Automatic sand core machine for mocha coffeemaker

A technology of coffee pots and clay core machines, which is applied in the field of casting molding, can solve the problems affecting the direct quality of casting mocha coffee pots, difficulty in unifying specifications and quality, and slow production speed, so as to protect the health of workers, reduce the risk, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the technical solution of the present invention will be further described in detail through embodiments and the accompanying drawings:

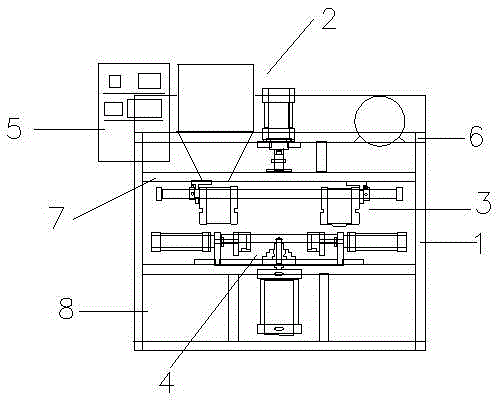

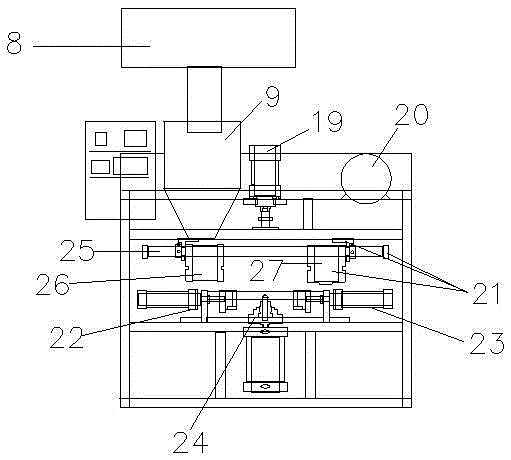

[0035] Such as Figure 1-4 As shown, an automated mocha coffee pot mortar machine includes a frame (1), a sand supply module (2), a sand filling module (3), a mold clamping module (4), and a control module (5), in which: The frame is a three-layer structure, the whole is square, the top is a sand supply frame (6), which is composed of 3 I-frames side by side, the top is set with a collecting plate, and the middle part is a clamping frame (7) in a mouth shape , The bottom is the control frame (8); the sand supply frame is provided with a sand supply module and a sand filling module, the mold clamping frame is equipped with a mold clamping module, and the control frame is equipped with a control module and auxiliary modules;

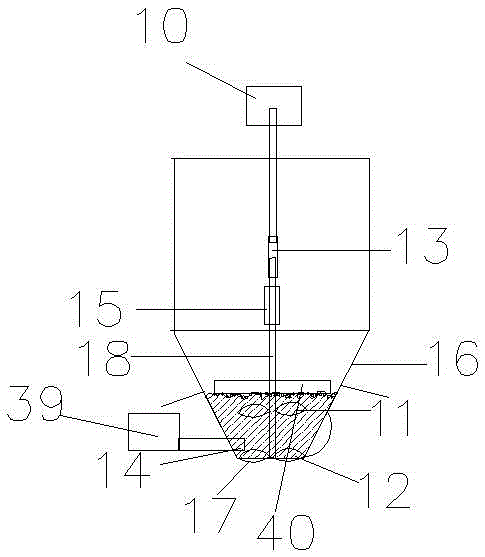

[0036] The sand supply module is composed of a sand supply device (8), a sand supply bucket (9), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com