A system and method for automatic unpacking of electric energy meters

An electric energy meter and automatic technology, which is applied in the field of electric energy meter, can solve the problems of increased labor cost and other problems, and achieve the effects of reducing labor intensity, high work efficiency and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

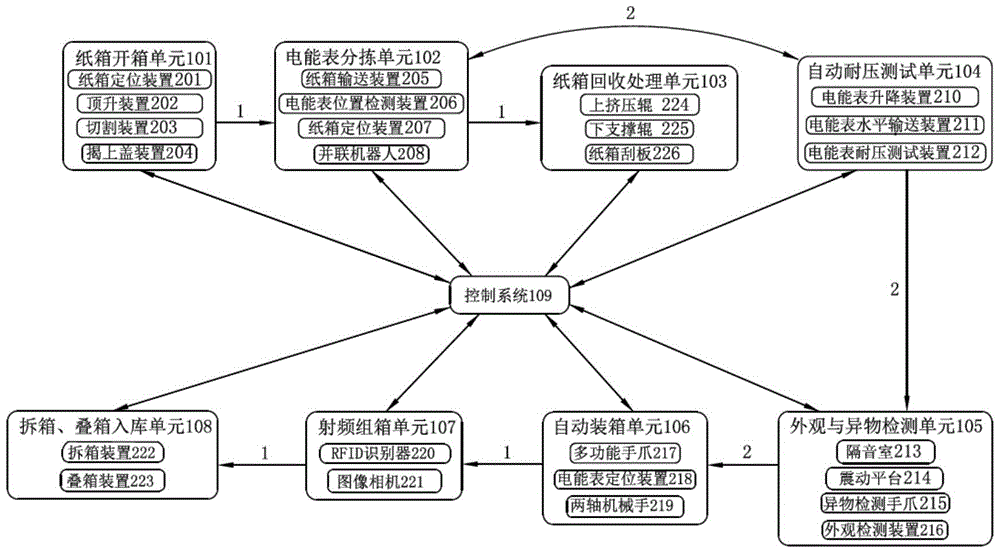

[0072] exist figure 1 with figure 2 Among them, the connection lines between each part are: roller conveying line 1; belt conveying line 2; carton 3; carton after opening the cover 4; empty carton 5; electric energy meter 6; Such as figure 1 As shown, a kind of electric energy meter automatic unpacking system provided by the present invention includes a control system 109 and an automatic unpacking unit 101 connected to the control system 109, an electric energy meter sorting unit 102, a carton recycling processing unit 103, an automatic withstand voltage Test unit 104, appearance and foreign object detection unit 105, automatic box packing unit 106, radio frequency box assembly unit 107 and unstacking / stacking storage unit 108;

[0073] The automatic unpacking unit 101, electric energy meter sorting unit 102, automatic withstand voltage testing unit 104, appearance and foreign matter detection unit 105, automatic packing unit 106, radio frequency grouping unit 107 and unst...

Embodiment 2

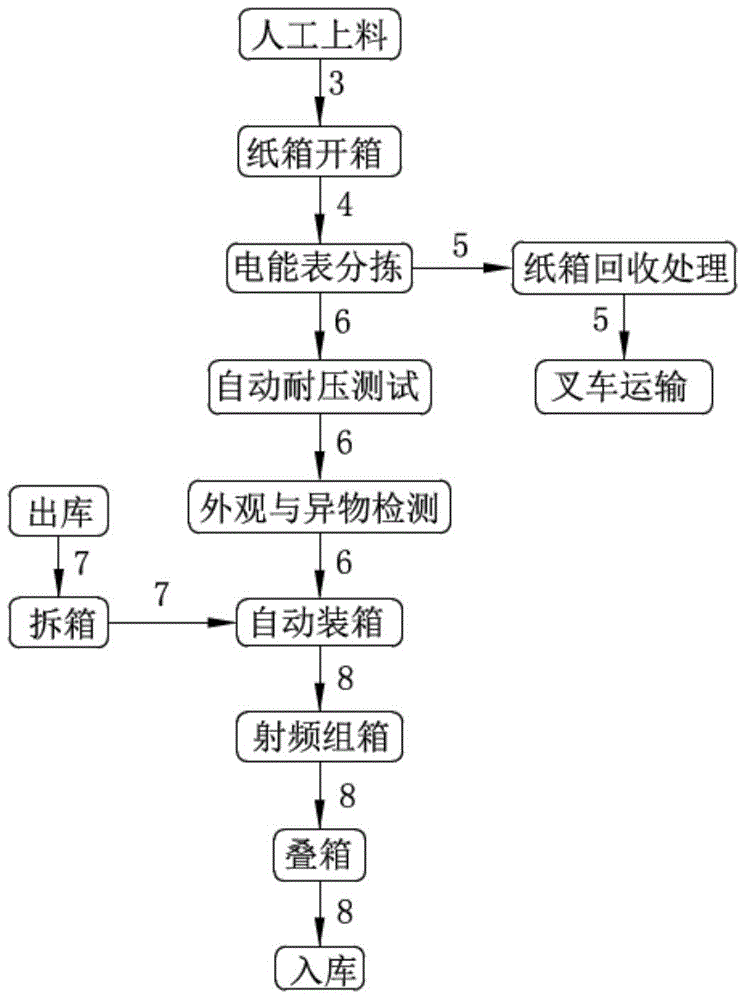

[0114] Such as figure 2 As shown, this embodiment also provides a method for automatically unpacking an electric energy meter, comprising the following steps:

[0115] S1: The control system of the control center issues a production task to deliver the electric energy meters that need to be unpacked;

[0116] S2: Transport the electric energy meter box out of the warehouse to the unpacking area through the conveying system;

[0117] S3: Put the electric energy meter carton on the unpacking conveyor line;

[0118] S4: Cut the electric energy meter carton into upper and lower parts and remove the upper part;

[0119] S5: Use the parallel robot to grab the electric energy meter from the cut carton and place it on the conveyor line;

[0120] S6: After transporting the empty cartons to the carton recycling unit, they are squeezed into sheet cartons by the upper and lower squeeze rollers between the upper and lower squeeze rollers inside the carton, stacked by carton scrapers an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com