing, cutting a notch symmetrically with respect to the center line of the inner cavity of the first layer of casing; Stress rods are filled in the incision, and an optical fiber preform core rod is embedded in the first layer of casing; a second layer of casing is nested outside the first layer of casing to form a polarization-maintaining optical fiber preform; The polarized optical fiber preform is drawn into a polarization-maintaining optical fiber; wherein, the structure of the gap is filled by a stress rod. During the high-temperature drawing process, the circular stress rod will greatly fill the gap in the cut after softening, forming a polarization-maintaining optical fiber. required stress zone. The invention proposes a polarization-maintaining optical fiber manufacturing method with double sleeves and stress rods, which has a simple structure, greatly simplifies the processing technology and reduces the requirements for labor and equipment; it can greatly improve the impact of impurities on product quality; at the same time, it avoids Various high-precision operation requirements in the prior art.

Owner:WUHAN BRIGHTCORE OPTICAL FIBER CO LTD

Automatic porcelain clay plasticization hammering machine

InactiveCN104249409AReduce lossIncrease security risksAuxillary shaping apparatusEngineeringSmall footprint

The invention discloses an automatic porcelain clay plasticization hammering machine. The automatic porcelain clay plasticization hammering machine comprises a rack and a mud containing tank, wherein the rack is provided with an electric motor, the electric motor drives a pulling rod through an eccentric rod, the pulling rod is connected with a supporting arm which is arranged on the rack, one end of the supporting arm is connected with a supporting arm fixing seat which is arranged on the rack, the other end of the supporting arm is provided with a steel wire rope pull-down wheel, a steel wire rope is connected with a mud hammering hammer head guide roller through the steel wire rope pull-down wheel, the mud hammering hammer head guide roller vertically and downwards stretches into a cavity of the mud containing tank, and one end, which is away from the steel wire rope, of the mud hammering hammer head guide roller is provided with a mud hammering hammer head. The automatic porcelain clay plasticization hammering machine disclosed by the invention has the beneficial technical effects that the occupied area is small, the working efficiency is high, the safety performance is high, the loss of accessories is less, the labor and the cost are reduced, the labor requirement is low, and the recovery value is high.

Owner:吴健鹏 +2

A campus library book automatic identification and sorting equipment

ActiveCN109499889BReduced labor requirementsImprove efficiencySortingMechanical engineeringIndustrial engineering

The invention relates to the field of book management and discloses a school library book automatic identifying and sorting device. The school library book automatic identifying and sorting device comprises a conveying table. A recognition table is fixedly connected to the left side of the conveying table. Stacking tables and sorting tables are arranged on the upper and lower sides of the conveying table correspondingly. The upper portion of the recognition table is fixedly connected with supporting rods. The tops of the supporting rods are fixedly connected with an inclined plate. The right side of the inclined plate is connected with a rotary seat. The rotary seat is fixedly connected with a baffle. The lower portion of the baffle is hinged to a first cylinder piston rod. The inclined plate is fixedly connected with a probe stand column. The probe stand column is fixedly connected with a recognition probe. The school library book automatic identifying and sorting device can be used for classifying returned library books, can automatically judge the type of the books under the combined action of sensors and cylinders and place the different types of books onto the different stacking tables, greatly reduces manual operation and is higher in efficiency, more accurate in sorting and suitable for application and popularization in various large libraries.

Owner:LUOHE MEDICAL COLLEGE

Method for synthesizing (3R,5S)-6-chloro-3,5-dihydroxyhexanoate

InactiveCN105087685AShorten the timeLow equipment requirementsFermentationHydrogenReaction temperature

