Sichuan pepper screening and impurity removal integrated machine

An all-in-one machine and prickly ash technology, which is used in sieves, solids separation, agricultural machinery and implements, etc., can solve problems such as inclusion of small granules of prickly ash, complicated screening process of prickly ash, and achieve the effect of low labor requirements, high degree of automation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

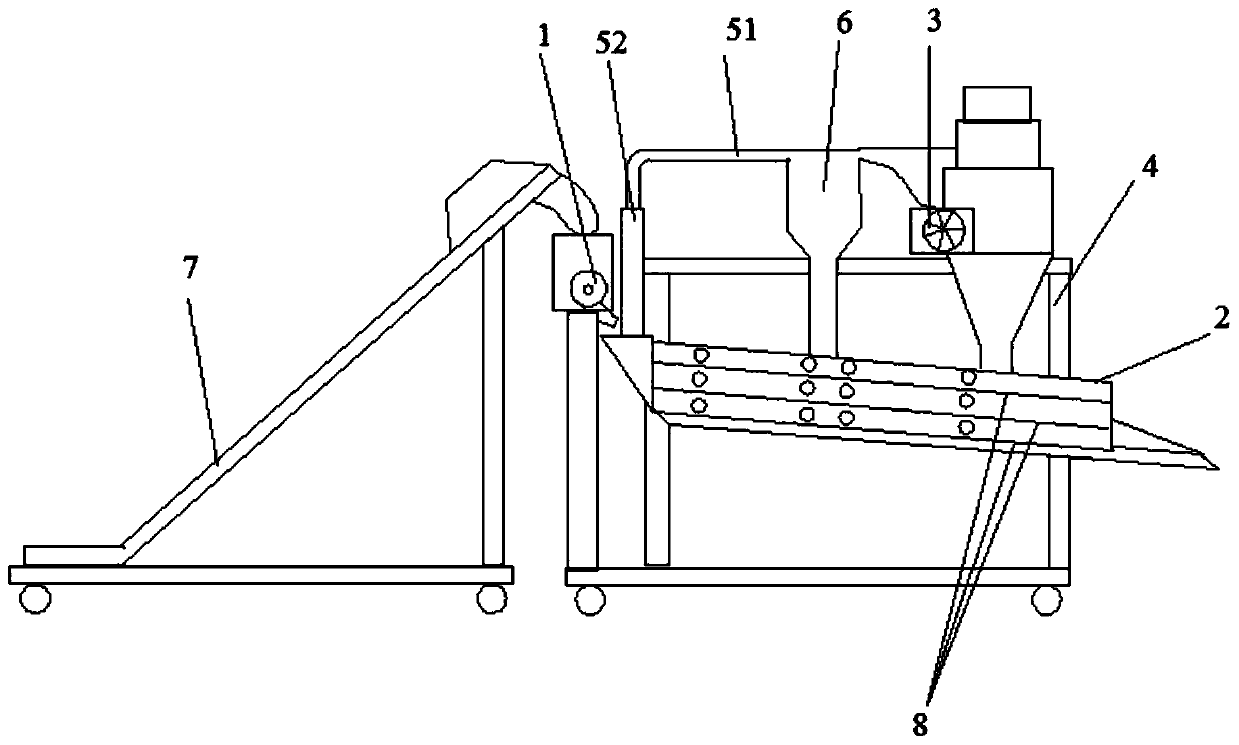

[0019] The invention discloses an all-in-one machine for screening and removing impurities of Chinese prickly ash, such as figure 1 As shown, it includes a threshing mechanism 1, a screen vibration mechanism 2 and a negative pressure device 3. The threshing mechanism 1 is located at the upper left part of the frame 4, the negative pressure device 3 is fixed at the upper right part of the frame 4, and the screen vibration mechanism 2 is fixed At the lower part of the frame 4, the detachment mechanism is used to separate the pepper granules and the pepper stalks, the screen vibrating mechanism 2 is used for multi-stage screening of the cleaned pepper, the threshing mechanism 1, the screen vibrating mechanism 2 and the negative pressure device 3 are located On the same frame 4, it is convenient to process the Zanthoxylum bungeanum granules seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com