The invention discloses a method for synthesizing (3R,5S)-6-chloro-3,5-dihydroxyhexanoate, wherein the method comprises the following steps: preparing 4-chloro-3-hydroxybutyrate; preparing tert-butyl (S)-6-chloro-5-hydroxy-3-oxo-hexanoate from the 4-chloro-3-hydroxybutyrate; adding proper amount of pure water to a reaction kettle as a solvent and adding hydrophosphate to prepare a pH buffer solution which is 0.05mol / L-0.15mol / L in molar concentration, so as to generate a (3R,5S)-6-chloro-3,5-dihydroxyhexanoate solution with the presence of a biological catalyst and a hydrogen donor, and reacting at 45-55 DEG C for 10-15h; and after reaction, sequentially filtering, extracting, decompressing and concentrating, and rectifying so as to obtain a finished (3R,5S)-6-chloro-3,5-dihydroxyhexanoate product; the mass-volume concentration of the (3R,5S)-6-chloro-3,5-dihydroxyhexanoate is 8g / mL-17g / mL, and the dosage of carboxyl reductase is 4-6% of the (3R,5S)-6-chloro-3,5-dihydroxyhexanoate. The method disclosed by the invention not only is capable of reducing production cost and is conducive to energy conservation and emission reduction, but also is higher in molar yield from a production reaction process.

Owner:LIANYUNGANG HONGYE CHEM

Method for separating platinum, palladium, rhodium and iridium from solution

PendingCN114737058AEasy to separateImprove direct yieldProcess efficiency improvementIridiumOxidizing agent

The invention relates to a method for separating platinum, palladium, rhodium and iridium from a solution, which comprises the following steps: adding a strong oxidant, and then adding a saturated ammonium chloride solution, so that platinum, palladium, rhodium and iridium form chloroplatinic acid amine, chloropalladic acid amine, chlororhodic acid amine and chloroiridic acid amine precipitates; adding ammonia water for slurrying, heating and stirring, and enabling palladium salt to enter the solution; the filtrate is palladium liquid, and the filter residues are ammonium chloroplatinate, ammonium chlororhodate and ammonium chloroiridate. And refining the palladium liquid to recover palladium. The method comprises the following steps: adding water into ammonium chloroplatinate, ammonium chlororhodate and ammonium chloroiridate salt slag, slurrying, heating, adding hydrazine hydrate, reducing platinum and rhodium into simple substances, reducing tetravalent iridium salt into trivalent iridium salt, adjusting the acidity of the solution, transferring the iridium salt into the solution, and refining the iridium liquid to recover iridium. The filter residues are platinum and rhodium powder, drying, dissolving with hydrochloric acid and hydrogen peroxide, transferring platinum into a solution, filtering, and transferring platinum liquid into refining; the filter residue is crude rhodium, and refining to obtain rhodium powder. The invention provides a method for separating complex precious metal materials, and solves the problems of incomplete separation, large amount of wastewater and waste liquid in separation, complicated process, high cost and the like.

Owner:HOOTECH

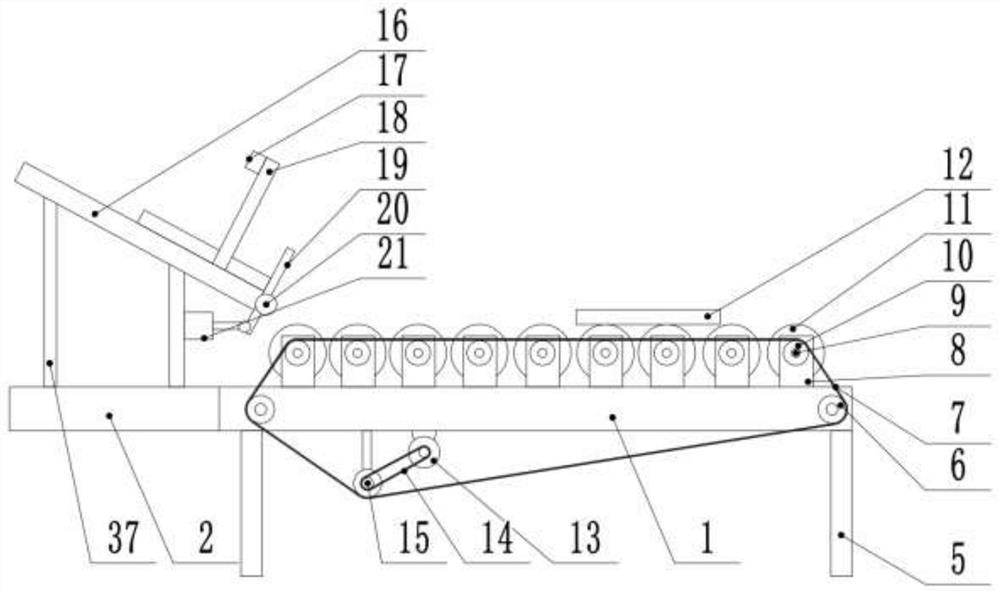

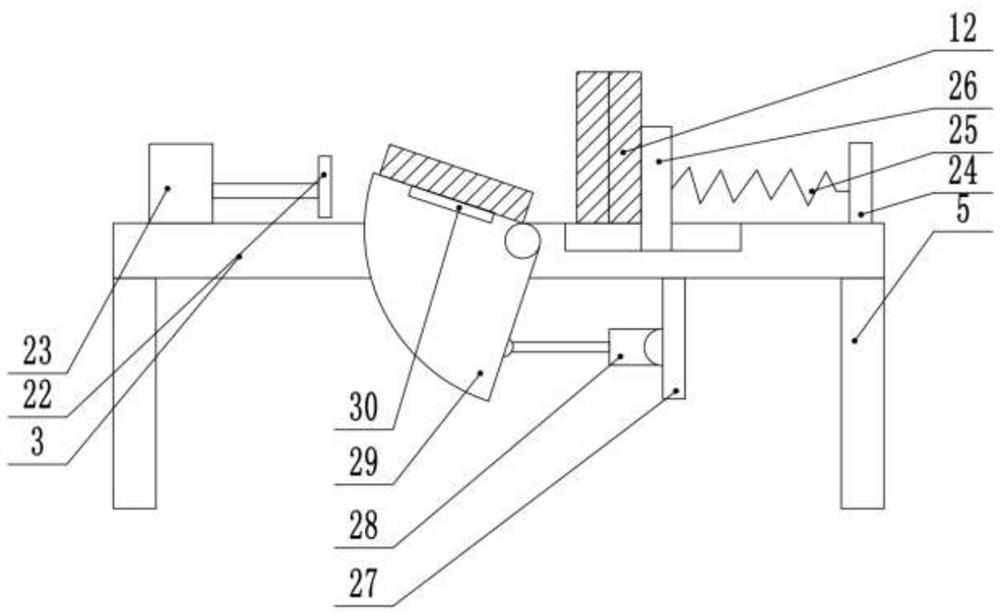

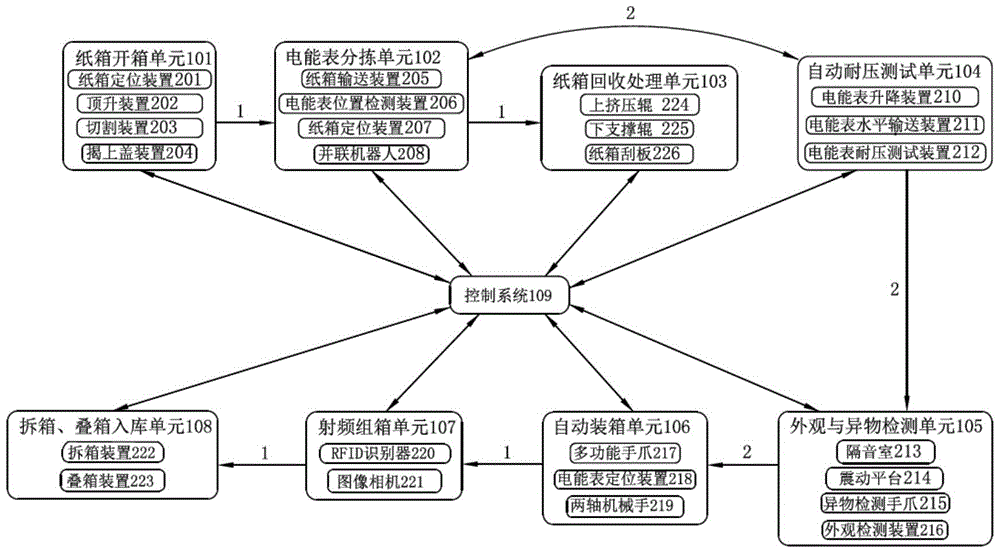

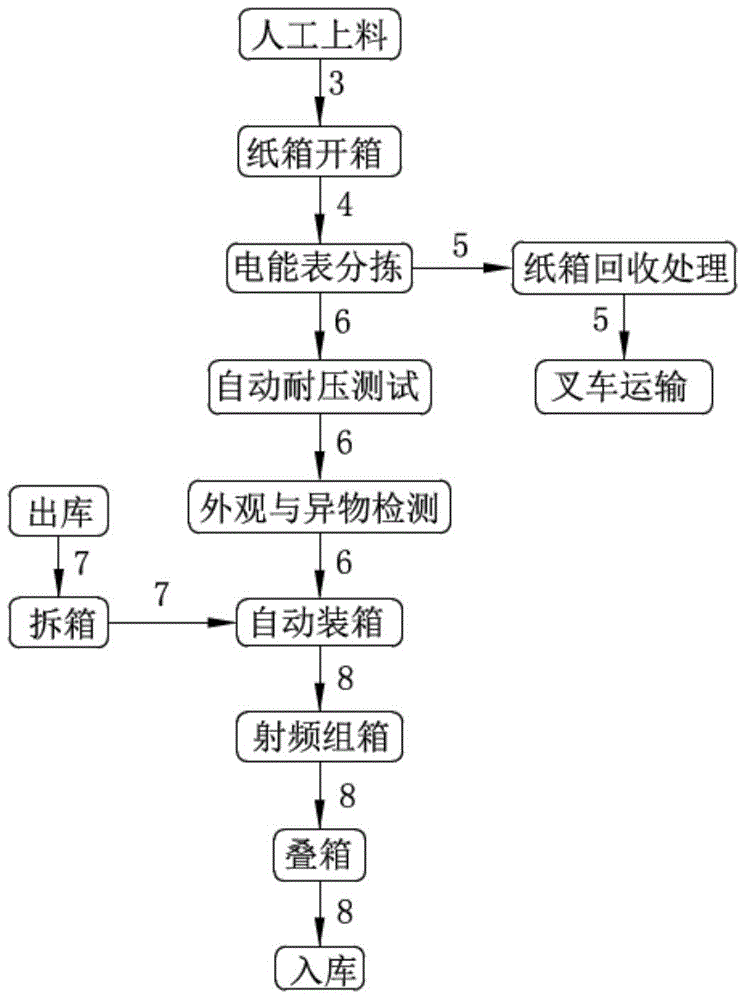

A system and method for automatic unpacking of electric energy meters

ActiveCN104443602BRealize intelligent controlFully automaticUnpacking by cuttingForeign matterControl system

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Full-automatic multi-station chamfering machine

The invention relates to a full-automatic multi-station chamfering machine. The full-automatic multi-station chamfering machine includes a machine frame, a workpiece moving device and a chamfering device; a work surface is formed at the surface of the machine frame; the workpiece moving device is disposed on the work surface and reciprocates in the axial direction of the work surface; the chamfering device includes chamfering units, a Z-axis moving device and a vertical frame; and the chamfering units are connected with the vertical frame through the Z-axis moving device and reciprocates in the vertical direction. A plurality of chamfering units are arranged to form corresponding chamfering stations so as to chamfer workpieces.

Owner:HAIWAIHAI IRONWARE ELECTRONICS HANGZHOU

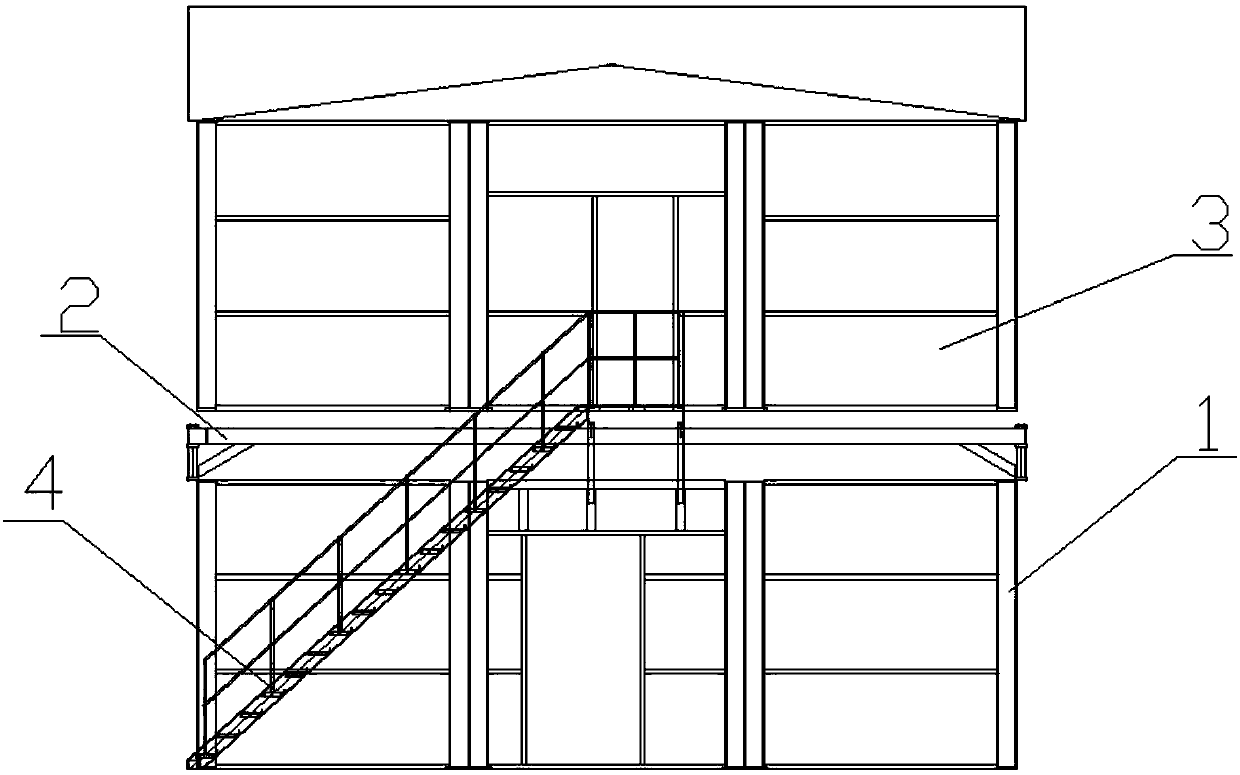

Frame structure of prefabricated modular transformer substation

PendingCN107795158AReduce the impactSimple construction processTransformer housesTransformerMechanical engineering

The invention provides a frame structure of a prefabricated modular transformer substation. The frame structure comprises a base pre-embedded piece, modular wall frames and modular beam frames. The modular wall frames are connected with the base pre-embedded piece and the modular beam frames through bolts. The adjacent modular wall frames are connected mutually through bolts. The modular wall frames are provided with internal and external wall plate keels, and internal and external wall plates are installed on the internal and external wall plate keels. Modular layer plates are arranged between the adjacent modular beam frames. The modular layer plates are connected with the modular beam frames through bolts. According to the frame structure of the prefabricated modular transformer substation, the structure construction process is simple, the accumulative error is small, construction difficulty is low, the construction period is short, needed manpower is less, and the impact of the environment is low.

Owner:JIANGSU SUNEL TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com